Hinging-type dump truck container rear baffle and hinging-type dump truck

A technology for tailgates and dump trucks, which is applied in the direction of vehicles with inclined bearing movement, etc., and can solve the problems of poor sealing effect of tailgates, low opening and closing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

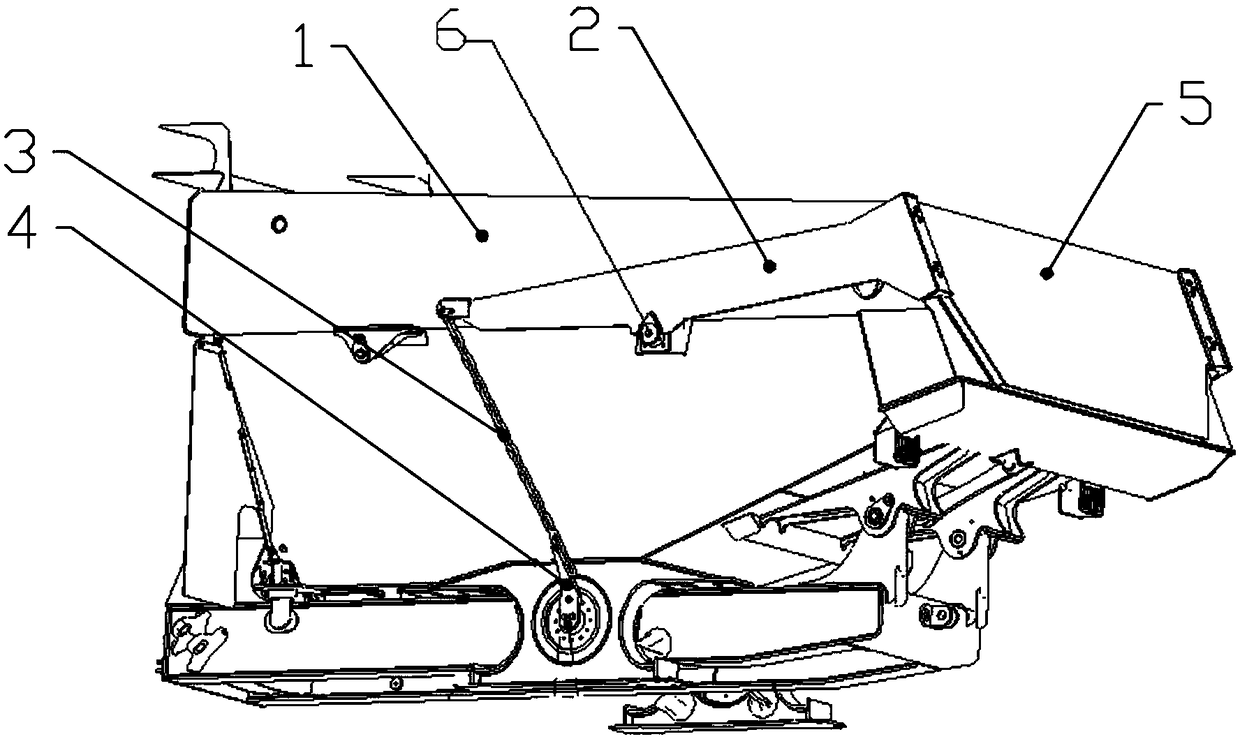

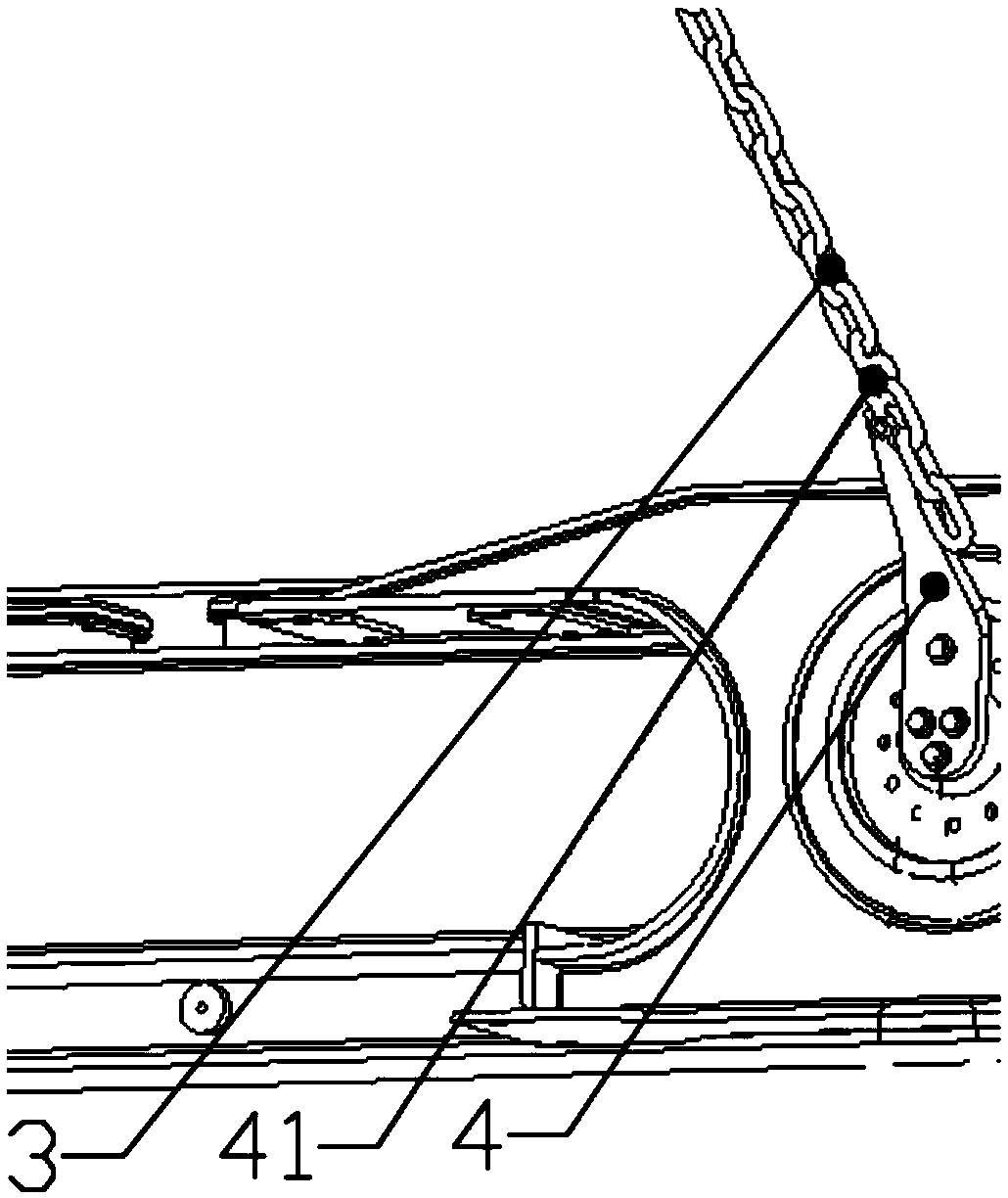

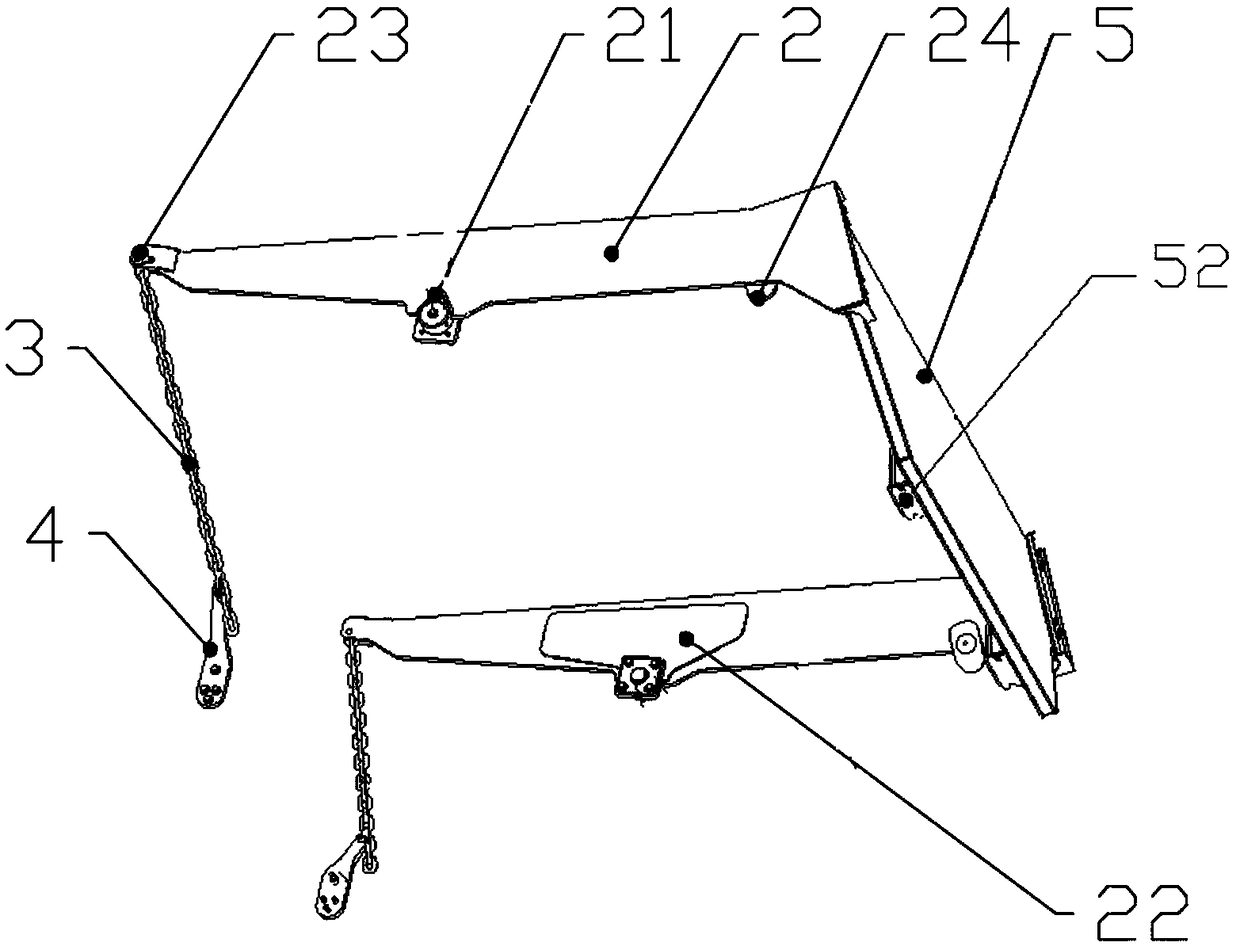

[0028] Such as Figure 1 to Figure 3 Shown: a articulated dump truck container tailgate, including side arm 2, chain 3, tailgate 5, mounting seat 6 and mounting plate 4 arranged on the side of vehicle frame 11, one end of side arm 2 is provided with Ear plate 23, the other end is provided with side arm baffle plate 25, also is provided with mounting block 21 between the ear plate 23 of side arm 2 and side arm baffle plate 25, and mounting seat 6 is connected to the side portion of cargo box 1, and tailgate Plate 5 two ends are provided with extension end 51 ( Figure 7 ), lug plate 23 connects chain 3, and side arm baffle plate 25 connects the two ends of tailgate 5, and mounting block 21 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com