A kind of preparation method of electrolytic indium sulfate solution used in indium industry

A preparation method and technology of indium sulfate, which are applied to the improvement of process efficiency, instruments, optics and other directions, can solve the problems of refined indium products such as tin and lead exceeding the standard, high impurities in the electrolyte, and poor quality of precipitated indium, etc., and achieve fast preparation and low cost. The effect of low and stable quality of precipitated indium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The indium electrolytic cell electrolyte being used in production is 100L. After one cycle (7 days), 20L was lost due to evaporation and out of the tank, and a sample was taken for full analysis (see Table 4 for the analysis results). And use the method of the present invention to prepare suitable indium sulfate electrolyte solution 20L according to the analysis result of electrolyte solution.

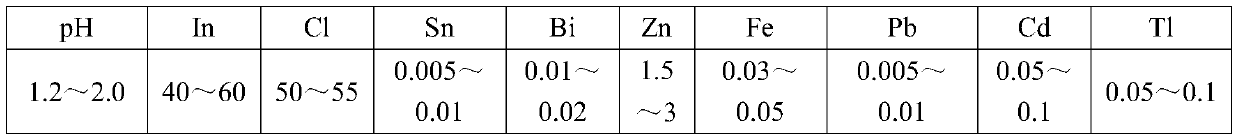

[0036] Table 4 takes the detection and analysis results of indium sulfate electrolyte used in production (g / L)

[0037] pH In Cl sn Bi Zn Fe Pb Cd Tl 2.0 90 52 0.0012 0.013 1.5 0.033 0.004 0.037 0.051

[0038] From the analysis results in Table 4, it can be seen that the impurities in the analyzed electrolyte are relatively high, and the indium content in the electrolyte is normal. It is planned to replenish 20L of new electrolyte and stabilize the indium ion in the electrolyte to 90-100g / L, while reducing the impurities in the electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com