Magnetic rubber having high magnetic flux density and preparation method thereof

A technology of magnetic induction intensity and magnetic rubber, which is applied in the field of composite materials, can solve the problems of poor magnetic induction intensity and flexible elastic performance, and achieve the effect of good flexible elastic performance, simple process flow and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

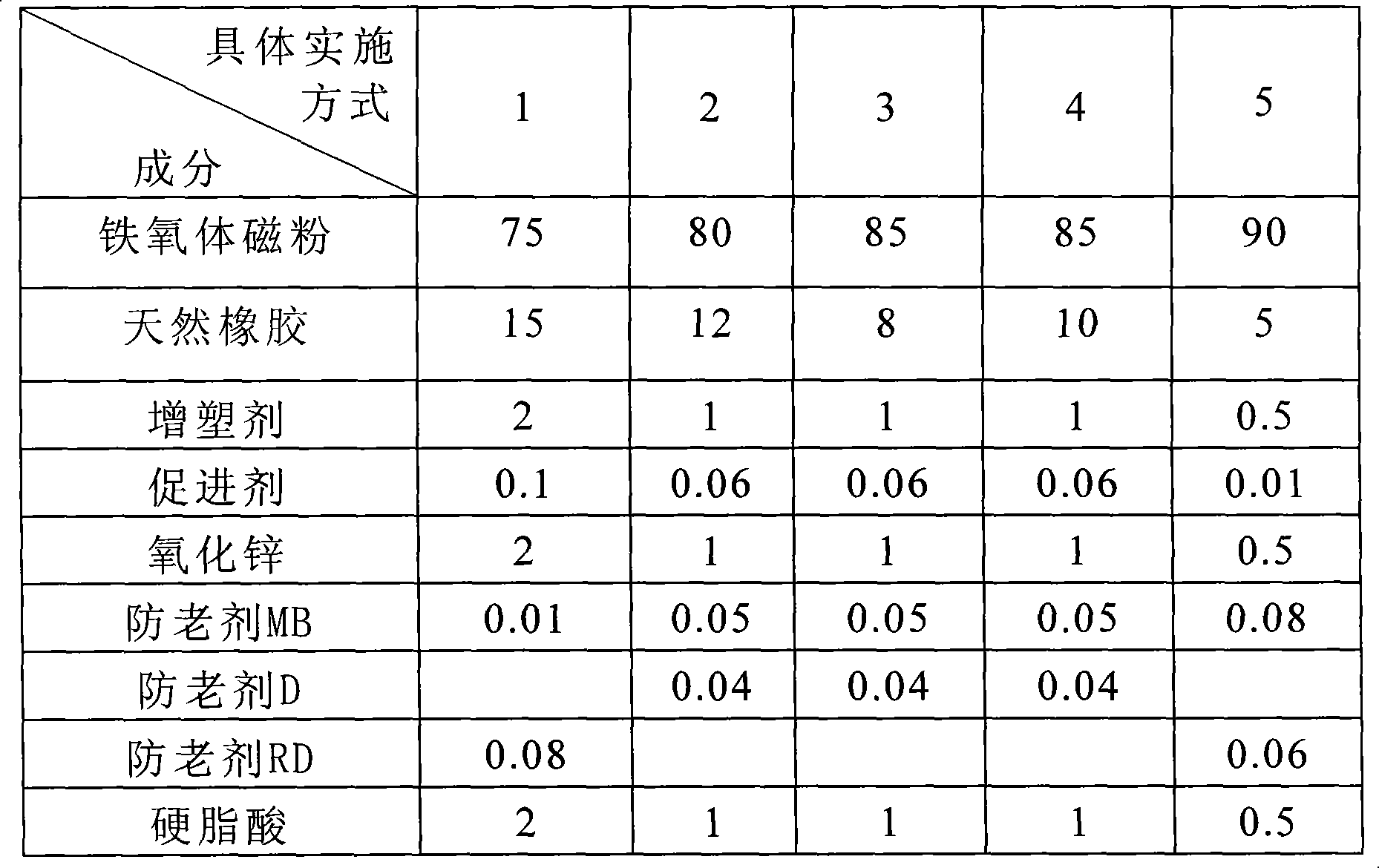

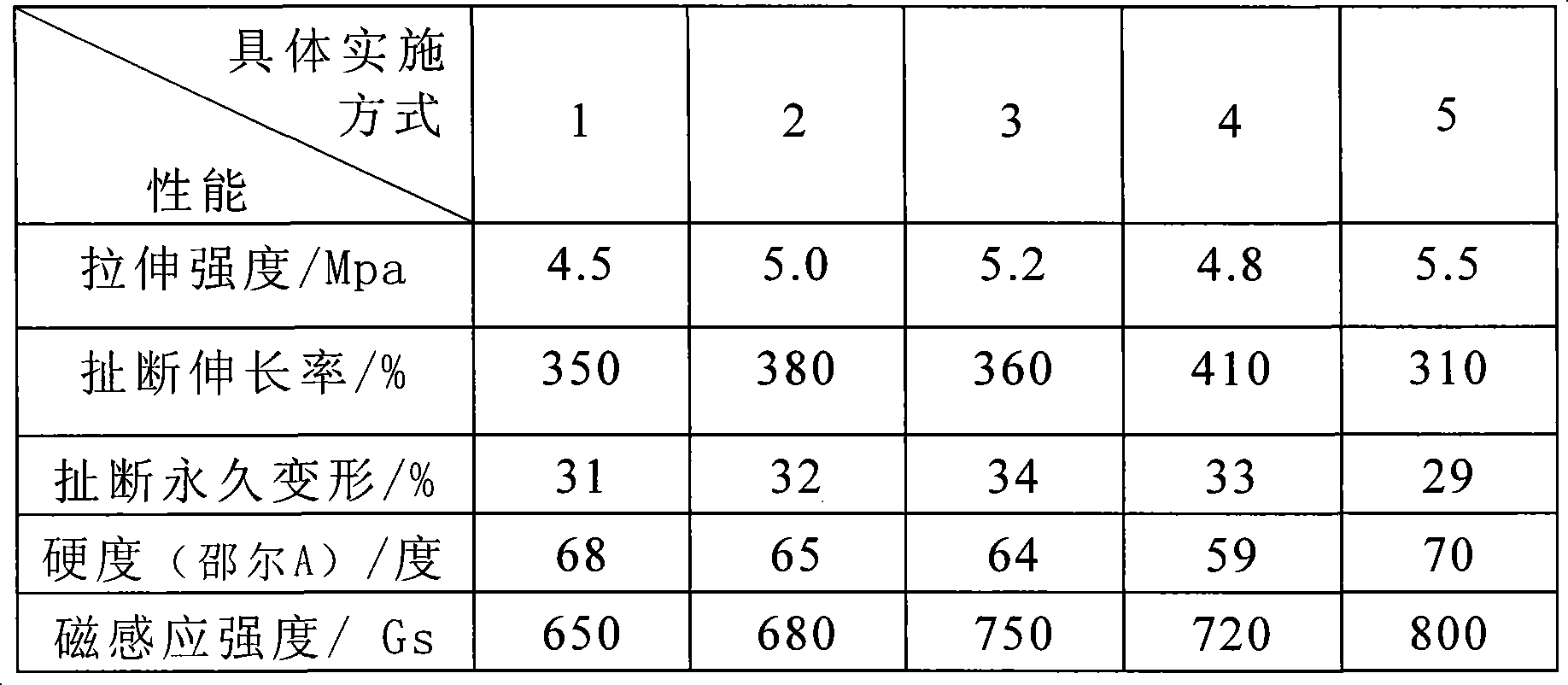

Embodiment 1

[0039] Take the strontium ferrite magnetic powder in Example 1 of the above table 1 and put it in a grinder to grind it into a magnetic powder with a particle size of 100-300 mesh, and then use a silane coupling agent that accounts for 0.5% by weight of the strontium ferrite magnetic powder. Ferrite magnetic powder carries out surface modification treatment, and surface modification treatment is carried out according to the method for the surface treatment of inorganic filler conventional in rubber industry; Then get other composition and natural rubber in the embodiment 1 of table 1, after it is pulverized and above-mentioned after grinding The strontium ferrite magnetic powder is fully mixed; the mixed ingredients are put into the rubber mixer, and at room temperature, the rubber is mixed for 50 minutes under the action of the upper roller of the rubber mixer, and then it is ground into a synthetic Paste block; put the above-mentioned paste block composition after rubber mixi...

Embodiment 2

[0041] Take the barium ferrite magnetic powder in Example 2 of Table 1 above and put it in a grinder to grind it into a magnetic powder with a particle size of 100-300 mesh, and then use a titanate coupling agent accounting for 1% by weight of the barium ferrite magnetic powder Carry out surface modification treatment to barium ferrite magnetic powder, surface modification treatment is carried out according to the method for surface treatment of inorganic filler conventional in rubber industry; Then take other composition and natural rubber in the embodiment 2 of table 1, grind it and mix with above-mentioned The ground barium ferrite magnetic powder is fully mixed; the mixed ingredients are put into the rubber mixer, and the rubber is mixed under the action of the upper roller of the rubber mixer for 30 minutes at room temperature, and then it is mixed Grinding into a paste block; put the above-mentioned paste block composition after rubber mixing into a mold, and form it into...

Embodiment 3

[0043] Take the strontium ferrite magnetic powder in Example 3 of the above table 1 and put it in a grinder to grind it into a magnetic powder with a particle size of 100-300 meshes, and then use a silane coupling agent that accounts for 1% by weight of the strontium ferrite magnetic powder to react the strontium Ferrite magnetic powder is carried out surface modification treatment, and surface modification treatment is carried out according to the method for the surface treatment of inorganic filler of rubber industry routine; Then get other composition and natural rubber in the embodiment 3 of table 1, after it is pulverized and above-mentioned after grinding Fully mix the barium ferrite magnetic powder; put the mixed ingredients into the rubber mixer, under room temperature, mix the rubber under the action of the upper roller of the rubber mixer for 20 minutes, and then grind it into Paste block; put the above-mentioned paste block composition after rubber mixing into the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com