Combined cutoff device for large axial flow pump

A cut-off device and combined technology, which is applied in the field of combined cut-off devices for large axial flow pumps, can solve problems such as high manufacturing requirements, difficult hydraulic structure layout, and increased water leakage, so as to reduce the closing force And the effect of opening resistance, reducing actual working capacity and reducing working energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

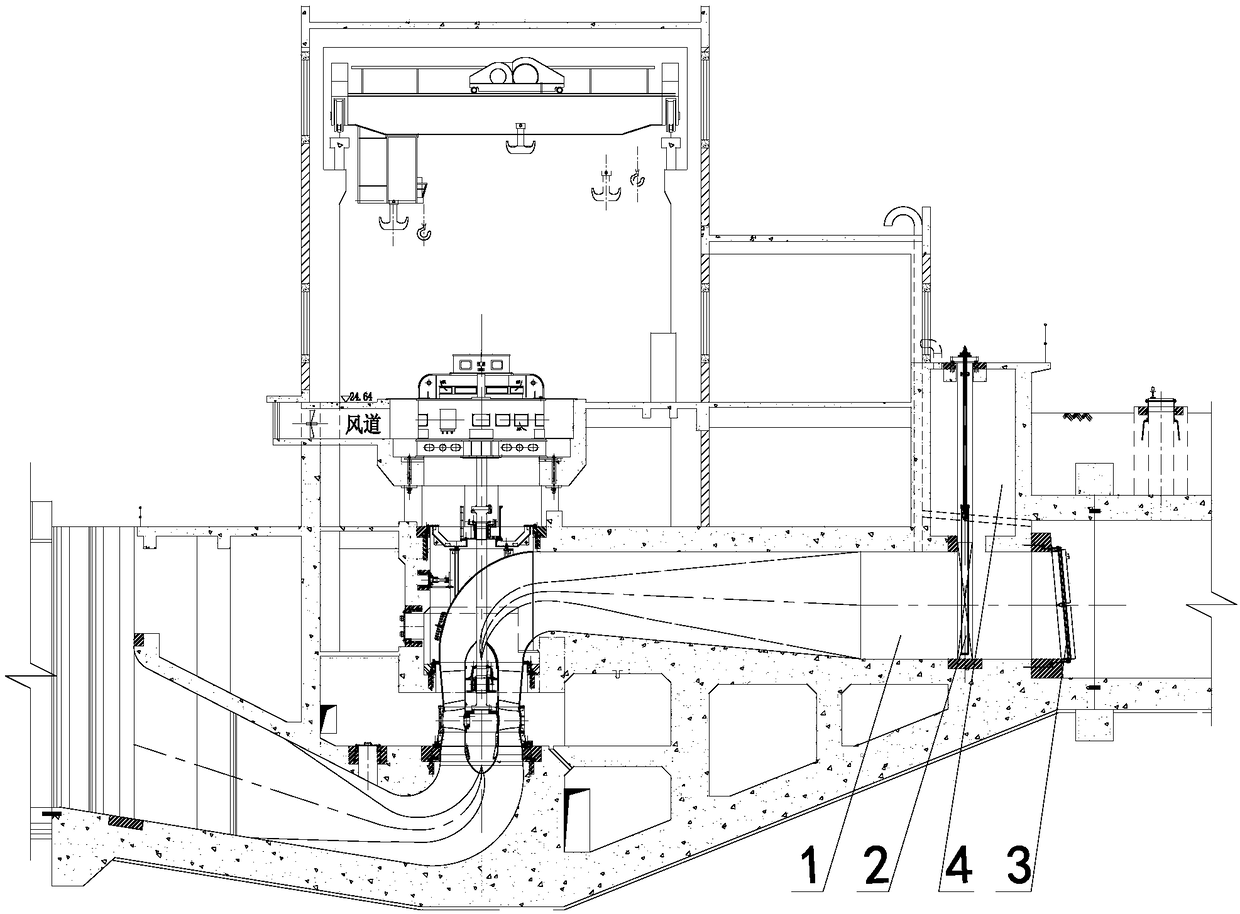

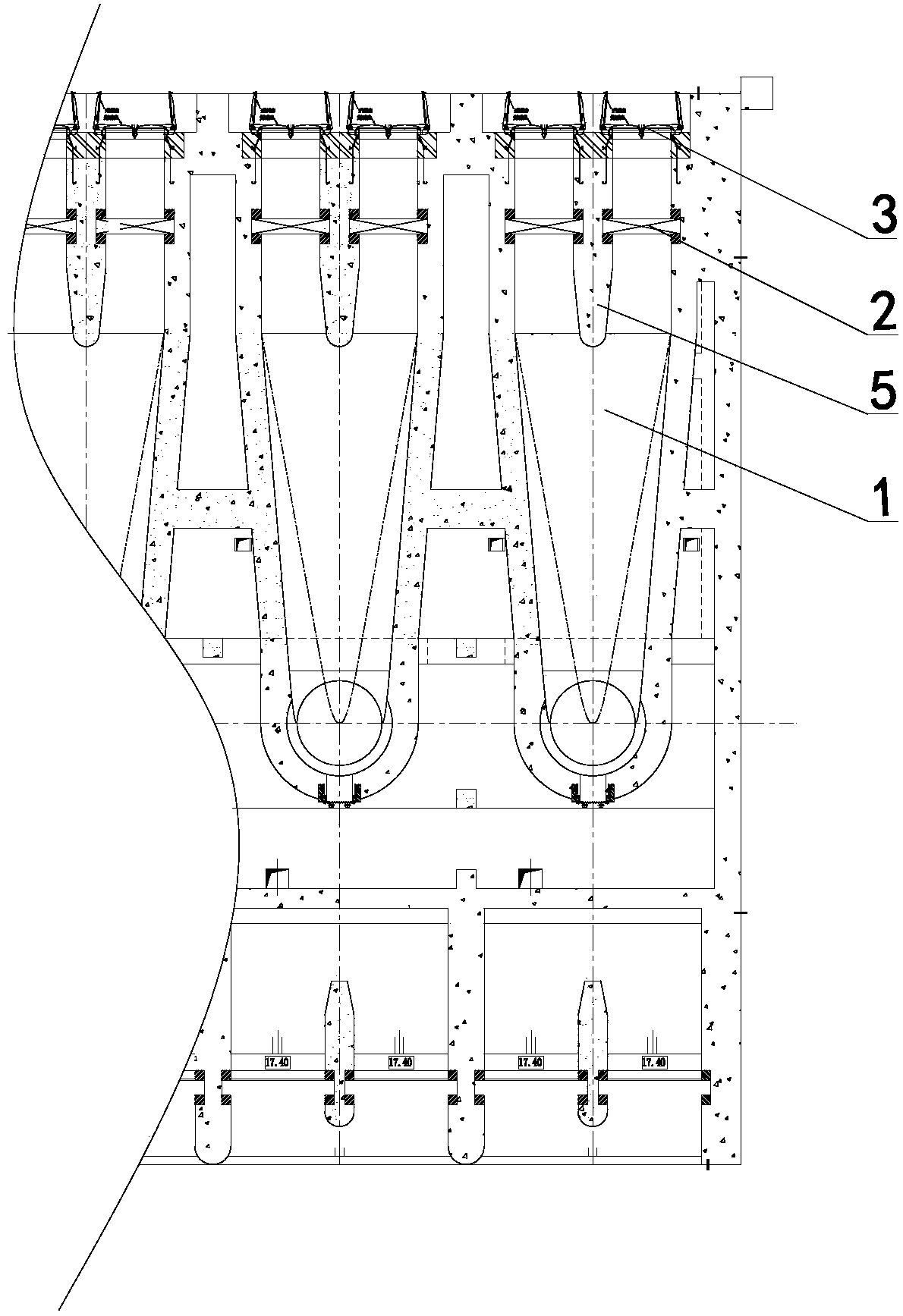

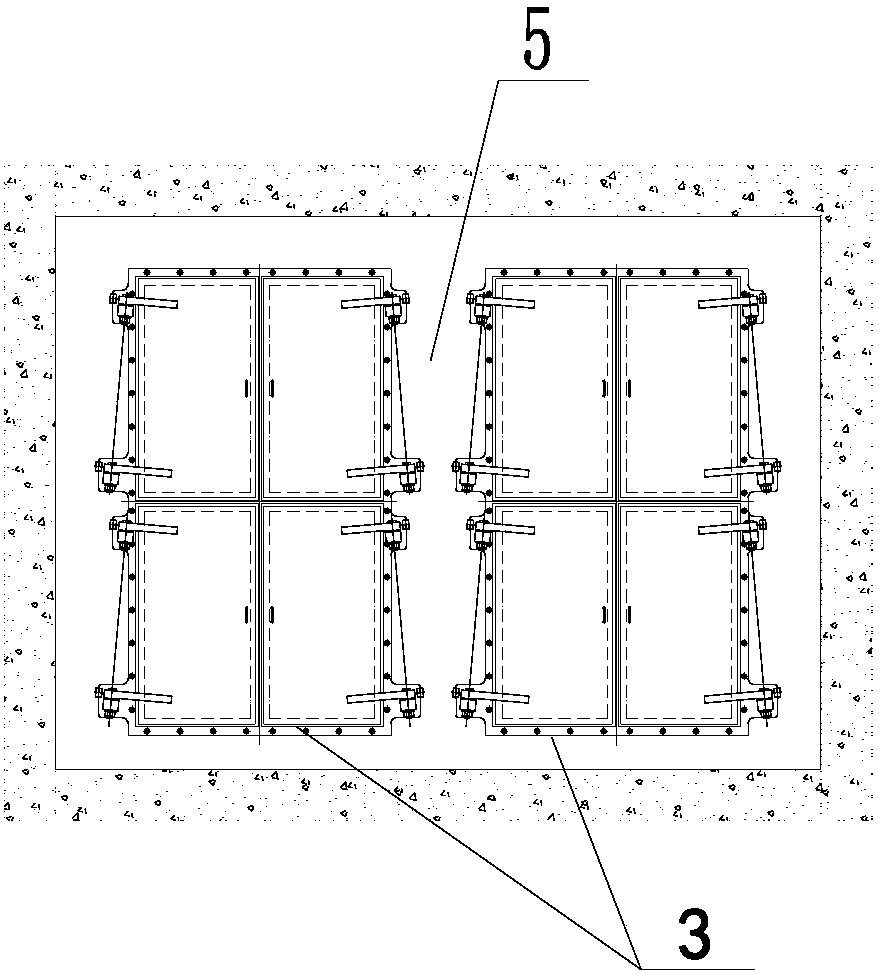

[0019] figure 1 , figure 2 , image 3 Shown is the layout of a large-scale axial flow pump combined flow breaking device proposed by the present invention. Specifically, the water outlet channel 1 of the straight pipe of the water pump is equally divided into two holes by the concrete pier 5 on the plane, and a set of fast gates 2 and a set of multi-door gates with the same door seat are arranged on the water outlet channel 1 of each hole. The side-turning flap door 3 forms the combined flow breaker.

[0020] Two holes are set, and each set of multi-leaf side-turning flap door with the same door seat contains 4 door leaves, which is beneficial to reduce the impact force of the side-turning flap door 3 when the pump is stopped and the door is closed. In this embodiment, the width of each hole does not exceed 2.4m, the height of the water outlet channel 1 of each hole is determined according to the flow rate of the water pump, and its outlet area meets the outlet water flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com