Safety shut-off valve

A technology of safety cut-off valve and cut-off mechanism, which is applied in the direction of safety valve, lifting valve, valve details, etc., can solve the problems of reducing the service life of the valve disc, making it difficult to manufacture, and occupying a large space, so as to improve the internal organizational structure and avoid maintenance The effect of assembly error and convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

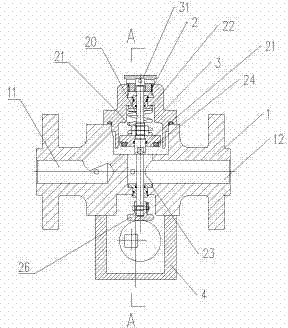

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

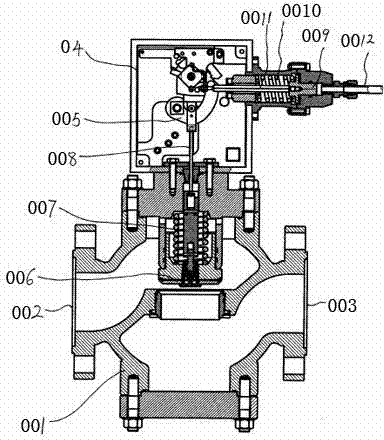

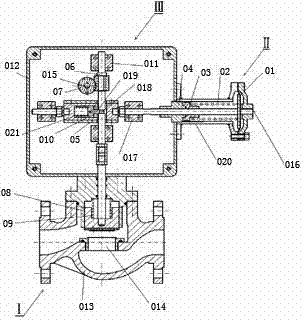

[0034] Such as image 3 with Figure 4 As shown, the safety cut-off valve of the present invention includes a valve body 1, an upper valve body 3 and a cut-off mechanism, the upper valve body 3 is connected to the upper end of the valve body 1 by screws for sealing the valve body 1, and the upper valve body 31 acts as a sealing bearing Pressure, reduce air scour, prolong the life of the valve plate components. The cut-off mechanism includes a cut-off part 2 and a cam connection device 4, and the cut-off part 2 and the cam connection device 4 are separately provided. The cut-off mechanism is arranged in the middle of the valve body 1 for connecting or cutting off the air inlet and the air outlet. The safety cut-off valve of the present utility model also includes a balance valve 6, which is used to connect the air inlet and the air outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com