Clamping punching clamp for inertia friction welding

A punching fixture and friction welding technology, which is applied in the field of clamping and punching fixtures for inertial friction welding, can solve the problems of inability to carry out continuous production, cost and efficiency waste, and difficult clamping of parts, so as to avoid clamping difficulties and save cost, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

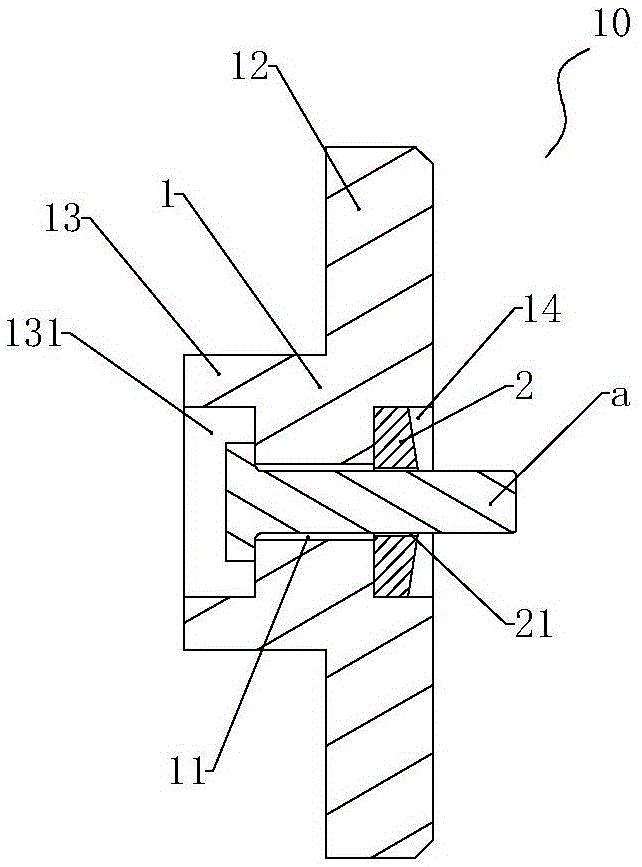

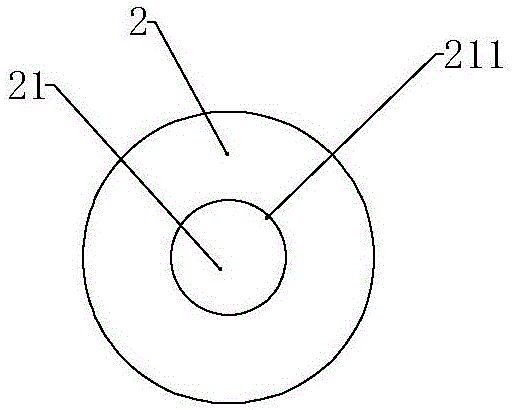

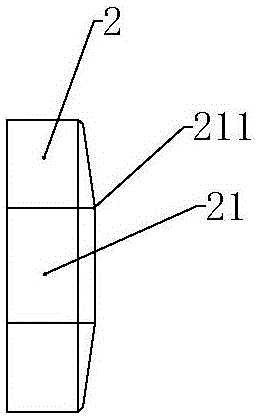

[0025] Such as figure 1 As shown, the present invention provides a clamping and punching fixture 10 for inertia friction welding, which is used for welding small rod-shaped parts, such as bimetallic rivets, and can continue to cut off welding burrs after welding is completed. Different from the prior art, the clamping and punching jig 10 includes a detachable and split jig base 1 and a punching core 2 . The fixture base 1 is provided with a first channel 11 for passing through the workpiece. The rod-shaped workpiece a has heads of various shapes such as countersunk heads, flat heads, etc., and the diameter of the head is larger than that of the rod. The workpiece a passes through the first passage 11, and the diameter of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com