Hot rolling box for shearing strip steel head by hot continuous rolling and method for shearing strip steel head

A technology for shearing strips and hot coil boxes, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of length error, waste, and low temperature of the strip head of the shear strip, and achieve The effect of avoiding scrap, avoiding waste and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

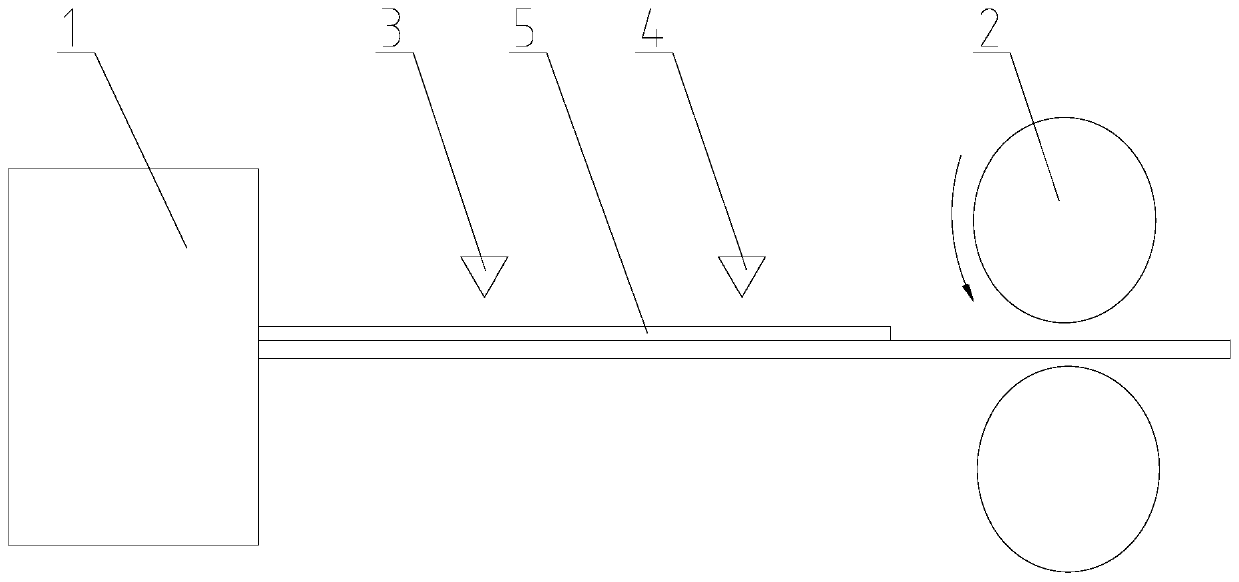

Image

Examples

Embodiment 1

[0027] The distance between the first pyrometer and the second pyrometer is 5m, the distance between the second pyrometer and the cutting position of the flying shear is 10m, the radius of the flying shear is 1m, and the initial position of the cutting blade of the flying shear is If it is -45°, the cutting blade of the flying shear needs to rotate to the vertical cutting position. The rotation angle required is 135°. The operator inputs the line speed on the HMI system as 1m / s, and the head shear length of the strip is input as 1m, then the time difference measured by the first high-temperature detector and the second high-temperature detector is 5s from the PLC system, and the running speed of the strip is calculated to be 1m / s, and the strip reaches the flying shear shearing position from the second high-temperature detector The required time is (10+1) ÷ 1 = 11s, the time required for the cutting edge of the flying shears to go from the initial position to the cutting positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com