Feeding mechanism of automatic cutting machine for welded steel tube coil

A technology of welding steel pipe and feeding mechanism, which is applied in the field of automation, can solve the problems of fixed-length cutting, beveled edge, inability, etc., and achieve the effect of correcting parallelism and preventing cutting out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0009] see figure 1 , the embodiment of the present invention includes:

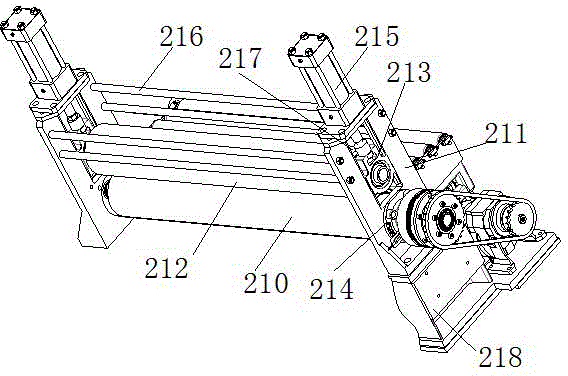

[0010] A feeding mechanism of a welded steel pipe coil automatic cutting machine, the feeding mechanism of the welded steel pipe coil automatic cutting machine includes a main feeding roller shaft 210, a "U" shaped plate 211, a pressing roller shaft 212, a pressing The material roller shaft seat 213, the main feed roller shaft seat 214, the pressure material cylinder 215 and the pull rod 216, the two parallel corresponding "U" shaped plates 211 are installed on the frame 218, and the two parallel corresponding "U" shaped plates The plates 211 are connected and supported by four ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com