Method for controlling thickness of hot-continuous-rolled intermediate slab and length of cast ingot

A control method and hot continuous rolling technology, applied in the field of metal pressure processing, can solve problems such as low yield of hot continuous rolling production, and achieve the effects of improving yield, avoiding additional head and tail cutting damage, and avoiding equipment accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is described in further detail:

[0029] The method for controlling the thickness of the hot continuous rolling intermediate slab and the length of the ingot in this embodiment adopts "1+4" hot continuous rolling, and the method includes the following steps:

[0030] A. According to the set rolling pass reduction rate of each stand of the continuous rolling mill and the finished product thickness of the rolled piece, back calculate the reference value of the intermediate billet thickness and the rolling pass reduction of each stand.

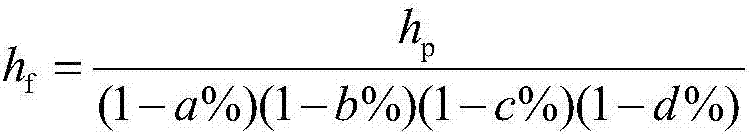

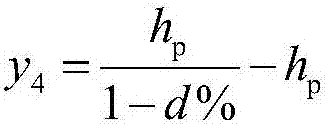

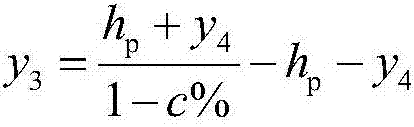

[0031] Assume that the reference value of the intermediate billet thickness is h f , the unit is mm; according to the setting principle of the rolling process, the reduction rate of the rolling pass from the first stand to the fourth stand is a%=45%, b%=42%, c%=40% , d%=38%; the rolling reductions from the first stand to the fourth stand are y in turn 1 、y 2 、y 3 、y 4 , the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com