Bar steel full fixed-length intelligent control system and fixed-length control method

An intelligent control system and steel technology, applied in the direction of length control, metal rolling, manufacturing tools, etc., can solve problems such as affecting market sales and corporate reputation, affecting the improvement of output, and increasing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, technical solution of the present invention is elaborated:

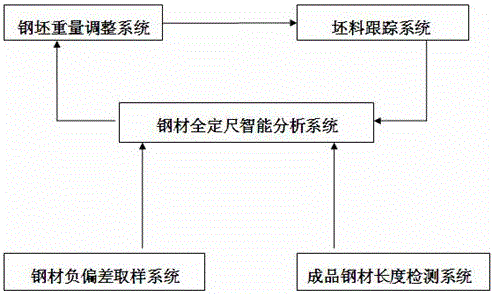

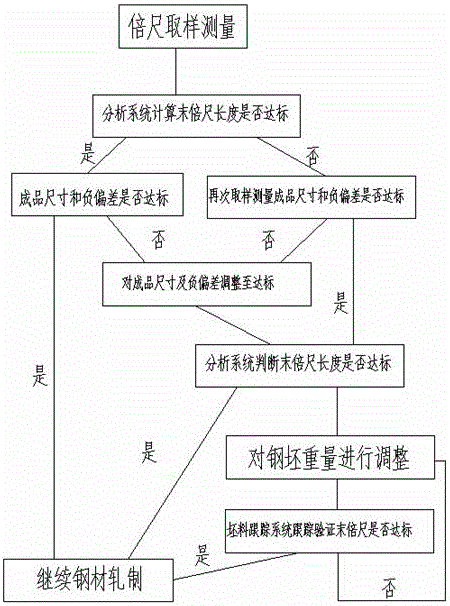

[0017] A full-scale intelligent control system for bar-shaped steel, which includes a billet weight adjustment system, a billet tracking system, a finished steel length detection system, a steel full-scale intelligent analysis system, and a steel negative deviation sampling system. Take samples for sample measurement, and transmit the measurement data to the steel full-scale intelligent analysis system for analysis. The steel full-scale intelligent analysis system judges whether the final sizing rate meets the standard. If it does not meet the standard, the analysis data is transmitted to the billet weight adjustment system. The billet weight is adjusted, and the billet tracking system monitors the subsequent process of the adjusted billet, and the finished steel length detection system collects data on the final cut-to-size material and feeds it back to the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com