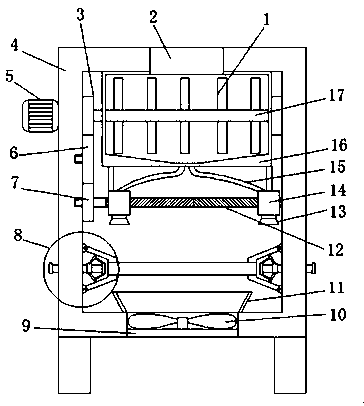

Automatic washing machine sheet metal production device

A technology for making a device and a washing machine, applied in the field of sheet metal processing, can solve the problems affecting the beauty and efficiency of spray paint, uneven purity of paint raw materials, affecting the quality of spray paint, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

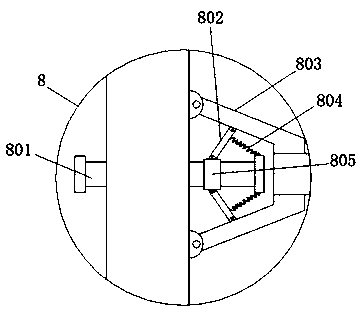

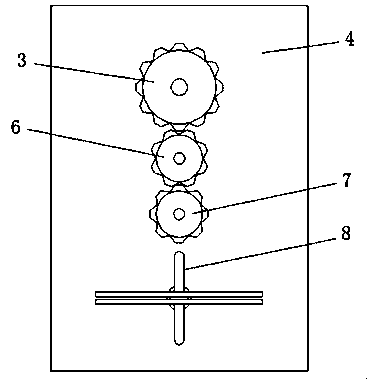

[0020] Embodiment: When in use, first open the door panel at the bottom of the paint spraying box 4, place the sheet metal on the top of the clamping plate 803 below, then close the door panel, and then turn the second threaded rod 801, which makes the movable sleeve The cylinder 805 slides on the second threaded rod 801, and the movable sleeve 805 drives the handover stem 802, and the hinged rod 802 pulls the splint 803, and the two splints 803 approach each other to clamp the sheet metal, and then start the rotating motor 5 and The drying machine 10 and the liquid pump pour paint raw materials into the material storage box 16 through the feed port 2 at the same time. The paint raw materials in the tank are fully stirred, and the stirred paint raw materials are input into the feed pipe 15 through the liquid pump in the storage tank 16, and then flow into the nozzle 13 through the feed pipe 15, and spray to the paint spray box 4 through the nozzle 13. On the internally fixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com