Compensation system for rail specification fluctuation

A technology of fluctuation compensation and rail, applied in the field of steel rolling production, can solve the problems of limited accuracy, efficiency, low robustness, no self-learning ability, etc., and achieve the effect of creating significant benefits and improving compensation accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

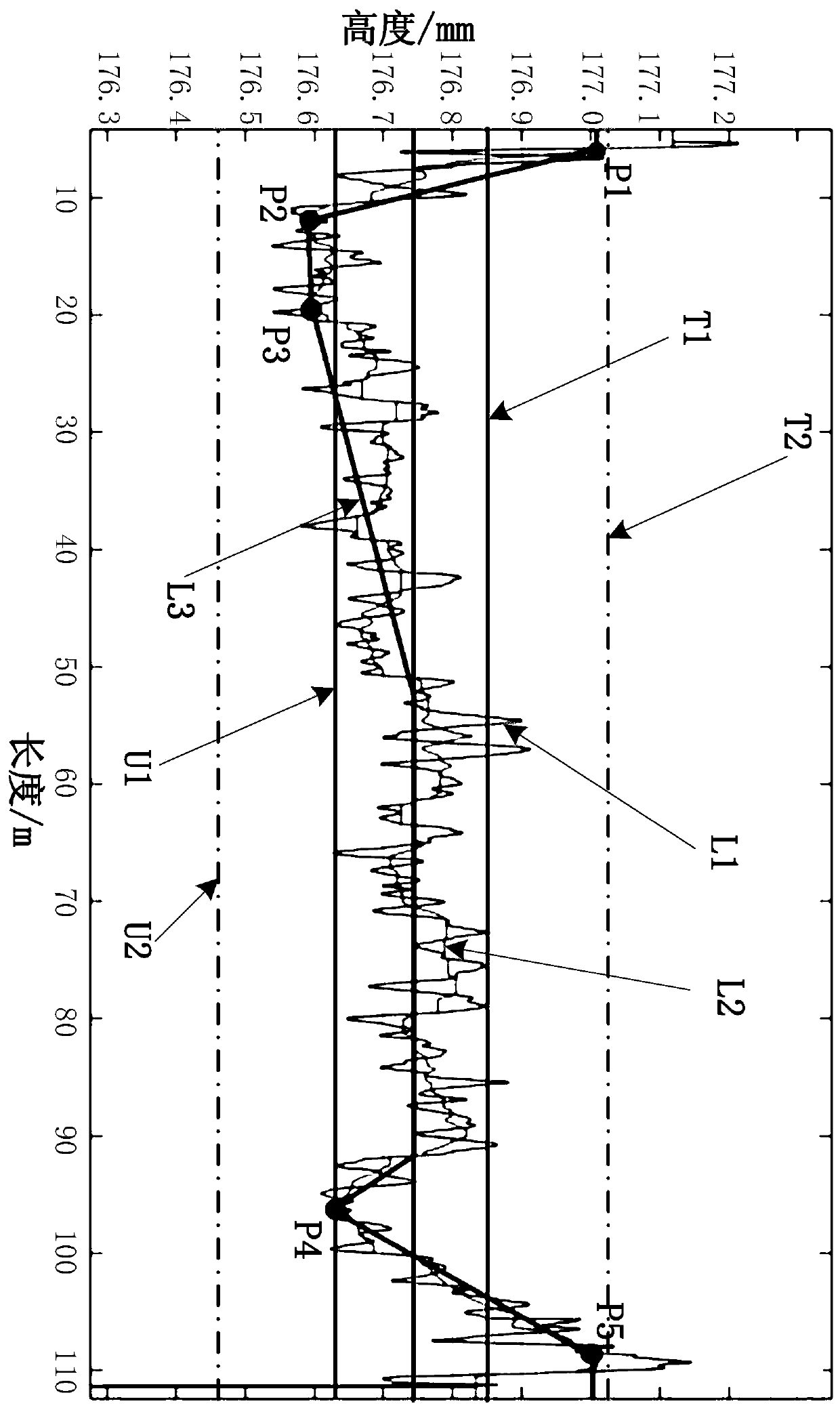

[0048] The present invention will be further described below by taking the height fluctuation compensation of a 100-meter rail as an example.

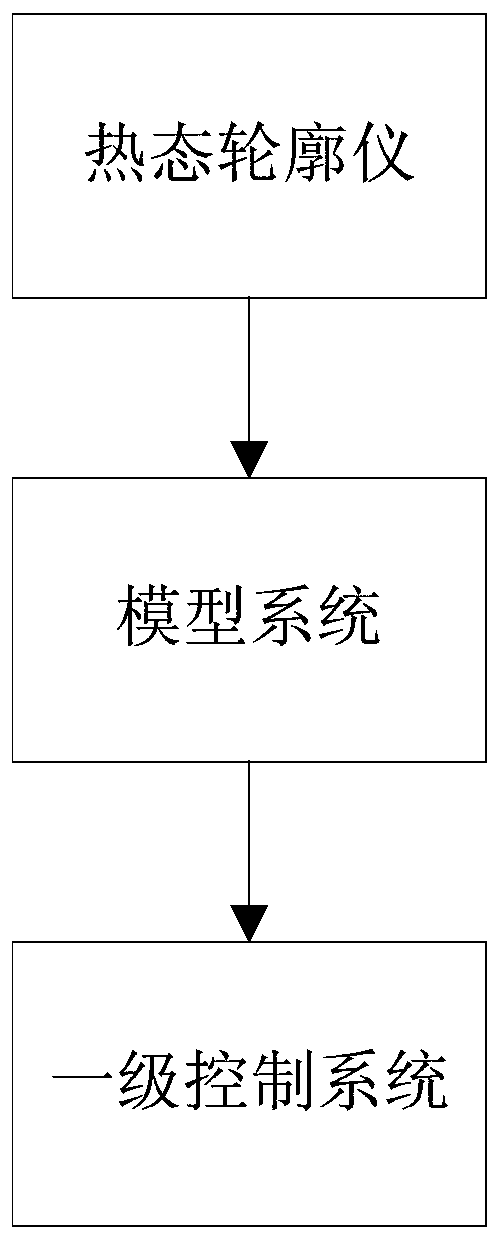

[0049] The embodiment provides a rail specification full length fluctuation compensation system, the system includes a thermal profiler, a model system and a primary control system; wherein the thermal profiler is mainly responsible for the generation of height data; the model system is mainly responsible for the establishment of the fluctuation model , including searching for compensation points and fluctuation compensation curves; the primary control system is sequential control, which is responsible for issuing fluctuation commands. Each part of the system of the embodiment will be described in detail below through the workflow of the embodiment.

[0050] 1. Raw data acquisition

[0051] The thermal profiler is based on the FTP file transfer protocol. When the thermal profiler generates a new height record, it will be exported and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com