System and method for optimizing cutting of rolling mill

A rolling mill and hot cutting technology, applied in the direction of metal rolling, shearing device, metal rolling, etc., can solve the problems of running delay and discrepancy of the rolling mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

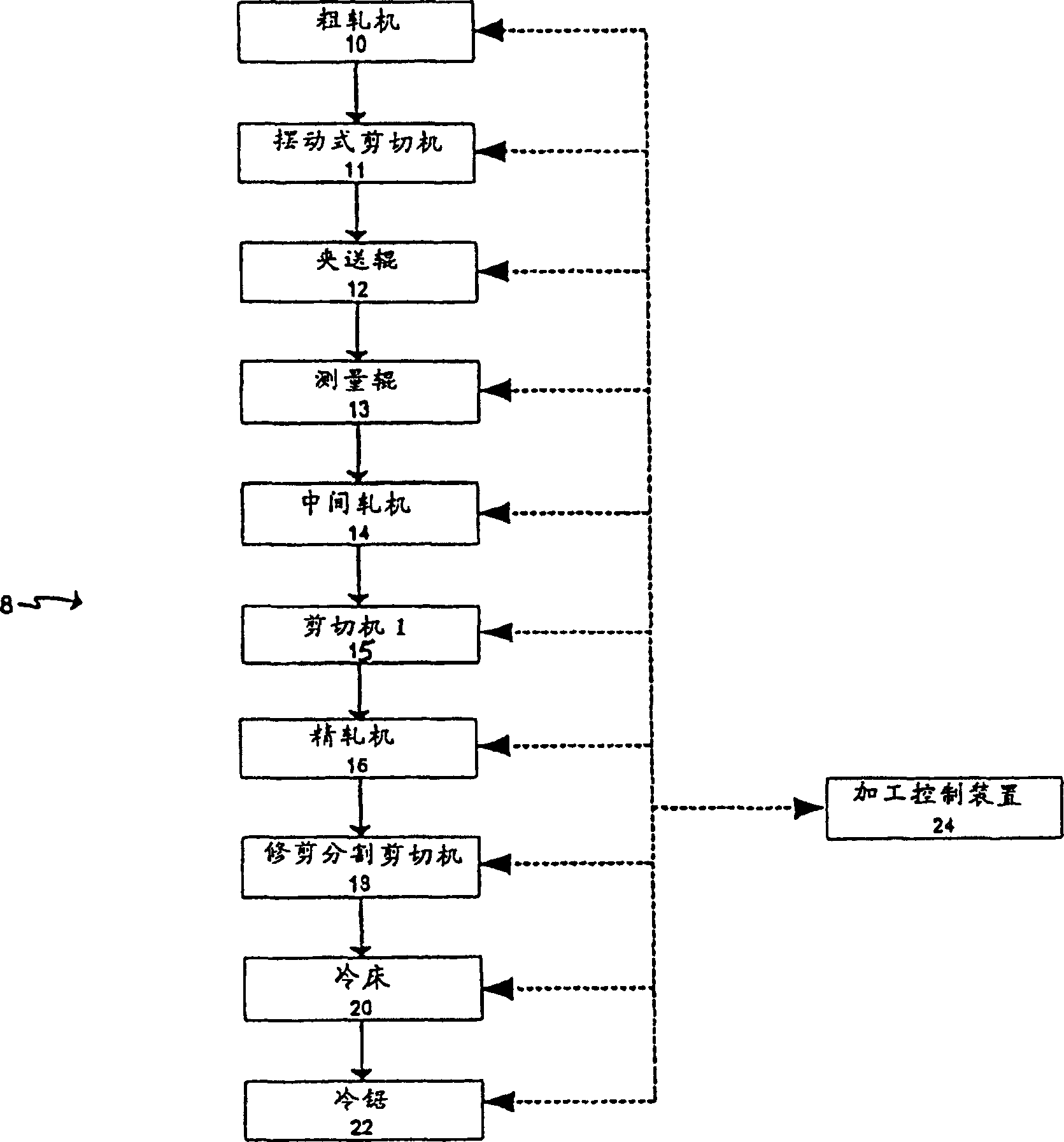

[0012] figure 1 is a simplified schematic diagram of a bar working mill 8 according to one embodiment of the present invention. Other types of bar working mills are also possible and the invention is not limited to the embodiments described here.

[0013] Such as figure 1 As shown, one embodiment of a bar working mill 8 may include a roughing mill 10, an oscillating shear 11, pinch rolls 12, measuring rolls 13, an intermediate mill 14, and a shear 15, a finishing mill 16, trimming and splitting shears. Cutting machine 18, cooling bed 20, cold saw 22.

[0014] The bar rolling machine components 10-18 can be used to roll the billet or billet into bars of different specifications according to customer orders. Any suitable bar rolling mill may be used to roll billets or billets into round or square shapes, eg by reducing area and increasing length. In some embodiments, bar mill 8 may include several stands to assist in bar processing. For example, ten to twenty three stands m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com