Activity excitation type grinding aid used for vertical mill grinding mineral slag

A technology of active stimulation and grinding aid, applied in the field of admixtures for slag, can solve the problems of few research and application reports, unfavorable concrete durability, low early activity of slag, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

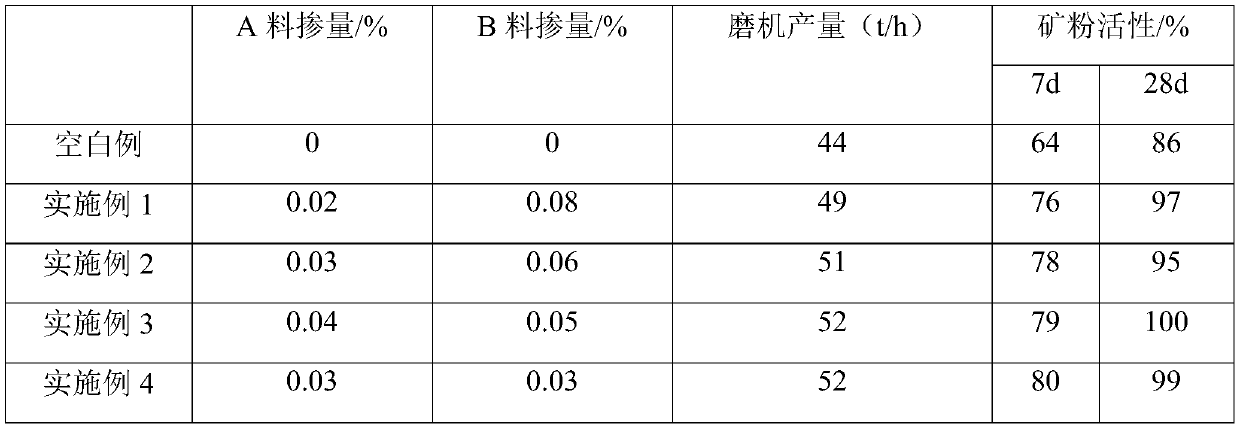

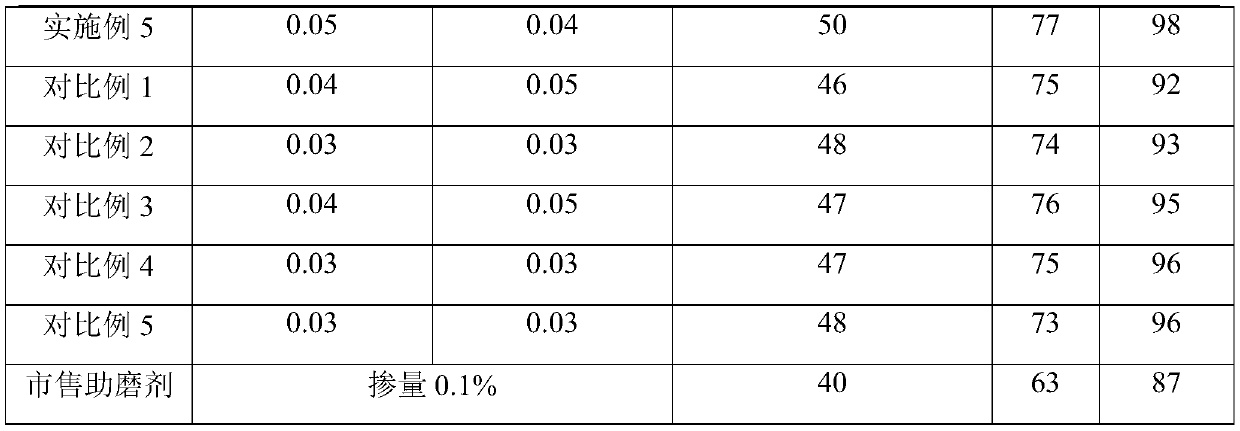

Examples

Embodiment 1

[0023] An active stimulating grinding aid for grinding slag in a vertical mill, which is composed of material A and material B, material A is composed of the following raw materials in parts by weight: 15 parts of polypropylene amine salt, 15 parts of diisopropylethanolamine, 5 parts of triethylene glycol, 10 parts of ethylene glycol butyl ether acetate, and 50 parts of water; material B is composed of the following raw materials in parts by weight: 8 parts of redispersible latex powder, 10 parts of superfine aluminum silicate, and 20 parts of activator parts, 40 parts of limestone powder.

[0024] The polyacrylamine salt is prepared by the following method: methacryloyloxyethyltrimethylammonium chloride and sodium methacrylsulfonate are mixed in a weight ratio of 3:1 and placed in a four-necked flask , add distilled water to dilute to a mass percent concentration of 20%, pass N 2 After 30 minutes, the temperature was raised to 75°C, and the initiator solution was added drop...

Embodiment 2

[0033] An active stimulating grinding aid for grinding slag in a vertical mill, which is composed of material A and material B, material A is composed of the following raw materials in parts by weight: 30 parts of polypropylene amine salt, 10 parts of diisopropylethanolamine, 10 parts of triethylene glycol, 3 parts of ethylene glycol butyl ether acetate, and 75 parts of water; material B consists of the following raw materials in parts by weight: 5 parts of redispersible latex powder, 20 parts of superfine aluminum silicate, and 10 parts of activator parts, 70 parts of limestone powder.

[0034] The polyacrylamine salt is prepared by the following method: methacryloyloxyethyltrimethylammonium chloride and sodium methacrylsulfonate are mixed in a weight ratio of 5:1 and placed in a four-necked flask , add distilled water to dilute to a mass percent concentration of 35%, pass N 2 After 20 minutes, the temperature was raised to 65°C, and the initiator solution was added dropwis...

Embodiment 3

[0043] An active stimulating grinding aid for grinding slag in a vertical mill, which is composed of material A and material B, material A is composed of the following raw materials in parts by weight: 20 parts of polypropylene amine salt, 12 parts of diisopropylethanolamine, 8 parts of triethylene glycol, 7 parts of ethylene glycol butyl ether acetate, and 60 parts of water; material B consists of the following raw materials in parts by weight: 7 parts of redispersible latex powder, 15 parts of superfine aluminum silicate, and 16 parts of activator parts, 55 parts of limestone powder.

[0044] The polyacrylamine salt is prepared by the following method: methacryloxyethyltrimethylammonium chloride and sodium methacrylsulfonate are mixed in a weight ratio of 4:1 and then placed in a four-necked flask , add distilled water to dilute to a mass percent concentration of 25%, pass N 2 After 25 minutes, the temperature was raised to 70°C, and the initiator solution was added dropwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com