Online length measuring method for thermal-state steel pipe

A steel pipe and length measuring technology, which is applied in length measuring device, length control, metal rolling, etc., can solve the problems of low adjustment accuracy, high investment cost and short service life of continuous rolling mills, and achieves the improvement of continuous rolling adjustment accuracy and production unit. The effect of yield and investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

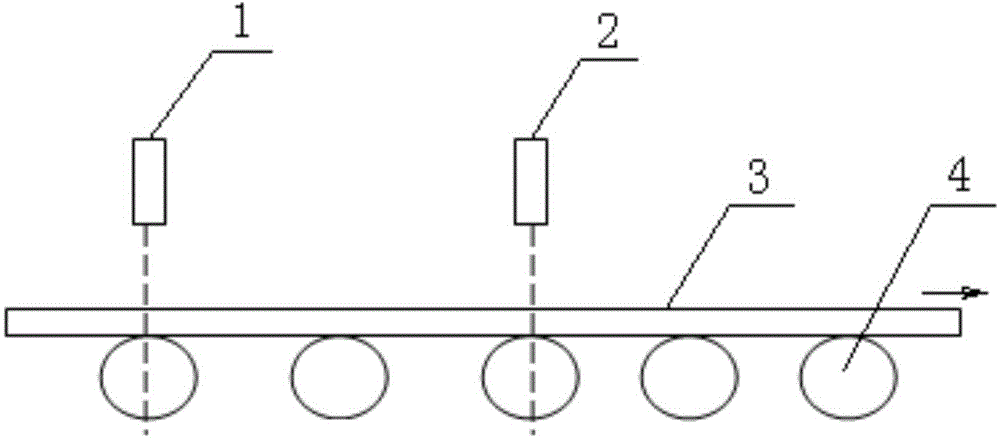

[0020] The online length measurement method for hot steel pipes of the present invention utilizes the original PLC control system, and at the same time installs the first hot metal detector 1 above the roller table 4 at 2 meters from the outlet of the continuous rolling mill, and installs the first hot metal detector 1 at the roller table 4 at 14 meters. The second hot metal detector 2 is installed on the top, and the response time of the two hot metal detectors is an optical fiber hot metal detector with a response time of 5ms. Both hot metal detectors are connected and communicated with the PLC.

[0021] When the hot steel pipe 3 is rolled by the continuous rolling mill, the head of the hot steel pipe 3 first passes through the first hot metal detector 1 at a relatively short distance, and the first hot metal detector 1 converts the detected value into an electrical signal and inputs it to the PLC At this time, the PLC starts timing; when the head of the hot steel pipe passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com