Hot rolling high strength steel plate for two-sided porcelain enamel and manufacturing method thereof

A high-strength steel plate and manufacturing method technology, applied in the direction of length control, etc., can solve the problems of high cost, coarse particles, unfavorable steel plate formability and surface quality, etc., and achieve good plasticity, high strength, and good anti-scaling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

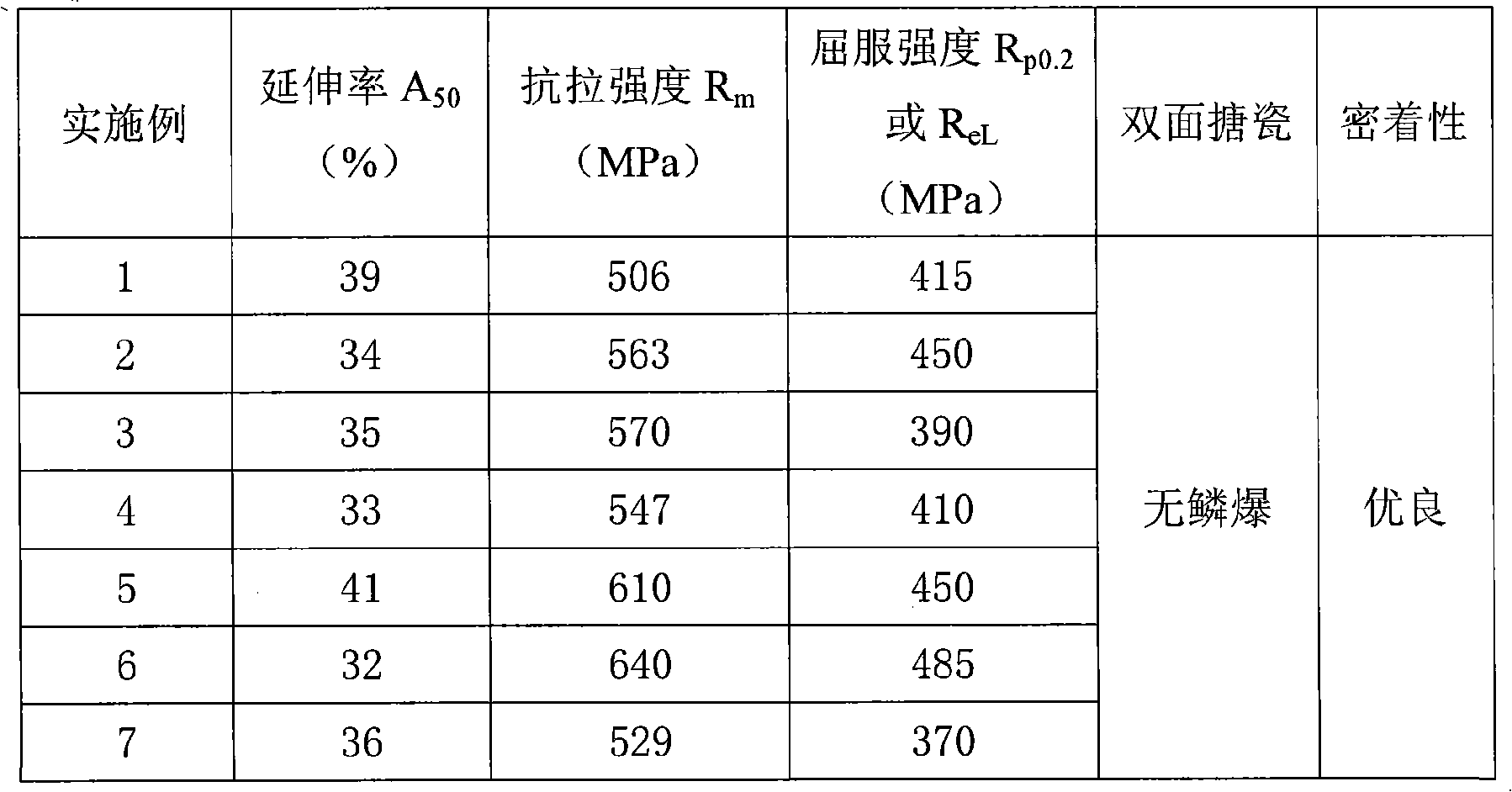

Examples

Embodiment 1

[0034] Smelt molten steel according to the following chemical composition: C: 0.12wt%, Si: 0.80wt%, Mn: 1.2wt%, P: 0.015wt%, S: 0.035wt%, Al: 0.039wt%, N: 0.0150wt%, Ti : 0.050wt%, V: 0.020wt%, the balance is Fe and unavoidable impurities.

[0035] The molten steel blown in the converter according to the above ratio is vacuum degassed and then continuously cast. The obtained continuous casting slab is heated at 1150°C and then rolled for multiple passes within the austenite recrystallization temperature range. The total reduction rate is ≥50%, and then rolled in one or more passes within the temperature range of austenite recrystallization zone or non-recrystallization zone, the total reduction ratio is ≥50%, and the final rolling temperature is 820°C. Then it is cooled to the coiling temperature by two stages of water cooling, the front and rear of the water cooling are air-cooled, the water cooling rate of the front stage is 45°C / s, the water cooling rate of the rear stage i...

Embodiment 2

[0037] Smelt molten steel according to the following chemical composition: C: 0.05wt%, Si: 0.10wt%, Mn: 1.8wt%, P: 0.011wt%, S: 0.008wt%, Al: 0.018wt%, N: 0.0080wt%, Ti: 0.015wt%, V: 0.045wt%, and the balance is Fe and unavoidable impurities.

[0038]The molten steel blown by the converter according to the above ratio is subjected to vacuum degassing treatment and then die-casted. The steel ingot after die-casting is rolled into a billet. Pass rolling, the total reduction rate is ≥ 50%, and then rolled in one or more passes within the temperature range of the austenite recrystallization zone or non-recrystallization zone, the total reduction rate is ≥ 50%, and the final rolling temperature is 1050 ℃. Then through multi-stage water cooling to the coiling temperature, air cooling before and after the water cooling, the water cooling rate is 35°C / s, and the coiling temperature is 700°C.

Embodiment 3

[0040] Molten steel is smelted according to the following chemical composition: C: 0.09wt%, Si: 0.29wt%, Mn: 1.3wt%, P: 0.011wt%, S: 0.017wt%, Al: 0.019wt%, N: 0.0085wt%, Ti: 0.020 wt%, V: 0.090 wt%, the balance being Fe and unavoidable impurities.

[0041] The molten steel blown by the converter according to the above ratio is vacuum degassed and then die-cast. The steel ingot after die-casting is initially rolled into a billet. Pass rolling, the total reduction rate is ≥ 50%, and then rolled in one or more passes within the temperature range of the austenite recrystallization zone or non-recrystallization zone, the total reduction rate is ≥ 50%, and the final rolling temperature is 1000 ℃. Then it is water-cooled to the coiling temperature in two stages, the front and rear are air-cooled, the water-cooling rate in the front stage is 41°C / s, the water-cooling rate in the rear stage is 20°C / s, and the coiling temperature is 640°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com