Manufacturing method of thin-strip continuous casting high magnetic induction non-oriented silicon steel

A technology of oriented silicon steel and manufacturing method, which is applied in the field of metal material processing, can solve problems such as the difficulty in producing thin-gauge cold-rolled products, and achieve the effects of low production cost, improved surface quality, and increased magnetic induction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

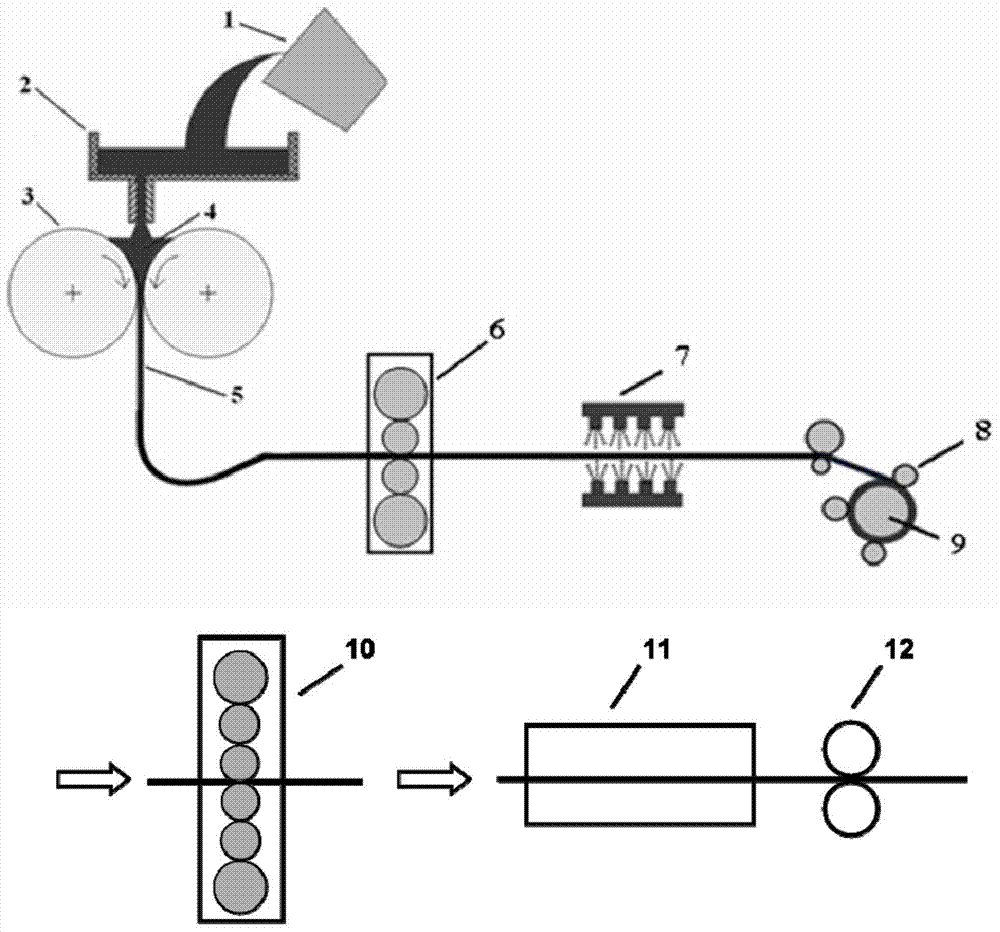

Method used

Image

Examples

Embodiment 1

[0039] Use medium frequency vacuum induction furnace to smelt molten steel whose composition is: C0.003%, Si0.7%, Mn0.2%, Al0.3%, and the balance is Fe and unavoidable impurities. The rotating crystallization roll directly casts a 1mm cast strip. The cast strip is cooled to 850°C for hot rolling, and the hot rolling reduction is 30%. The hot rolled strip is then coiled at 630°C. The hot-rolled steel strip was cold-rolled with a reduction of 29%, then annealed at 860° C. for 30 seconds, and coated to obtain a 0.5 mm thick non-oriented silicon steel sheet. The magnetic induction intensity B of the non-oriented silicon steel finished plate prepared by the present invention 50 =1.81T.

Embodiment 2

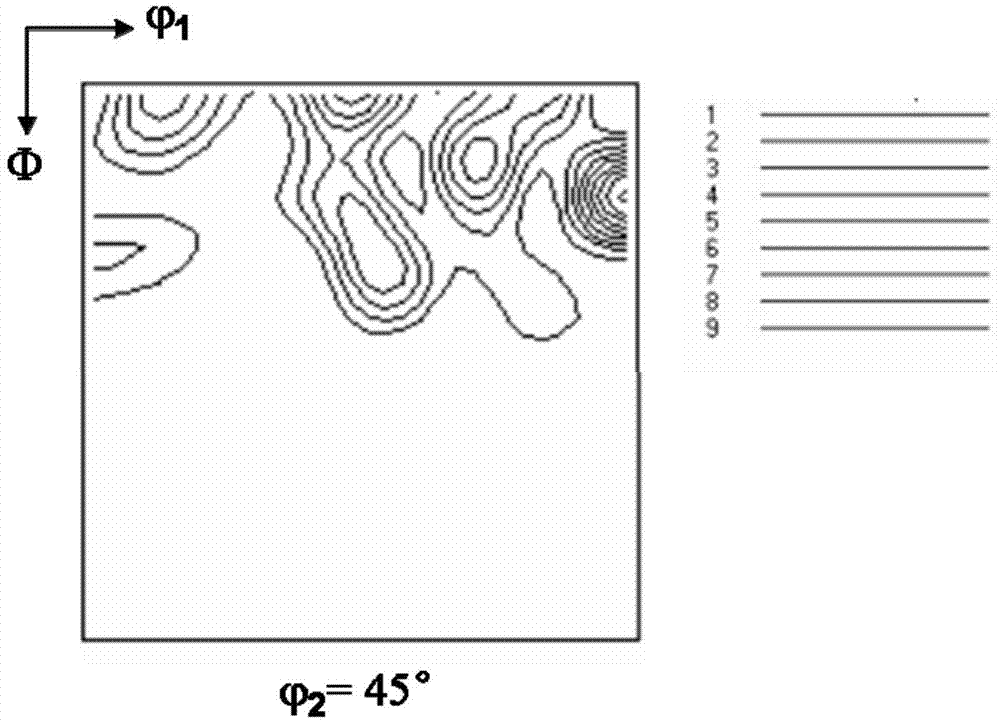

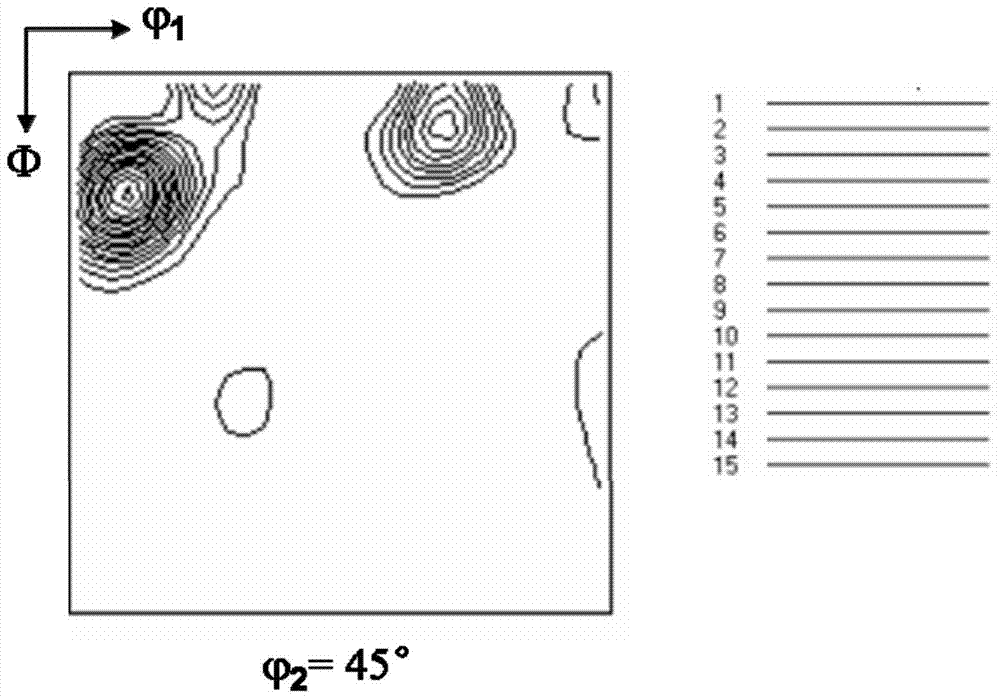

[0041] Use medium frequency vacuum induction furnace to smelt molten steel whose composition is: C0.004%, Si1.0%, Mn0.3%, Al0.35%, and the balance is Fe and unavoidable impurities. The rotating crystallization roll directly casts a 2.5mm cast strip (the macroscopic texture diagram of the cast strip can be referred to figure 2 shown), the cast strip was hot-rolled by water cooling to 950°C (see image 3 shown), the hot rolling reduction is 50%, and the hot rolled strip is then coiled at 650°C. The hot-rolled steel strip is cold-rolled with a reduction of 60% (the macro-texture diagram of the cold-rolled plate can be referred to as Figure 4 shown), followed by annealing at 890°C for 30s (see Figure 5 Shown), and coated to obtain 0.5mm thick non-oriented silicon steel plate. The magnetic induction intensity B of the non-oriented silicon steel finished plate prepared by the present invention 50 =1.83T.

Embodiment 3

[0043] Use medium frequency vacuum induction furnace to smelt molten steel whose composition is: C0.002%, Si1.4%, Mn0.39%, Al0.4%, and the balance is Fe and unavoidable impurities. A 1.8mm cast strip is directly cast from the rotating crystallization roll, and the cast strip is cooled to 1050°C for hot rolling with a hot rolling reduction of 40%, and the hot rolled strip is then coiled at 670°C. The hot-rolled steel strip was cold-rolled with a reduction of 53%, then annealed at 940° C. for 30 seconds, and coated to obtain a non-oriented silicon steel sheet with a thickness of 0.5 mm. The magnetic induction intensity B of the non-oriented silicon steel finished plate prepared by the present invention 50 =1.82T.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com