A kind of production method of optical fiber preform cone head

A technology for optical fiber preform and production method, which is applied to manufacturing tools, glass manufacturing equipment and other directions, can solve the problems of waste of optical fiber preform and difficult operation, and achieve the effects of improving the utilization rate of wire drawing, the uniformity of taper, and the improvement of efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

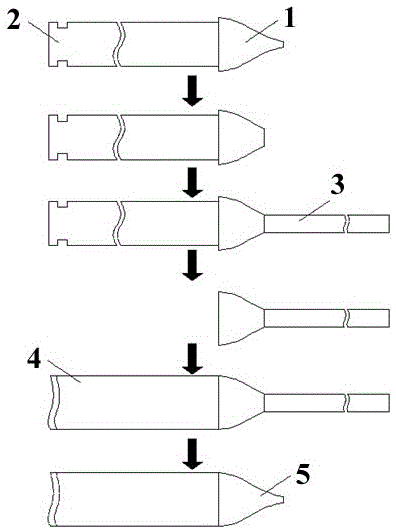

[0035] Example 1 is the production of a solid optical fiber preform cone with an outer diameter of 150 mm. (The outer diameter of an optical fiber preform with an outer diameter of 150mm is generally (150±2) mm.)

[0036] Select an optical fiber preform with an outer diameter of 150mm and draw the remaining cone head 1 of the optical fiber preform, and the remaining cone head of the optical fiber preform should be equipped with a tail rod (or tail pipe) 2;

[0037] Cut off the pointed part from the diameter 60mm of the remaining taper 1 of the optical fiber preform drawing with an outer diameter of 150mm;

[0038] Clamp the remaining cone head 1 of the 150mm optical fiber preform with the tail rod (or tail pipe) 2 after cutting and the auxiliary quartz rod 3 with a diameter of 60mm on the chucks at both ends of the glass fusion lathe, light the furnace heat source The end faces of the two are gradually preheated, and the two slowly enter the center of the heat source, burn un...

example 2

[0042] Example 2 is the production of the cone head of a solid optical fiber preform with an outer diameter of 180mm. (The outer diameter of an optical fiber preform with an outer diameter of 180mm is generally (180±2) mm.)

[0043] Select an optical fiber preform with an outer diameter of 180 mm and the remaining cone 1 of the optical fiber preform that has been drawn, and the remaining cone of the optical fiber preform must be equipped with a tail rod (or tail pipe) 2;

[0044] Cut off the pointed part of the remaining taper 1 from the diameter of 70mm for drawing the optical fiber preform with an outer diameter of 180mm;

[0045] Clamp the remaining cone head 1 of the cut 180mm optical fiber preform with the tail rod (or tail pipe) 2 and the auxiliary quartz rod 3 with a diameter of 70 mm at both ends of the glass fusion lathe, and gradually heat the two ends after igniting the furnace heat source. Preheating, the two slowly approach the center of the heat source, burn unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com