Variable thickness rolling length control method

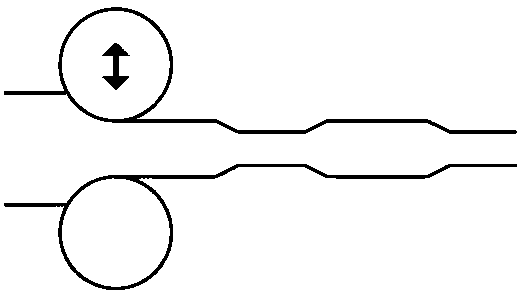

A technology of variable thickness rolling and control method, which is applied in the field of cold rolling, and can solve the problems that the length accuracy needs to be improved, and the strip deviation after rolling is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

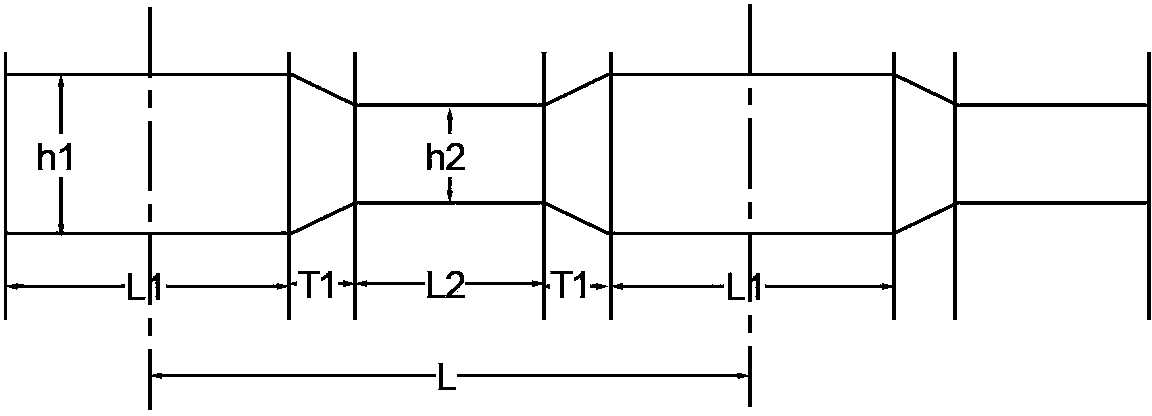

[0101] A certain sample requires a profile after rolling such as Figure 5 As shown, the distance from the roll gap exit of the rolling mill to the thickness gauge is L gauge =1500mm, the distance from the mill roll gap exit to the length measuring roll is L0=1800mm.

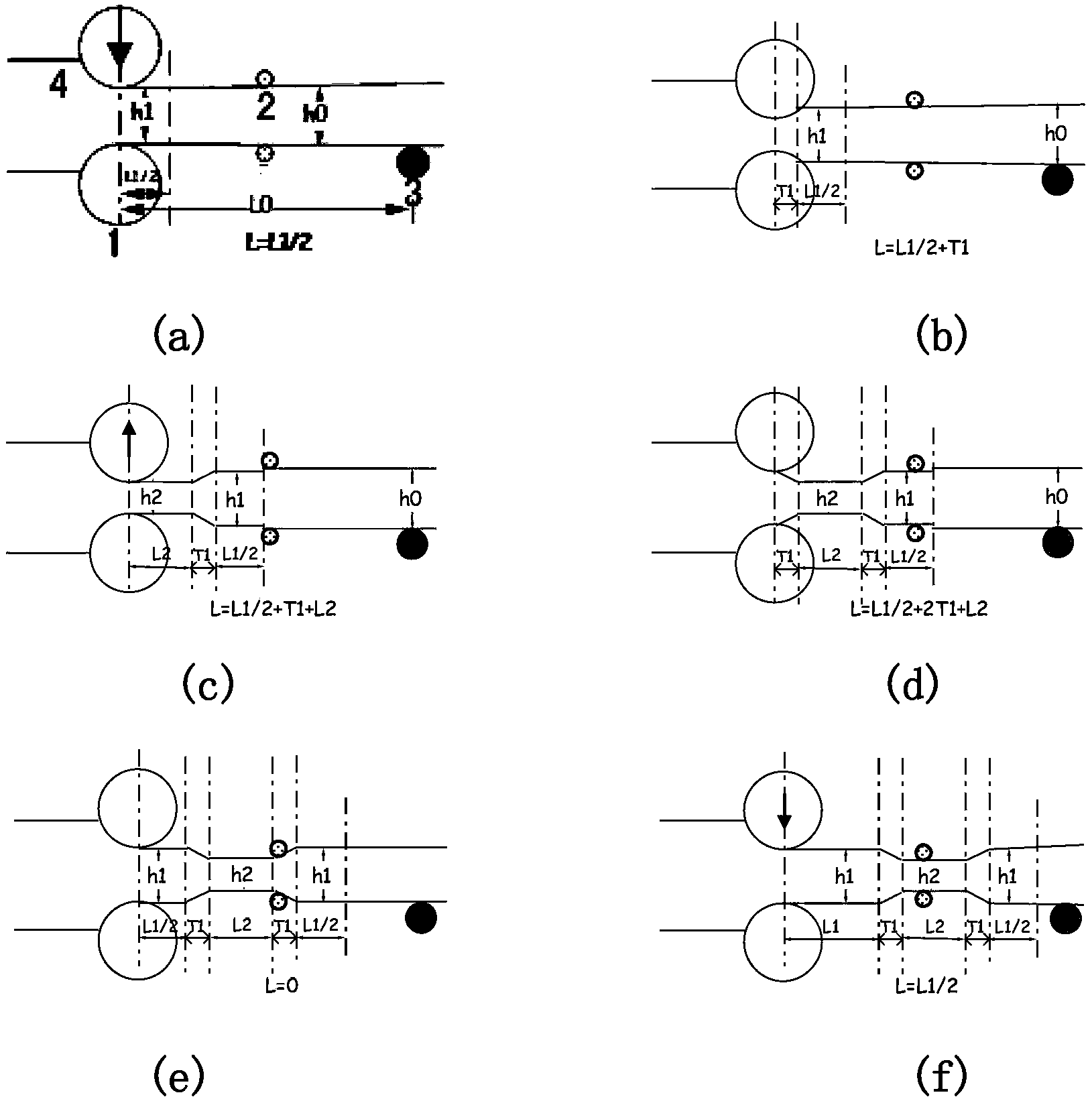

[0102] according to Figure 5Indication, h1=2.0mm, L1=200mm, T1=100mm, h2=1.0mm, L2=700mm, a control cycle is L cycle =L1+L2+2×T1=200+700+100×2=1100mm, the rolling speed is kept at v=100mm / s. The control steps are as follows, see Figure 6 .

[0103] 1) When the thickening rolling is not put into operation, the rolling mill runs stably at the speed of v=100mm / s. At this time, the thickness of the roll gap exit is h0, and the counts of the two counters of the control system are 0, that is, L=L total =0;

[0104] 2) When thickening rolling is put into operation, the speed of the rolling mill remains unchanged, and the length measuring rollers start to accumulate the measured lengths L and L total , the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com