Furniture mutelabor-savingpressingand reboundingopening-closing structure

An open-close structure, silent technology, applied in furniture parts, home appliances, wing fan openers, etc., can solve the problem of user inconvenience, abnormal noise, loud, and the push element will collide with the fixed bracket when it pops up, swinging The components will collide with the heart-shaped chute and other problems, so as to improve the user experience, prolong the service life and reduce the noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

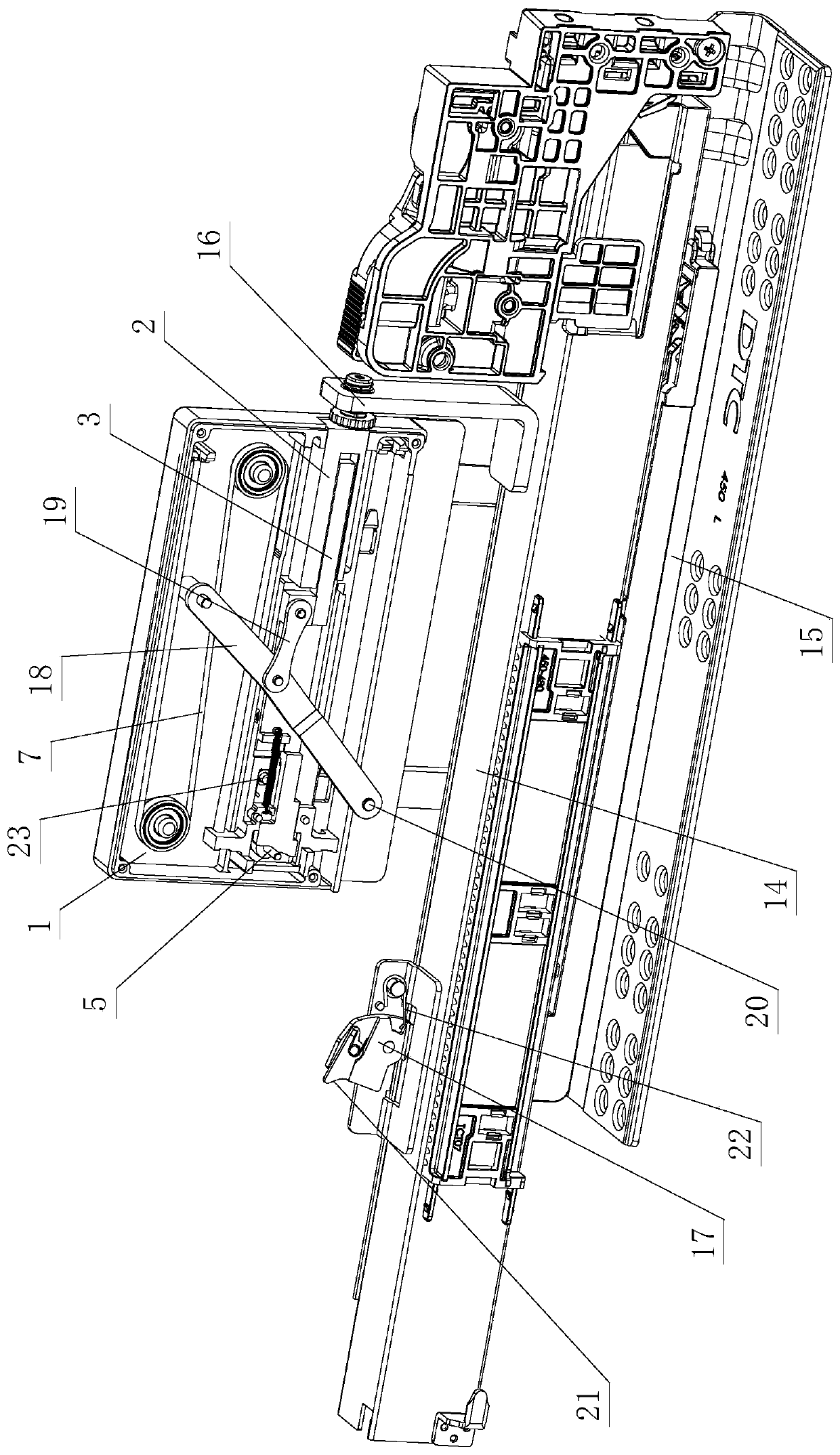

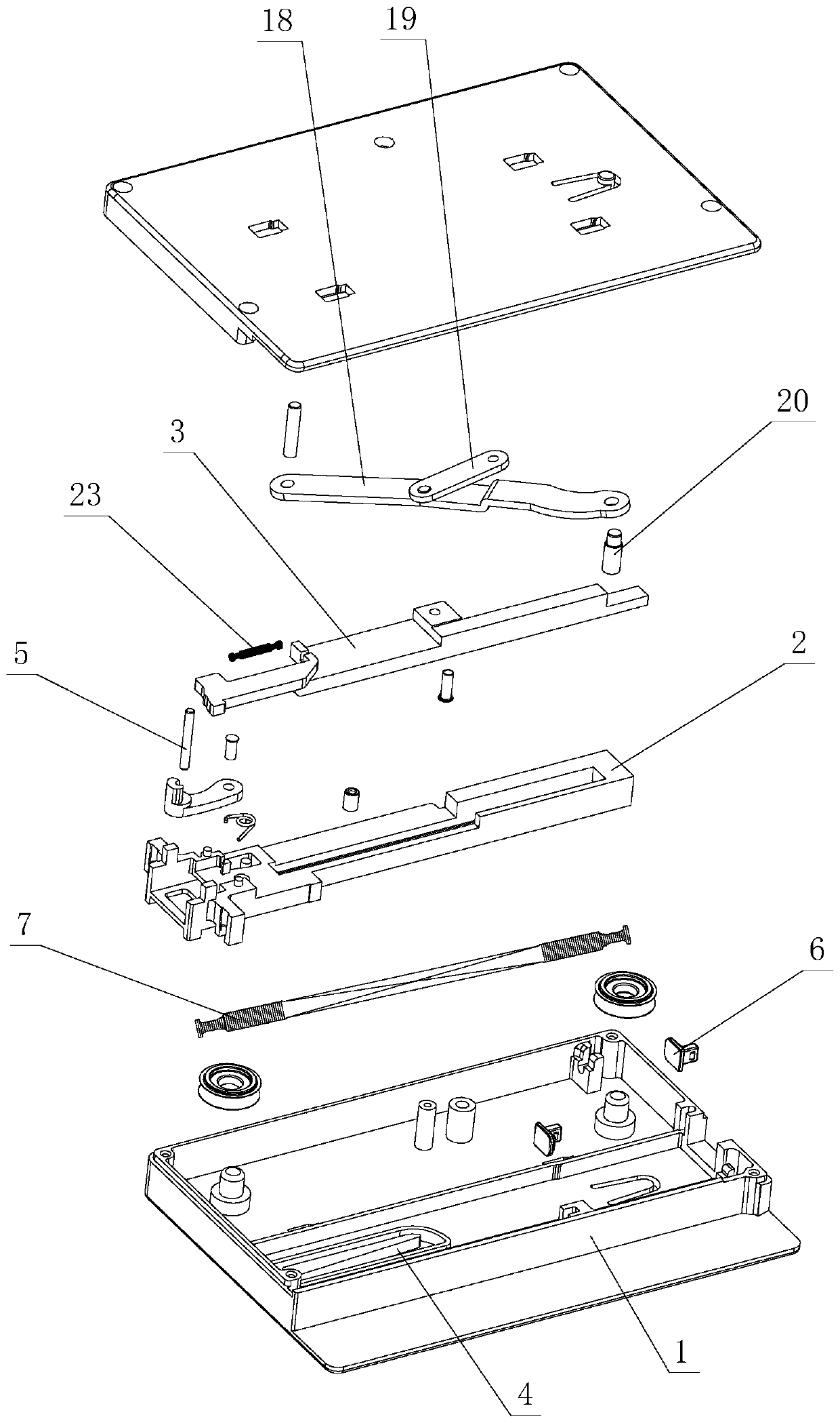

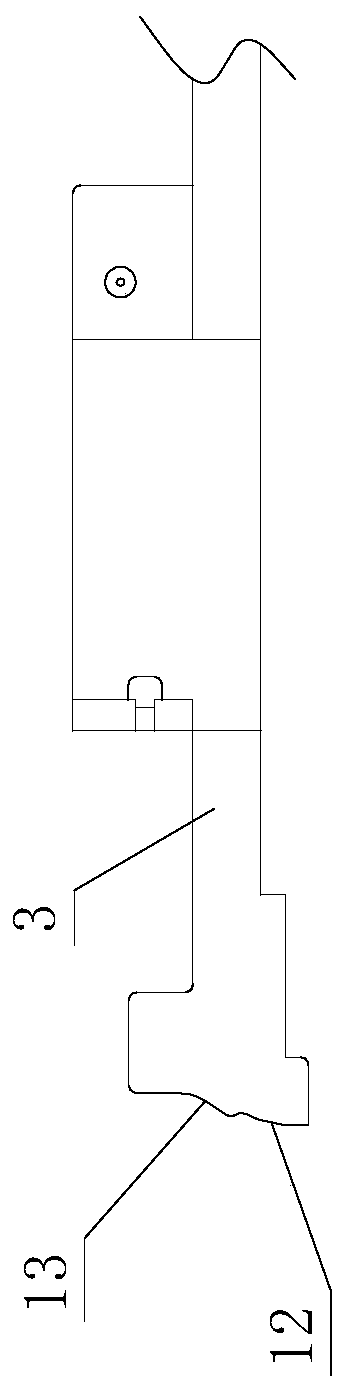

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0044] see Figure 1-Figure 13 , the quiet and labor-saving press rebound opening and closing structure of this furniture includes a press rebound device. The press rebound device at least includes a rebound bracket 1, a pushing element 2 and a sliding element 3, wherein the rebound bracket 1 is provided with a heart-shaped chute 4, and the pushing element 2 is provided with a heart-shaped chute. A sliding part 5 is provided, and the sliding element 3 is slidably arranged on the pushing element 2, and is drivingly connected to the sliding part 5 through a guide part provided thereon when sliding, and the sliding part 5 is driven in a sequential direction by the guiding part. The track positioning and / or sliding of the heart-shaped chute 4 drives the pushing element 2 to slide out of the rebound bracket 1 when sliding; an anti-collision part 6 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com