Scroll-type compressor with variable displacement mechanism

A variable capacity compressor, scroll type technology, applied in the direction of liquid variable capacity machines, rotary piston machines, mechanical equipment, etc., can solve the problems of increasing the axial size and weight of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

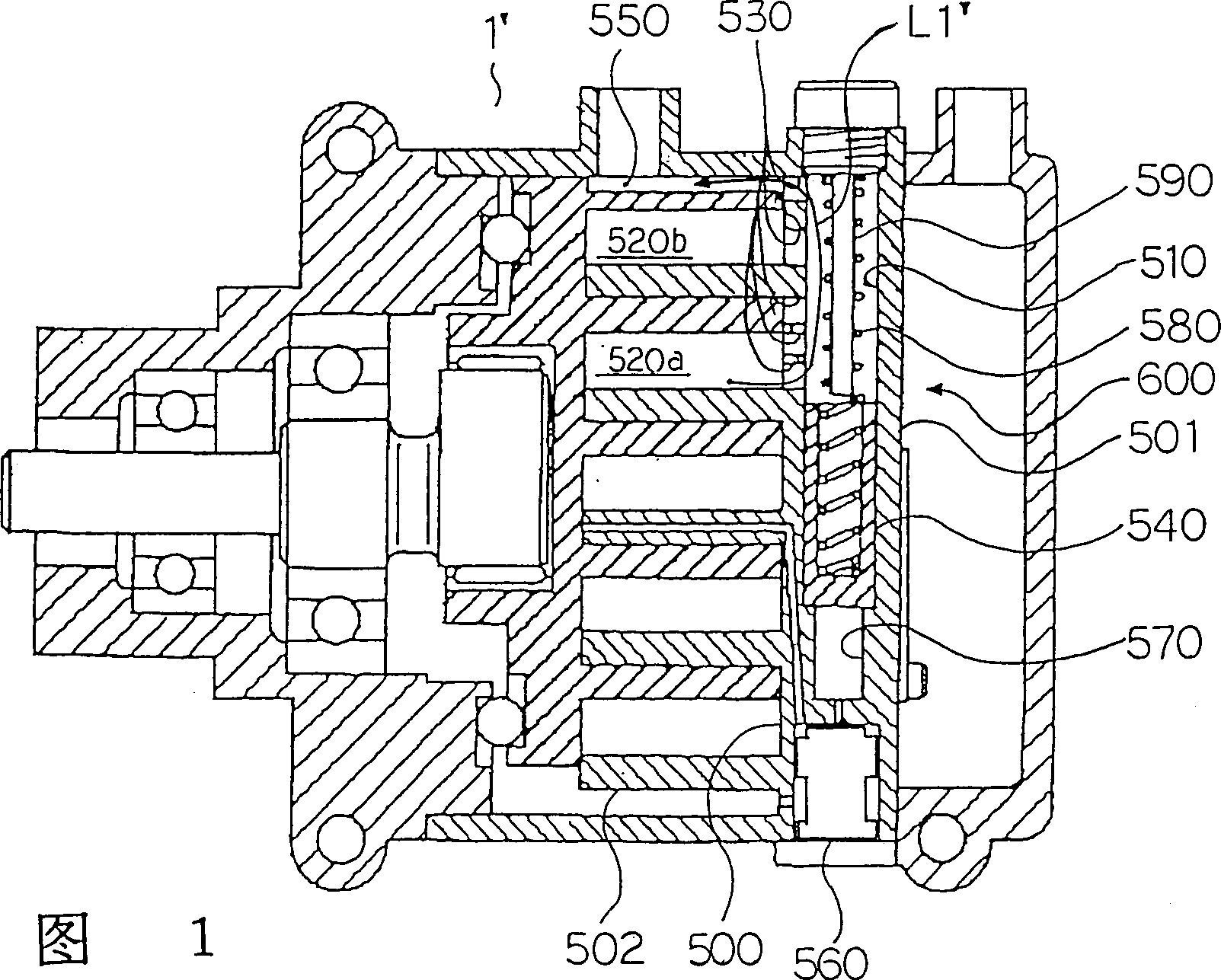

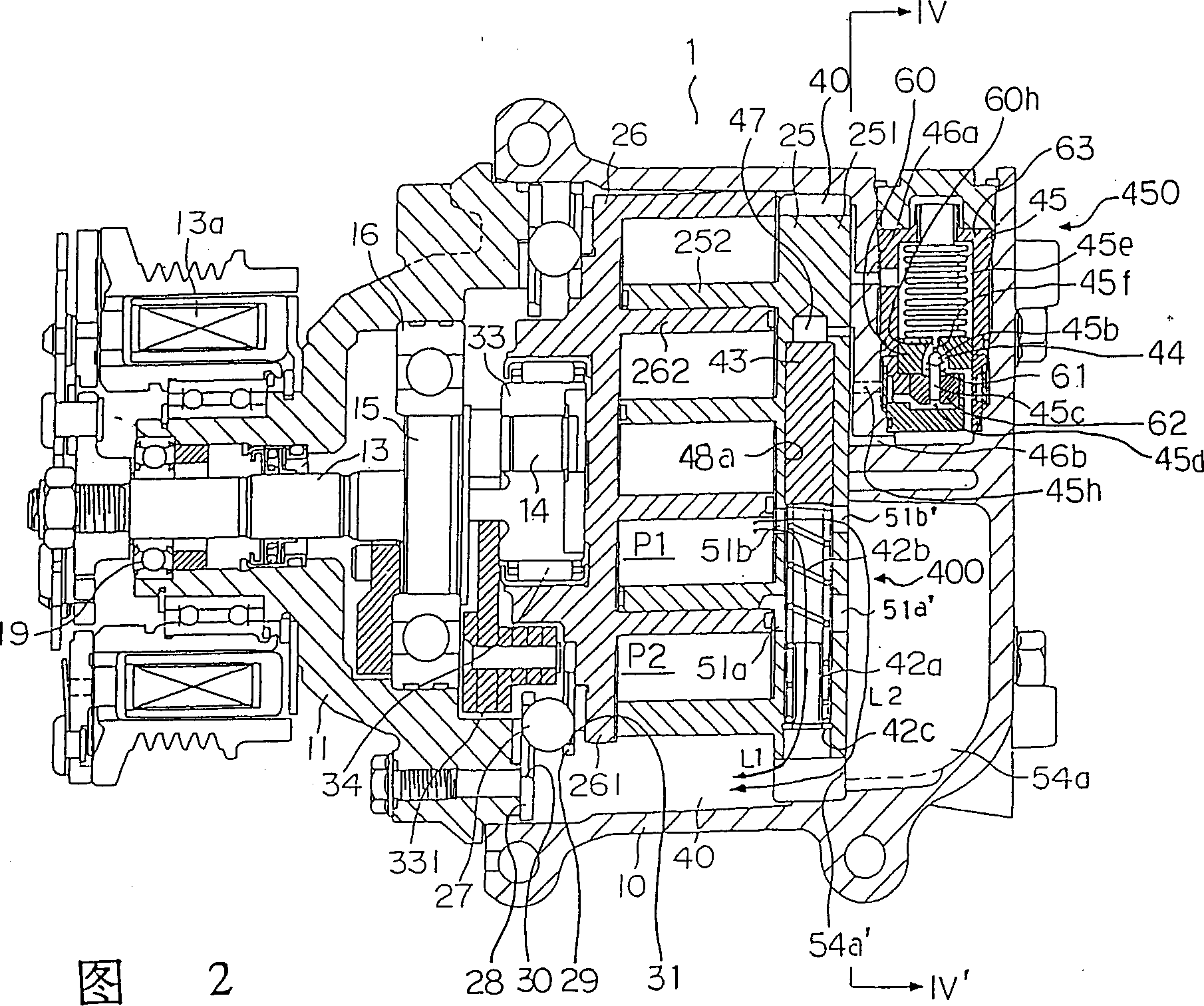

[0028] A first embodiment of the present invention will now be described with reference to FIGS. 2-4. As shown in FIG. 2, the scroll compressor 1 has a housing 10 and a front plate 11 connected thereto. In the casing 10, a fixed scroll 25 is fixedly placed, and an orbiting scroll 26 is provided.

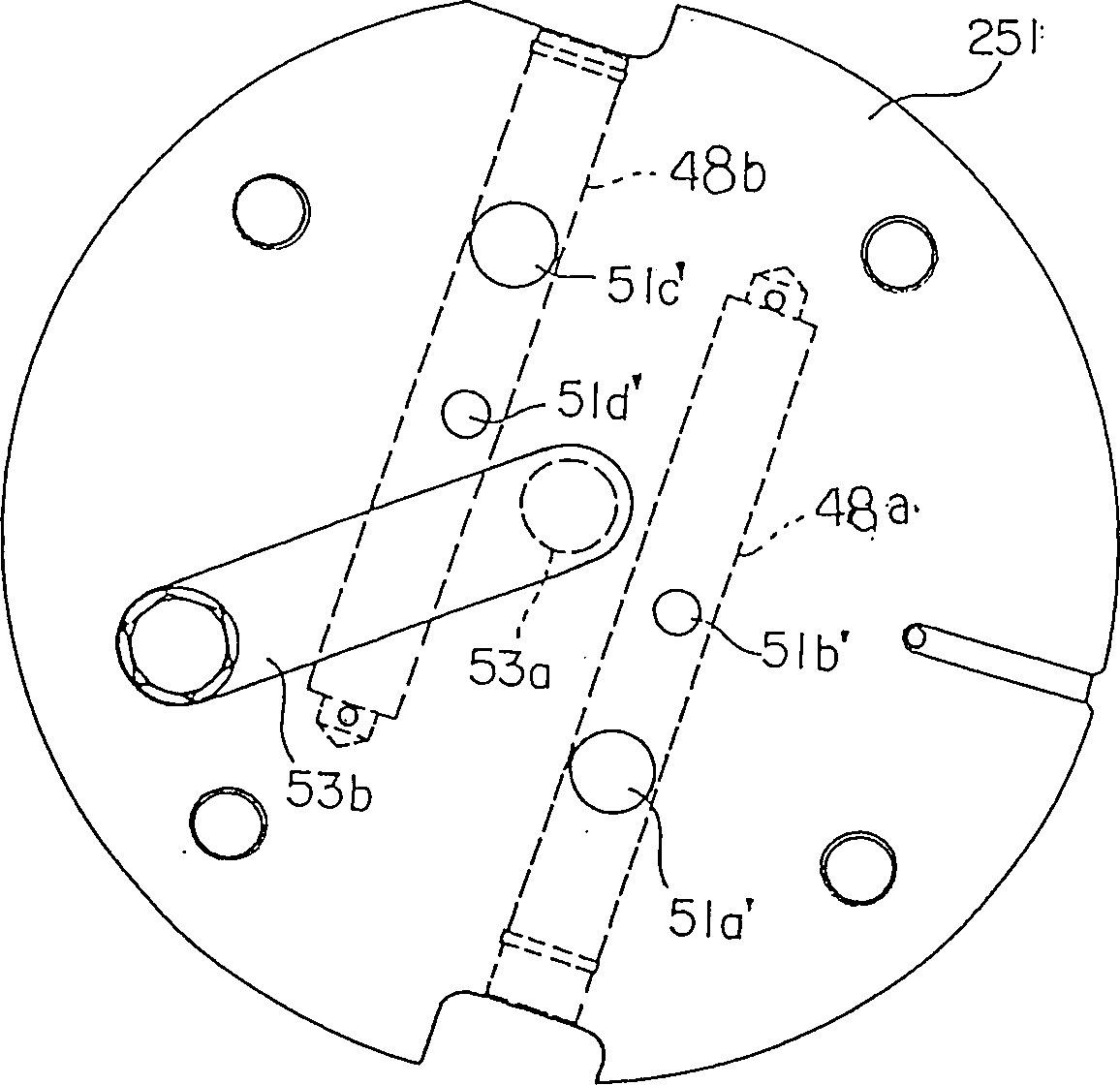

[0029] The fixed scroll 25 includes a disk-shaped fixed end plate 251, and a fixed screw 252 integrally formed therewith and protruding from the fixed end plate 251. As shown in FIG. Similarly, the orbiting scroll 26 includes a disk-shaped orbiting end plate 261 , and an orbiting screw 262 integrally formed therewith and protruding from the orbiting end plate 261 . Since the spiral members 252 and 262 are opposed to each other, compression pockets P1, P2 are formed between the fixed scroll member 25 and the orbiting scroll member 26 .

[0030] On the front plate 11, a drive shaft 13 is rotatably supported by radial bearings 16 and 19. As shown in FIG. An eccentric rod 14 axially p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com