Rolling method and rolling device of uneven thickness steel plate

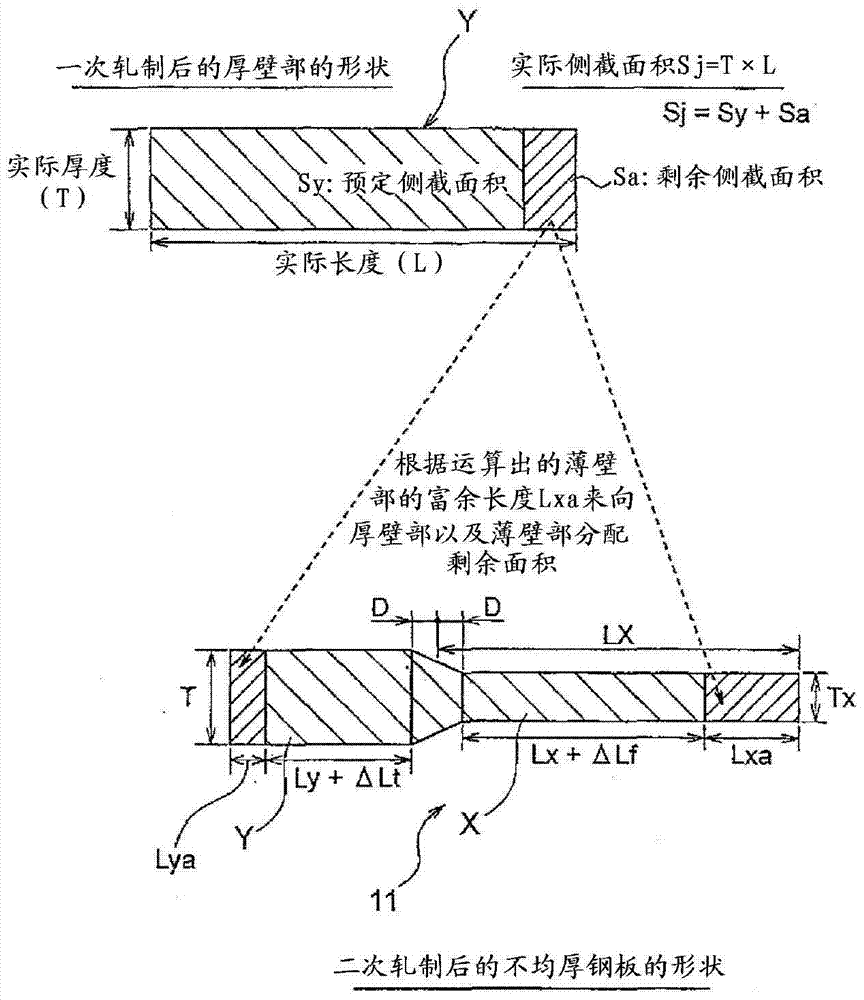

A steel plate and uniform thickness technology, which is applied in the rolling of uneven thickness steel plates and rolling equipment, can solve the problems of reduced yield of thick steel plates and distribution of surplus length, etc., and achieve the effect of increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, modes for implementing the present invention (hereinafter, referred to as embodiments) will be described in detail with reference to the drawings.

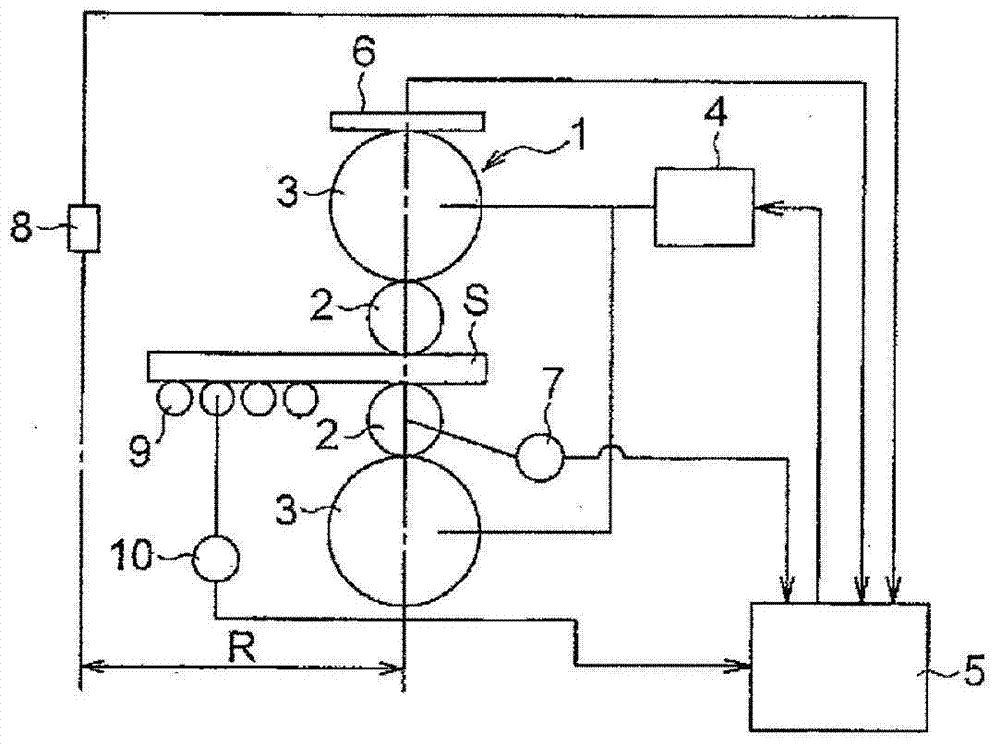

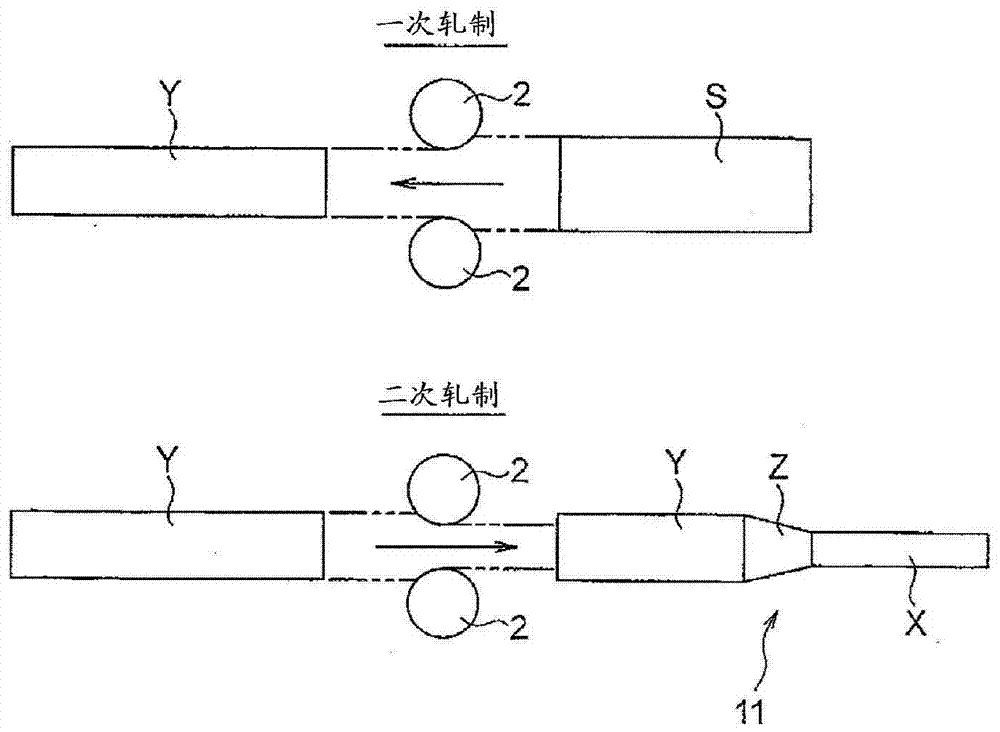

[0033] figure 1 A reversible rolling mill 1 for obtaining uneven-gauge steel plates by rolling a slab S is shown.

[0034] The rolling mill 1 includes vertical work rolls 2 and vertical backup rolls 3 . The gap (roll gap) between the upper and lower work rolls 2 is adjusted by the gap changing mechanism 4 . The opening degree changing mechanism 4 sets and changes the opening degree of each pass according to an opening degree instruction from the controller 5 . The rolling load during rolling is detected by a load cell 6 , and the detected value is output to the controller 5 . Reference numeral 8 is a plate width meter (plate width meter) for measuring the plate width of the thick part Y mentioned later. Reference numeral 9 denotes table rolls for conveying the slab S toward the work rolls 2 . A first pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com