Step ejection method

A step and billet technology, applied in the direction of metal rolling, length control, etc., to achieve the effect of long-distance automatic measurement and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

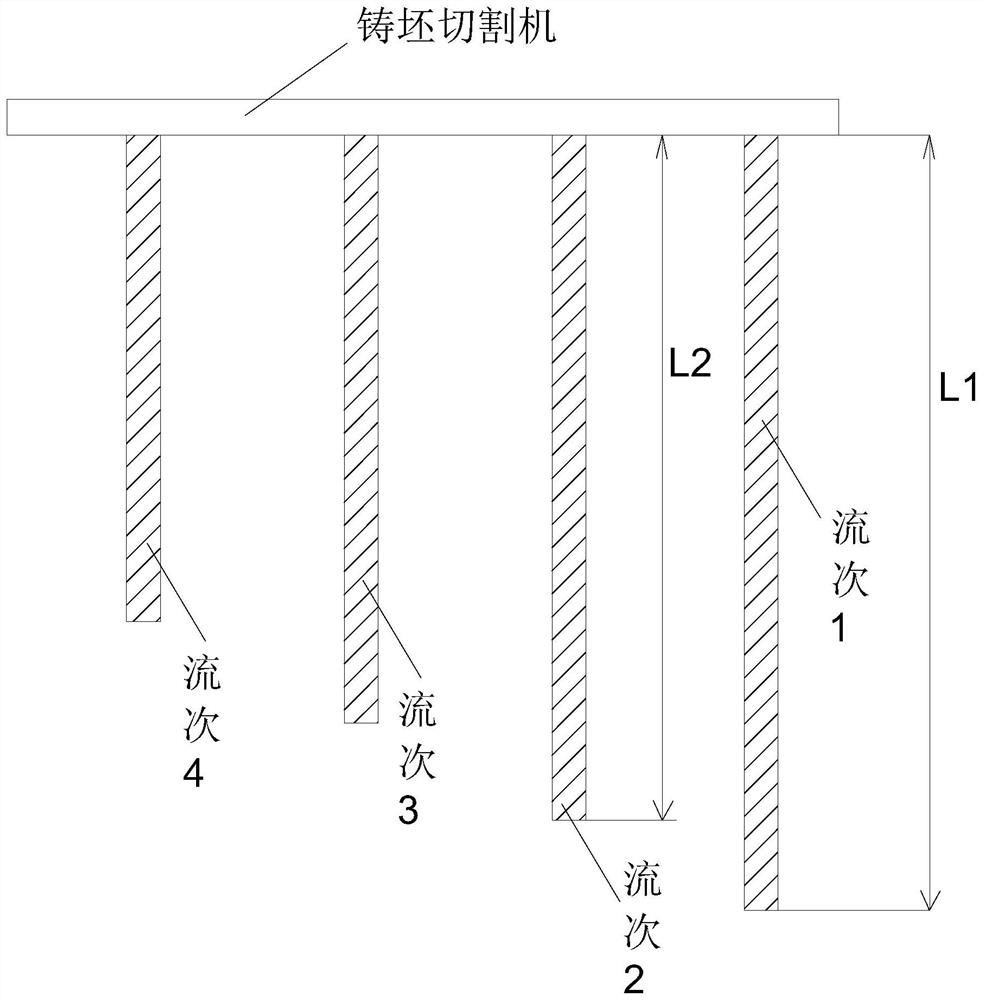

[0049] Such as figure 1 As shown, in this embodiment, a 4-machine 4-strand continuous casting machine is used to connect with a roller table of a bar rolling production line, and the rolling production capacity is greater than that of the continuous casting machine.

[0050] 1. The billet continuous casting machine uses the continuous casting billet infrared automatic sizing cutting system of Beijing COSCO Technology Co., Ltd. to measure the billet length. After the continuous casting machine starts production, the billet length is measured and sent to the control computer.

[0051] 2. The billet continuous casting machine uses the RAMON stopper numerical control system of Hunan Ramon Technology Co., Ltd., and the stopper controls the casting speed to realize stable and accurate control of the casting speed of each flow of the billet continuous casting machine.

[0052] 3. Production of the set slab length L 设 = 8m, after the computer receives the slab length, the flow with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com