The Control Method of Thickness and Ingot Length of Hot Continuous Rolling Intermediate Billet

A control method and technology of hot continuous rolling, which is applied in the field of metal pressure processing, can solve the problems of low yield rate of hot continuous rolling production, and achieve the effects of improving yield rate, avoiding equipment accidents, and avoiding additional head and tail cutting losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the examples:

[0029] The method for controlling the thickness of the intermediate billet and the length of the ingot in this embodiment adopts "1+4" hot continuous rolling, and the method includes the following steps:

[0030] A. According to the set rolling pass reduction rate of each stand of the continuous rolling mill and the finished product thickness of the rolled piece, backcalculate the reference value of the intermediate billet thickness and the rolling pass reduction of each stand.

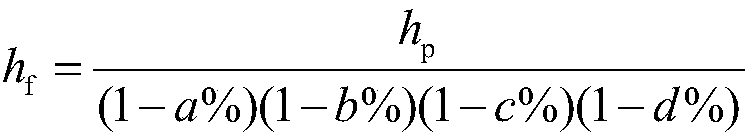

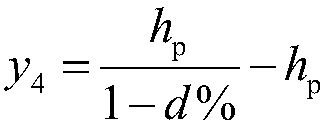

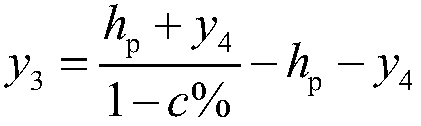

[0031] Assuming the reference value of the intermediate billet thickness is h f , The unit is millimeter; according to the setting principle of the rolling process, the rolling pass reduction rate of the first stand to the fourth stand is a%=45%, b%=42%, c%=40% , D% = 38%; the rolling pass reduction from the first stand to the fourth stand is y 1 , Y 2 , Y 3 , Y 4 , The unit is millimeters; the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com