Patents

Literature

34results about "Length control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

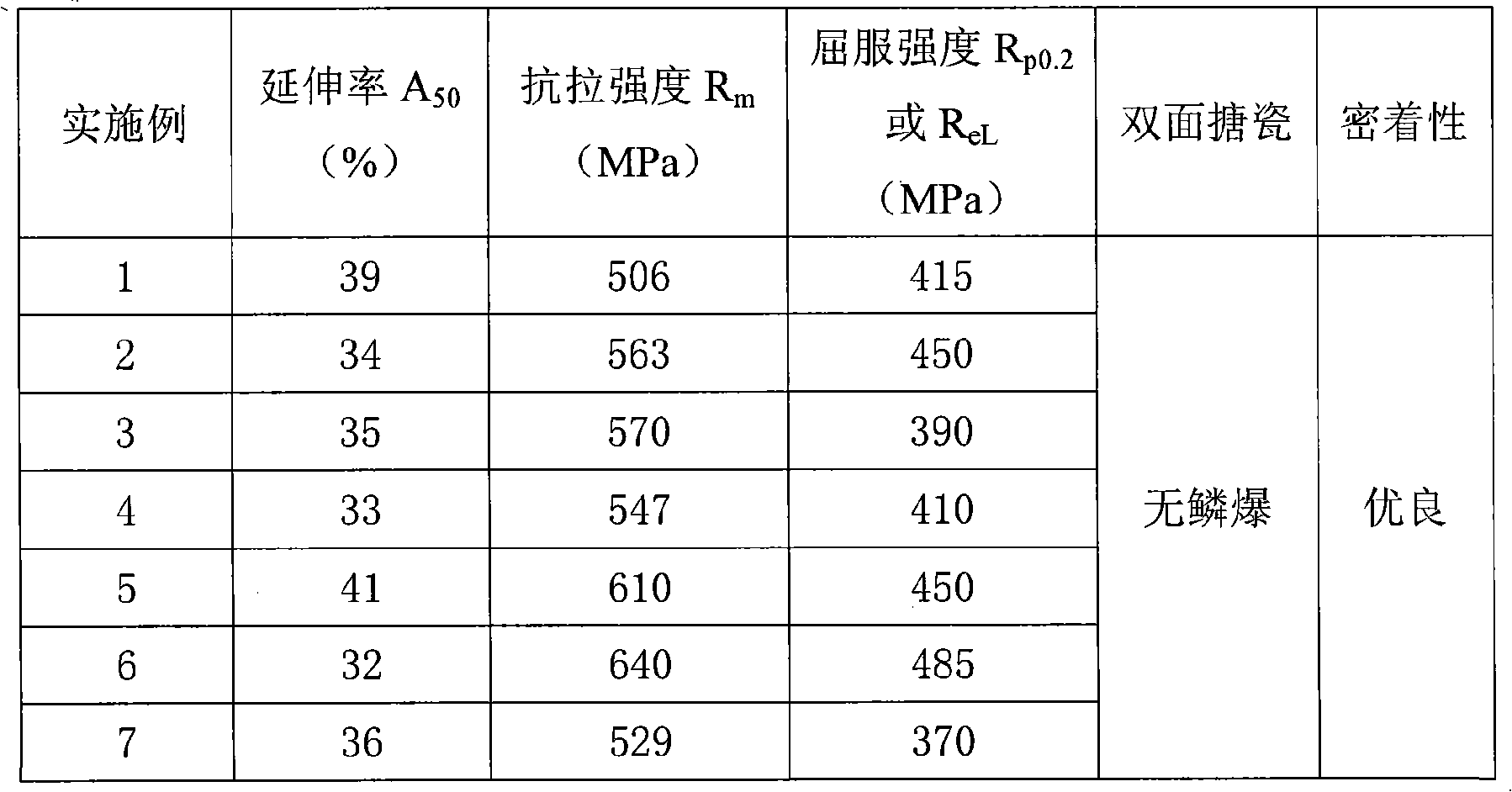

Hot rolling high strength steel plate for two-sided porcelain enamel and manufacturing method thereof

InactiveCN101353758AHigh strengthMeet pressure requirementsLength control deviceChemical reactionSheet steel

The invention provides a hot-rolled high strength steel sheet used in double-face enamel and a preparation method thereof, comprising the following chemical composition: C: 0.05 to 0.15 weight percent, Si: less than or equal to 1.0 weight percent, Mn: 0.5 to 2.0 weight percent, P: less than or equal to 0.05 weight percent, S: less than or equal to 0.05 weight percent, Al: 0.01 to 0.10 weight percent, N: 0.008 to 0.015 weight percent, Ti: less than or equal to 0.05 weight percent, V: 0.02 to 0.2 weight percent, and the rest are Fe and inevitable impurities. By controlling the hot rolling technology and the cooling speed, second phase particles which are tiny and dispersed are ensured to be generated from vanadium and titanium in the steel, thus enhancing the strength, fish scaling resistance and adherence of the steel sheet; and the products after enamel firing can still maintain higher strength, thus better meeting the compression resistance requirements of different porcelain products, and being capable of being used for producing chemical reaction tanks and water treatment tanks and the like from double-face enamel.

Owner:BAOSHAN IRON & STEEL CO LTD

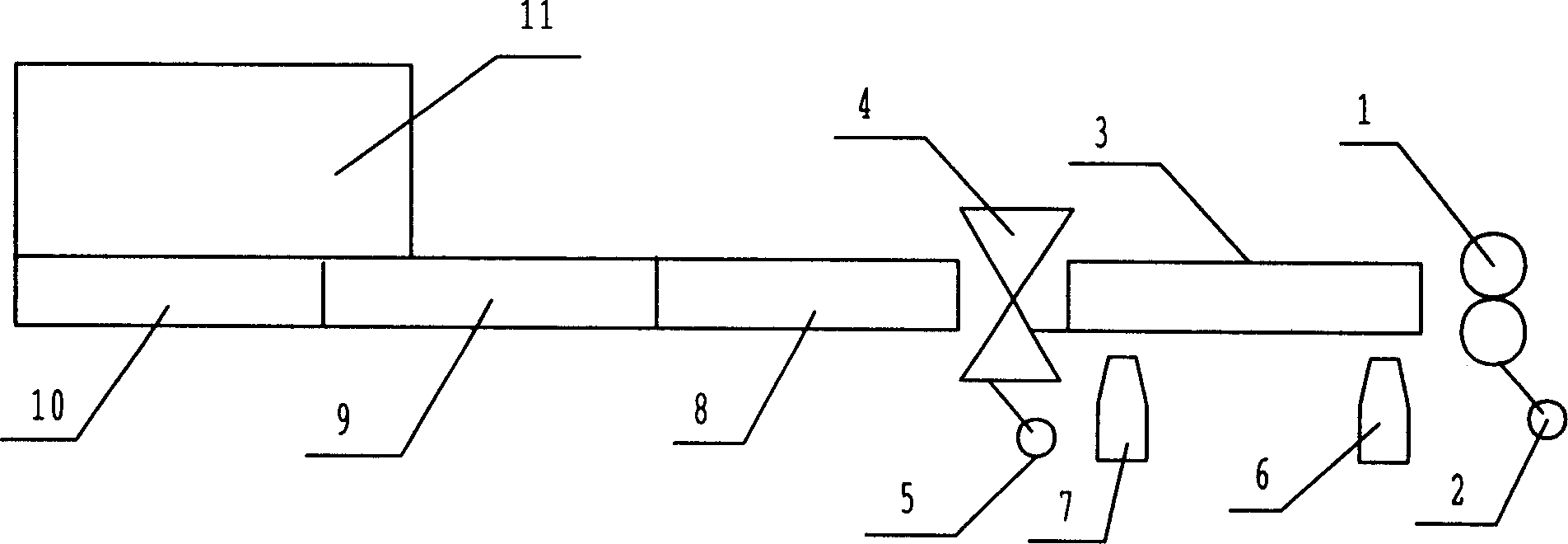

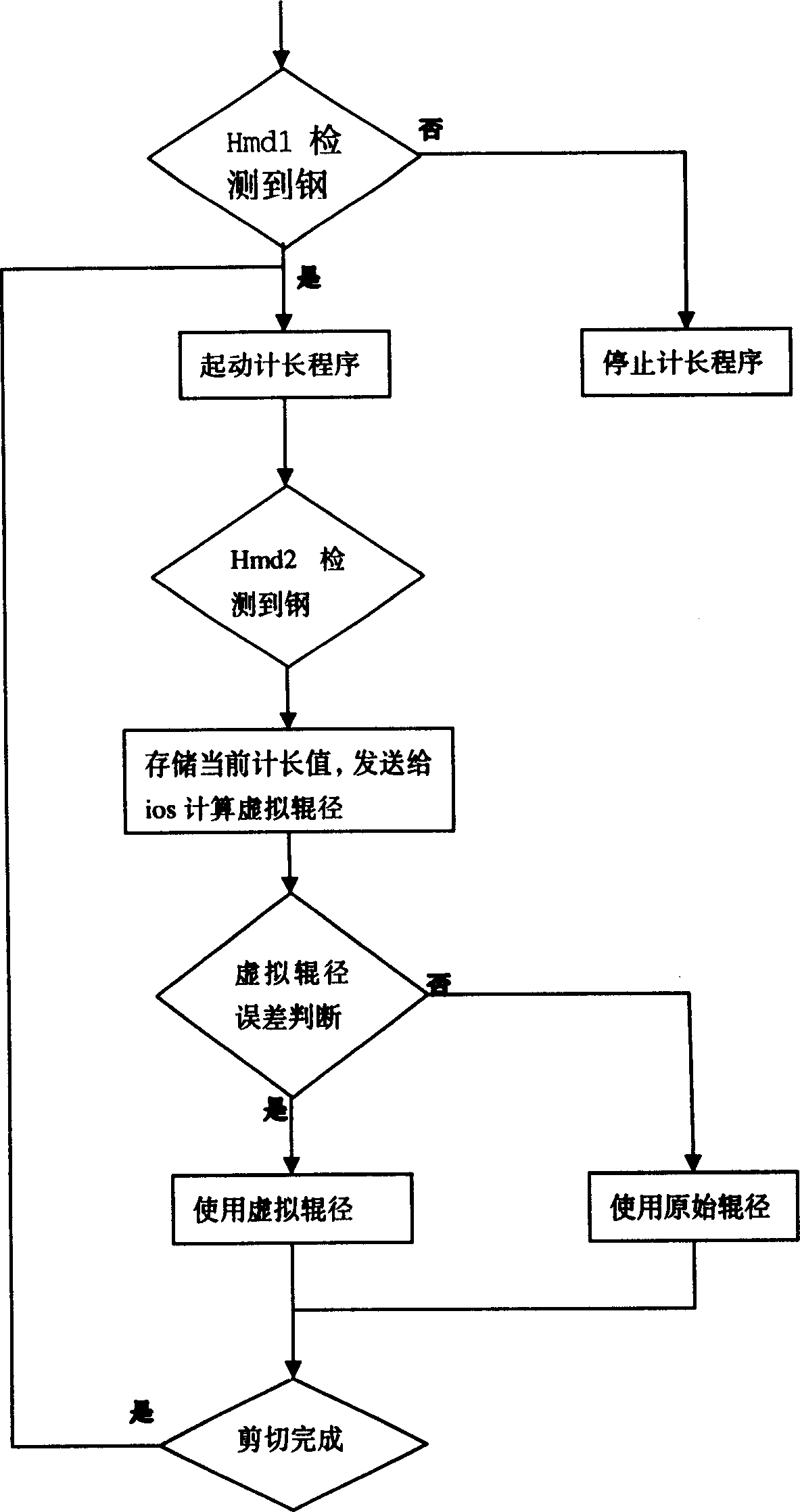

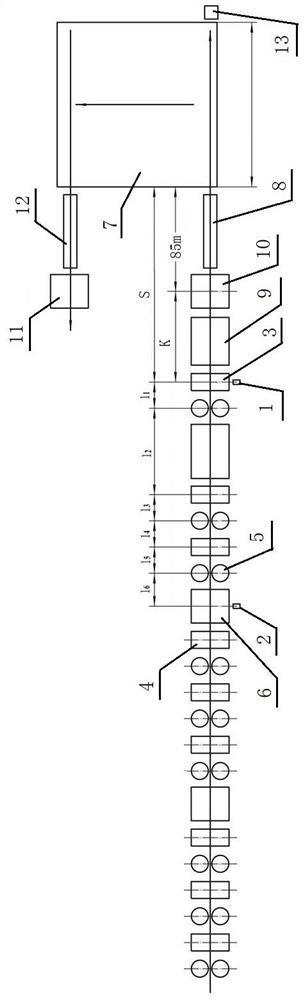

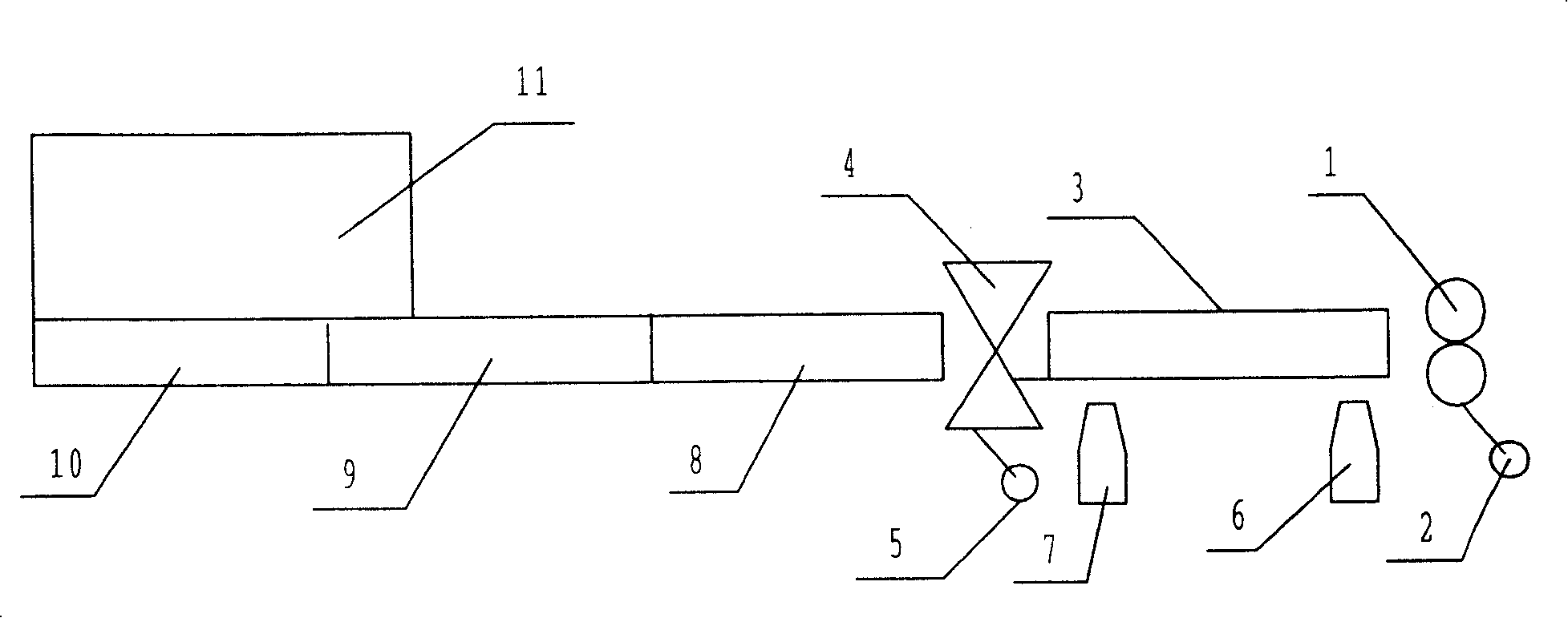

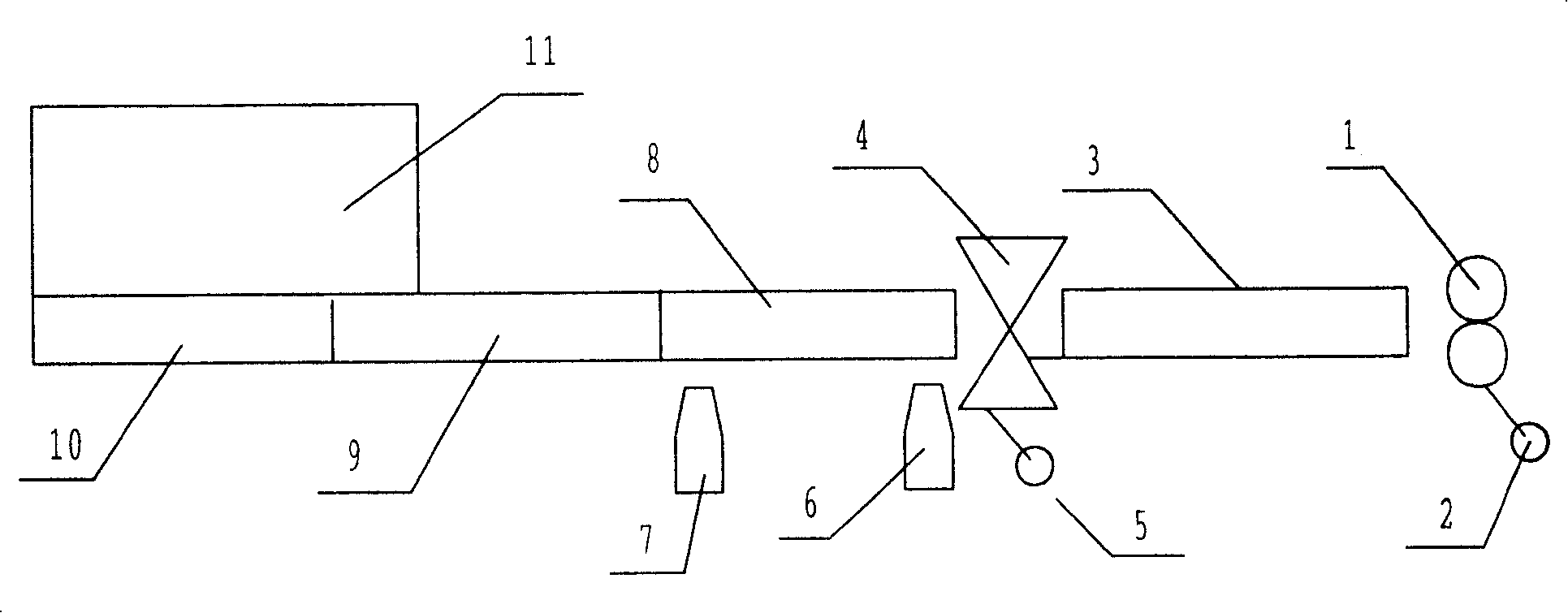

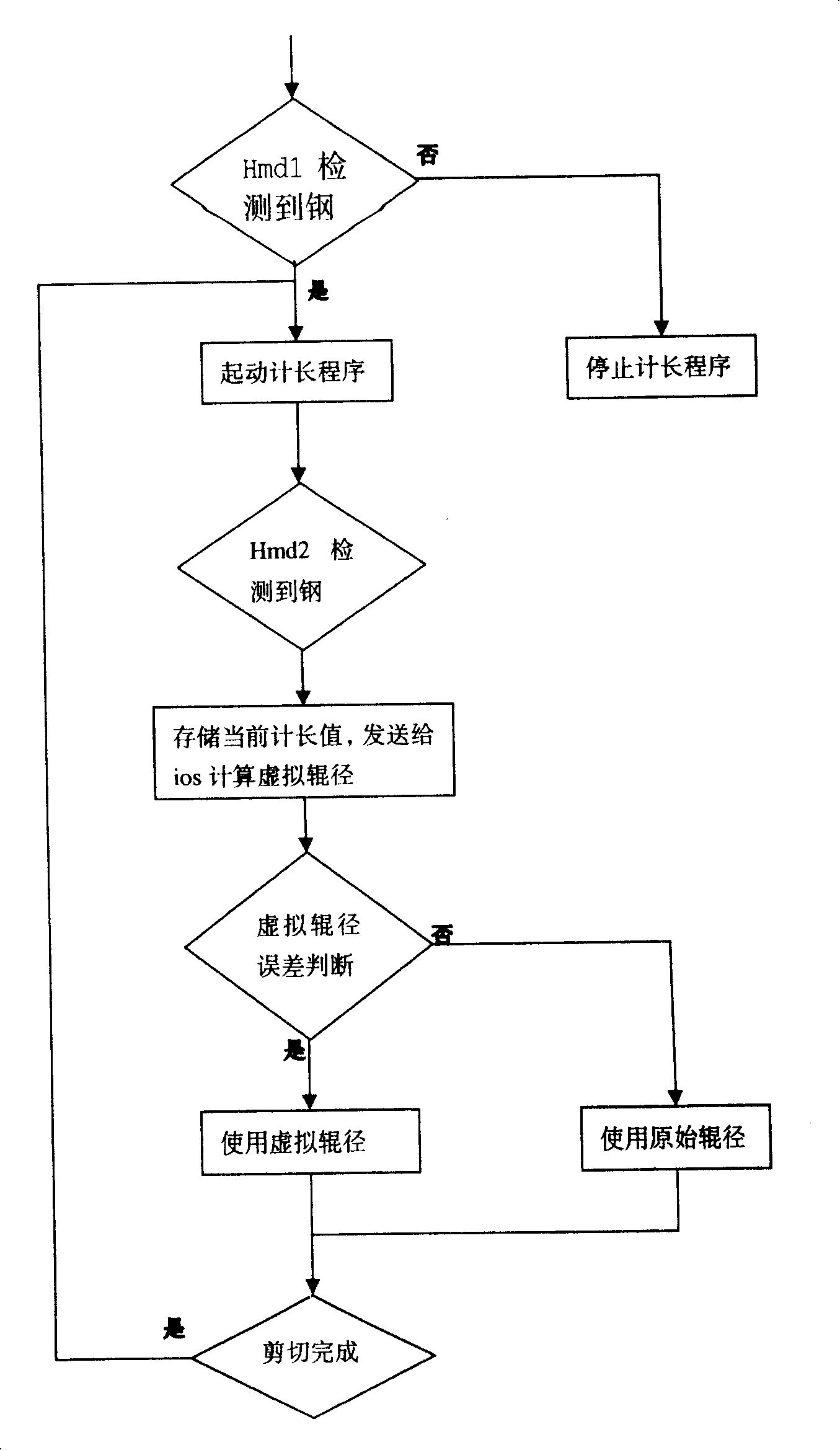

Thermomultiplying ruler shear precision optimizing method for bar production

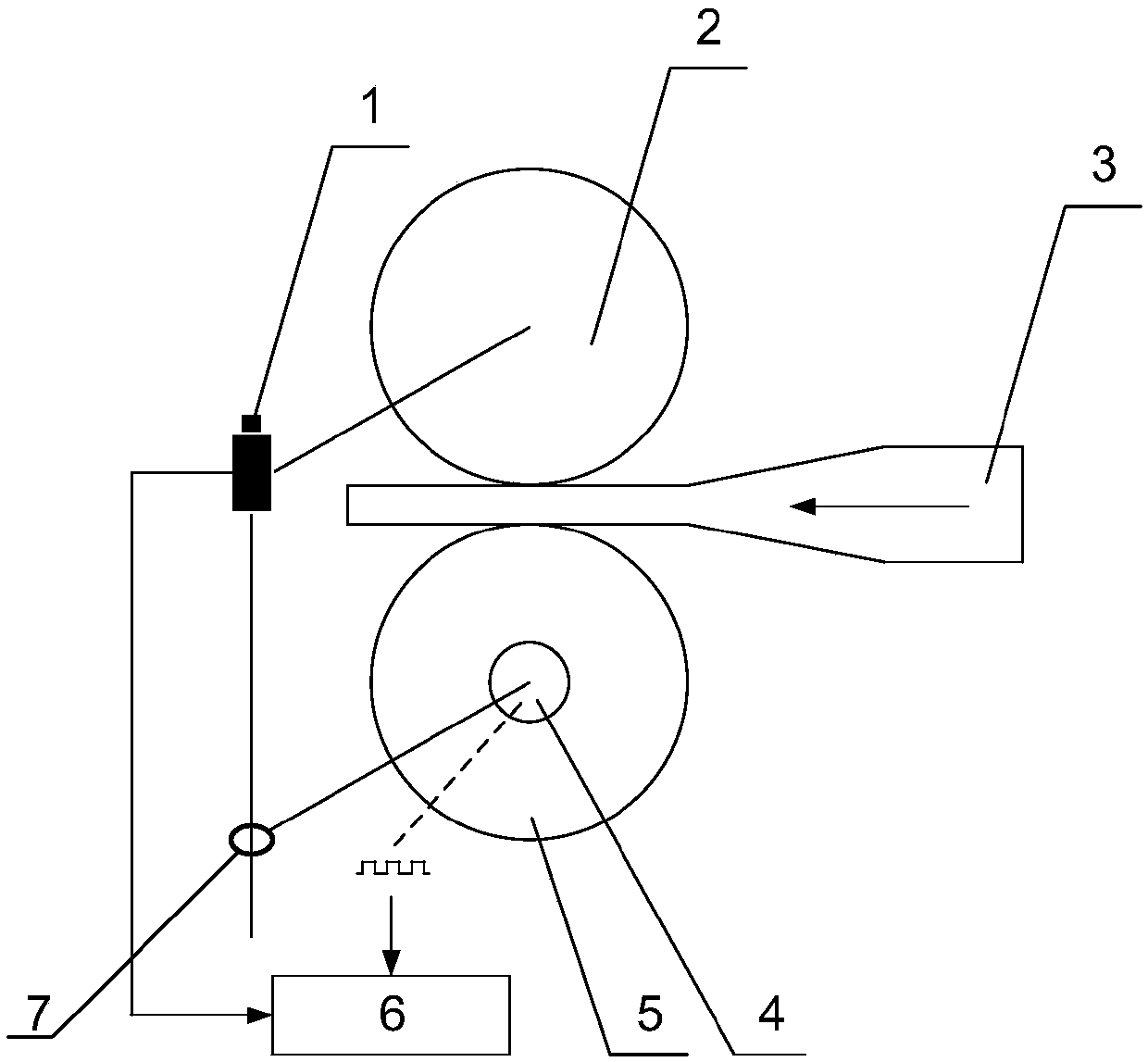

InactiveCN1850380AImprove the accuracy of length measurement and shearingEliminate the effect of length measurementLength control deviceMeasuring devicesEngineeringMetal detectors

The present invention relates to a thermal multiple-length shearing accuracy optimization method in production of rod material, belengting to the field of pressure processing technology for raising rod material shearing accuracy. Said invention uses two rotating speed pulse coders and two hot-metal detectors as speed-measuring sensor and uses a programmable controller as speed-measuring controller. Its optimization method includes the following steps: firstly, utilizing shearing point of thermal multiple length shears and two hot-metal detectors after shearing operation to detect out the line speed of every thermal multiple length steel; then utilizing sail line speed to calculate the 'virtual roll diameter' value which can be used to reach said line speed under the rotating speed of said finished product rolling mill; transferring the 'virtual roll diameter' value into tength-measuring program and substituting original inputted roll diameter value; after every shearing operation repeating the above-mentioned steps. The invented shearing accuracy can be up to plus or minus 50mm.

Owner:HEBEI IRON AND STEEL

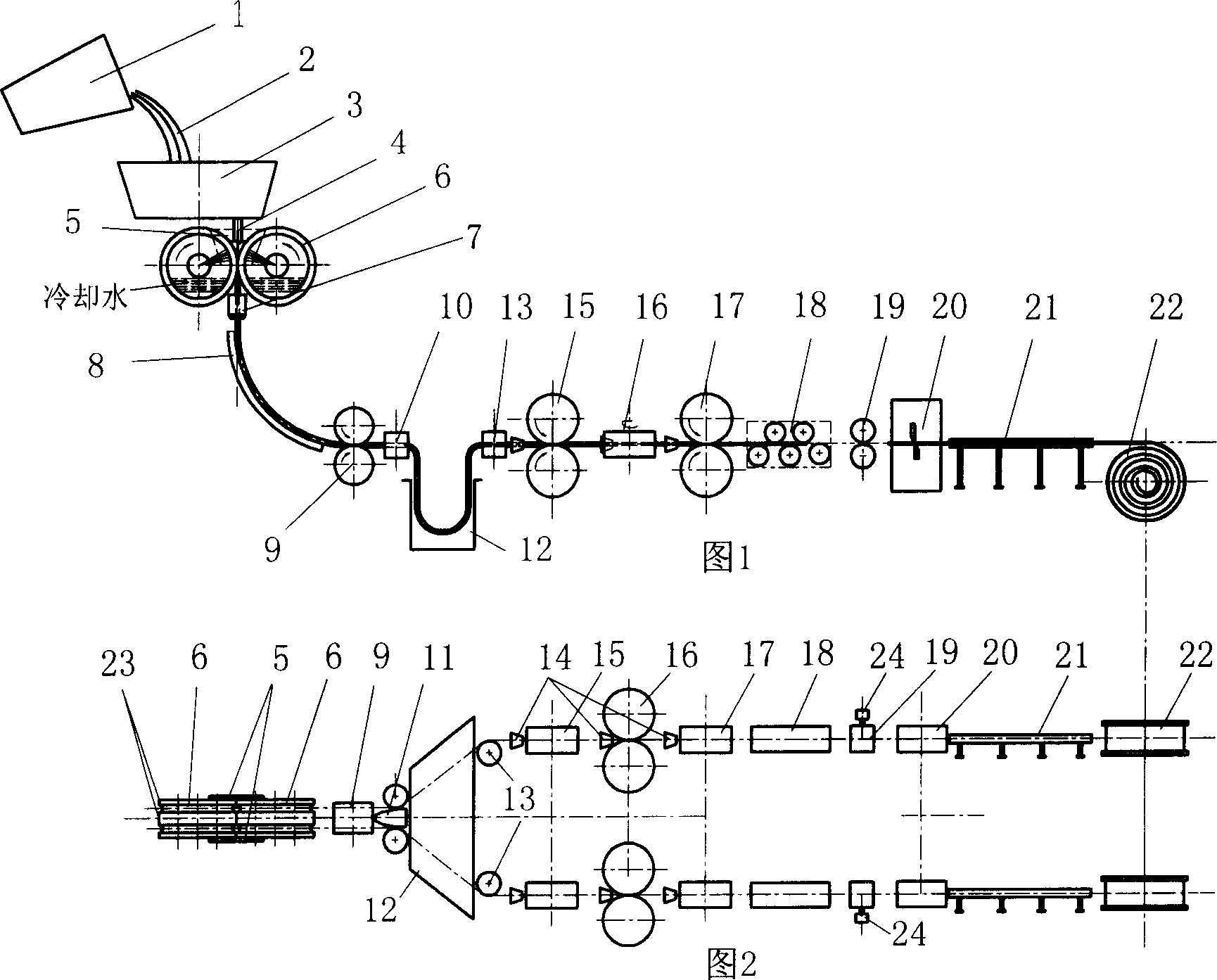

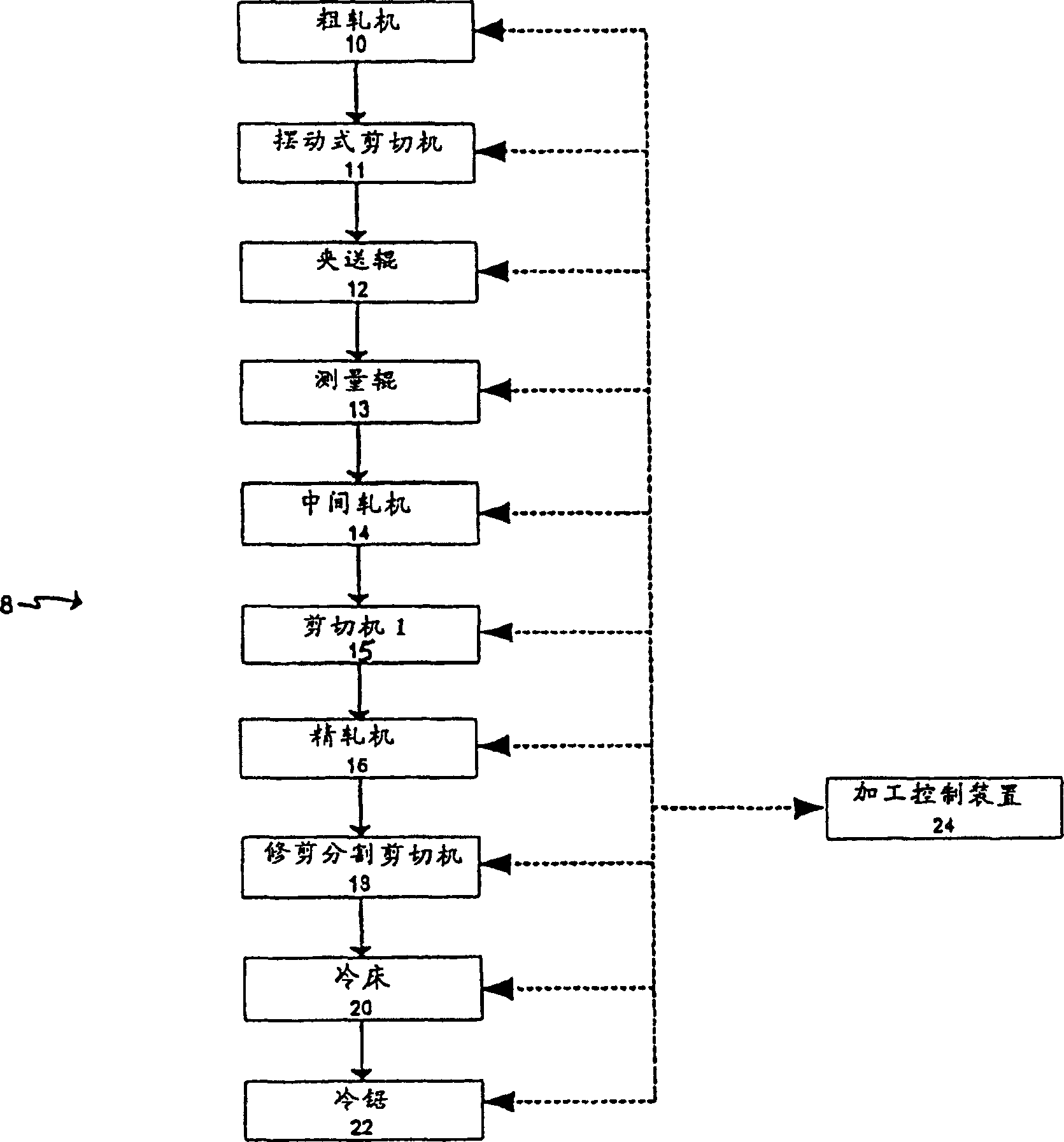

New technology of bar material contiauous casting and milling

InactiveCN1824399AReduce the number of process passesReduce production capacityLength control deviceMeasuring devicesMelting tankLiquid metal

The present invention relates to a new process for continuously casting and rolling bar material, belonging to the field of metallurgical forming technology. It is characterized by that it is a technical process for directly casting liquid metal and rolling it to make it be formed into bar material. Said invention also provides the concrete steps of said new process.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

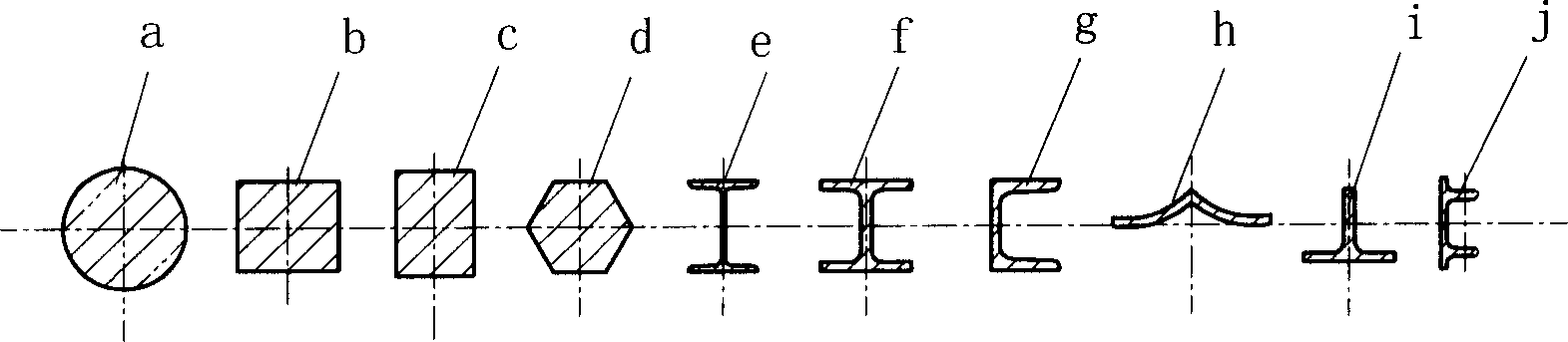

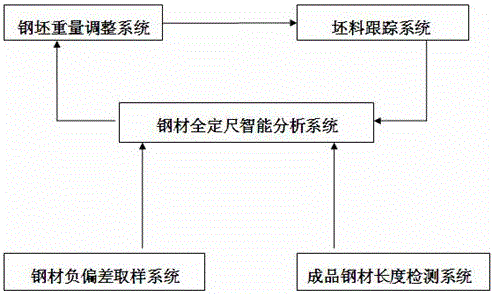

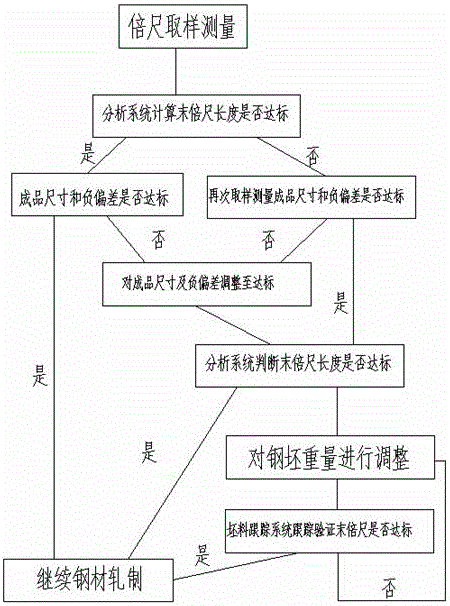

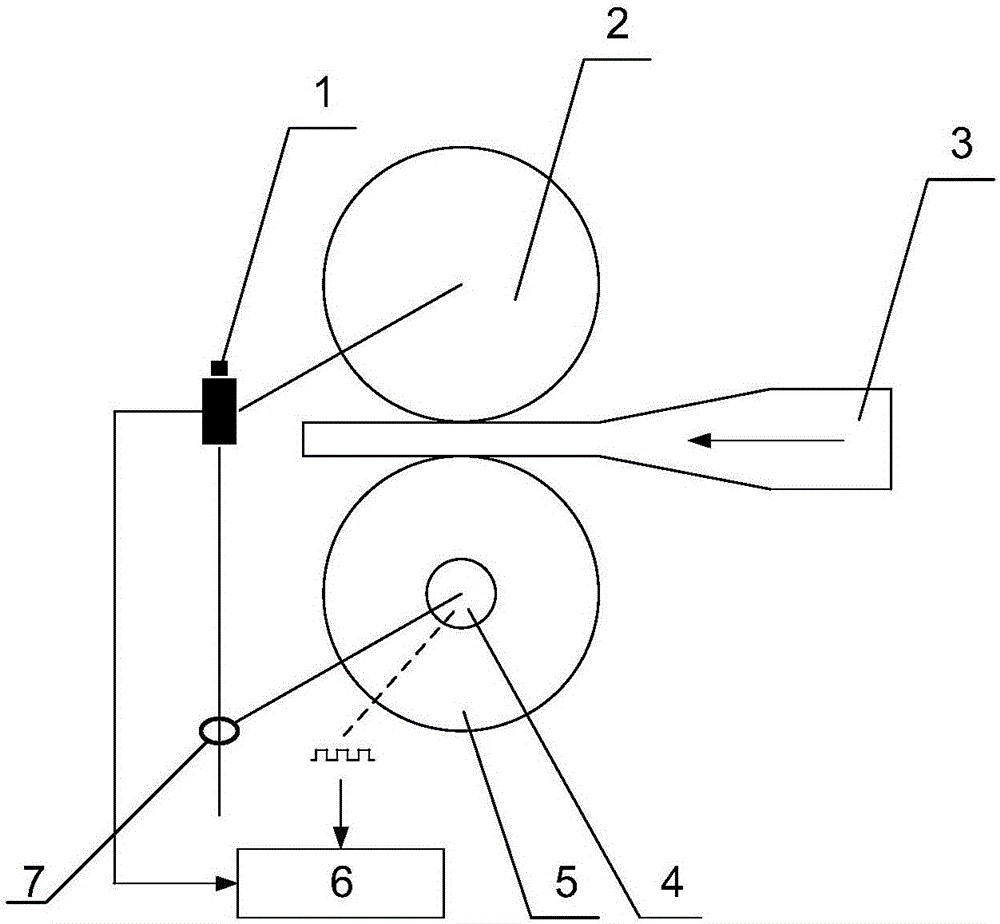

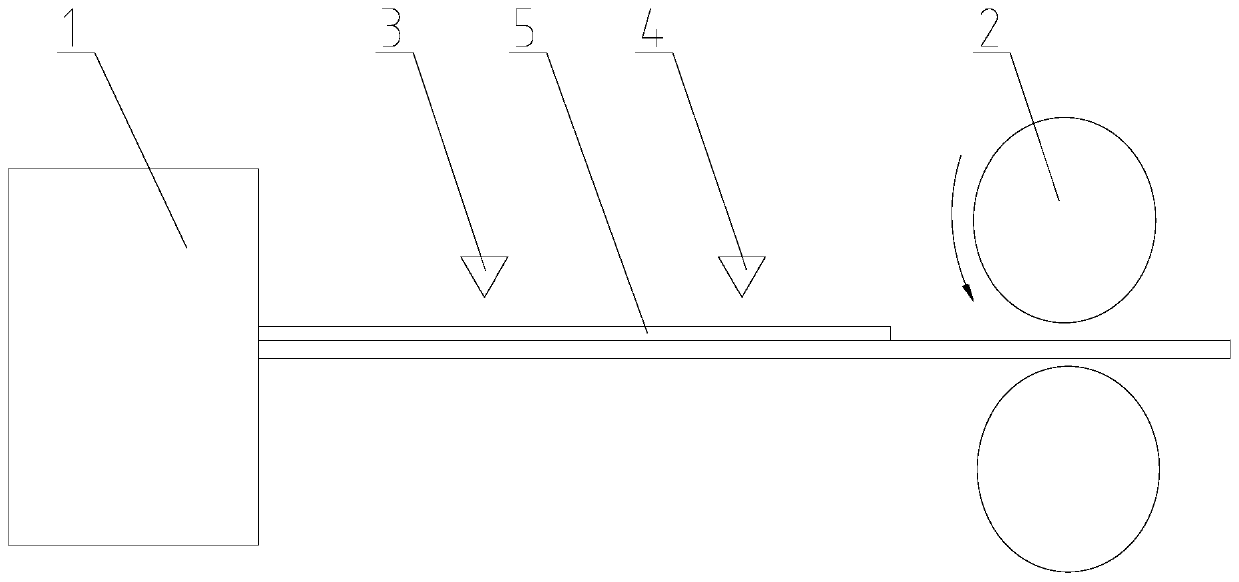

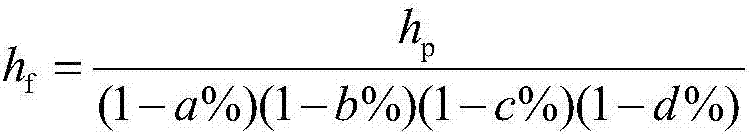

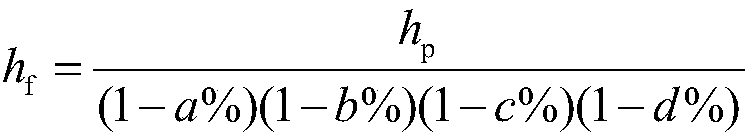

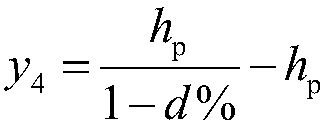

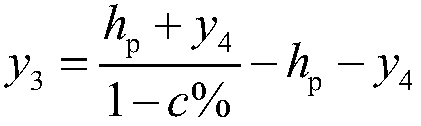

Bar steel full fixed-length intelligent control system and fixed-length control method

ActiveCN106799406ASize realizationSolve production difficultiesLength control deviceMeasuring devicesAnalysis dataSample Measure

The invention provides a bar steel full fixed-length intelligent control system and a fixed-length control method. The bar steel full fixed-length intelligent control system comprises a billet weight adjusting system, a blank tracking system, a finished product steel length detecting system, a steel full fixed-length intelligent analyzing system and a steel minus deviation sampling system. The steel minus deviation sampling system carries out sample measuring on samples, measured data is transmitted to the steel full fixed-length intelligent analyzing system to be analyzed, the steel full fixed-length intelligent analyzing system judges whether the final rate of fixed-length reaches the standard or not, if the standard is not reached, the analyzed data is transmitted to the billet weight adjusting system so that the billet weight can be adjusted, the blank tracking system monitors the following procedures of adjusted billets, the finished product steel length detecting system collects and feeds data of finally fixed-length materials back to the steel full fixed-length intelligent analyzing system to judge whether the billet weight needs to be adjusted again or not, and the rate of fixed-length can reach 99.7 %.

Owner:SHANDONG PENGHAI ENERGY SAVING TECH CO LTD

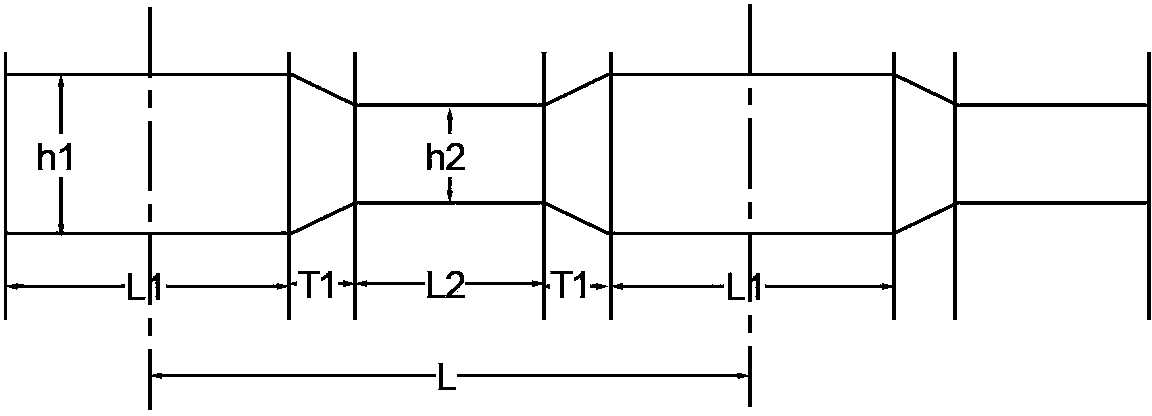

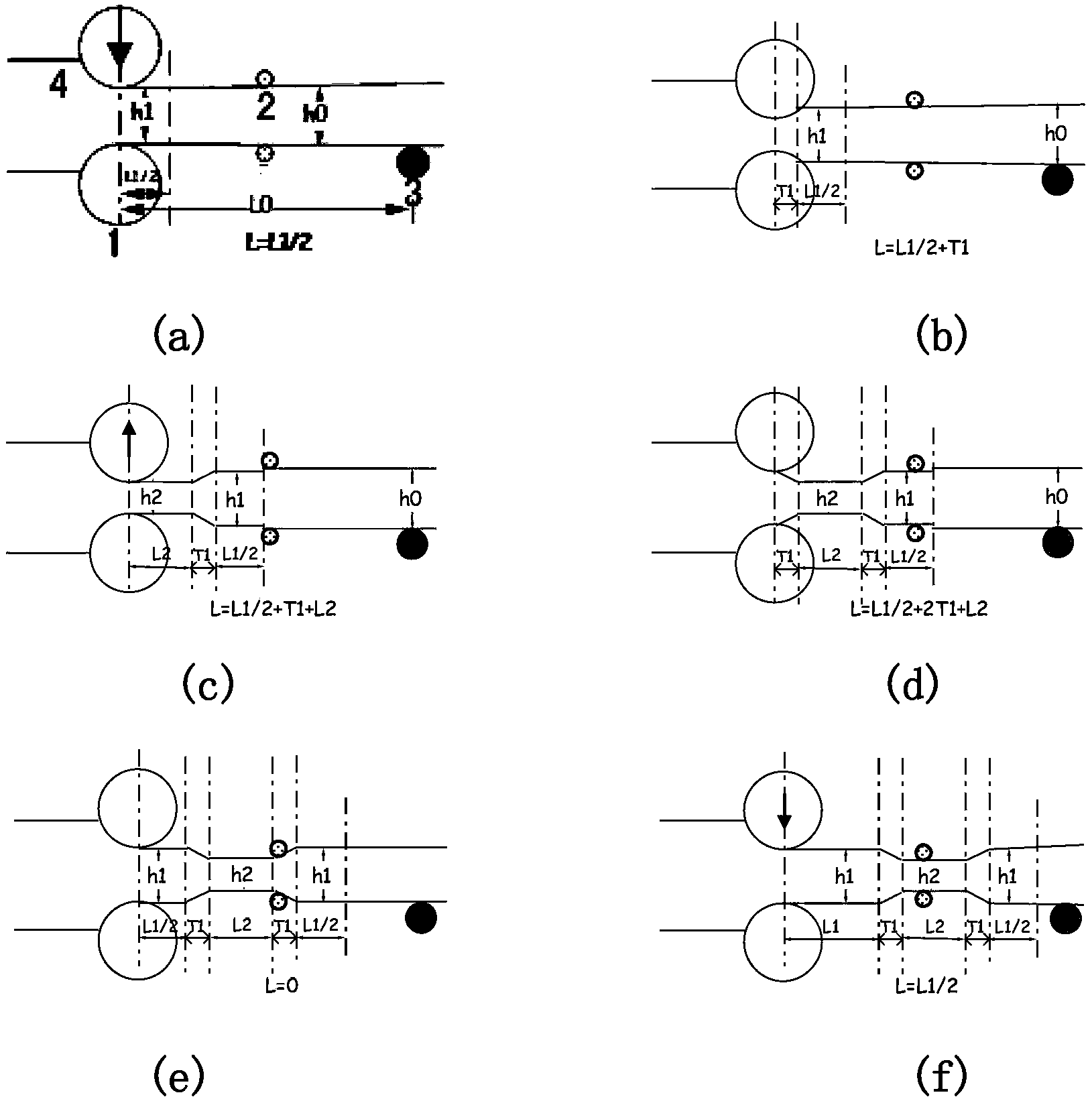

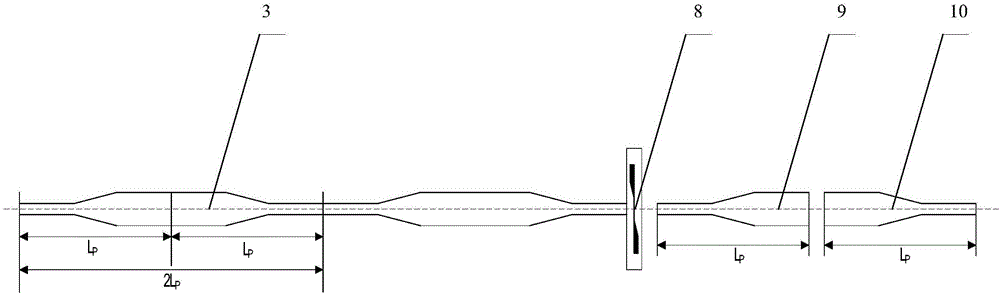

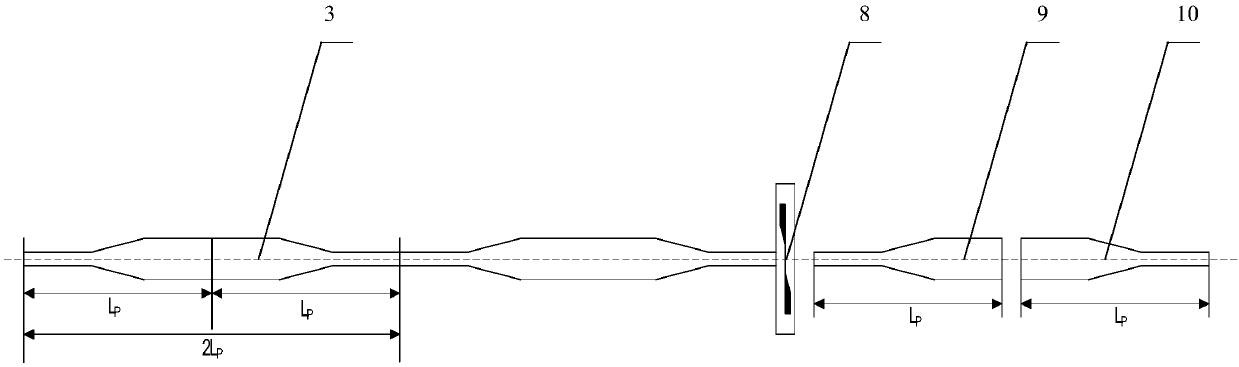

Variable thickness rolling length control method

ActiveCN104338752AControl lengthReduce the effect of length controlLength control deviceMeasuring devicesVariable thicknessControl theory

Disclosed is a variable thickness rolling length control method. The variable thickness rolling length control method comprises the steps of, when variable thickness rolling is not performed, setting the count of a length measuring roller to be 0; when the variable thickness rolling is performed, starting to record the lengths of rolled strips through the length measuring roller, and enabling the length measuring roller to work as follows that the working roller presses downwards at a certain speed when the measured length reaches L1 / 2, stops downward pressing when the measured length reaches L1 / 2+T1, moves up at a certain speed when the measured length reaches L1 / 2+T1+L2, and maintains the position without moving up when the measured length reaches L1 / 2+2*T1+L2; when the measured length reaches L1+L2*T1*2, clearing the count of the length measuring roller and repeating the steps above. According to the variable thickness rolling length control method, the pressing position of the working roller is adjusted in real time according to the length measured by the length measuring roller and by referring to a set strip contour.

Owner:BAOSHAN IRON & STEEL CO LTD

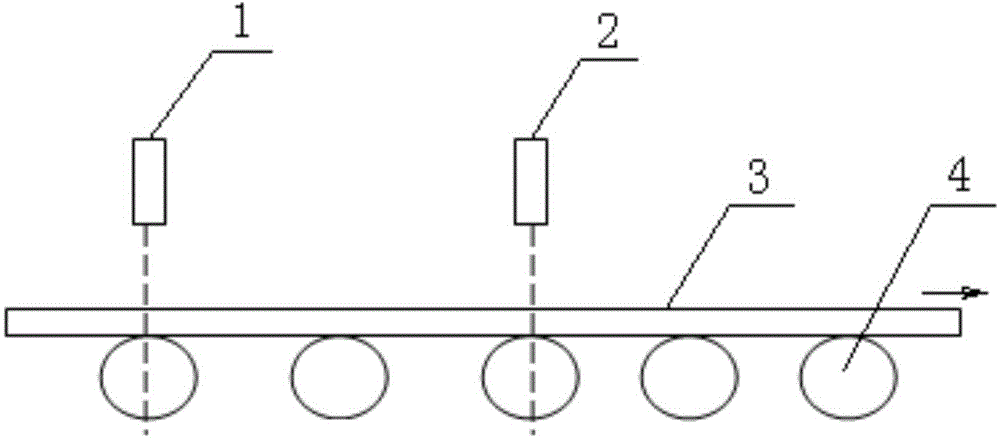

PLP strip fixed-length conveying measurement device and method

ActiveCN106391729ARealize high-precision length measurementLow measuring length errorLength control deviceMeasuring devicesComputer control systemMeasurement device

The invention provides a PLP strip fixed-length conveying measurement device and method, and belongs to the technical field of rolling. The device comprises a clamping roller, a length measurement coder, a position sensor used for detecting a roller seam of the clamping roller and a computer control system having a pulse calibration manner and a fixed-length conveying manner. According to the control method, by identifying changes of the roller seam of the clamping roller, the unit pulse length of the length measurement coder of the clamping roller can be corrected in real time, high-accuracy length measurement of a PLP strip is achieved, and the measurement length error is smaller than + / -0.5 mm; and the number of shorn finished product unequal thickness plates between two times of adjustment of the PLP strip can be effectively increased.

Owner:NORTHEASTERN UNIV

Online length measuring method for thermal-state steel pipe

InactiveCN106140830AEffective lengthHigh yieldLength control deviceMeasuring devicesThermal stateShortest distance

The invention provides an online length measuring method for a thermal-state steel pipe. The online length measuring method is characterized in that an optical fiber type hot metal detector with response time being 5ms is separately above each of a roller way with a distance of 1.5-2m from an outlet of a tandem mill and a roller way with a distance of 12-14m from the outlet of the tandem mill. After the thermal-state steel pipe is rolled by the tandem mill, the head part of the thermal-state steel pipe firstly passes through the first hot meal detector with a shorter distance, the first hot metal detector is used for converting a detected value into an electric signal which is input into a PLC, and the PLC starts timing; when the head part of the thermal-state steel pipe passes through the second hot metal detector, the PLC reads a first timing interval; and when the tail end of the steel pipe deviates from the first hot metal detector, timing of PLC is ended, and the PLC calculates length Y of the steel pipe by setting procedures. The online length measuring method is simple and reliable, can completely meet technological requirements, can operate on an HMI of a computer and can display effective steel pipe length, wherein detected length is 12-35m, and detection errors are + / -10mm; and the length of the steel pipe is detected, so that tandem-rolling regulating precision is improved and unit yield is increased.

Owner:ANGANG STEEL CO LTD

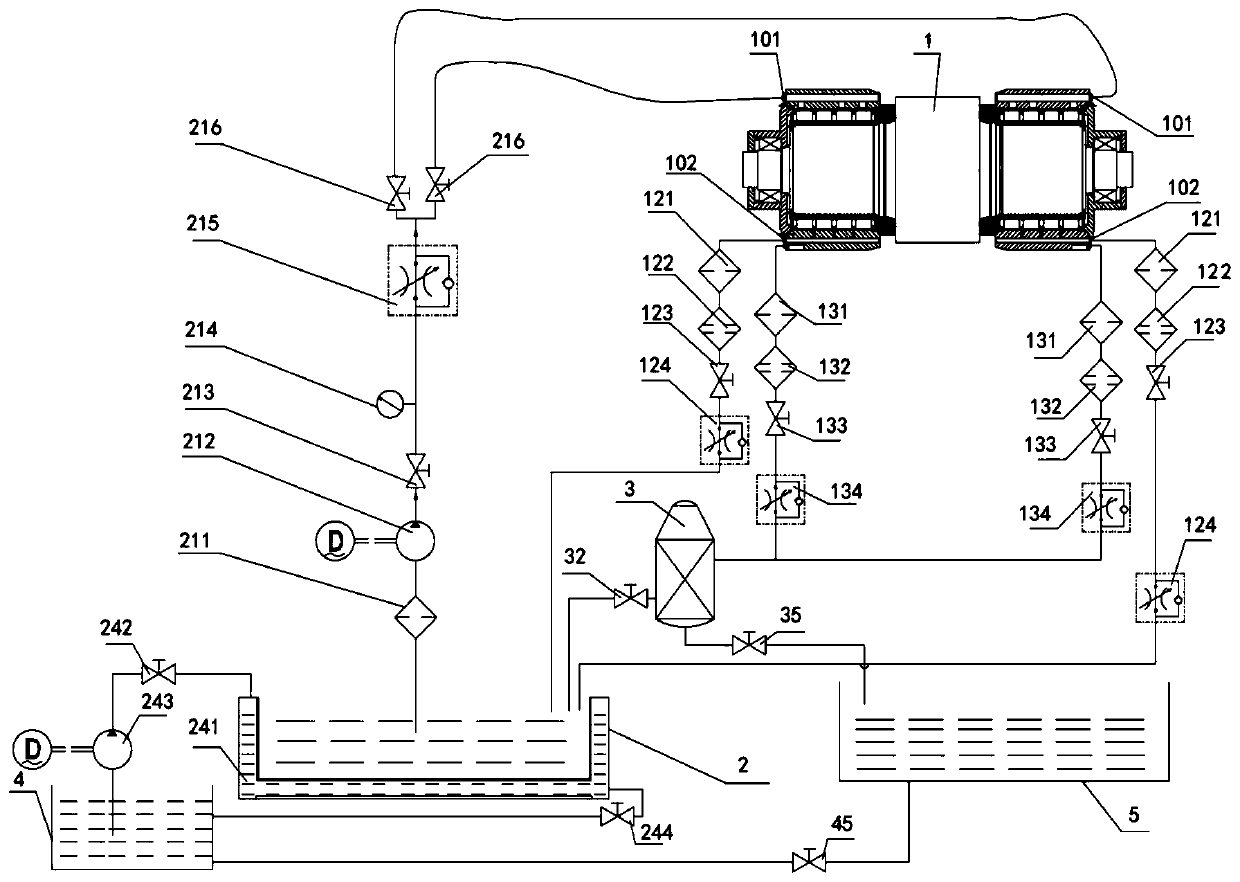

Monitoring and controlling device of roller lubricating system

InactiveCN110594569AIncrease temperatureAvoid damageEngine temperatureLength control deviceControl systemMonitoring and control

The invention discloses a monitoring and controlling device of a roller lubricating system. The device comprises a temperature detecting device, a constant-temperature oil storage system and a controlsystem, wherein the constant-temperature oil storage system is connected with a lubricating oil inlet and a lubricating oil outlet of a target roller through pipelines, so that the lubricating oil can circularly flow in the target roller and the constant-temperature oil storage system, and the lubricating oil level in the target roller is kept within a preset liquid level interval value; the constant-temperature oil storage system is also used for adjusting the temperature of the lubricating oil; the temperature detection device is used for detecting the temperature information of the lubricating oil in the target roller; and the control system is used for controlling the constant-temperature oil storage system to adjust the temperature of the lubricating oil according to the temperatureinformation of the lubricating oil in the target roller, so that the temperature of the lubricating oil in the target roller is within a preset temperature interval value. The device solves technicalproblem that the service life of the roller is decreased due to the fact that the roller lubricating oil is not monitored and controlled in place.

Owner:武汉钢铁有限公司

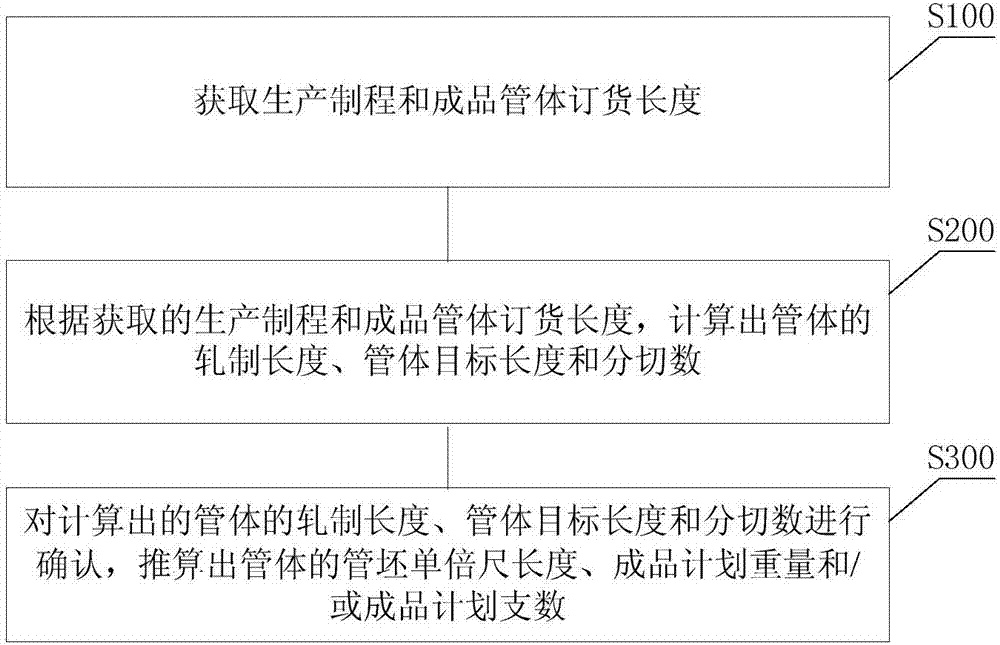

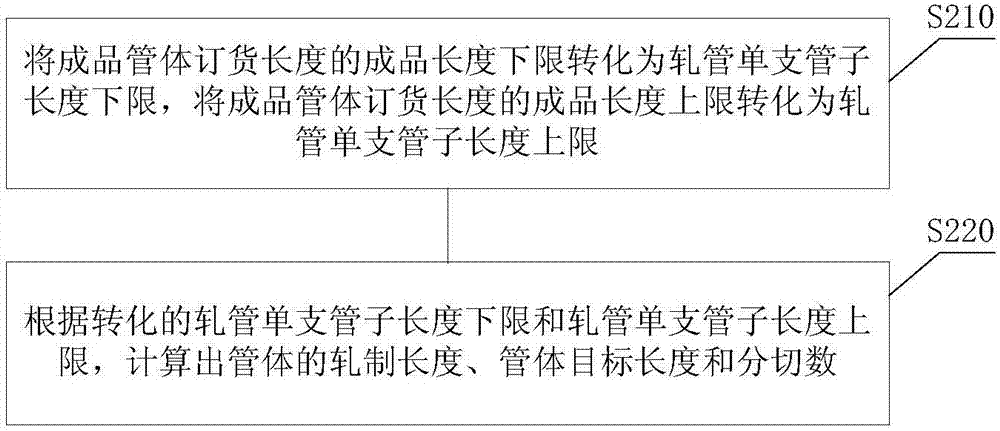

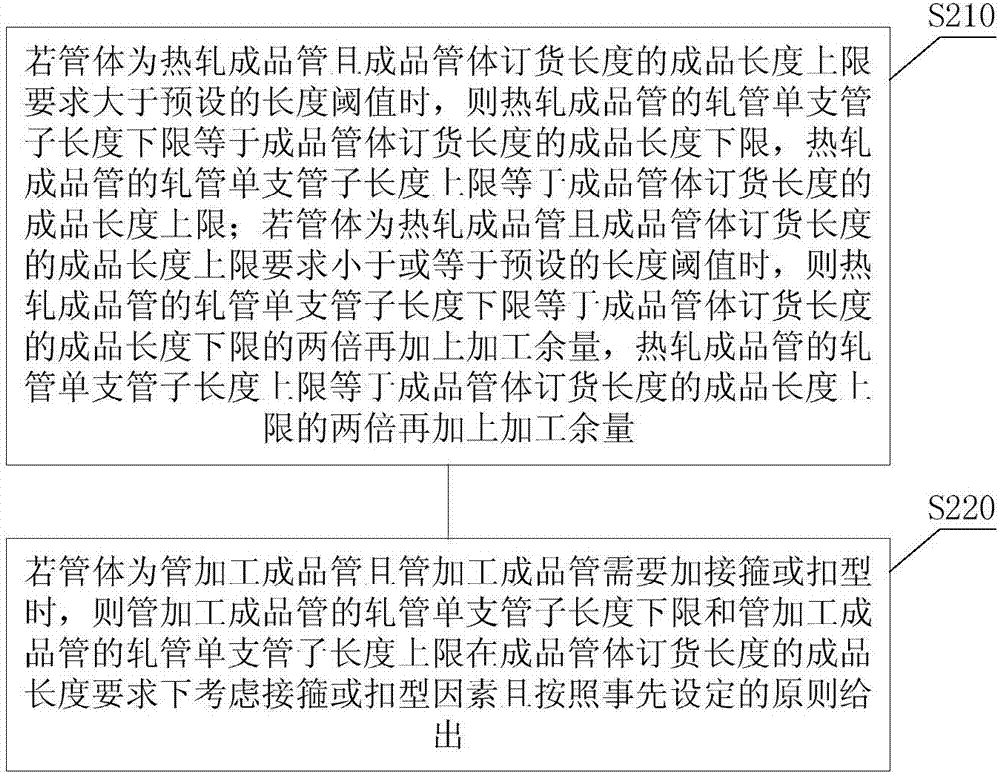

Method and device for optimizing and controlling length of pipes

InactiveCN107537865AReduce single furnace multi-slittingTube length optimizationLength control deviceOrder formIndustrial engineering

The invention discloses a method and device for optimizing the length of a pipe body. By obtaining the production process and the order length of the finished pipe body; according to the obtained production process and the order length of the finished pipe body, the rolling length, pipe body Target length and number of cuts; confirm the calculated rolling length of the pipe body, target length of the pipe body and number of cuts, and calculate the single length of the tube blank, the planned weight of the finished product and / or the planned cost of the finished product number. The method and device for optimizing the length of the pipe body provided by the present invention realize the automatic transformation from sales order to production order and then to process order, and automatically calculate the rolling length, the number of cuts, The tonnage and / or count of the finished product and the single length of the required billet realize the optimization of the rolling length and improve the yield. production efficiency.

Owner:湖南视拓信息技术股份有限公司

Automatic cutting machine of steel pipe welding coiled materials

ActiveCN104148527AQuick straightening roll levelingPrevent cut outLength control deviceMetal-working feeding devicesHydraulic cylinderEngineering

Owner:江苏金日管业有限公司

Hot rolling box for shearing strip steel head by hot continuous rolling and method for shearing strip steel head

InactiveCN110153182AAchieve precise cuttingAvoid wastingLength control deviceMetal rolling arrangementsStart timeProgrammable logic controller

The invention discloses a hot rolling box for shearing a strip steel head of the hot continuous rolling and a method for shearing the strip steel head. The hot rolling box comprises flying shears anda PLC (programmable logic controller) system, wherein the flying shears are arranged behind a hot rolling box body, and the PLC system controls the hot rolling box to work; the hot rolling box furthercomprises a first high-temperature detector and a second high-temperature detector; the first high-temperature detector and the second high-temperature detector are controlled by the PLC system; andthe first high-temperature detector and the second high-temperature detector are arranged between the hot rolling box body and the flying shears at intervals. The first high-temperature detector and the second high-temperature detector are additionally arranged on the hot rolling box to monitor the strip steel head, and the starting time of the flying shears is calculated according to the monitored data, so that strip steel reaches the shearing position and is subjected to the set shearing length, shear blades of the flying shears are just rotated to a shearing position for shearing operation,accurate shearing of the strip steel head is realized, waste can be avoided, the production cost is reduced, the temperature of the strip steel head is ensured to meet the production requirements, and waste steel caused by too low temperature of the head is avoided.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Method for controlling thickness of hot-continuous-rolled intermediate slab and length of cast ingot

ActiveCN107030119AAvoid cutsPrevents interruptions in the rolling processLength control deviceMetal rolling arrangementsReduction rateIngot casting

The invention discloses a method for controlling a thickness of a hot-continuous-rolled intermediate slab and a length of a cast ingot, and relates to the technical field of metal pressure machining. The method comprises the following steps: according to a set rolling pass reduction rate of each frame of a continuous rolling machine and a thickness of a finished rolled piece, a thickness reference value of the intermediate slab and a rolling pass reduction quantity of each frame are inversely computed; the rolling force checking and the correction are performed for the thickness reference value of the intermediate slab; if calculated rolling force exceeds a maximum rolling force allowed value allowed by each frame, the rolling pass reduction quantity is reduced, and the iterative computation is repeated until the calculated rolling force is lower than or equal to the maximum rolling force allowed value; then, the correction calculation is performed for the thickness reference value of the intermediate slab, and a rough rolling machine is used for rolling to reach the calculated thickness of the intermediate slab; according to the corrected thickness value of the intermediate slab, a length of a roller way from the rough rolling machine to a continuous rolling machine, and a thickness of the cast ingot, the length of the cast ingot is calculated; and the cast ingot is cast according to the calculated length of the cast ingot. The method solves the problem of low yield in traditional hot continuous rolling production.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND +1

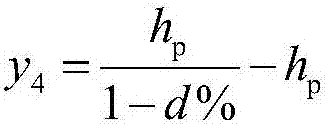

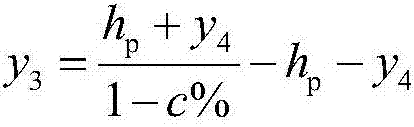

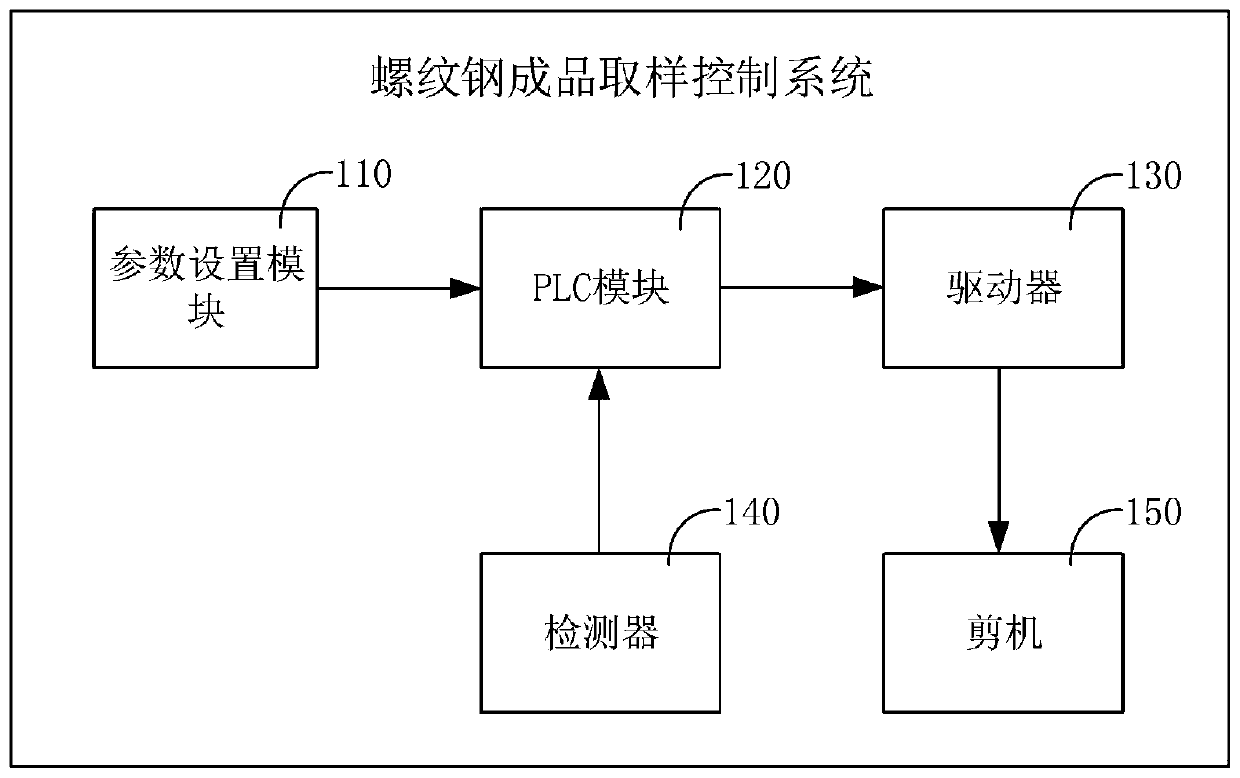

Deformed steel bar finished product sampling control system and method

InactiveCN110814035AImprove sampling efficiencyEasy to operateLength control deviceWithdrawing sample devicesControl systemControl engineering

The invention discloses a deformed steel bar finished product sampling control system and method. The system comprises a detector, a PLC module, a parameter setting module, a driver and a shearing machine, wherein the detector is electrically connected with the PLC module, the parameter setting module is in communication connection with the PLC module, the PLC module, the driver and the shearing machine are electrically connected in sequence, the detector is mounted on one side of the shearing machine and is used for detecting the length of a to-be-sampled deformed steel bar finished product through the shearing machine, the parameter setting module is arranged in an operating chamber and is used for setting sampling parameters of the deformed steel bar finished product and sending the sampling parameters to the PLC module, and when the detector detects that the length of the deformed steel bar finished product reaches a preset condition, the PLC module controls the driver to drive theshearing machine to shear the deformed steel bar finished product to complete sampling. Through the system, the sampling efficiency of the deformed steel bar finished product can be improved.

Owner:SGIS SONGSHAN CO LTD

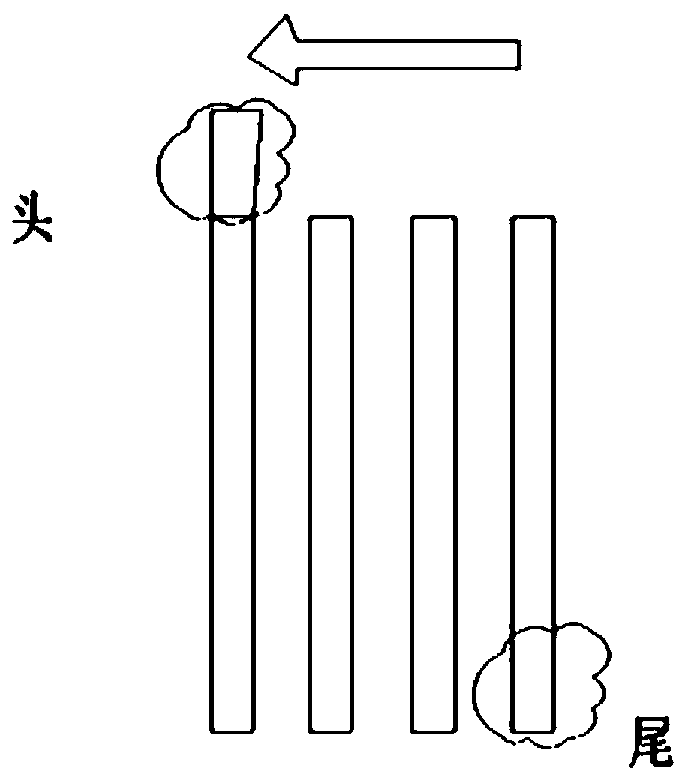

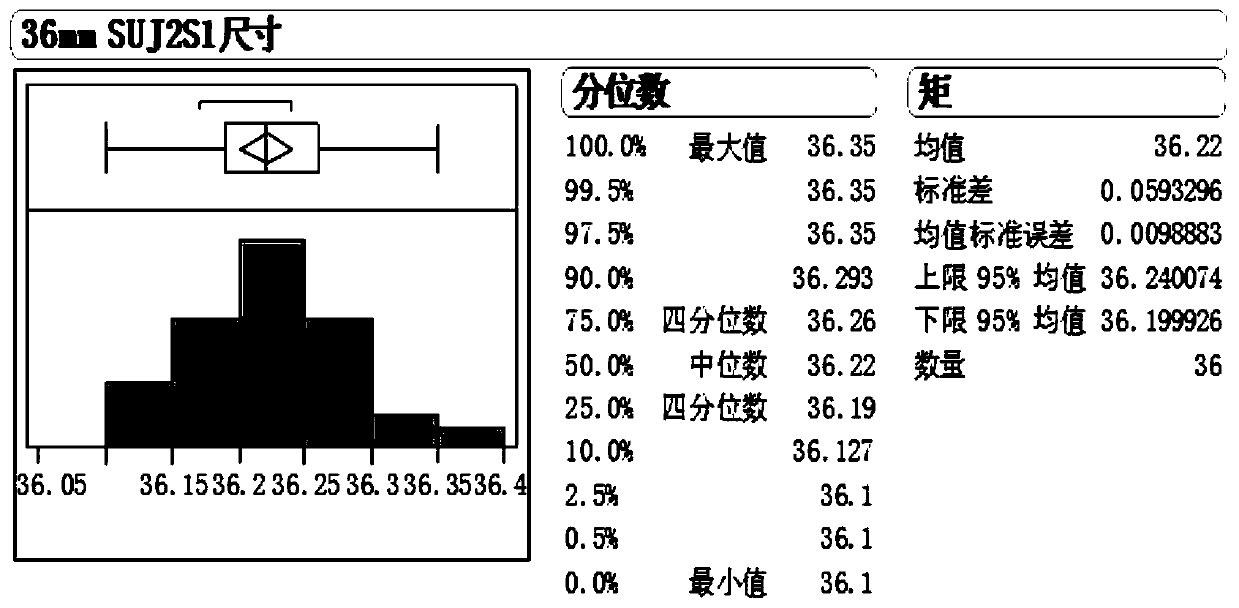

Technique for controlling size scatter difference of bearing steel of hot-rolled round steel

The invention discloses a technique for controlling the size scatter difference of bearing steel of hot-rolled round steel. The technique comprises the steps of (1) controlling the scatter differenceof the head and tail of the round steel; (2) controlling the size scatter difference of the middle part. According to the technique, the parts with high temperature of the head and tail are independently collected on line and are measured one by one in an offline mode, and the middle part is treated by organizing a debugging material, uniformly tapping, using a looper and specifying a measuring tool, so that the scatter difference of the whole batch is less than or equal to 0.30 mm, and the operating requirement of a customer is satisfied.

Owner:NANJING IRON & STEEL CO LTD

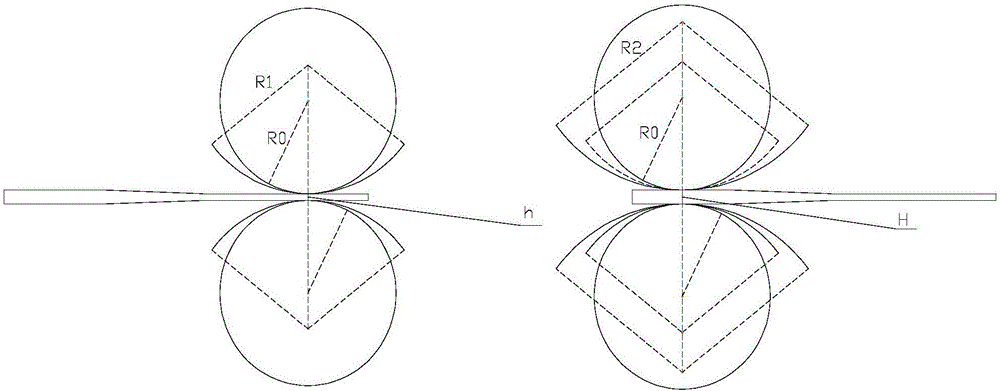

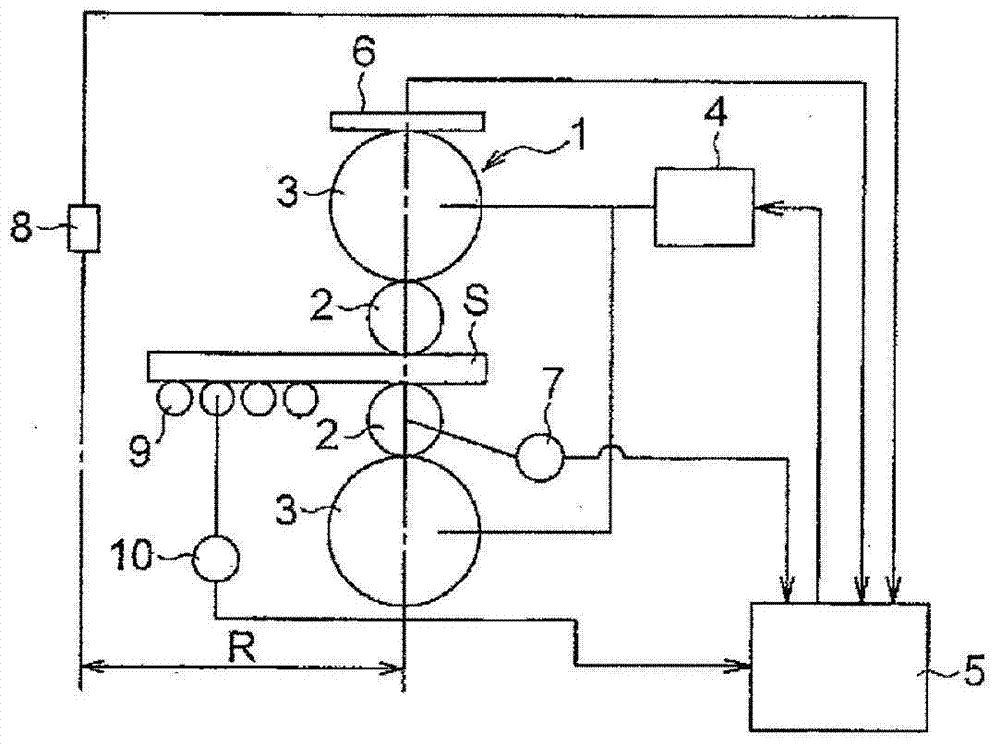

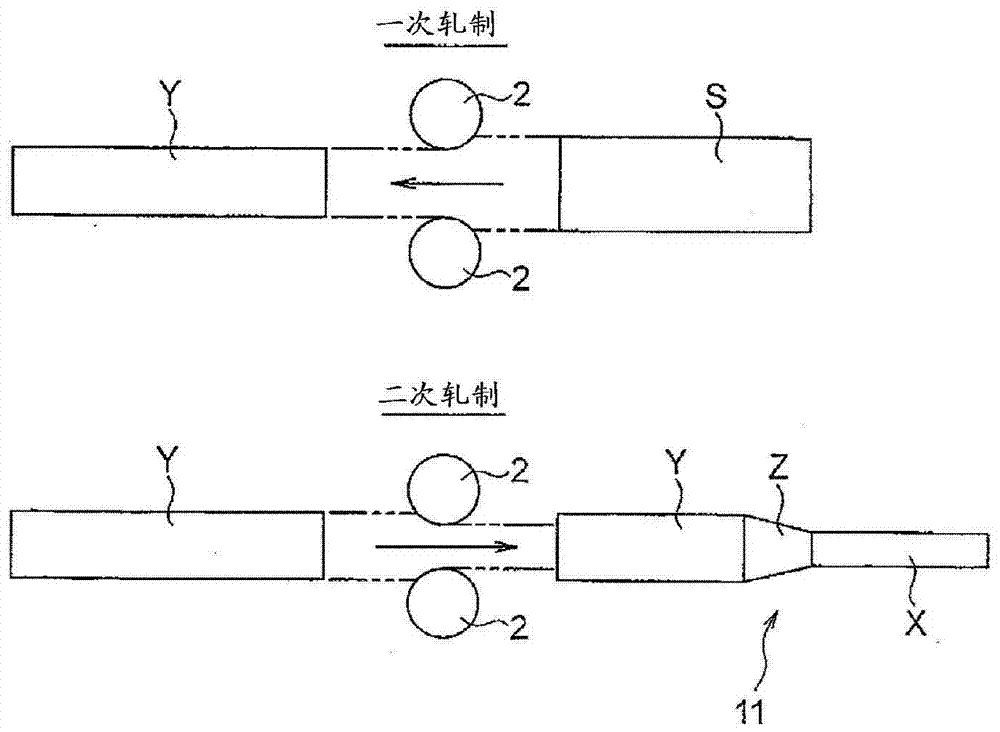

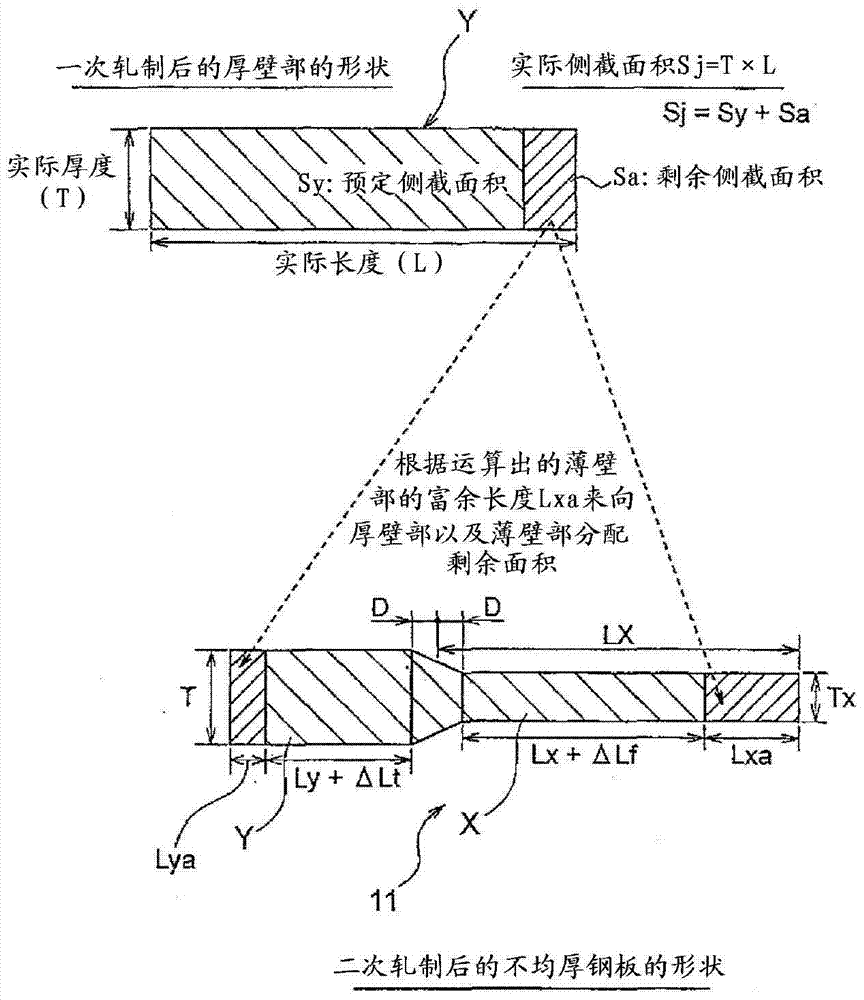

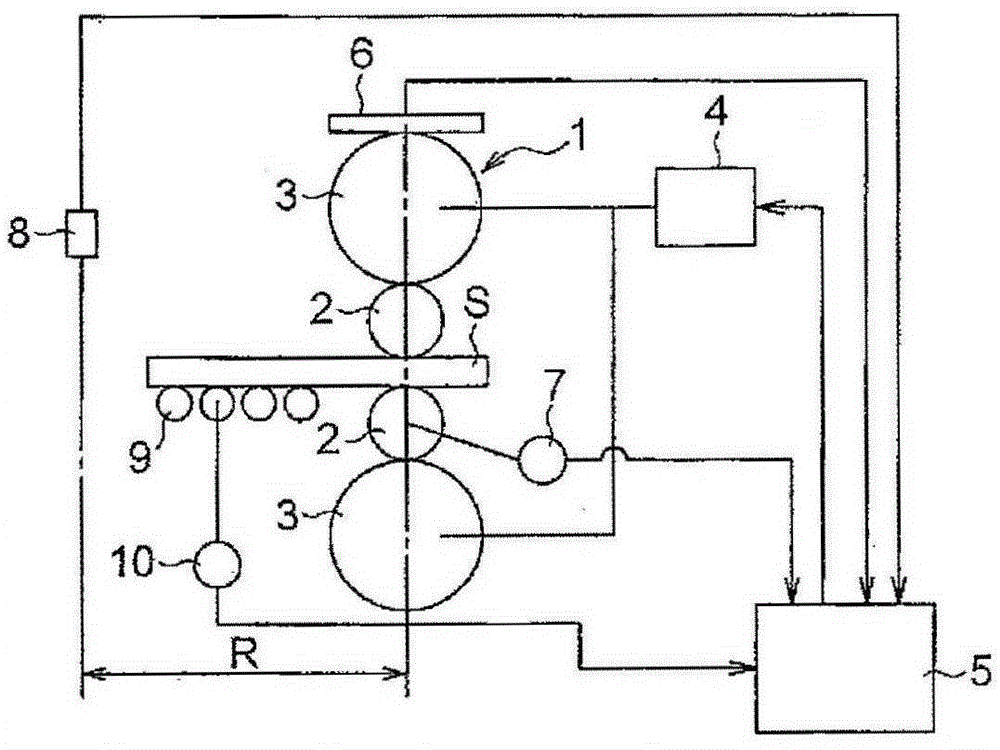

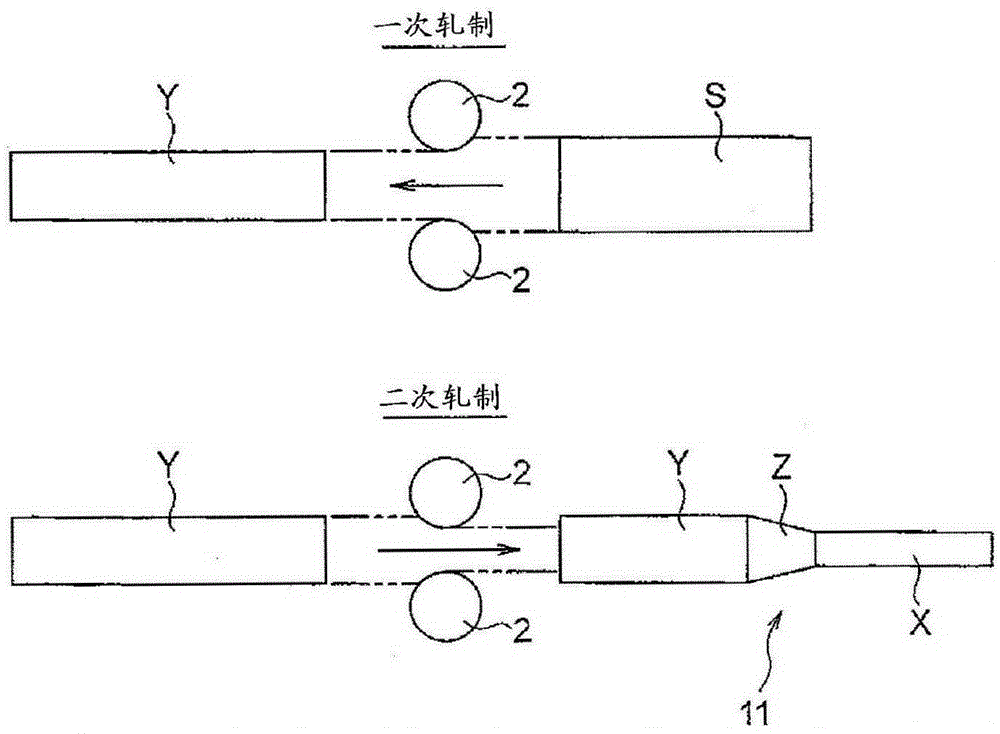

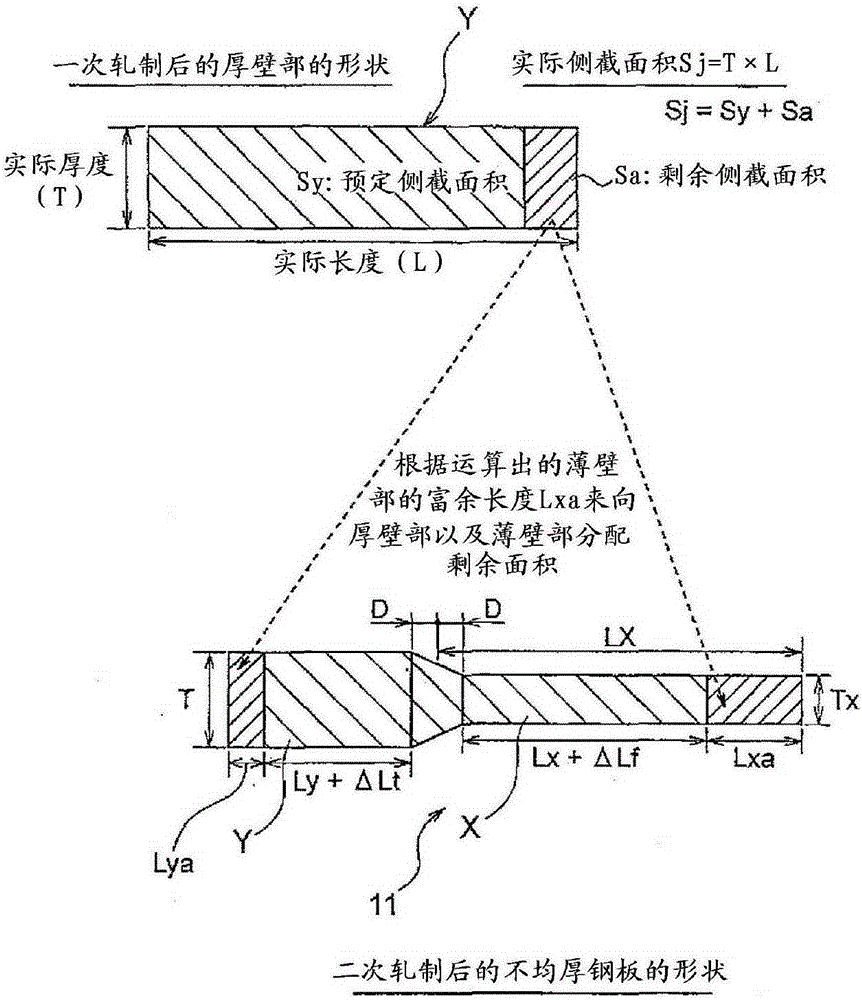

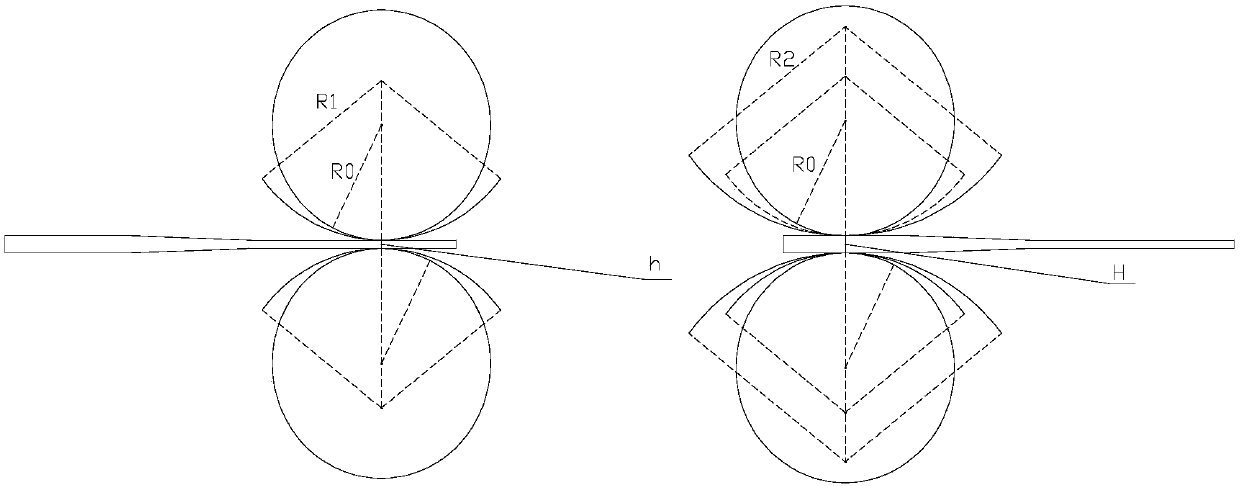

Rolling method and rolling device of uneven thickness steel plate

Owner:JFE STEEL CORP

Rolling method and rolling device for differential thickness steel sheet

ActiveCN105188972AImprove yieldLength control deviceMetal rolling arrangementsThick wallMaterials science

Owner:JFE STEEL CORP

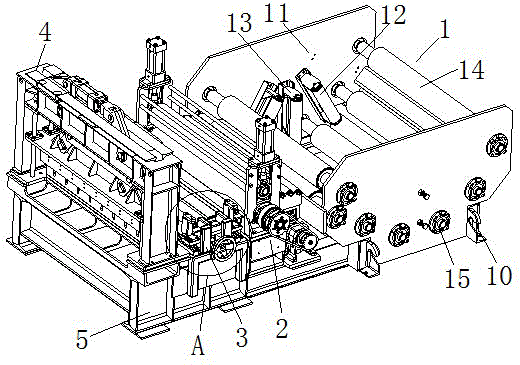

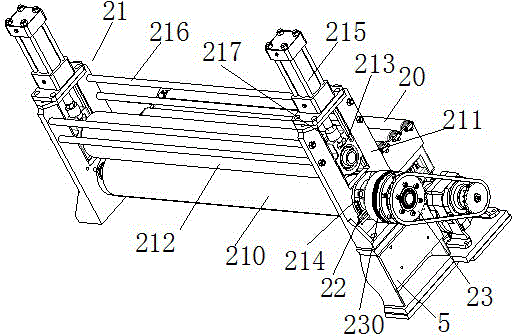

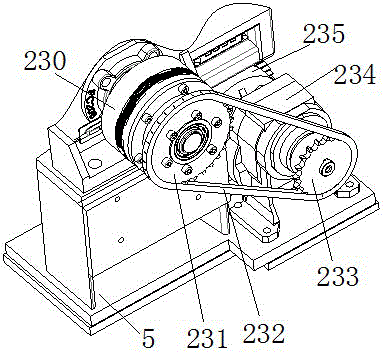

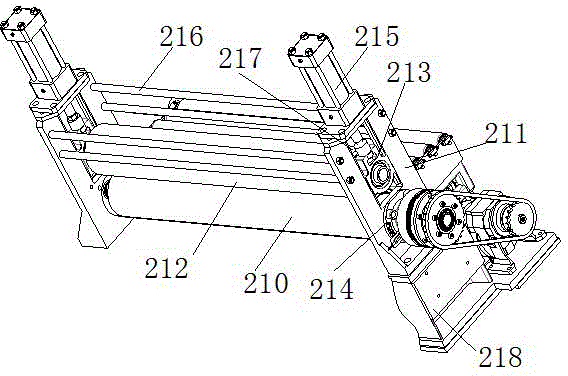

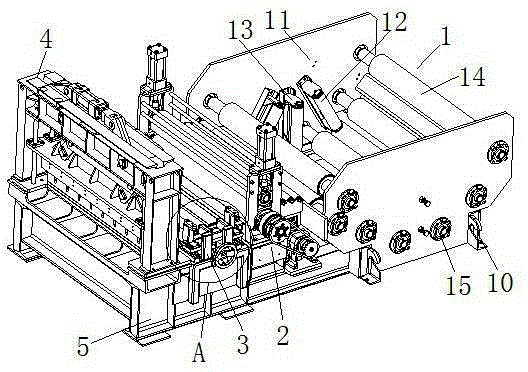

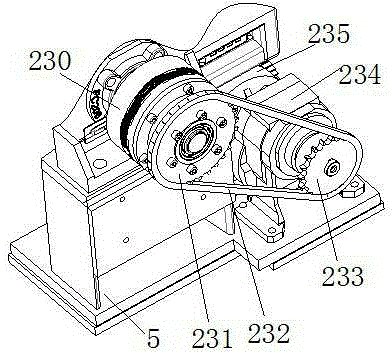

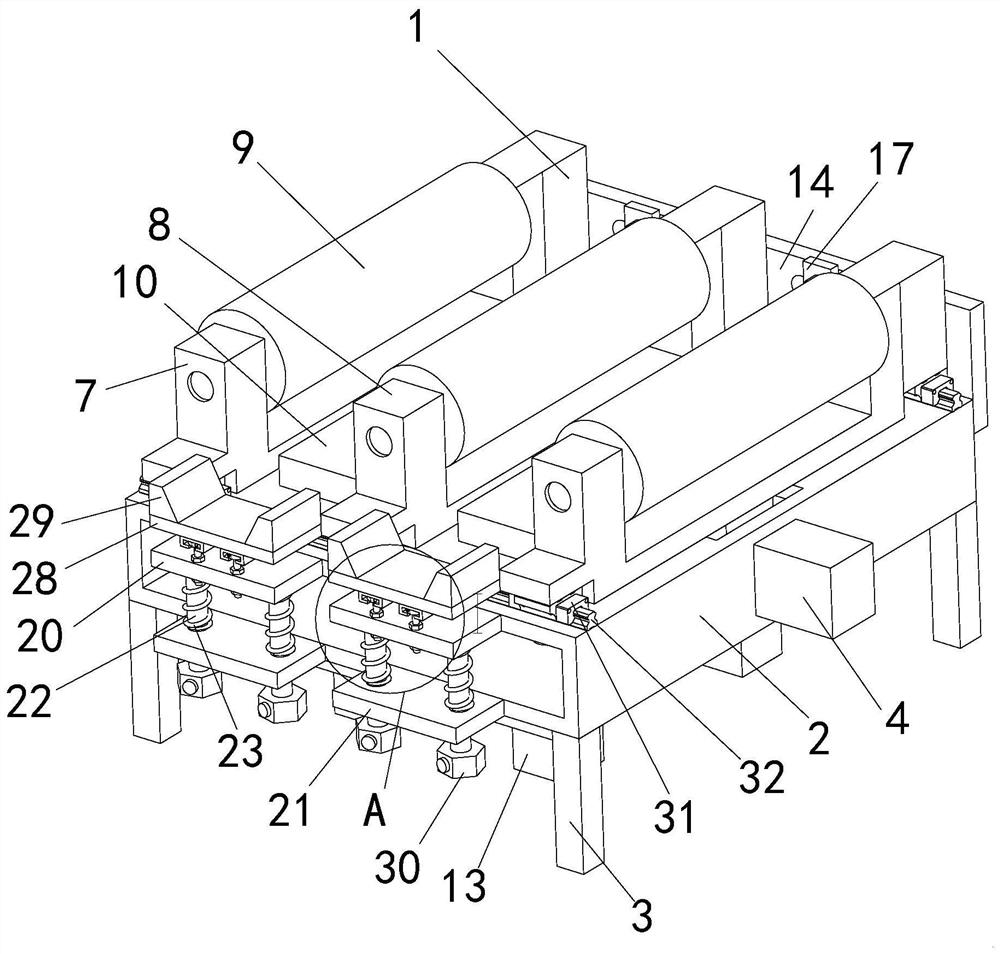

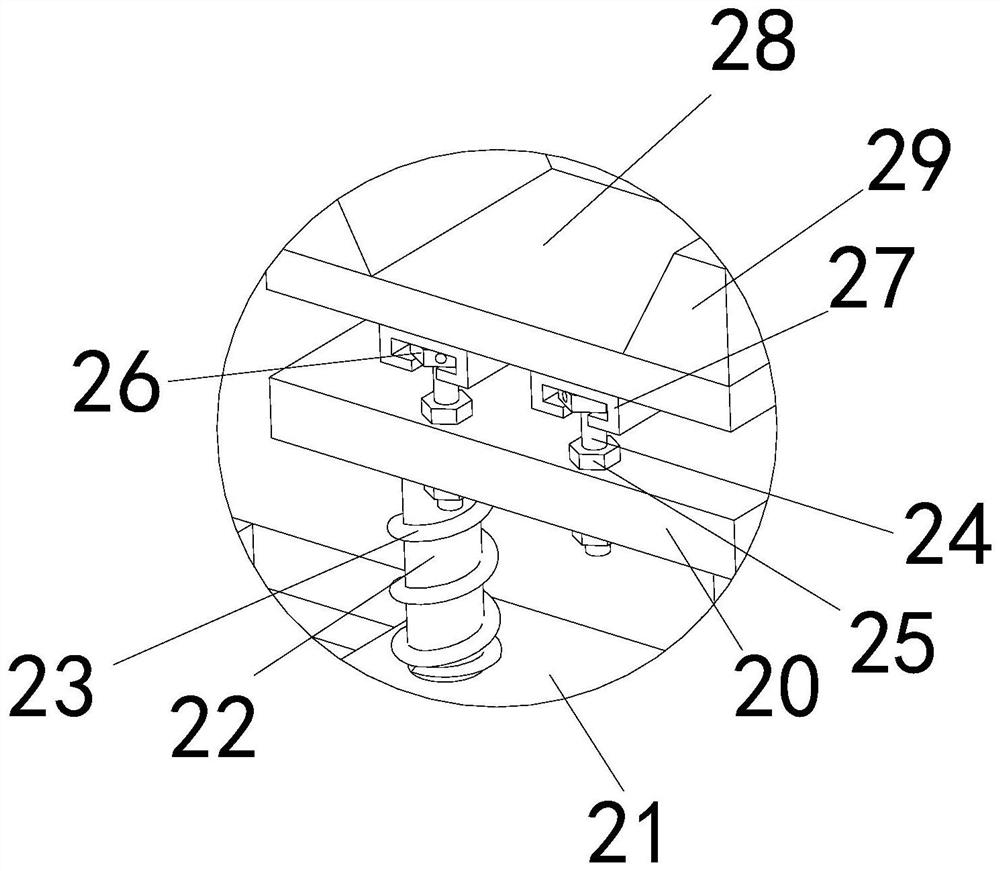

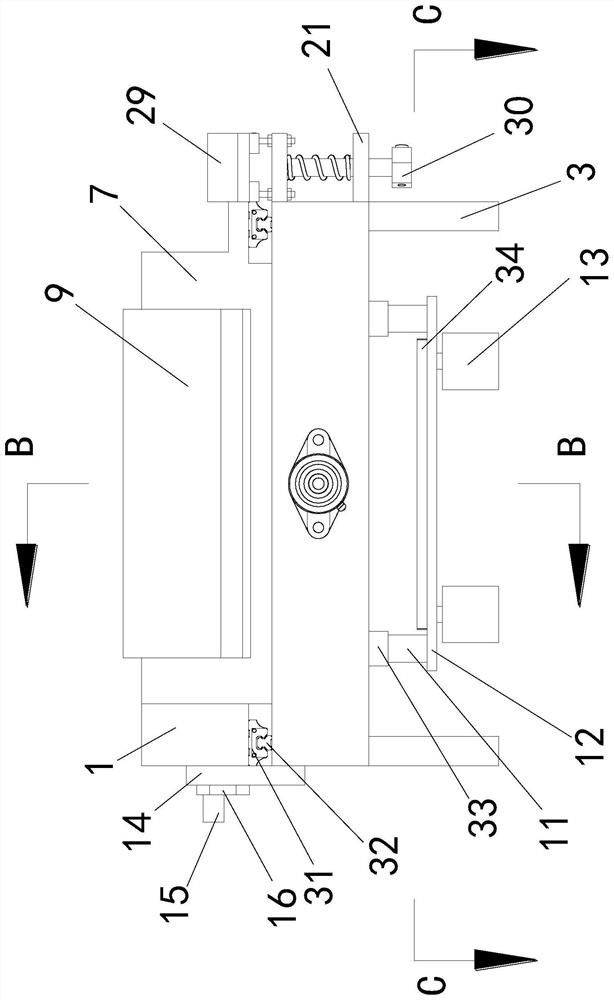

Feeding mechanism of automatic cutting machine for welded steel tube coil

InactiveCN104148528AQuick straightening roll levelingPrevent cut outLength control deviceMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a feeding mechanism of an automatic cutting machine for a welded steel tube coil. The feeding mechanism of the automatic cutting machine for the welded steel tube coil comprises a main feeding roll shaft, U-shaped plates, a pressing roll shaft, pressing roll shaft bases, main feeding roll shaft bases, pressing oil cylinders and pulling rods. The two parallel corresponding U-shaped plates are installed on a machine frame and are connected and supported through the four pulling rods, the pressing roll shaft bases are arranged in U-shaped grooves of the two U-shaped plates and installed at the two ends of the pressing roll shaft, the upper ends of the pressing roll shaft bases are connected with piston rods of the pressing oil cylinders which are installed at the top ends of the U-shaped plates, the pressing roll shaft and the main feeding roll shaft are attached to each other in the same direction, the two ends of the main feeding roll shaft are provided with the main feeding roll shaft bases, and the main feeding roll shaft bases are installed on the U-shaped plates through screws. In this way, a whole coiled steel plate can be rapidly straightened and rolled to be flat, the depth of parallelism is modified, and no diamond-shaped steel plates are obtained through cutting.

Owner:SUZHOU CHANG FEI AUTOMATION EQUIP FACTORY

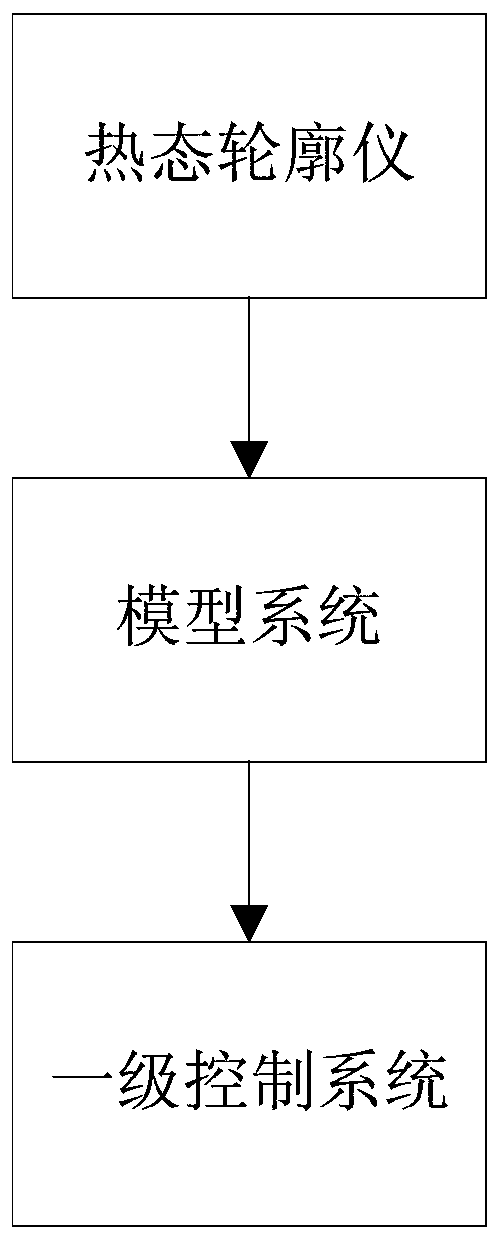

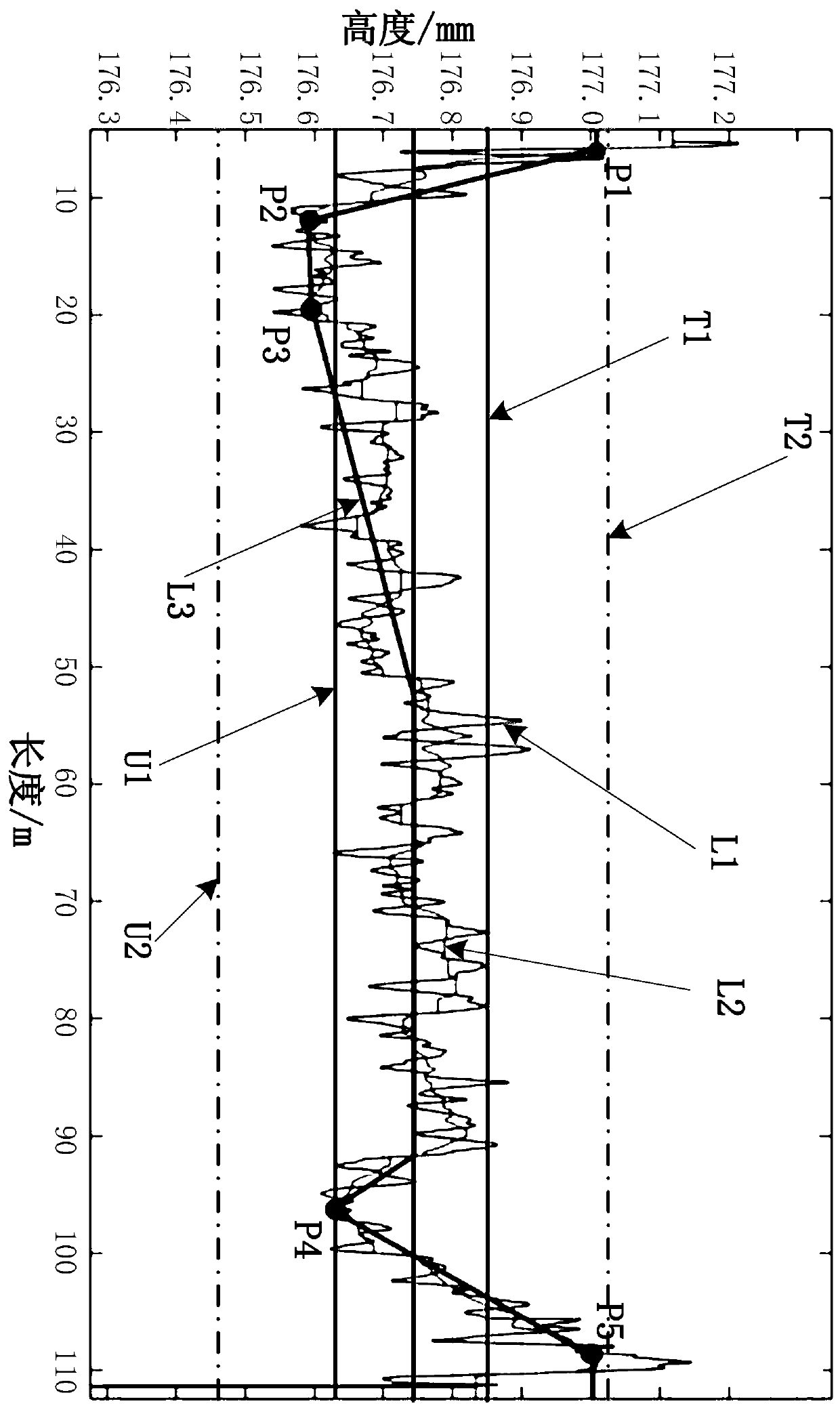

Compensation system for rail specification fluctuation

ActiveCN109465303BHigh compensation accuracyImprove compensation efficiencyLength control deviceControl systemControl engineering

The invention relates to the steel rolling production field and discloses a rail specification full-length fluctuation compensation system, which is used for automatically searching a rail specification compensation point and generating a fluctuation compensation curve to automatically complete the fluctuation compensation. The invention comprises a hot-state profilometer, a model system and a first-level control system. The model system comprises a compensation point search module and a compensation curve generation module, wherein, the hot-state profilometer is used for acquiring specification data in the length direction of the rail; the compensation point search module is used for searching out the compensation point from the specification data in the length direction of the rail; thecompensation curve generation module is used for generating a fluctuation compensation curve of the rail specification in the length direction according to the compensation point searched by the compensation point search module; the primary control system is used for controlling the compensation mechanism to compensate the fluctuation according to the fluctuation compensation curve. The inventionis applicable to the height specification fluctuation compensation control of rails.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

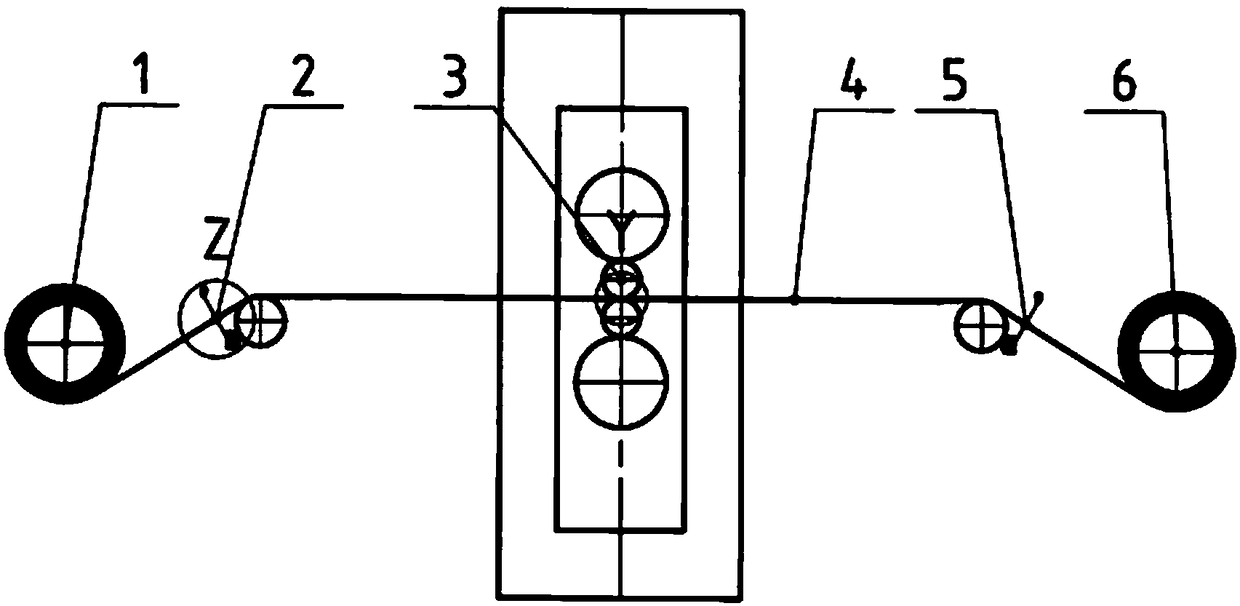

Reversible cold rolling accurate fixed-length rolling control device

InactiveCN108580552ASimple structure setupEconomical and reliableLength control deviceTension/compression control deviceCouplingEngineering

The invention discloses a reversible cold rolling accurate fixed-length rolling control device. The reversible cold rolling accurate fixed-length rolling control device comprises a left tension leading belt device and a right tension leading belt device; a tension leading belt of the left tension leading belt device is connected with one end of a plate rolling piece through a coupling; a tension leading belt of the right tension leading belt device is connected with the other end of the plate rolling piece; the plate rolling piece penetrates through a reversible cold rolling machine; the tension leading belts of the left tension leading belt device and the right tension leading belt device are provided with a left positioning detecting system and a right positioning detecting system; the left positioning detecting system and the right positioning detecting system are positioned above and below the tension leading belts for direct and accurate detection of the position of the plate rolling piece; and the left tension leading belt device and the right tension leading belt device cooperate with the reversible cold rolling machine for reciprocating rolling. The reversible cold rollingaccurate fixed-length rolling control device has the advantages of simple structural setting, economical and reliable use and convenience to operate and maintain.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

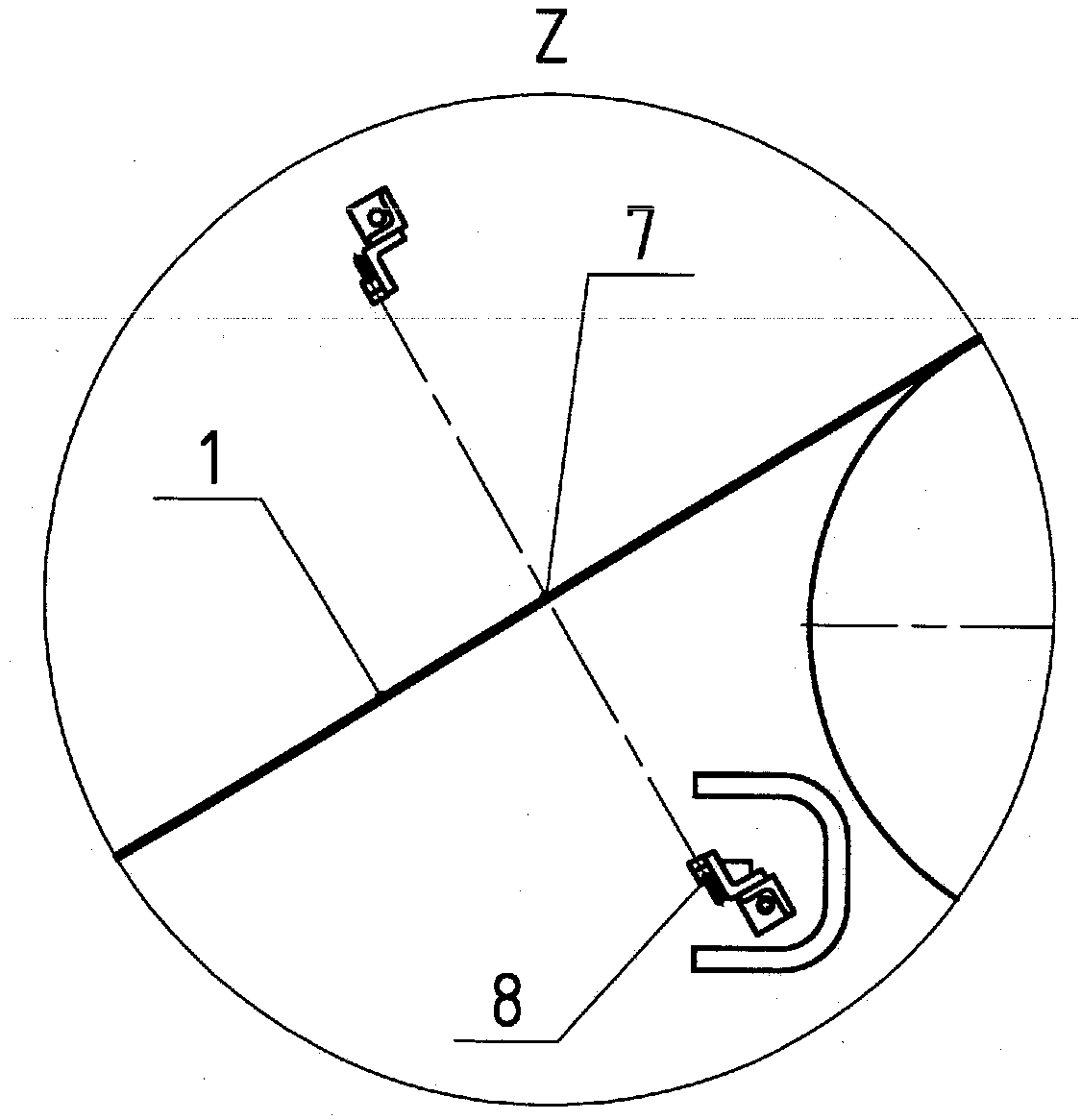

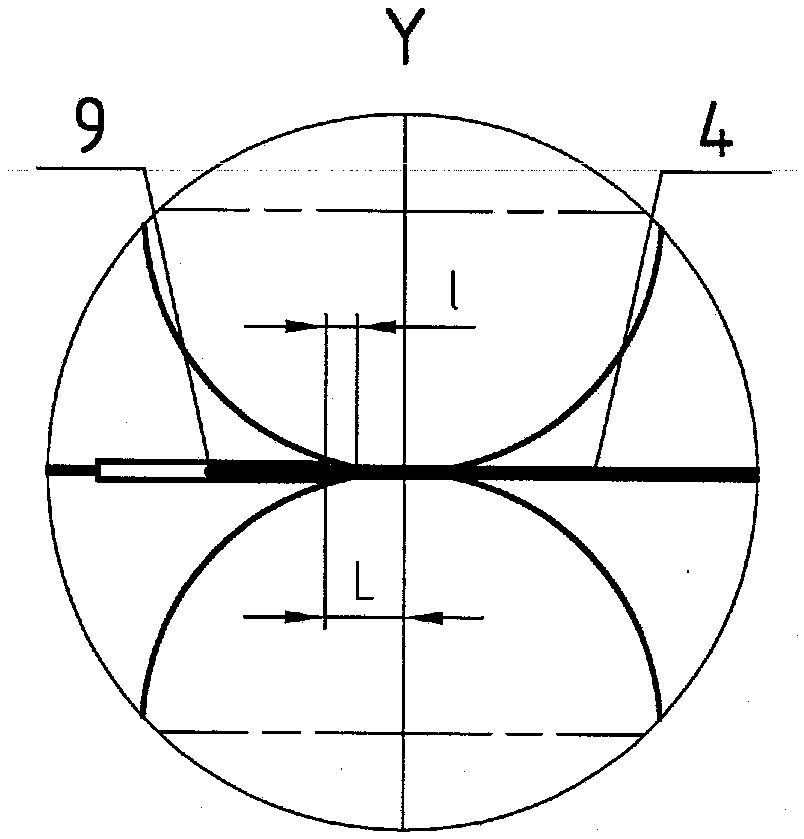

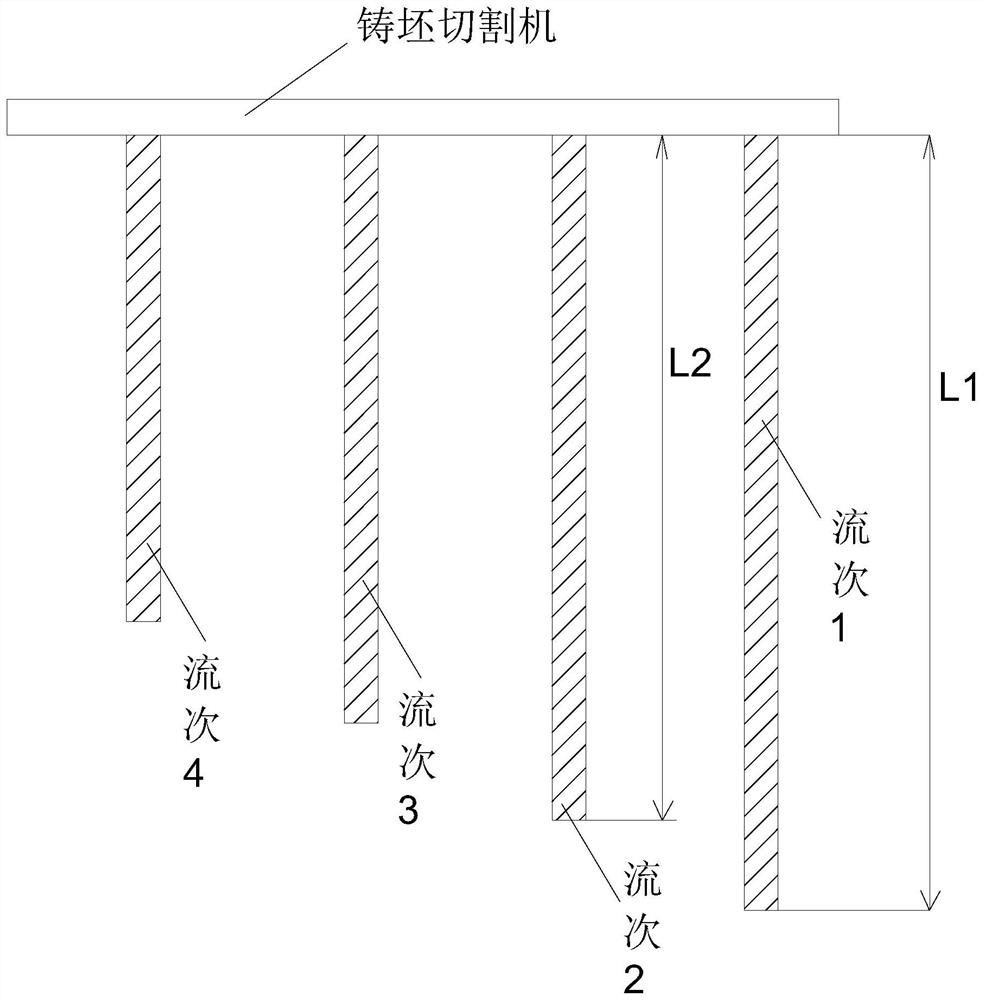

Step ejection method

PendingCN114433630ANo human intervention requiredDirect rolling without heatingLength control deviceMetal rolling arrangementsEngineeringProcess engineering

The invention provides a stepped ejection method which comprises the following steps: realizing online real-time measurement of the length of a multi-strand casting blank by utilizing an infrared imaging technology to obtain online real-time measurement data of the length of the multi-strand casting blank; the computer measures data on line in real time according to the length of the multi-stream casting blank, and the pulling speed of each stream of the continuous casting machine is controlled; wherein the pulling speed of each flow of the continuous casting machine is controlled according to the relation between the production capacity of the rolling mill and the production capacity of the continuous casting machine. According to the method, manual intervention is not needed, the equal time interval of each flow of feeding into a casting machine during stepped ejection can be conveniently and quickly realized, and heating-free direct rolling is realized.

Owner:LIUZHOU IRON & STEEL CO LTD +1

A measurement method using a measuring device for fixed-length transmission of plp strips

ActiveCN106391729BRealize high-precision length measurementLow measuring length errorLength control deviceMeasuring devicesComputer control systemThick plate

The invention proposes a measuring device and method for fixed-length transmission of PLP strips, which belongs to the field of rolling technology. The device includes: a pinch roller, a length measuring encoder, a position sensor for detecting the gap of the pinch roller, and a Computer control system for pulse calibration mode and fixed-length transmission mode. The control method of the present invention corrects the unit pulse length of the pinch roller length measurement encoder in real time by identifying changes in the gap of the pinch roller to achieve high-precision length measurement of PLP strips. , its measurement length error is less than ±0.5mm; it can effectively increase the number of finished thick plates sheared during the two PLP strip position adjustments.

Owner:NORTHEASTERN UNIV LIAONING

Welded steel pipe coil automatic cutting machine

ActiveCN104148527BQuick straightening roll levelingPrevent cut outLength control deviceMetal-working feeding devicesHydraulic cylinderEngineering

Owner:江苏金日管业有限公司

The Control Method of Thickness and Ingot Length of Hot Continuous Rolling Intermediate Billet

ActiveCN107030119BAvoid cutsPrevents interruptions in the rolling processLength control deviceMetal rolling arrangementsReduction rateIngot casting

The invention discloses a method for controlling a thickness of a hot-continuous-rolled intermediate slab and a length of a cast ingot, and relates to the technical field of metal pressure machining. The method comprises the following steps: according to a set rolling pass reduction rate of each frame of a continuous rolling machine and a thickness of a finished rolled piece, a thickness reference value of the intermediate slab and a rolling pass reduction quantity of each frame are inversely computed; the rolling force checking and the correction are performed for the thickness reference value of the intermediate slab; if calculated rolling force exceeds a maximum rolling force allowed value allowed by each frame, the rolling pass reduction quantity is reduced, and the iterative computation is repeated until the calculated rolling force is lower than or equal to the maximum rolling force allowed value; then, the correction calculation is performed for the thickness reference value of the intermediate slab, and a rough rolling machine is used for rolling to reach the calculated thickness of the intermediate slab; according to the corrected thickness value of the intermediate slab, a length of a roller way from the rough rolling machine to a continuous rolling machine, and a thickness of the cast ingot, the length of the cast ingot is calculated; and the cast ingot is cast according to the calculated length of the cast ingot. The method solves the problem of low yield in traditional hot continuous rolling production.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND +1

Hot-rolled ribbed bar double-length shearing control method

PendingCN114769327AGuaranteed smooth progressEasy to produceLength control deviceMeasuring devicesPunchingMathematical model

The invention discloses a hot-rolled ribbed steel bar double-length shearing control method, and belongs to the technical field of metal smelting, the method adopts a first detector and a second detector, when the head end of a deformed steel bar moves to the first detector, the first detector transmits detected information to a controller, the controller starts timing, and the second detector sends the detected information to the controller; according to a first mathematical model built therein, the time value needed when the head end of the deformed steel bar is moved to the large cooling bed is calculated, the time value is T, when timing reaches T, the double-length shear is controlled to conduct shearing, shearing is conducted circularly in this way until information detected by the second detector disappears, and at the moment, the time value is T; and the controller predicts the lengths of the remaining deformed steel bars according to a second mathematical model established in the controller, and controls the length of the tail section of deformed steel bar within a preset range value after segmented calculation. According to the method, the problem that steel blockage or birdcage punching is easily caused due to the fact that the length of the whole deformed steel bar cannot be pre-judged in existing double-length shearing can be solved.

Owner:广西钢铁集团有限公司 +1

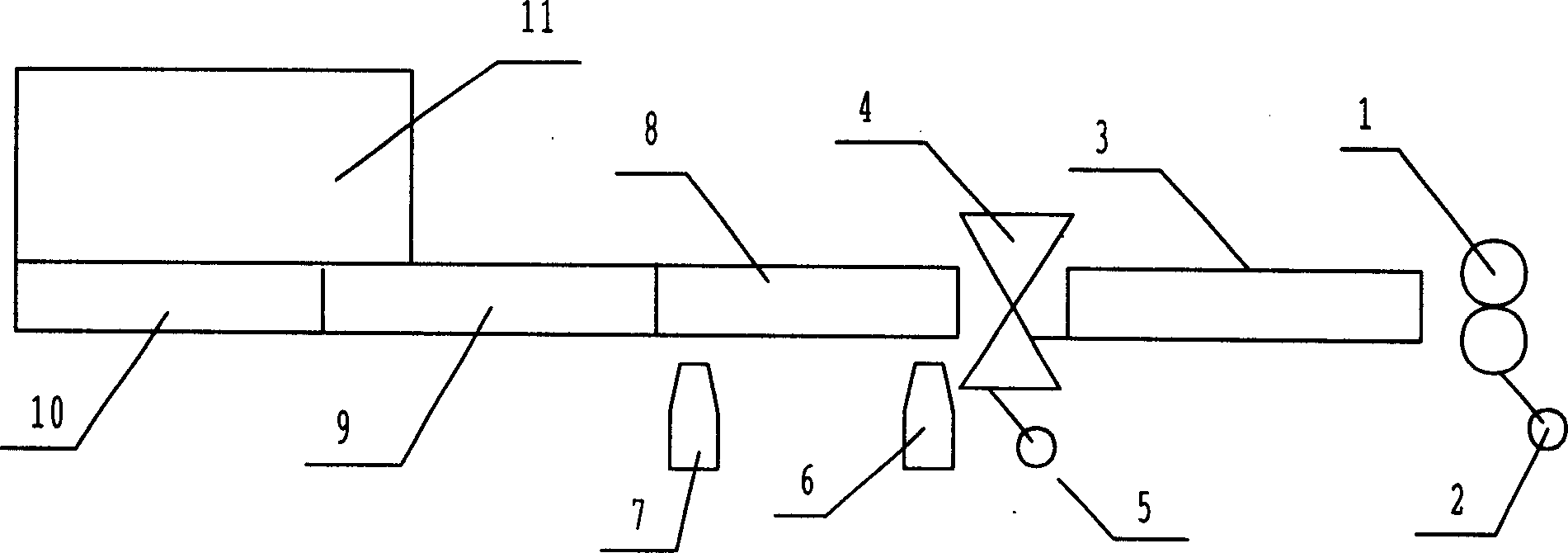

Thermomultiplying ruler shear precision optimizing method for bar production

InactiveCN100387369CImprove the accuracy of length measurement and shearingEliminate the effect of length measurementLength control deviceMeasuring devicesEngineeringMetal detectors

The present invention relates to a thermal multiple-length shearing accuracy optimization method in production of rod material, belengting to the field of pressure processing technology for raising rod material shearing accuracy. Said invention uses two rotating speed pulse coders and two hot-metal detectors as speed-measuring sensor and uses a programmable controller as speed-measuring controller. Its optimization method includes the following steps: firstly, utilizing shearing point of thermal multiple length shears and two hot-metal detectors after shearing operation to detect out the line speed of every thermal multiple length steel; then utilizing sail line speed to calculate the 'virtual roll diameter' value which can be used to reach said line speed under the rotating speed of said finished product rolling mill; transferring the 'virtual roll diameter' value into tength-measuring program and substituting original inputted roll diameter value; after every shearing operation repeating the above-mentioned steps. The invented shearing accuracy can be up to plus or minus 50mm.

Owner:HEBEI IRON AND STEEL

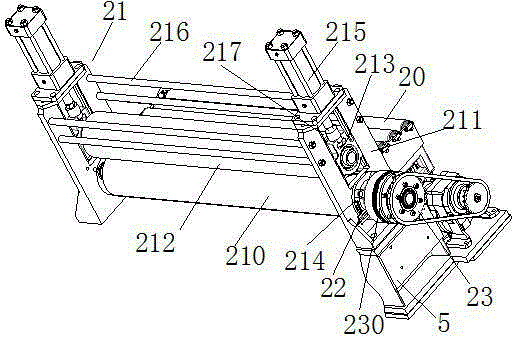

Multifunctional thread rolling machine

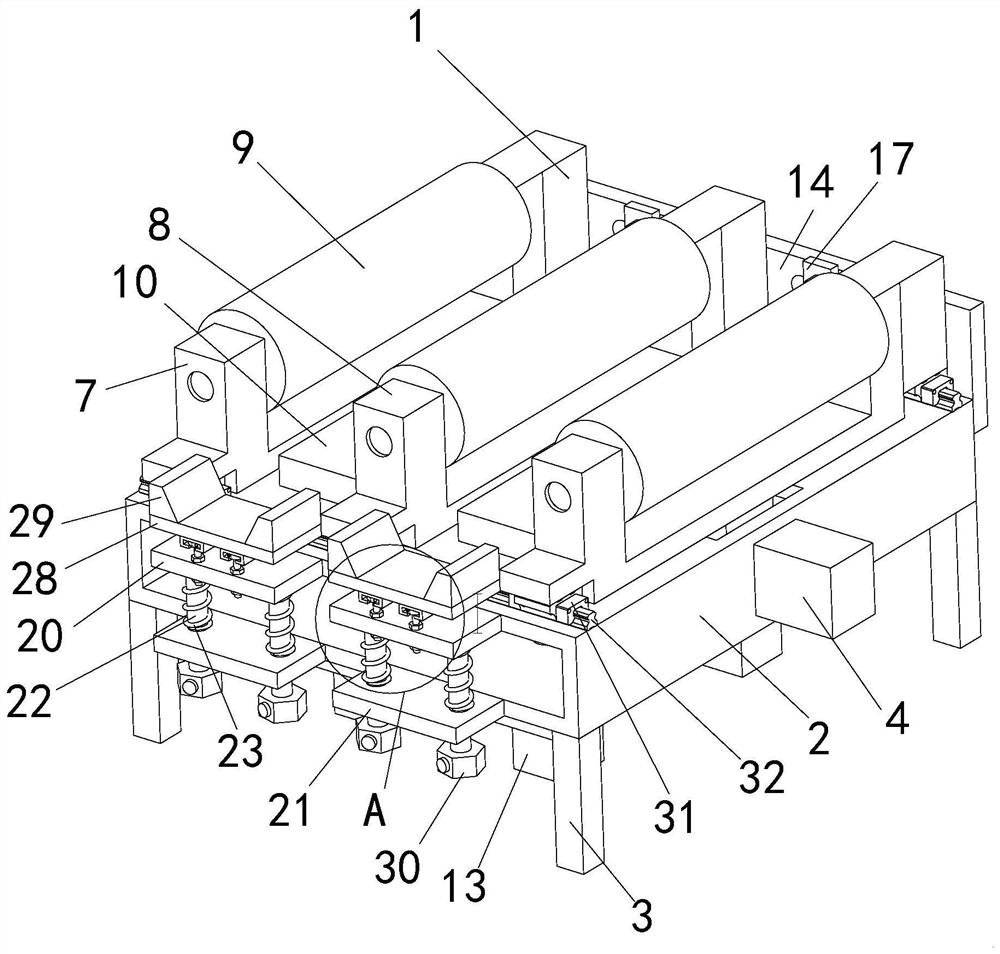

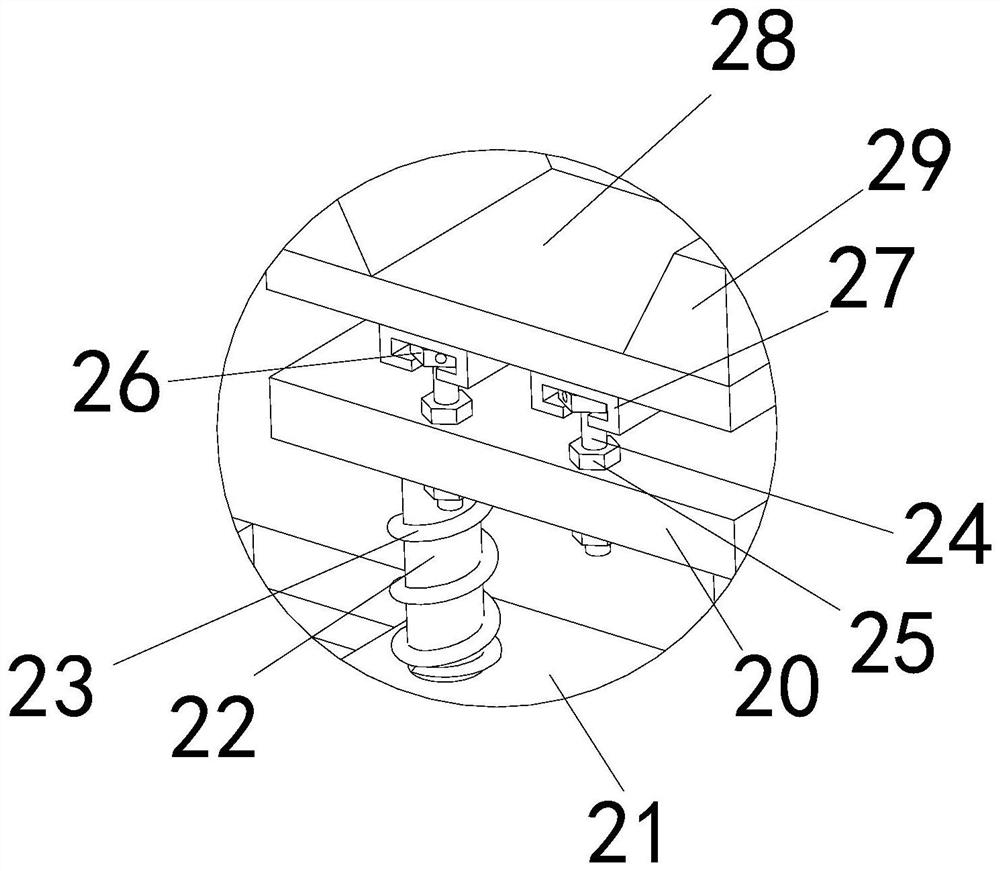

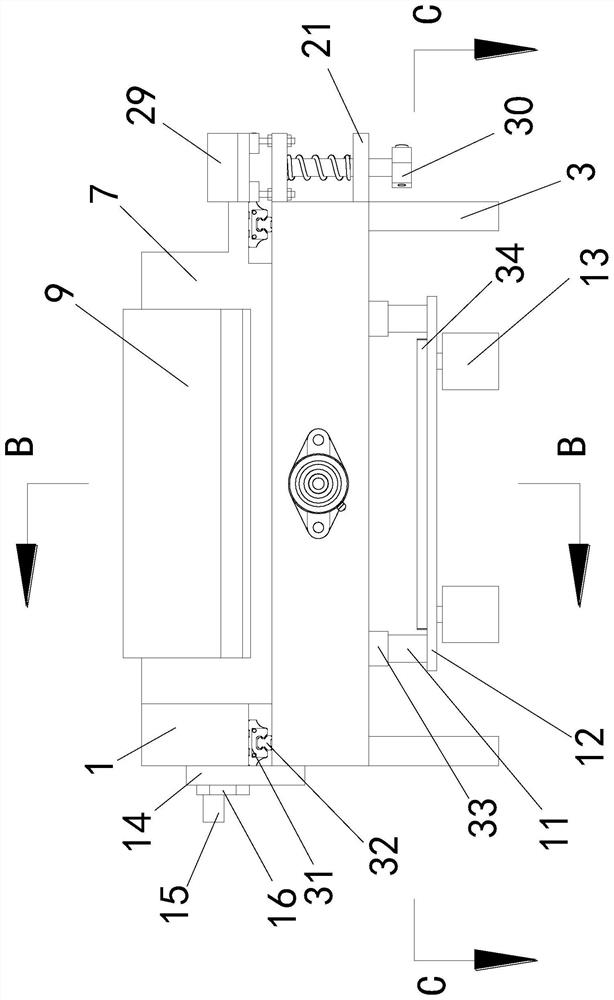

ActiveCN112846011AEasy to operateEasy to adjust the lengthLength control deviceScrew-threads articlesElectric machineryMachine

The invention relates to the technical field of thread rolling machines, in particular to a multifunctional thread rolling machine. The multifunctional thread rolling machine comprises a transmission device, a supporting box, a motor, a lengthened shaft, a linkage plate, a first adapter seat, a second adapter seat, a thread rolling shaft, an adjusting plate, a sliding shaft, two connecting plates, an electric push rod and a frame plate. First long-strip-shaped holes are formed in the left part and the right part of the frame plate, a supporting shaft is arranged in the middle of each first long-strip-shaped hole, a fixing nut is connected to the rear part of each supporting shaft through threads, an extension plate sleeves the front part of each supporting shaft, a second long-strip-shaped hole is formed in the middle of each extension plate, each supporting shaft penetrates through the corresponding second long-strip-shaped hole, a photoelectric sensor is installed on the upper part of each extension plate, clamping nuts are connected to the front parts of the supporting shafts through threads, and the rear ends of the clamping nuts make contact with the front ends of the corresponding extension plates. The height of a bottom supporting part can be conveniently adjusted, the length of a thread machined on the part can be conveniently determined, operation of a user is facilitated, and the machining efficiency is high.

Owner:邯郸市燕赵紧固件制造有限公司

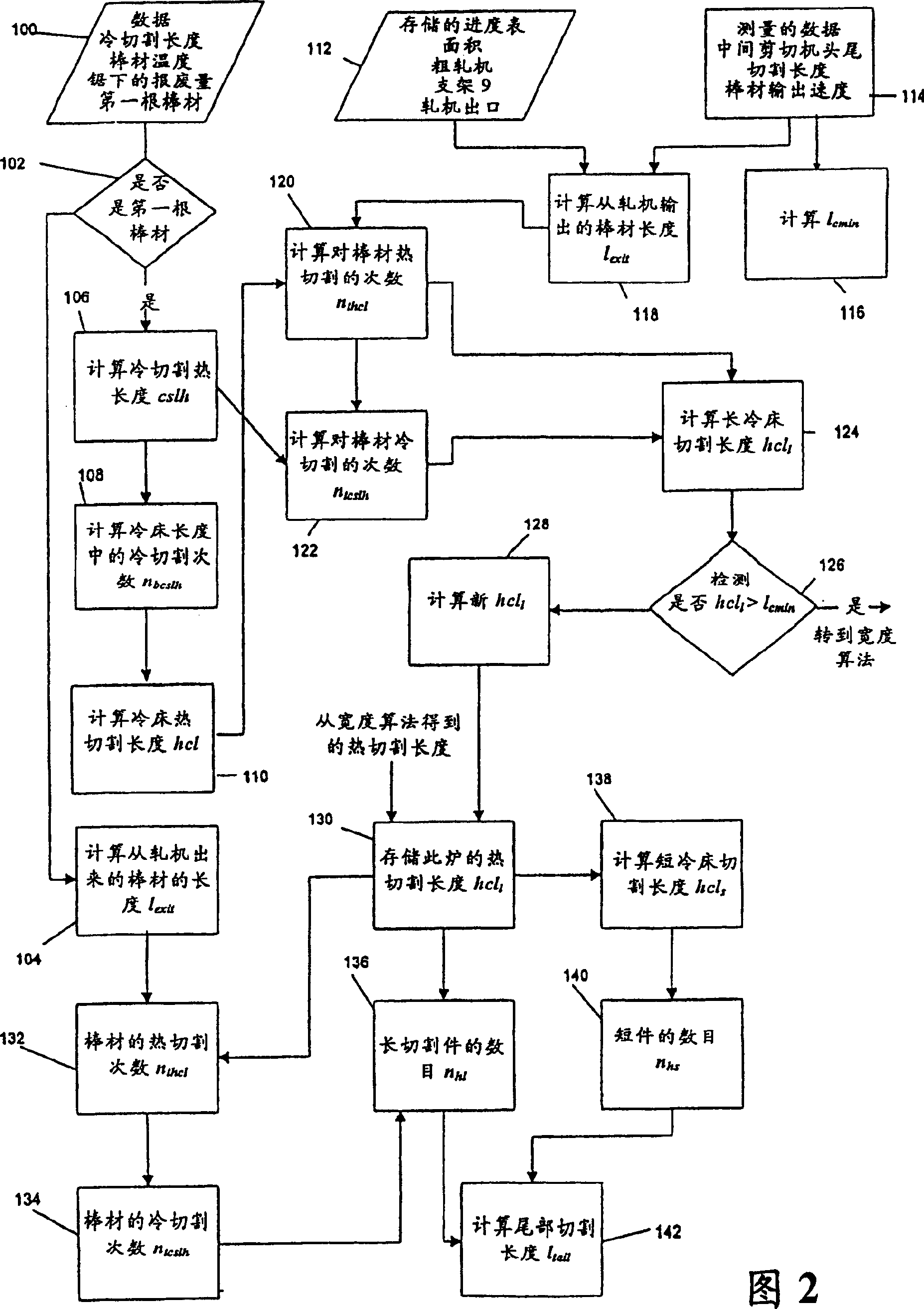

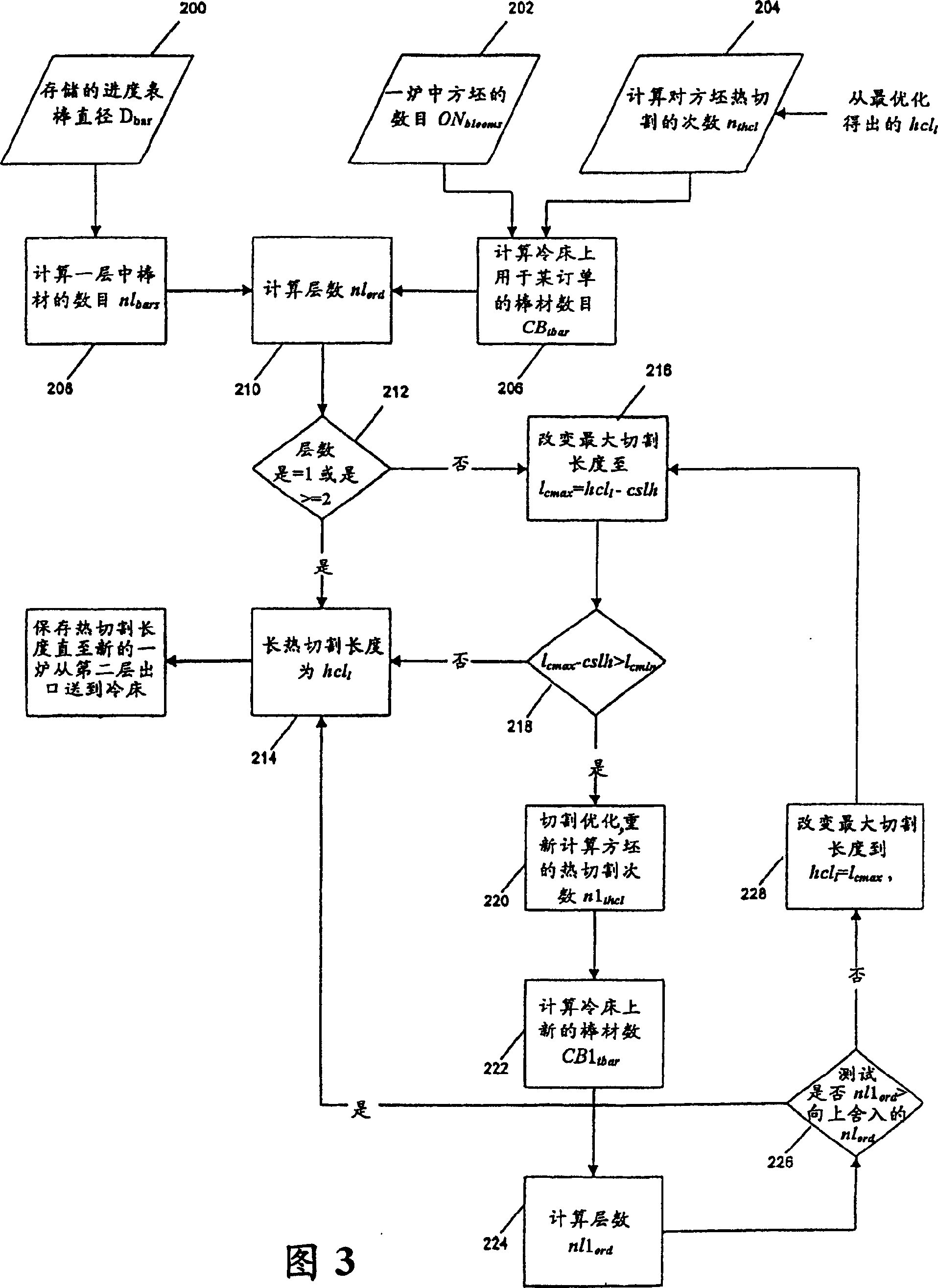

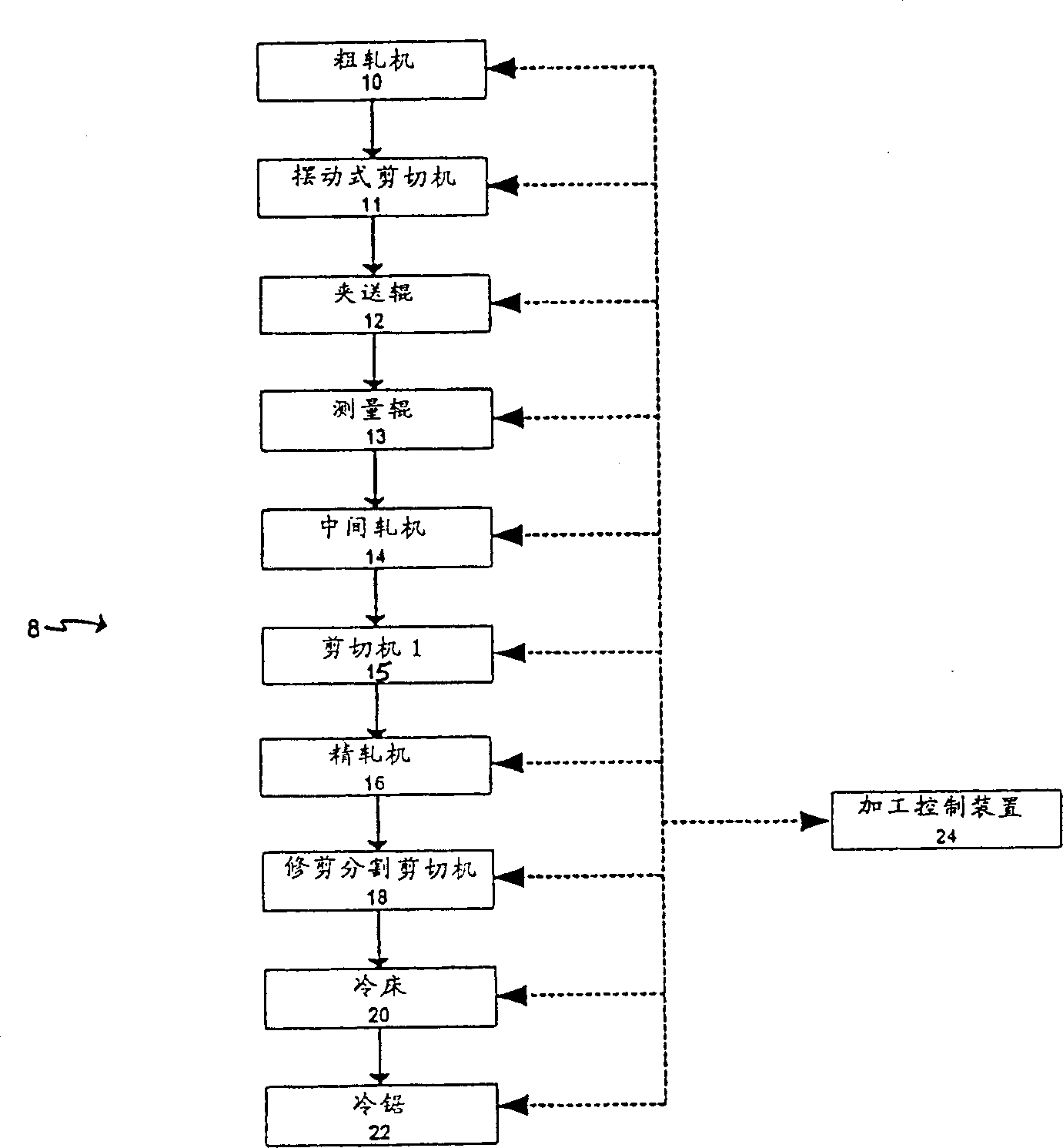

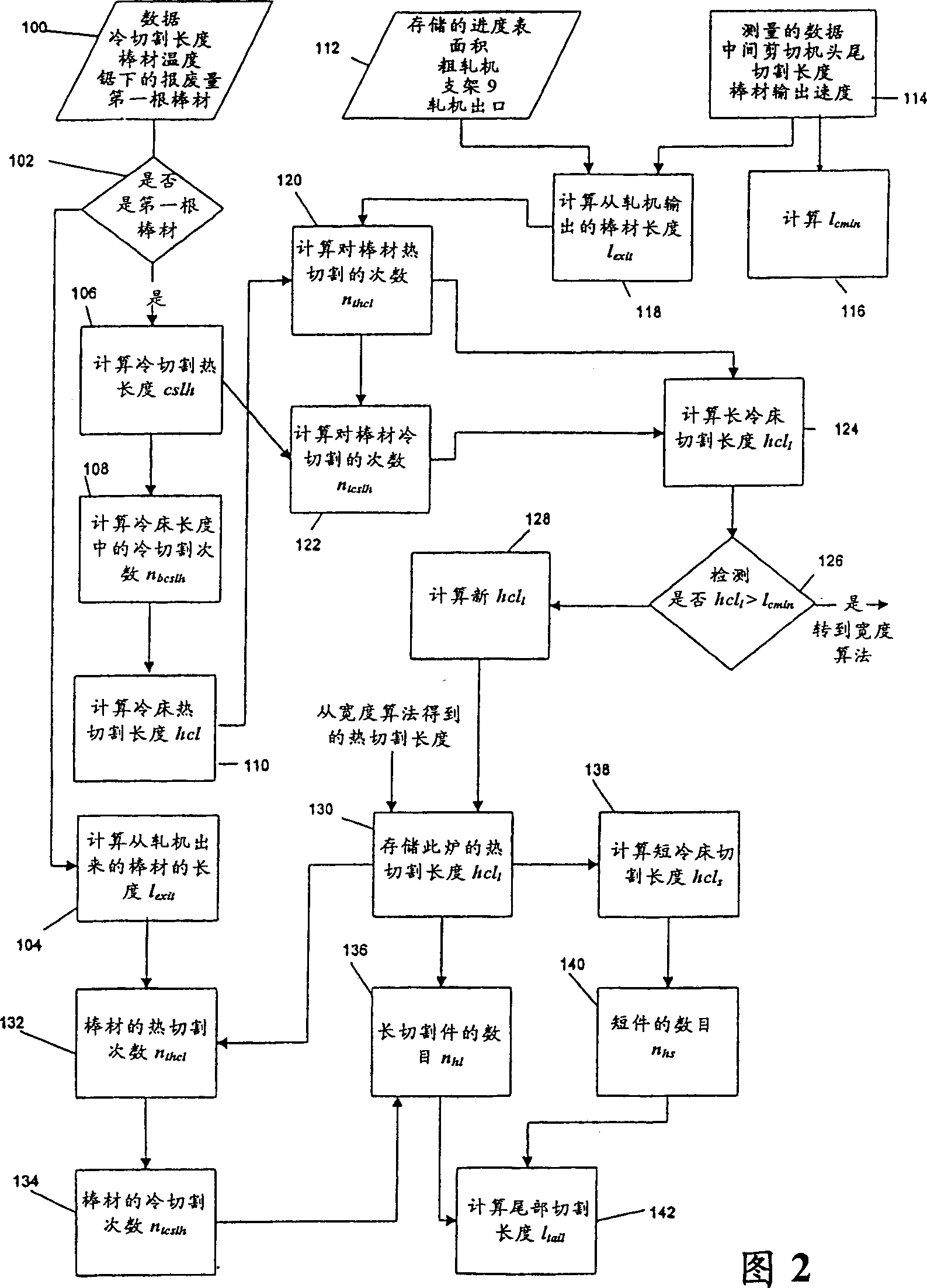

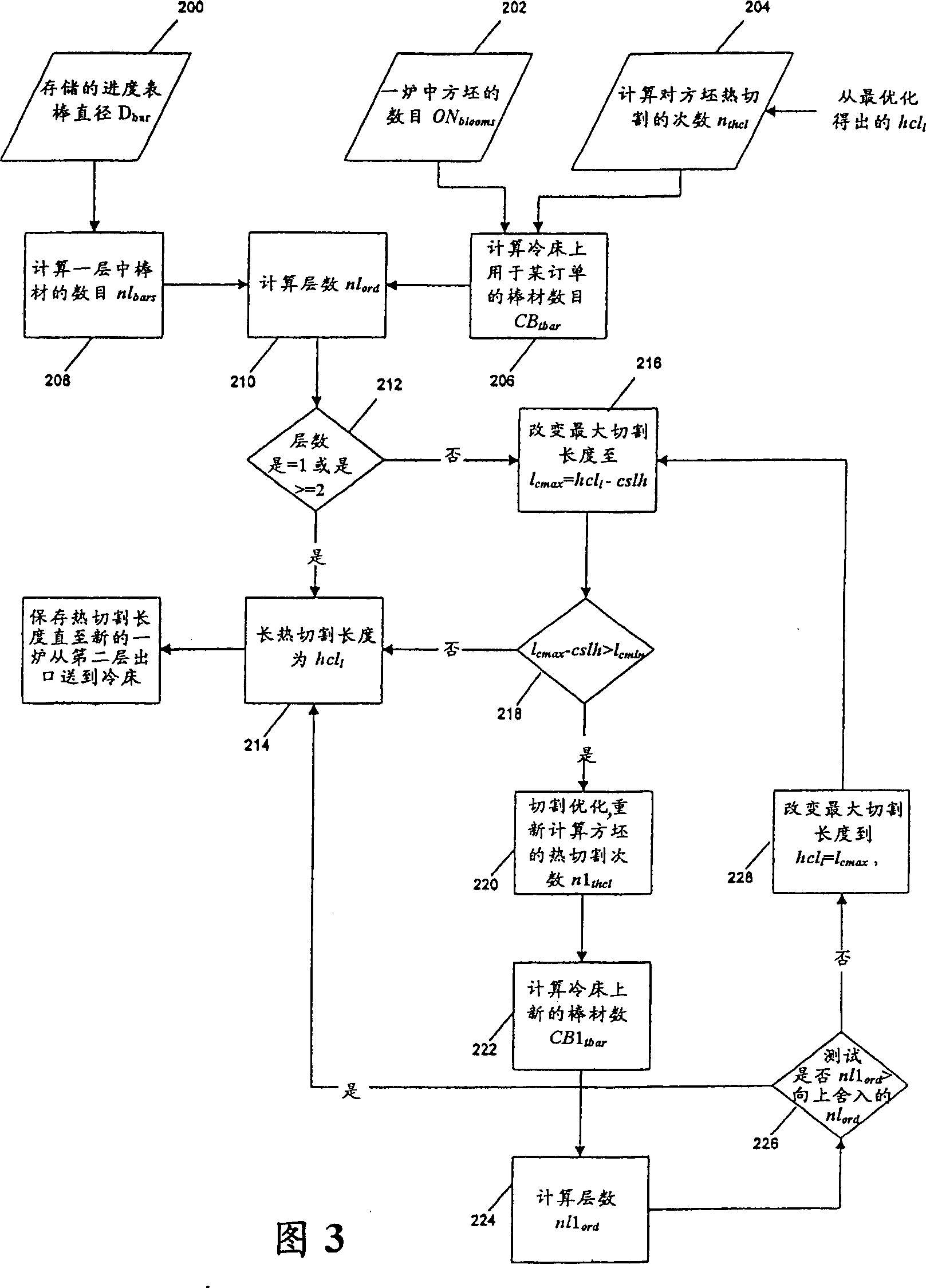

System and method for optimizing cutting of rolling mill

InactiveCN1235695CImprove efficiencyLow costLength control deviceCooling bedsEngineeringRolling mill

A method for controlling a bar processing mill having an exit and a cooling bed to produce bars of a predetermined cold length. The method includes, for a first bar in a processing order, calculating a long hot cut length based, at least in part upon a predetermined cold length . In addition, the method includes adjusting the long hot cut length based on a total length of bar exiting the exit, if the long hot cut length is greater than a minimum cooling bed length , and if a number of layers of bars to be processed on the cooling bed is less than a predetermined number.

Owner:GENERAL ELECTRIC CO

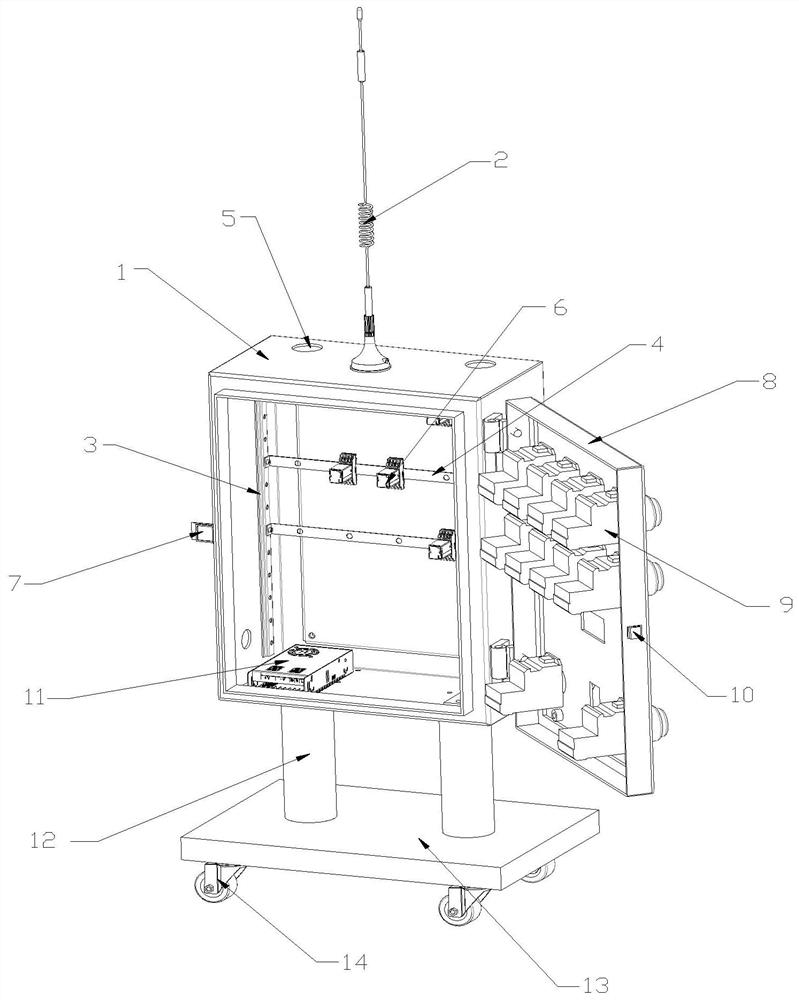

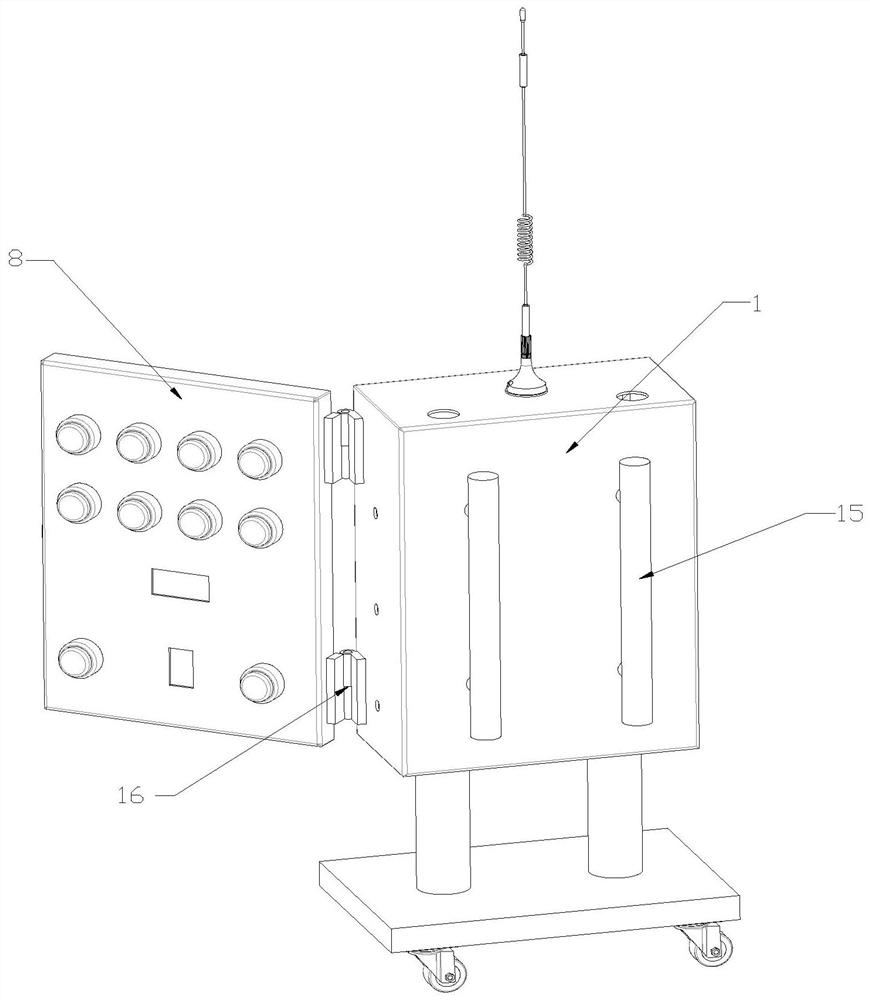

Wireless control device and system for post-cold-shearing roller way

PendingCN112588841AImprove convenienceImprove control performanceLength control deviceProgramme control in sequence/logic controllersWireless controlControl manner

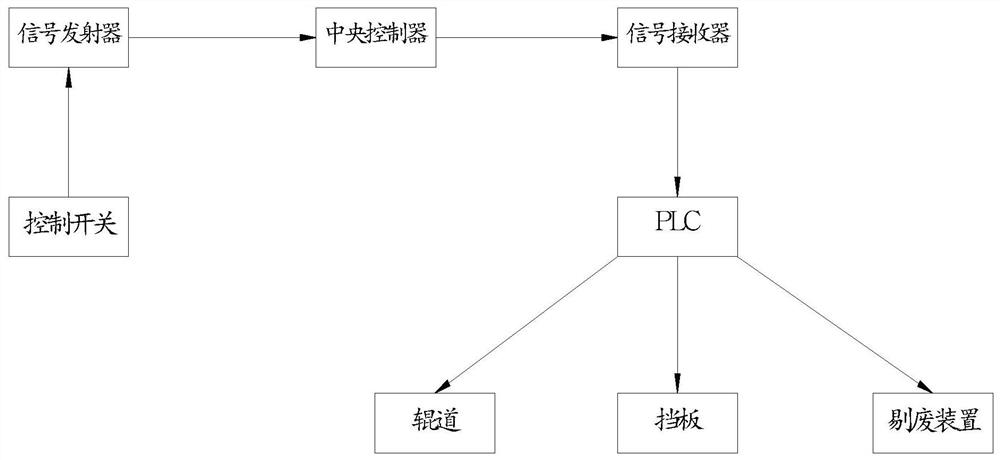

The invention discloses a wireless control device and system for a post-cold-shearing roller way. The wireless control device comprises an operation box, a signal transmitter, element height adjustingrods, an element containing rod, a clamping piece, a sealing plate, control switches, a clamping block, a power source, supporting columns, a supporting plate, universal wheels, pushing handles and hinges. The wireless control system comprises the control switches, the signal emitter, a central controller, a signal receiver, a PLC, a roller way, a baffle and a waste removing device. A traditionalwired control manner is replaced with a wireless control manner, convenience of actual operation of a traditional operation box is improved on the premise that stability of the control effect is guaranteed, and various kinds of inconvenience brought by wired control are successfully avoided. The problems that in the prior art, an operation box is fixed and connected with control equipment in a wired manner, due to the narrow operation space and scattered operation points in on-site operation of a metallurgy post-cold-shearing roller way platform, back-and-forth operation is not easy, and theoverhaul difficulty is improved are solved.

Owner:安徽长江钢铁股份有限公司

A multifunctional thread rolling machine

ActiveCN112846011BEasy to operateEasy to adjust the lengthLength control deviceScrew-threads articlesElectric machineryEngineering

The invention relates to the technical field of thread rolling machines, in particular to a multifunctional thread rolling machine, comprising a transmission device, a support box, a motor, an extension shaft, a linkage plate, a first adapter seat, a second adapter seat, a thread rolling shaft, The adjusting plate, the sliding shaft, the two connecting plates, the electric push rod and the frame plate, the left and right parts of the frame plate are provided with first elongated holes, and the middle of each first elongated hole is provided with a support shaft, and each support shaft The rear part is connected with a fixing nut through a thread, and the front part of each support shaft is sleeved with an extension plate, the middle part of the extension plate is provided with a second elongated hole, each support shaft passes through the corresponding second elongated hole, and the upper part of each extension plate is Photoelectric sensors are installed in all of them, and the front part of the support shaft is connected with a clamping nut through a thread, and the rear end of the clamping nut is in contact with the front end of each corresponding extension plate; it is convenient to adjust the height of the bottom support part, and it is convenient to determine the length of the thread processed on the part, It is convenient for users to operate and has high processing efficiency.

Owner:邯郸市燕赵紧固件制造有限公司

System and method for optimizing cutting of rolling mill

A method of controlling a bar processing mill having an outlet and a cooling bed for producing bar of predetermined cold length. The method includes, for a first bar in a work order, calculating a long hot cut length based at least in part on a predetermined cold length. In addition, the method includes: if the long thermal cutting length is greater than the minimum cooling bed length, and if the number of layers of rods to be processed on the cooling bed is less than a predetermined value, adjusting the long thermal cutting length according to the total length of the rods output from the outlet.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com