Method for producing a liquid container, liquid container for a motor vehicle and injection molding tool

A liquid container, injection molding technology, used in household appliances, other household appliances, applications, etc., can solve the problems of incomplete layer formation, layer thickness and layer distribution unevenness, and inability to guarantee complete layer formation, etc., to save The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

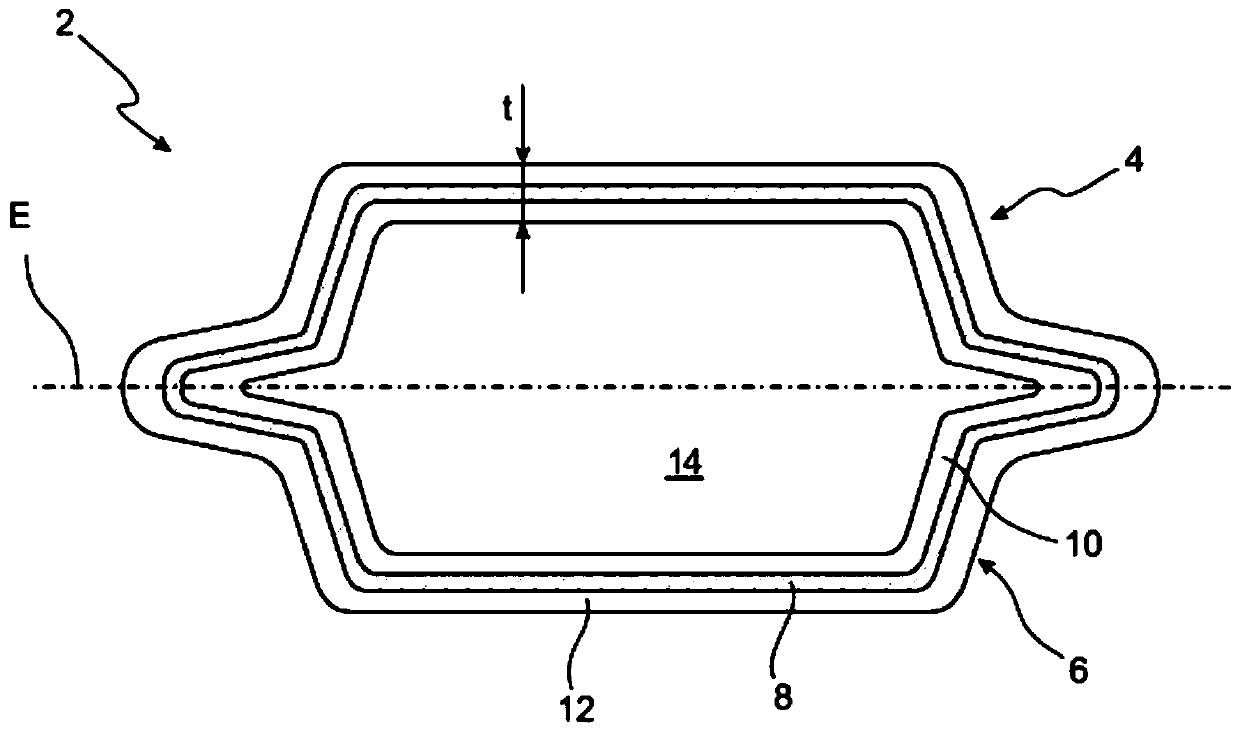

[0107] figure 1 A liquid container 2 for a motor vehicle (not shown), wherein this is a fuel tank 2 , is shown. The fuel tank 2 consists of two half shells 4 , 6 , a first shell 4 and a second shell 6 , which are connected to one another in the region of a plane E.

[0108] The liquid container 2 has a triple wall structure. The barrier layer 8 is surrounded on both sides by an inner covering layer 10 and an outer covering layer 12 .

[0109] The barrier layer 8 is formed over the entire surface of the wall structure. exist figure 1 In the cross-section shown, the cavity volume 14 is provided for storing fuel and is completely surrounded by the barrier layer 8 . The barrier layer 8 constitutes a diffusion barrier in order to minimize diffusion-induced emissions during fuel storage.

[0110] The wall thickness t of the housing 4 , 6 of the liquid container 2 is 3 mm+ / −1 mm.

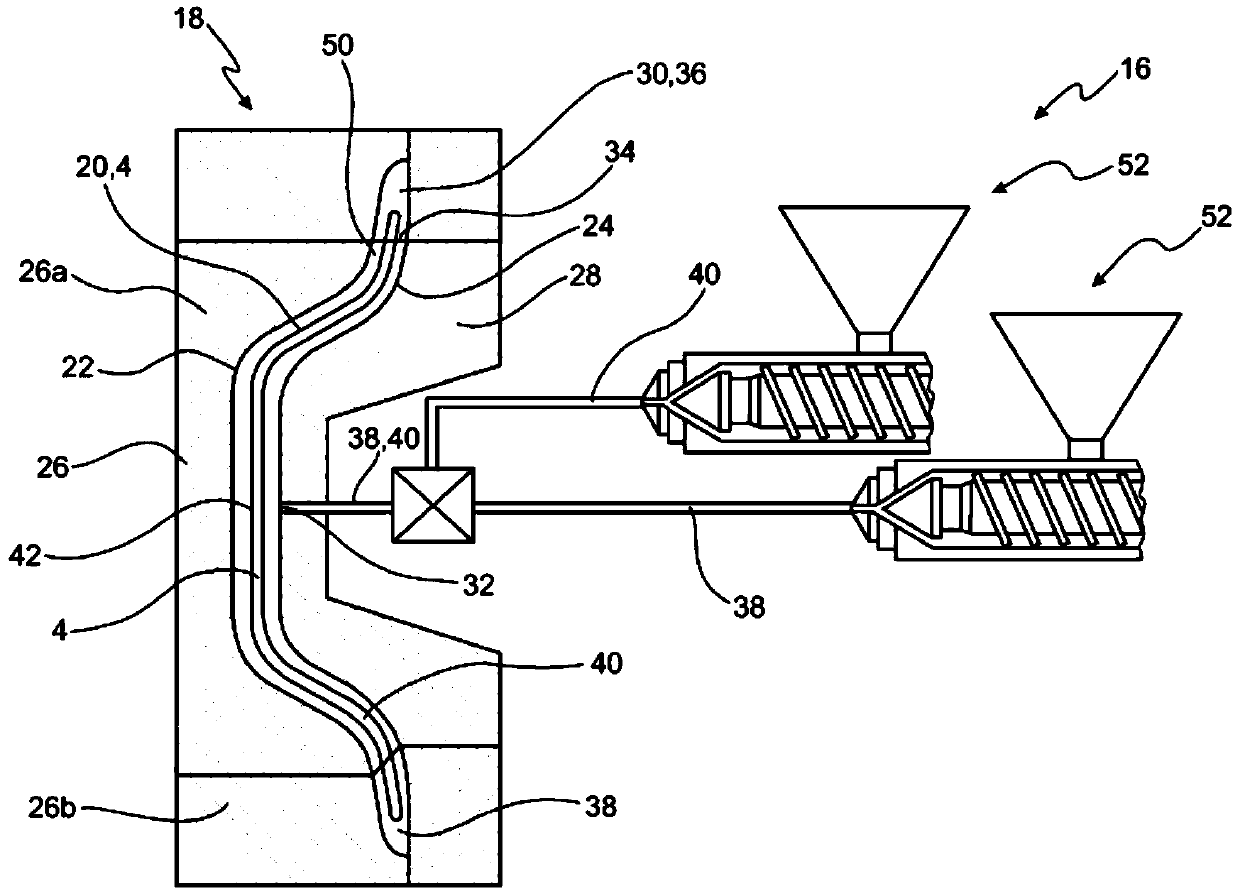

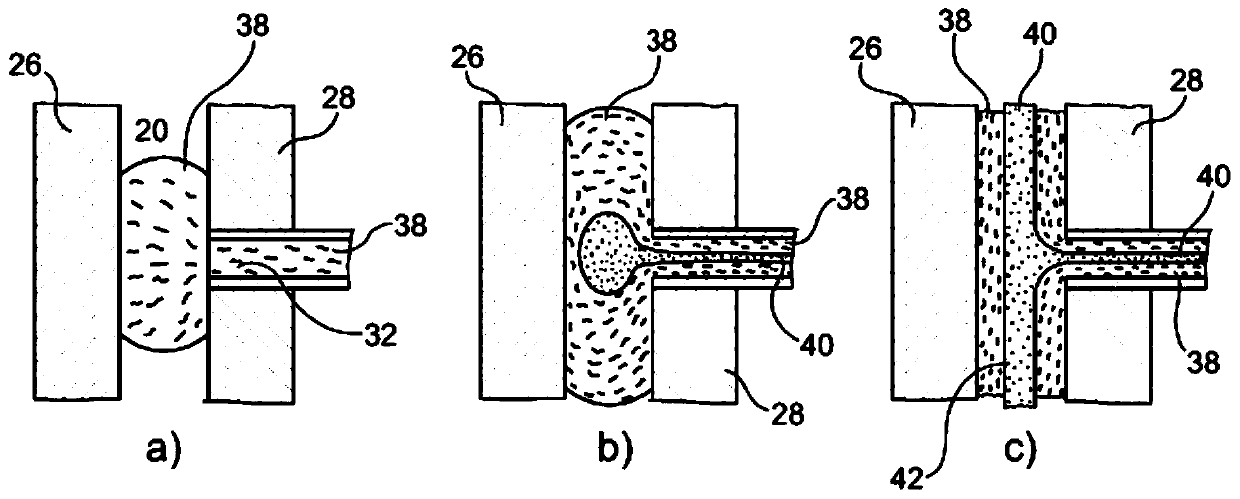

[0111] The liquid container 2 is produced by the method according to the present invention, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com