New technology of bar material contiauous casting and milling

A bar-shaped material and new process technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of large production equipment, many production passes, long workshop spans, etc., and reduce production costs , improve the internal quality, reduce the effect of the intermediate heating link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

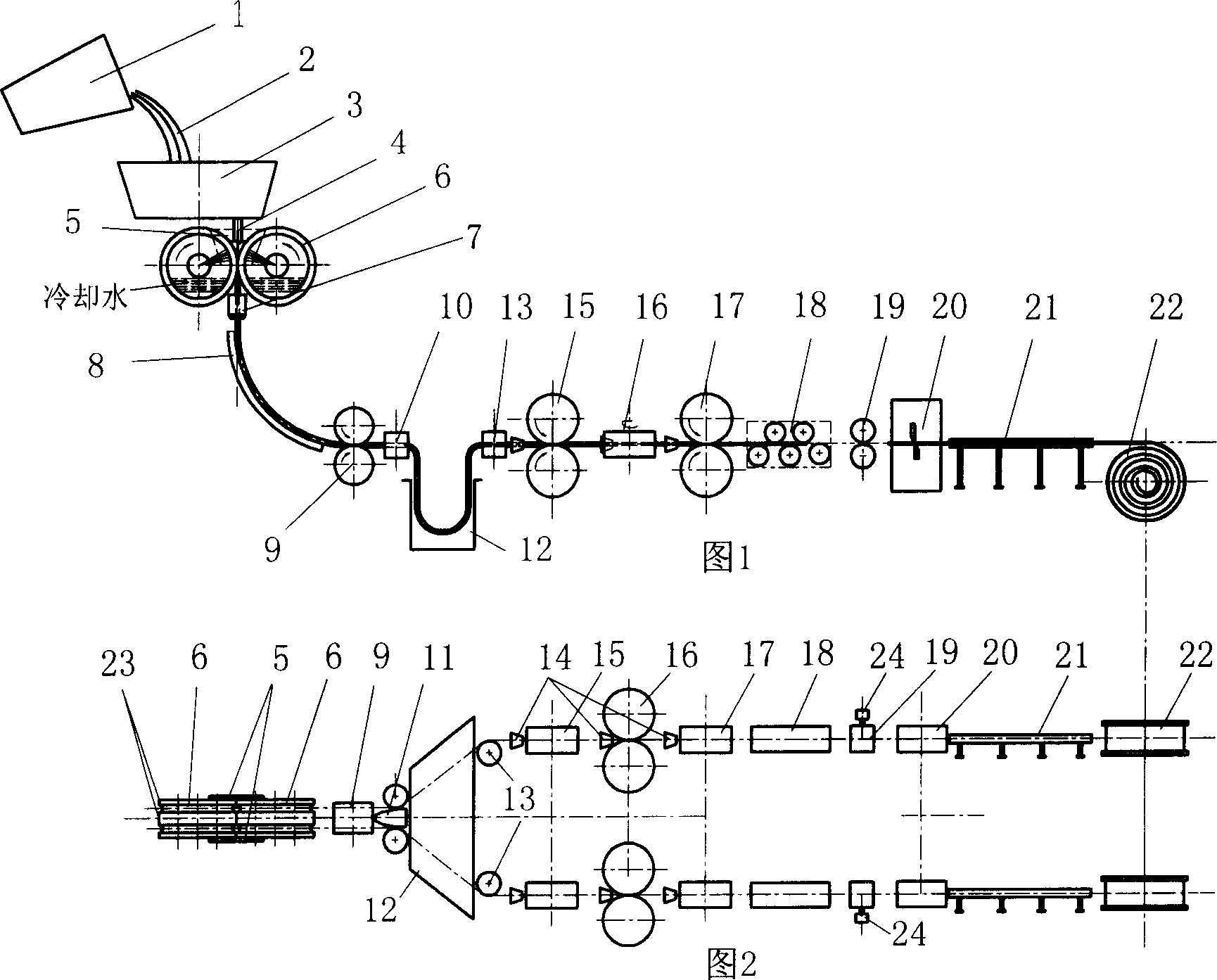

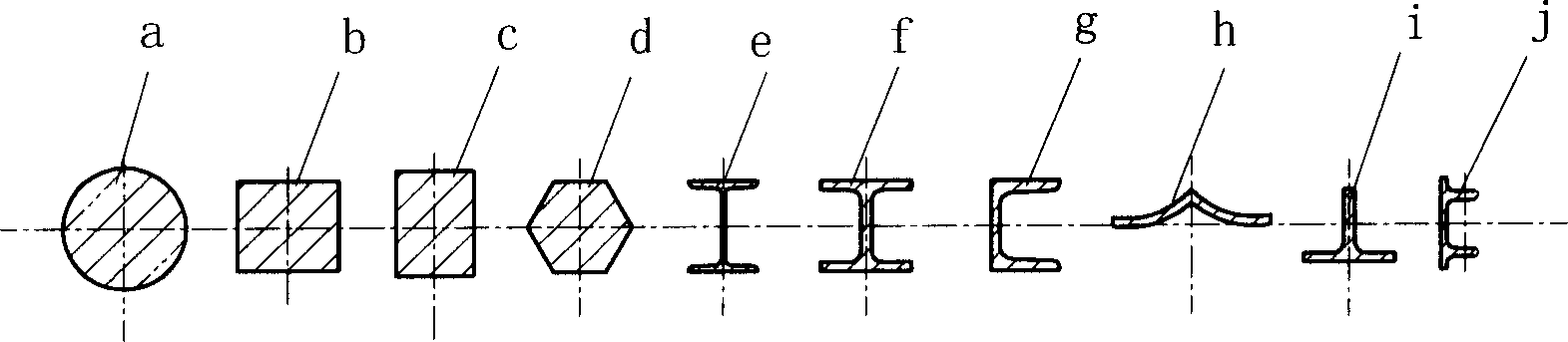

[0016] ①As shown in Figure 1 and Figure 2, the molten steel 2 in the ladle 1 is injected into the tundish 3, and then the nozzle 4 connected with the tundish 3 flows into the tundish formed by a pair of casting rolls 6 and two side sealing plates 5. In the wedge-shaped molten pool, a pair of casting rolls 6 that continuously rotate in reverse (see the direction of the arrow of casting roll 6 in Figure 1) through which cooling water passes through, exchange the molten metal in the wedge-shaped molten pool through heat exchange, so that the molten metal is gradually cooled and solidified , deformation, casting and rolling out two-way strips with a section consistent with the pass type (limited to circular section, square section, rectangular section, and hexagonal section), enter the cooler 7 to continue cooling, and are guided by the arc guide plate 8 to enter the pinch roller 9. The two-way strips that come out are separated by the separation block 11, and enter the rolling mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com