Plasma cutting device and method for underground oil casing

A cutting device and plasma technology, applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of large cutting force, complex ground equipment, tool wear, etc., and achieve the effect of high cutting success rate, simple equipment and precise cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

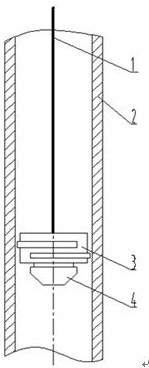

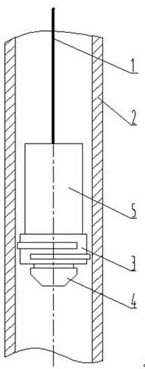

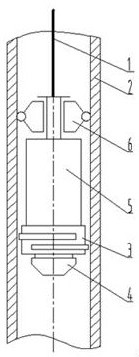

[0055]Preferred embodiment 1, the downhole cutting string mainly includes cables, electrode feeding mechanism, guide shoe and so on. In the plasma cutting process, after the cable carrying the tool string enters the specified position inside the stuck oil / casing, first apply positive and negative voltages between the downhole oil / casing and the tool electrodes, and the electrodes in the electrode feeding mechanism are under the control of the servo system Continuously moving to the inner wall of the pipe string, when the electrode and the inner wall of the pipe string reach a certain gap, a violent plasma discharge will occur. Under the high temperature and high pressure of the plasma discharge, the pipe string material will be removed. Through the surface rotary table and other equipment, the electrode feeding mechanism is rotated to realize the circumferential cutting of downhole oil / casing.

[0056] In order to improve the cutting performance of stuck oil / casing string down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com