Multifunctional thread rolling machine

A thread rolling machine, multi-functional technology, applied in the direction of threaded products, length control, household appliances, etc., can solve the problems of low processing efficiency, inconvenient adjustment of the height of the bottom support parts, inconvenient operation, etc., to achieve high processing efficiency , Easy to adjust, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

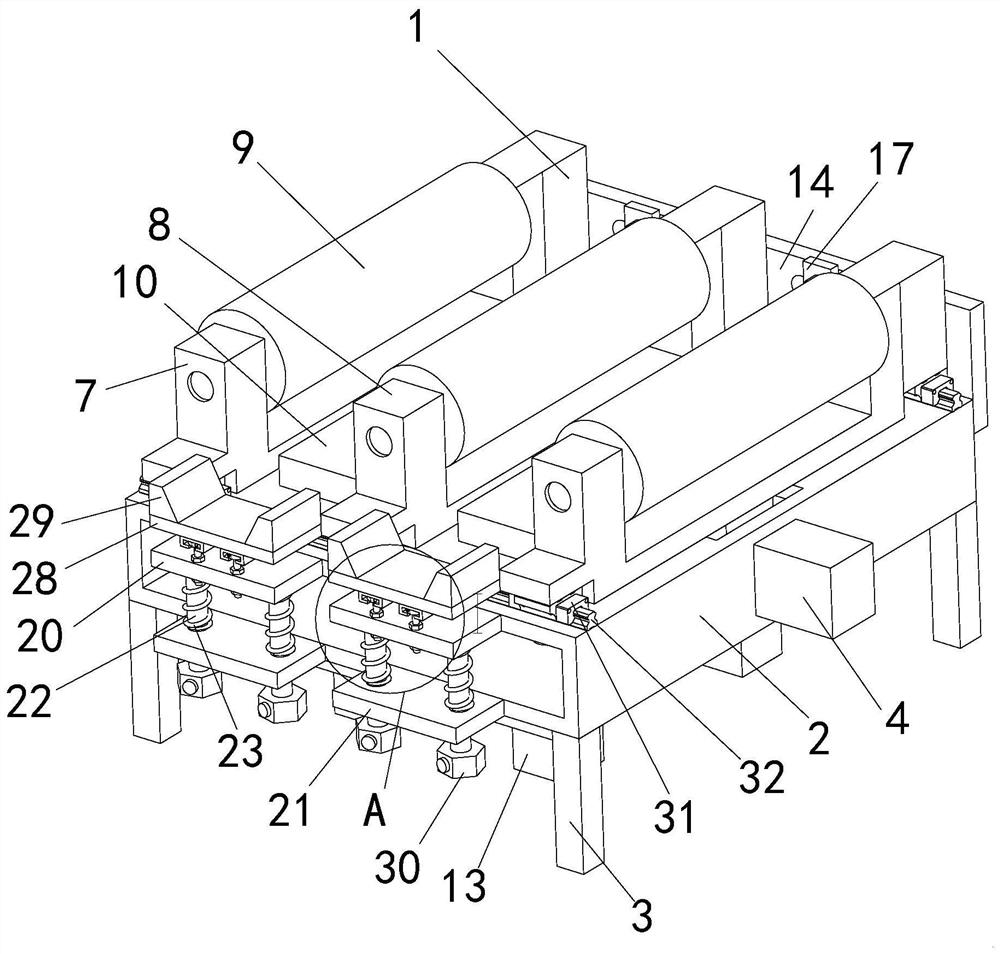

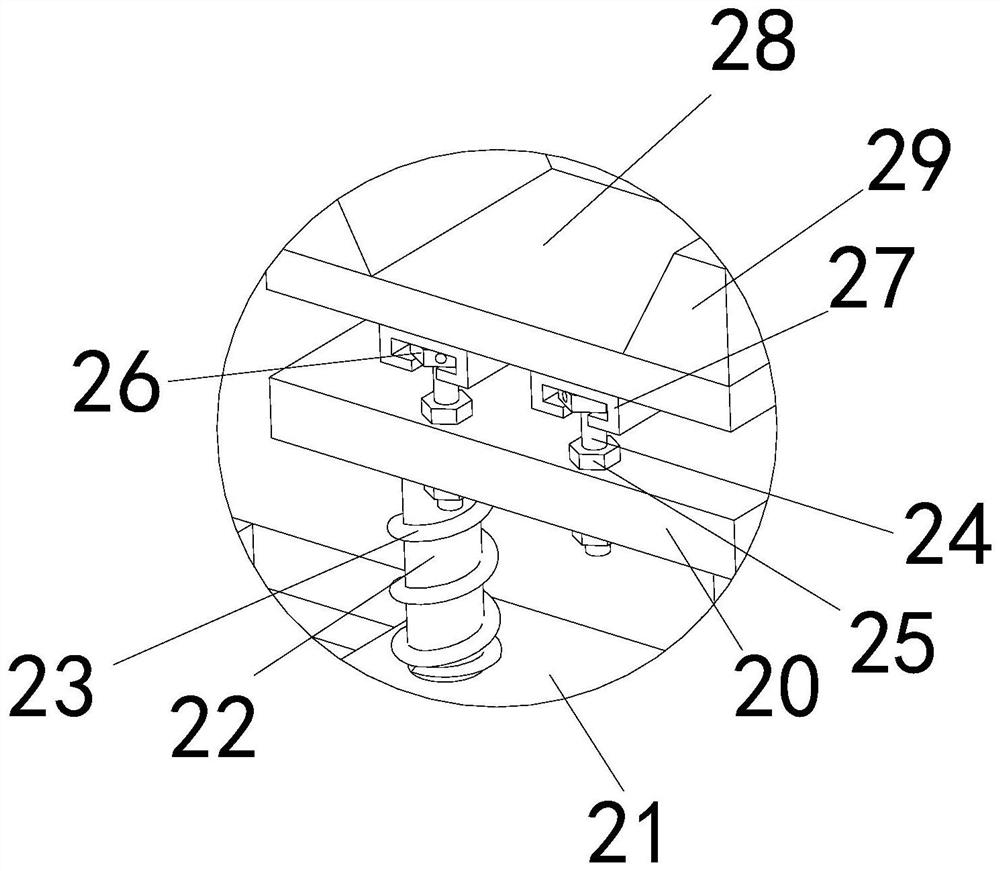

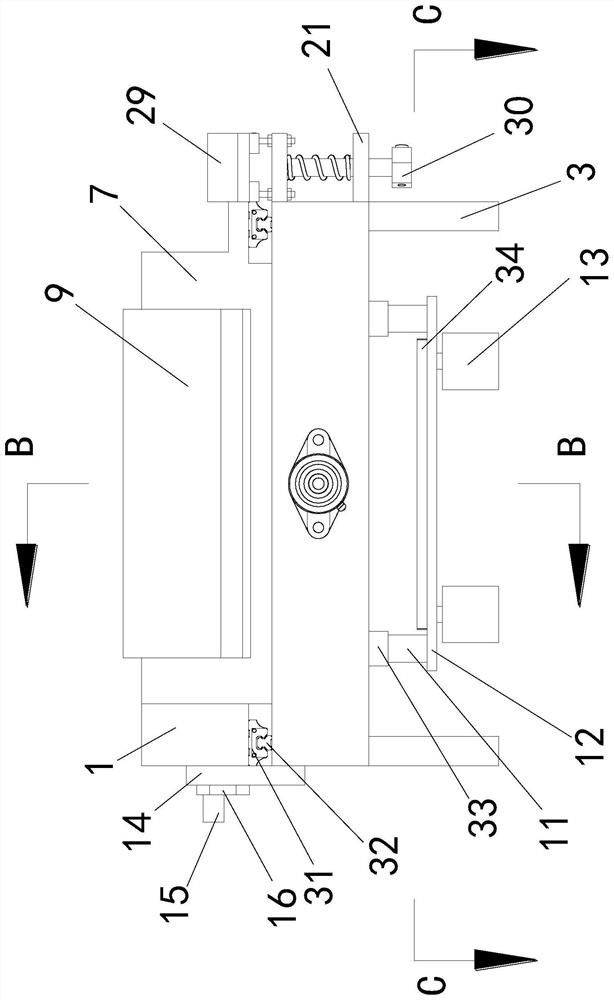

[0028] see Figure 1-6 , a multifunctional thread rolling machine, including a transmission device 1 and a support box 2, the four corners of the bottom of the support box 2 are fixedly connected with legs 3, the inside of the support box 2 is provided with a cavity, and the right end of the support box 2 A motor 4 is installed, and the output shaft end of the motor 4 is fixedly connected with an extension shaft 5. The left and right parts of the extension shaft 5 are provided with threads with opposite directions of rotation, and the left part of the extension shaft 5 is rotatably connected with the left side wall of the support box 2. , the left and right parts of the extension shaft 5 are threadedly connected with a linkage plate 6, the top side wall of the support box 2 is provided with a long hole corresponding to the linkage plate 6, and the top of each linkage plate 6 passes through the relief The top of each linkage plate 6 is fixedly connected with the first adapter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com