Method for producing titanium alloy pipe

A technology of titanium alloy tubes and production methods, applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of unfavorable cost saving, waste of energy, etc., and achieve the effects of reducing process passes, high production efficiency, and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

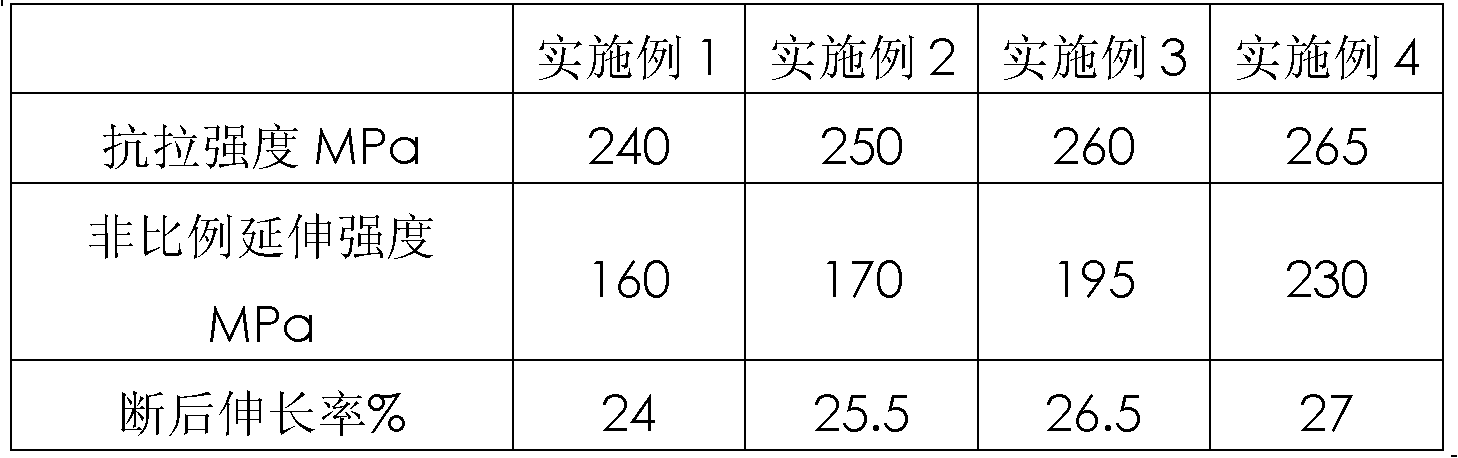

Embodiment 1

[0010] Carry out dimensional inspection, surface inspection, and quality inspection on the raw material tube blanks, and use a direct-reading spectrometer 750B to analyze the chemical composition and elements of the titanium tube. The mass components are Fe 0.20%, C 0.08%, N 0.03%, H 0.015%, and O 0.18%. , The balance is Ti. The inspector will inspect the surface one by one, mark the places with cracks, folds, scars, pits and other defects, and carry out local grinding, so that the removed parts are smooth and have no edges and corners. Then the raw material is processed by two-roll rolling. During the processing, an appropriate amount of chlorinated paraffin can be added to reduce the friction coefficient and provide corresponding rolling force. The rolling energy consumption is low, the surface brightness is high, and the wall thickness of the titanium tube is uniform. . Degreasing and pickling is carried out on the rolled titanium alloy pipe, the mass ratio of the pickling...

Embodiment 2

[0012] Carry out dimensional inspection, surface inspection, and quality inspection on the raw material tube blanks, and use a direct-reading spectrometer 750B to analyze the chemical composition and elements of the titanium tube. The mass components are Fe 0.16%, C 0.07%, N 0.03%, H 0.013%, and O 0.16%. , The balance is Ti. The inspector will inspect the surface one by one, mark the places with cracks, folds, scars, pits and other defects, and carry out local grinding, so that the removed parts are smooth and have no edges and corners. Then the raw material is processed by two-roll rolling. During the processing, an appropriate amount of chlorinated paraffin can be added to reduce the friction coefficient and provide corresponding rolling force. The rolling energy consumption is low, the surface brightness is high, and the wall thickness of the titanium tube is uniform. . Degreasing and pickling is carried out on the rolled titanium alloy pipe, the mass ratio of the pickling...

Embodiment 3

[0014] Carry out dimensional inspection, surface inspection, and quality inspection on the raw material tube blanks, and use a direct reading spectrometer 750B to analyze the chemical composition and elements of the titanium tube, and the mass components are Fe 0.08%, C 0.04%, N 0.02%, H 0.009%, O 0.10% , The balance is Ti. The inspector will inspect the surface one by one, mark the places with cracks, folds, scars, pits and other defects, and carry out local grinding, so that the removed parts are smooth and have no edges and corners. Then the raw material is processed by two-roll rolling. During the processing, an appropriate amount of chlorinated paraffin can be added to reduce the friction coefficient and provide corresponding rolling force. The rolling energy consumption is low, the surface brightness is high, and the wall thickness of the titanium tube is uniform. . Degreasing and pickling is carried out on the rolled titanium alloy pipe, the mass ratio of the pickling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com