Parallel semicontinuous or continuous reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

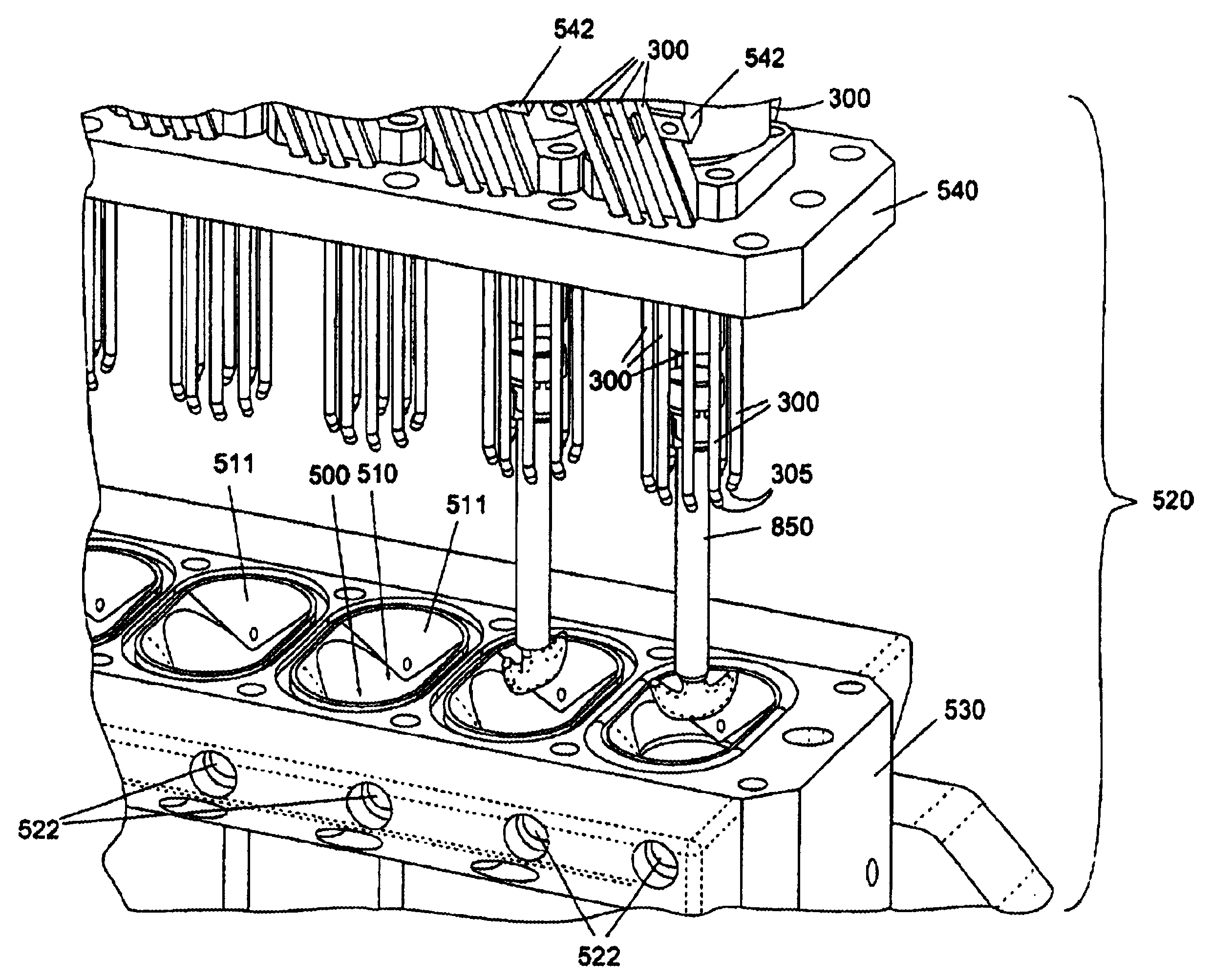

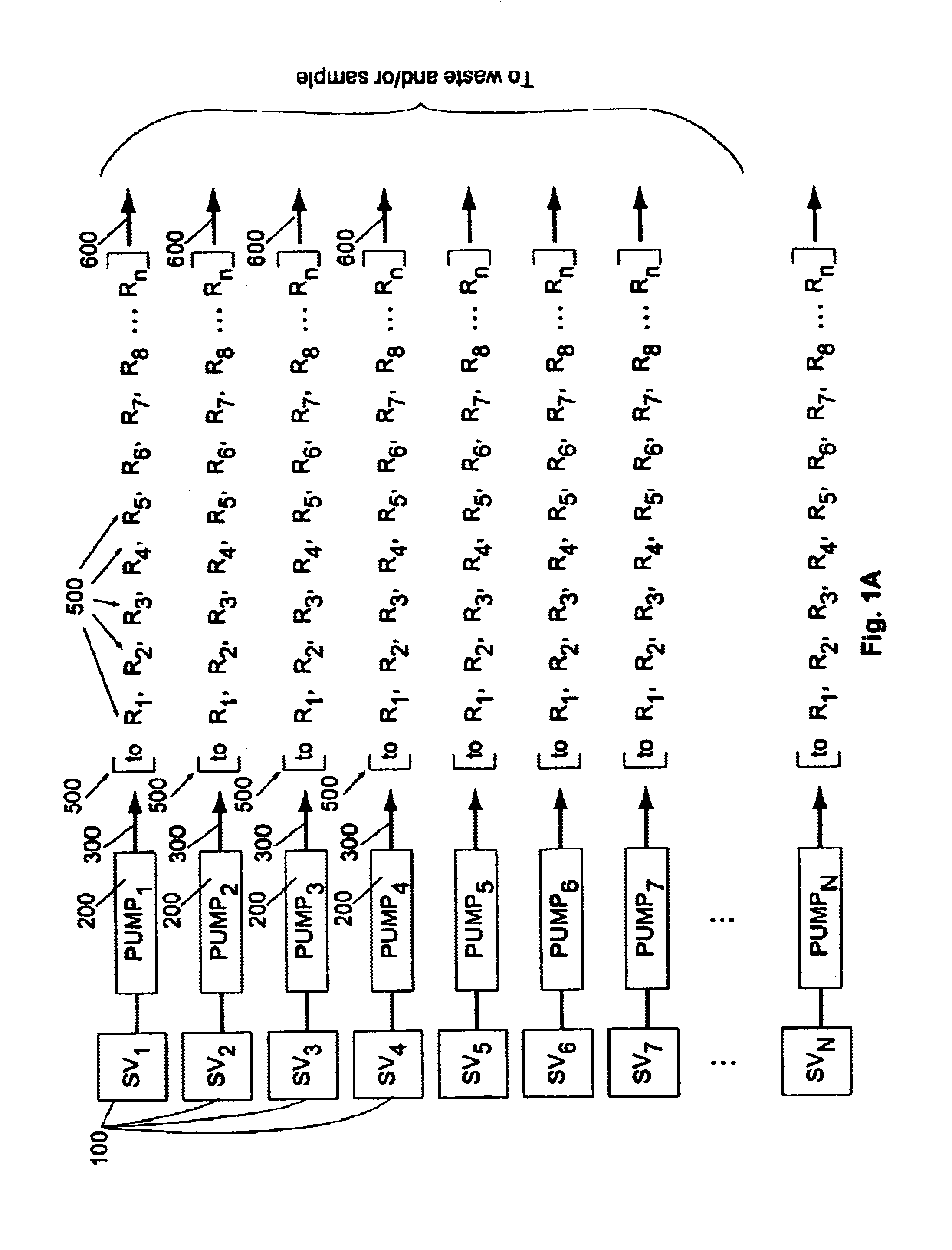

[0136]A parallel semi-batch reactor having eight reaction vessels was configured as follows: an array of eight sealed stainless steel reactor chambers, each equipped with speed-controlled rotary shaft stirrer paddles, disposable glass liner reaction vessels with volume capacity of about 12 ml, argon gas manifold inlet and outlet, thermostatically controlled heating, and five inlet lines into each of the eight reactor vessels, supplied by five pump and valve distribution systems of the invention. The feed lines of each distribution system were primed with the corresponding five liquid reagent solutions described below. The reactor was assembled in a clean, empty state, and sealed. The reactor was pressurized 5 times with argon to a pressure of 60 psig, followed by venting to flush air from the system, and then was maintained under an ambient (1 atm) argon atmosphere during the course of the reaction.

[0137]

FeedNumberLabelComposition1Monomerbutyl acrylate, 86.5%mixmethyl methacrylate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com