Automatic pouring jacket paper tray center positioning clamping device and paper carton clamping forming method

A technology of center positioning and clamping device, which is applied in the direction of packaging, etc., can solve the problems of incomplete casing, high cost, slow speed, etc., and achieve the effect of improving the success rate of casing, good centering, and increasing the supporting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

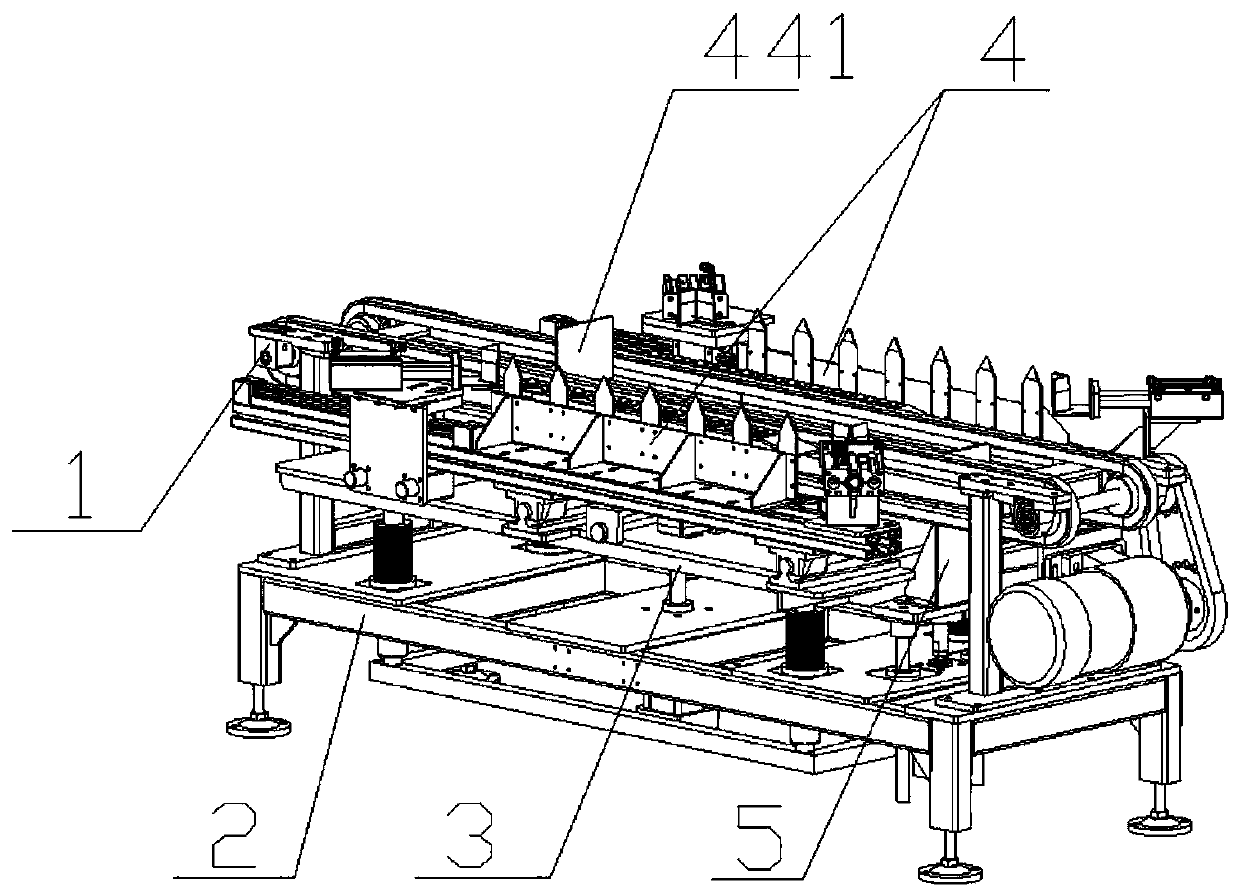

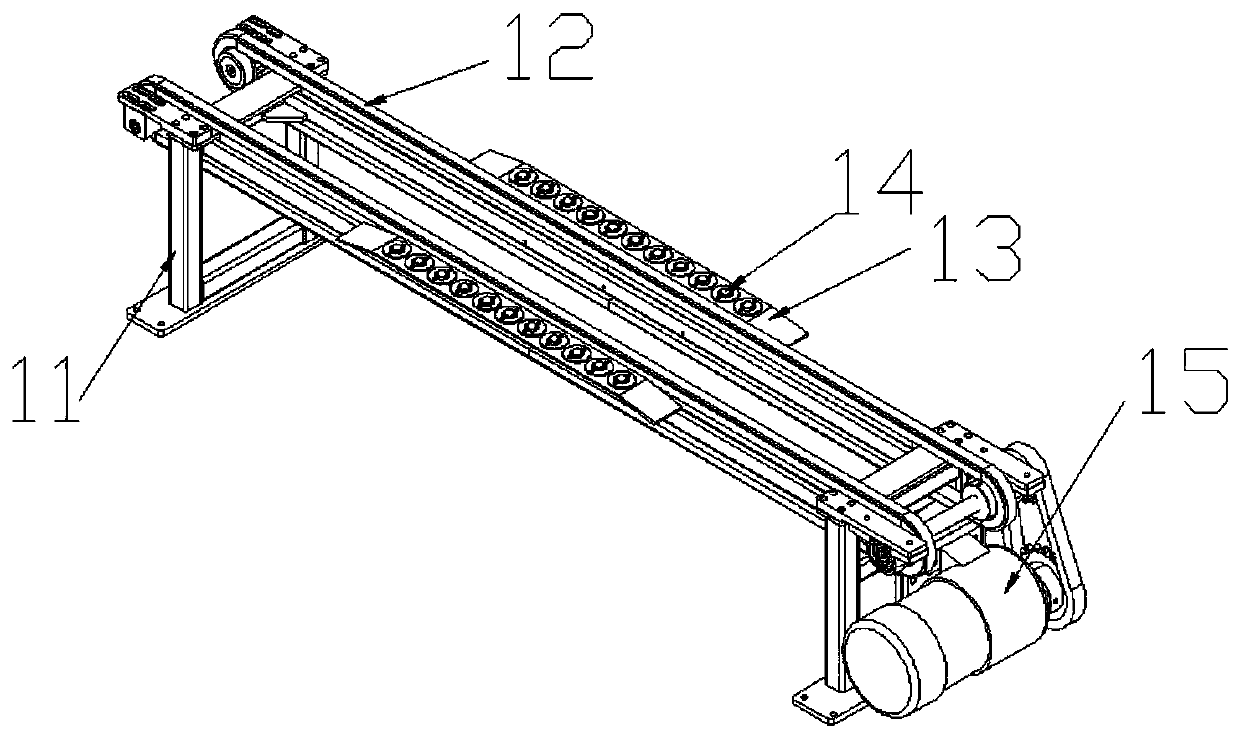

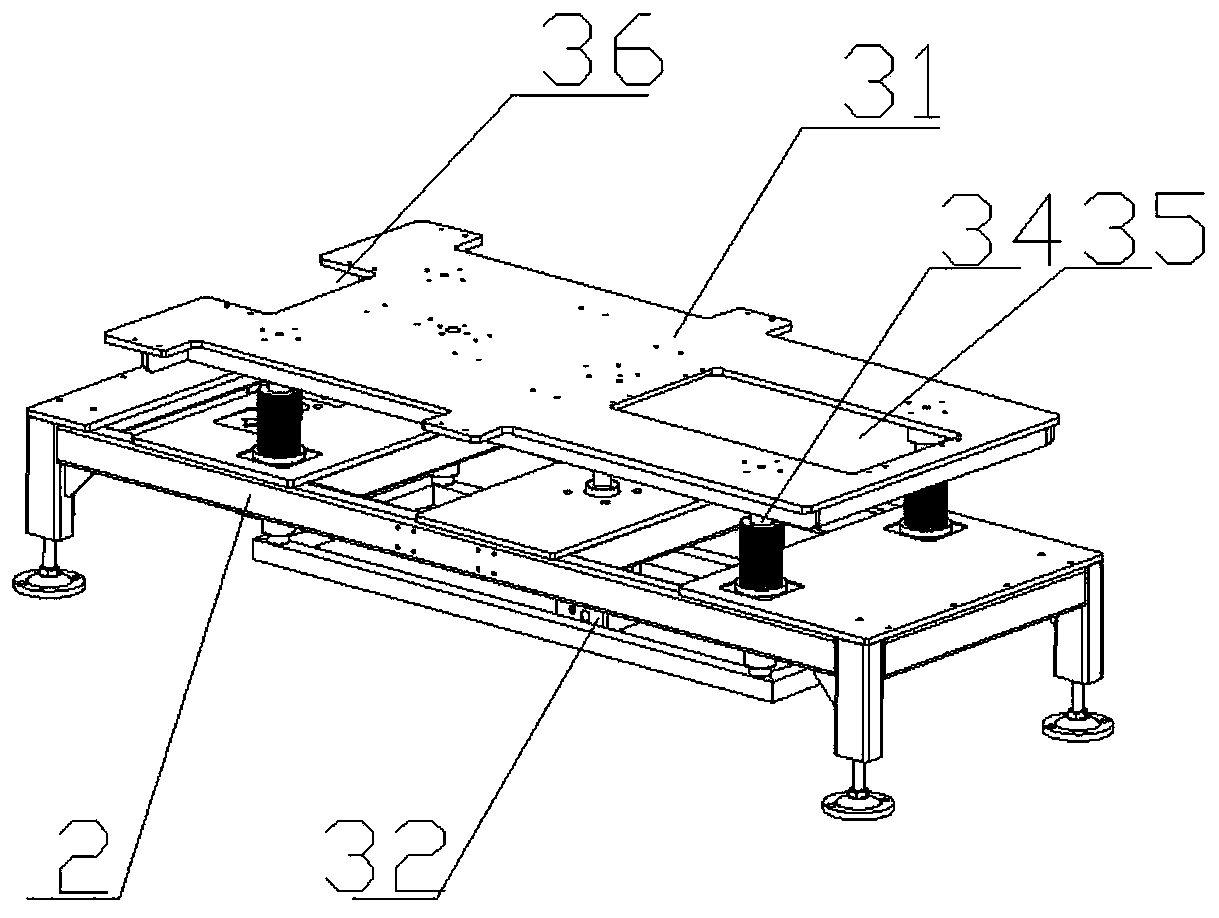

[0041] See attached Figure 1-8, is a paper tray center positioning and clamping device for an automatic box case of the present invention, including a double-speed chain mechanism 1, a bracket base 2, a lifting mechanism 3, a clamping and positioning shaping mechanism 4 and a front blocking mechanism 5. The lifting mechanism 3, the clamping and positioning shaping mechanism 4 and the front blocking mechanism 5 are respectively provided with cylinders; the clamping and positioning shaping mechanism 4 includes an angle clamping mechanism 43, a first positive pressure piece 441 and a side splint 45; the front blocking mechanism 5 includes a second positive pressure piece 57 and a photoelectric sensor 58; the cylinder on the lifting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com