Electromagnetic sensor of electromagnetic stirring device of slab continuous-casting crystallizer

An electromagnetic inductor and electromagnetic stirring technology, applied in the field of electromagnetic inductor structure, to achieve the effect of reducing carbon emissions, high electromagnetic force, and not difficult to manufacture and implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

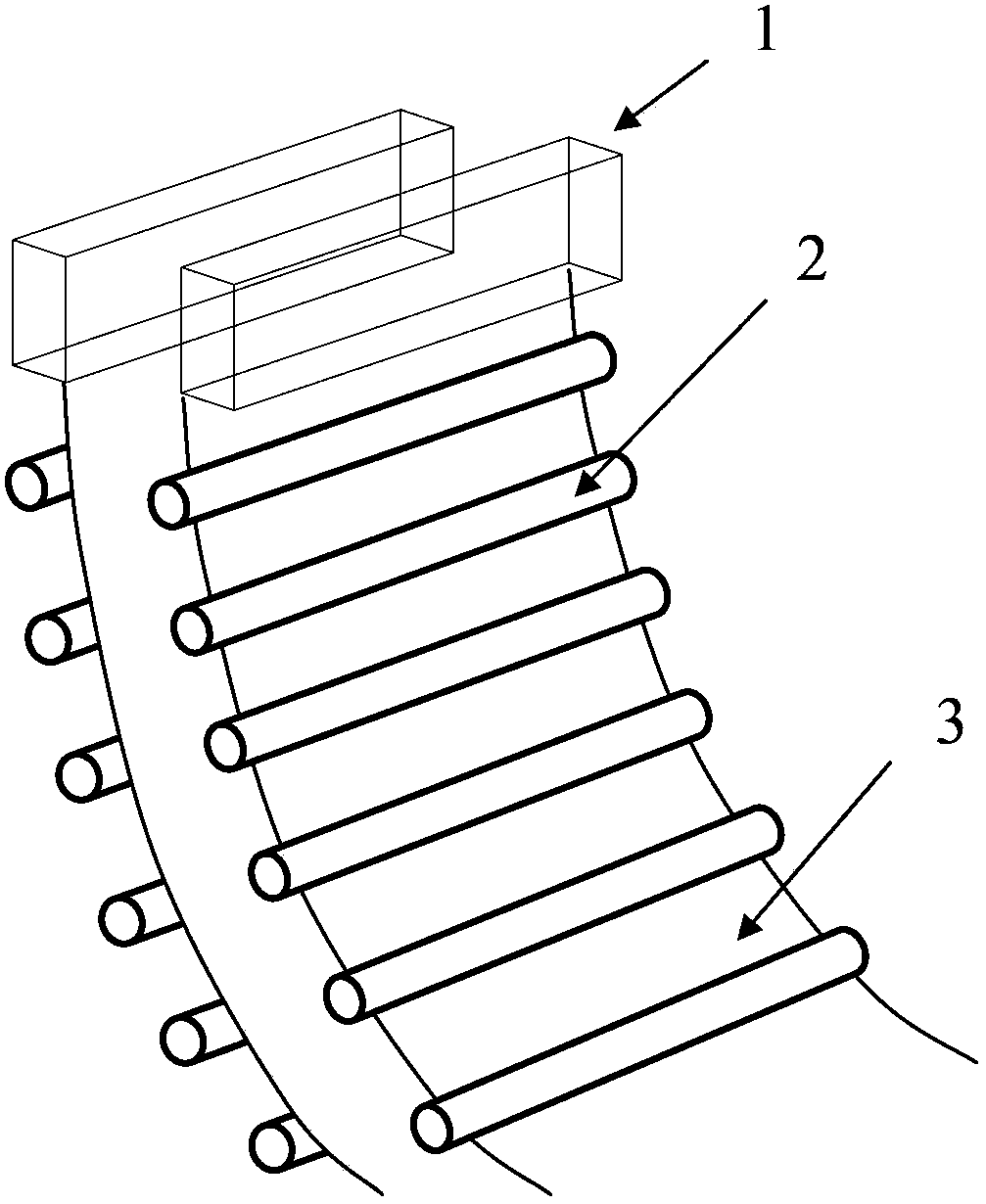

[0049] see Figure 9 , the electromagnetic inductor and the electromagnetic stirring device of the crystallizer in the present invention figure 2 As shown in the existing crystallizer electromagnetic stirring device, it is used in pairs and must be installed on the outside of the mold copper plate 101. The electromagnetic inductor of the crystallizer electromagnetic stirring device is mainly composed of iron core 10 and multiple groups of coils wound outside the iron core 12 compositions.

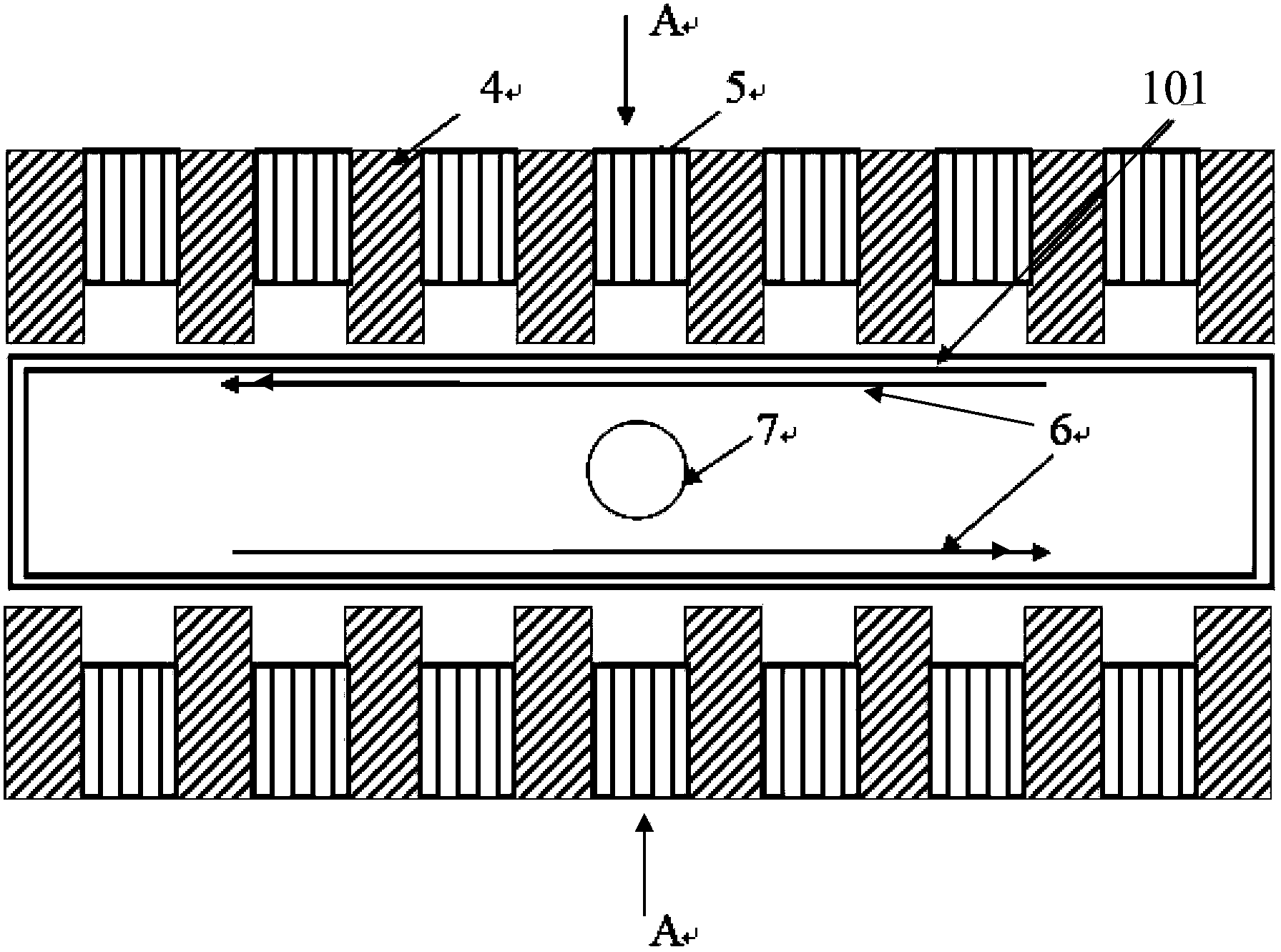

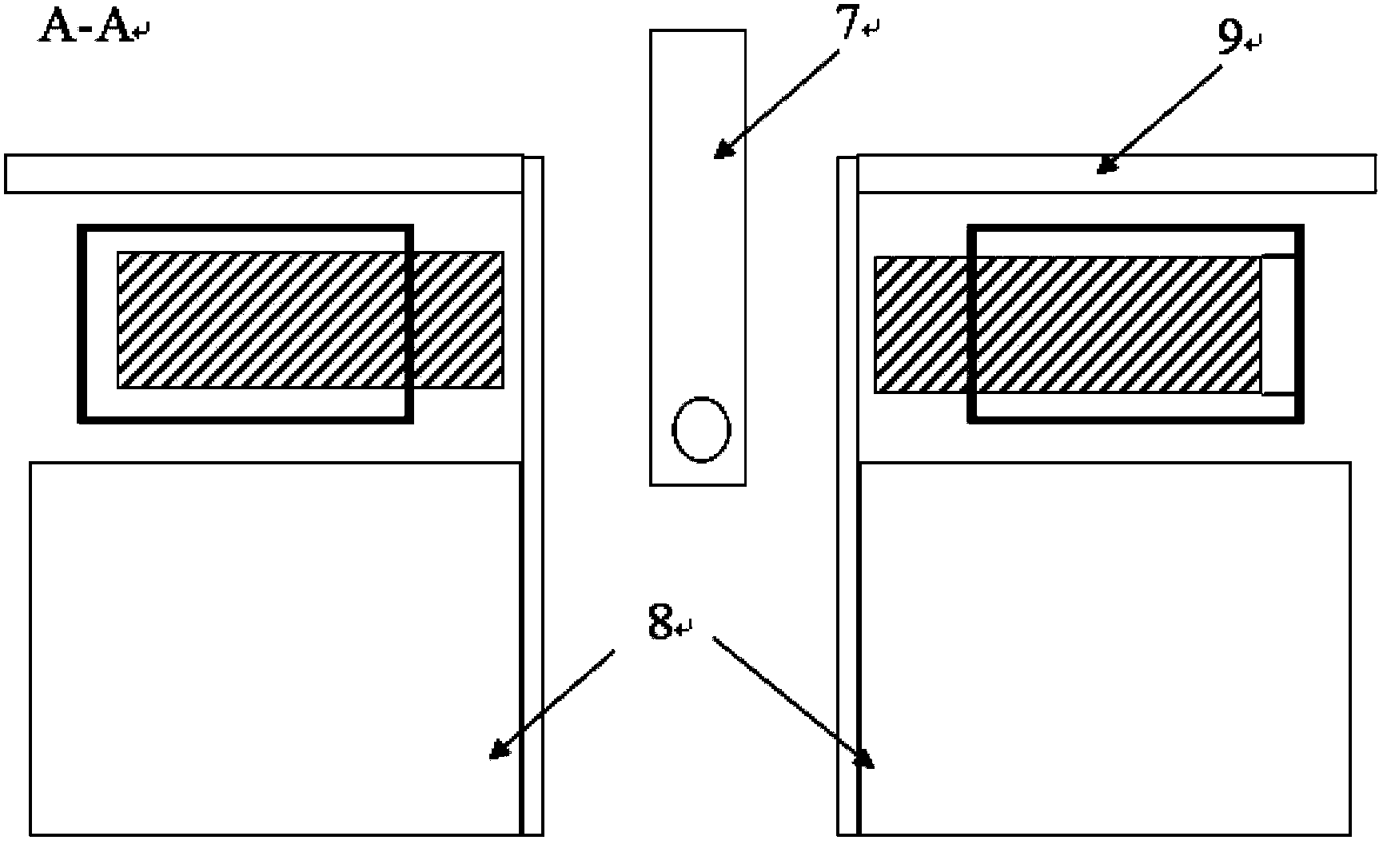

[0050] see Figure 4 , the electromagnetic inductor of the slab continuous casting crystallizer electromagnetic stirring device of the present invention comprises:

[0051] The iron core 10 is a cylindrical iron core formed by stacking multiple E-shaped iron cores in series, that is, a cylindrical iron core with multipl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com