Car door hinge

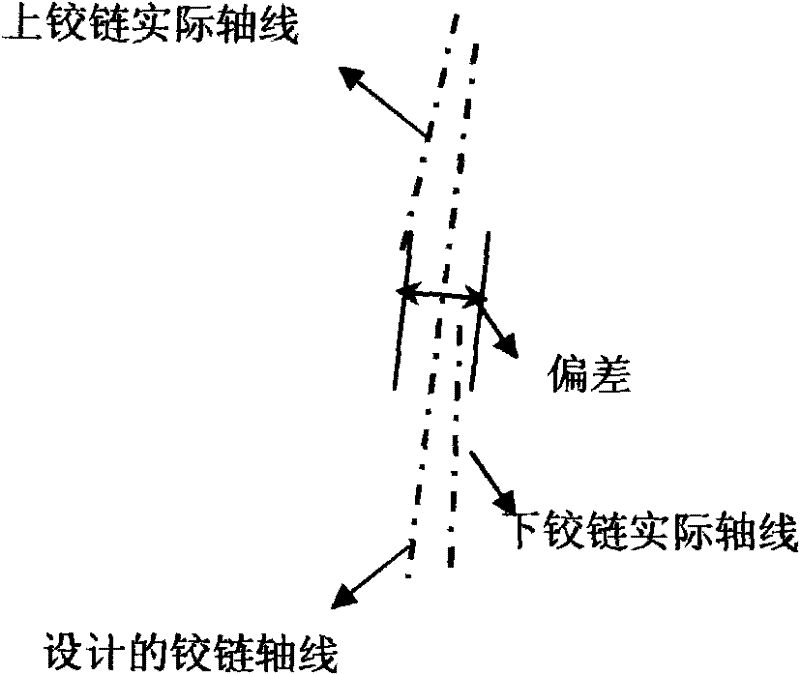

A technology of automobile doors and hinges, which is applied in the field of auto parts, can solve problems such as the deviation of the upper and lower hinges from different axes, and achieve the effects of reducing door closing force, saving manufacturing costs, and reducing possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

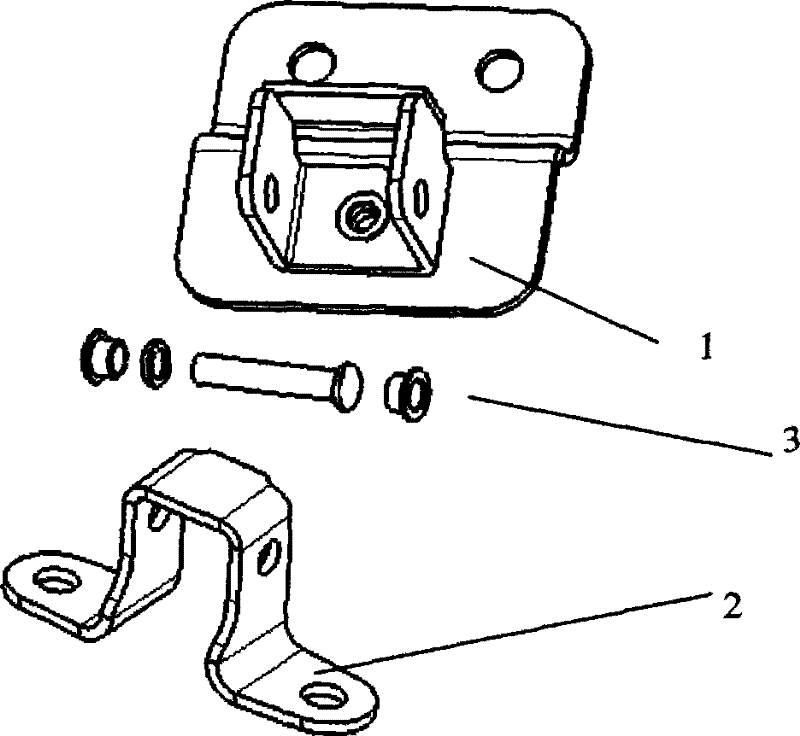

[0023] Attached below Figure 3-6 The present invention will be specifically described.

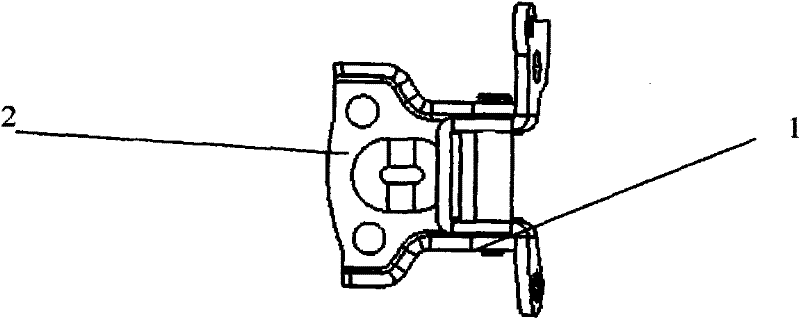

[0024] like Figure 3-5 As shown, the automobile door hinge of the present invention includes: a fixed leaf 1 , a movable leaf 2 and a connecting piece 3 . Fixed leaf 1 is suitable for being installed on the vehicle body structure, comprises the mounting part 11 that is installed on the vehicle body structure 103, is connected to the rotating part 14 on the mounting part 11 and the reinforcing plate 13 that is welded on the rotating part 14, and the mounting part 11 and rotating The parts 14 are connected together by rivets 12, and the rotating parts 14 can rotate around the rivets 12 in the installation plane of the mounting part 11, so as to adjust the axis of the hinge, so as to adapt to the axis of the lower hinge and eliminate the deviation of the coaxiality of the upper and lower hinges. Lubricant is required to reduce friction. like image 3 As shown, the rotating part 14 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com