Reversible cold rolling accurate fixed-length rolling control device

An accurate and cold rolling mill technology, applied in the direction of length control, metal rolling, tension/pressure control, etc., can solve the problems of complex preparation process and high cost of special alloy clad plate, and achieve convenient operation and maintenance, and economical use Reliable, easy-to-setup effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

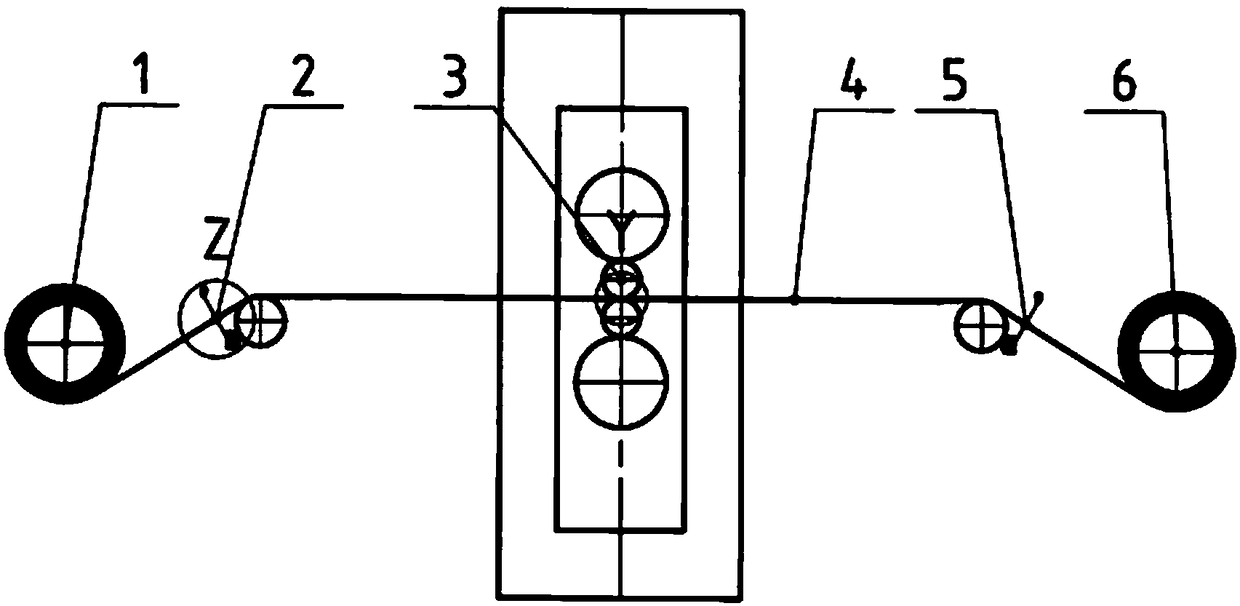

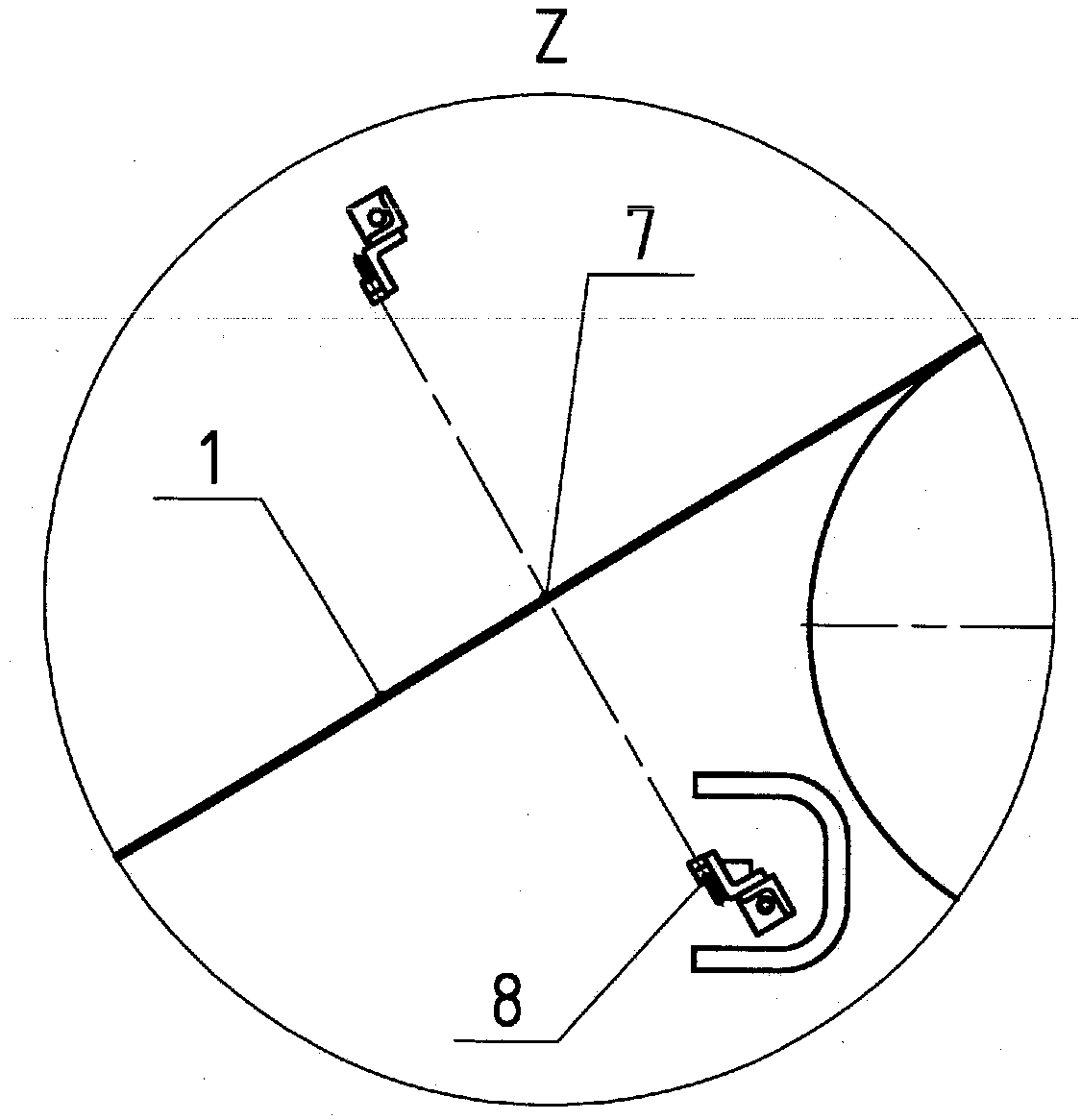

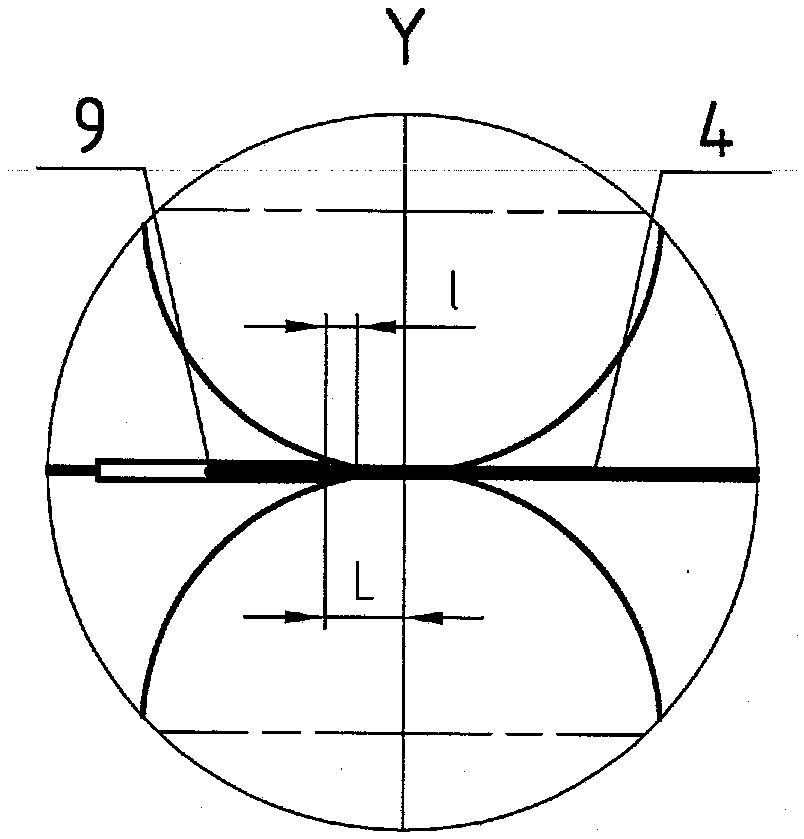

[0016] refer to figure 1 Shown, a kind of reversible cold-rolling accurately determines long-controlled rolling device, comprises left tension leader device 1 and right tension leader device 6, with reference to image 3 As shown, the tension leader of the left tension leader device 1 connects one end of the plate rolling piece 4 through a coupler 9, and the tension leader of the right tension leader device 6 connects the other end of the plate rolling piece 4; the left tension leader device 1 and the right tension leader device 6 are respectively arranged on the left and right sides of the reversible cold rolling mill 3, and are symmetrically arranged; the plate rolled piece 4 passes through the reversible cold rolling mill 3; the left tension leader device 1 and the right tension leader device 6 A left positioning detection system 2 and a right positioning detection syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com