Monitoring and controlling device of roller lubricating system

A lubricating system, monitoring and control technology, applied in the direction of length measuring device, roll, metal rolling, etc., can solve the problems of reducing the service life of the roll, and insufficient monitoring and control of the lubricating oil of the roll.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

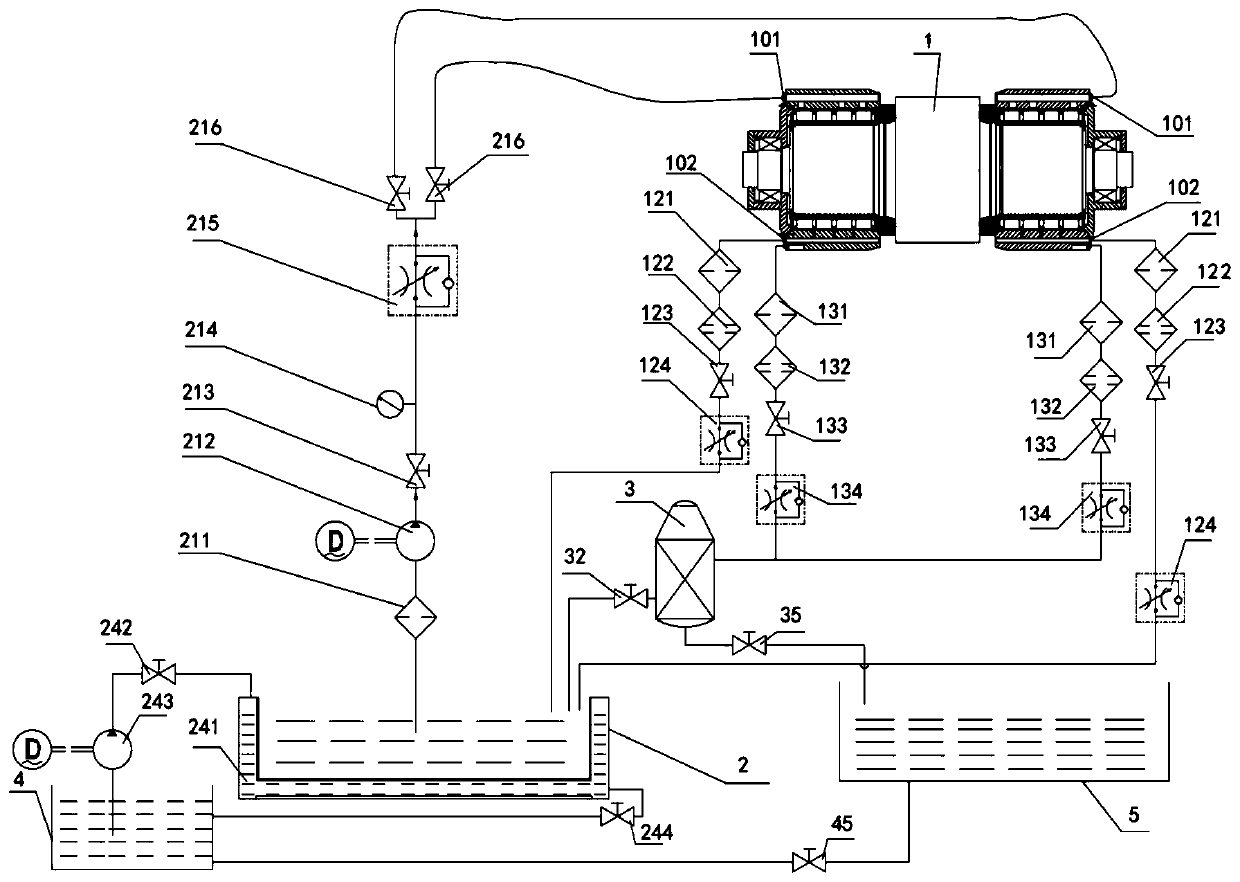

[0044] seefigure 1 , this embodiment provides a roll lubrication system monitoring and control device, including temperature detection equipment, constant temperature oil storage system and control system; wherein,

[0045] The constant temperature oil storage system is connected to the lubricating oil inlet 101 and the lubricating oil outlet 102 of the target roll 1 through pipelines, so that the lubricating oil can circulate between the target roll 1 and the constant temperature oil storage system flow, keeping the lubricating oil liquid level in the target roll 1 within the preset liquid level interval value;

[0046] The constant temperature oil storage system is also used to adjust the temperature of the lubricating oil;

[0047] The temperature detection device is used to detect the temperature information of the lubricating oil in the target roll 1;

[0048] The control system is used to control the constant temperature oil storage system to adjust the temperature of t...

Embodiment 2

[0070] In addition, in order to protect the surface quality of the rolled steel plate, the emulsion is sprayed on the surface of the steel plate, which will easily cause water seepage in the bearing housing, reduce the lubrication of the roll bearing, and easily damage the roll bearing. The liquid level of the lubricating oil in the roll bearing seat of the rolling mill is too high, the resistance is large, the efficiency is low, and leakage is easy to occur, thereby affecting the surface quality of the steel plate and polluting the environment.

[0071] Therefore, on the basis of Embodiment 1, in order to deal with the situation of water ingress in the lubricating oil in time, and recycle it, without causing environmental pollution, see figure 1 , the device also includes:

[0072] water content detection equipment, electrically connected to the control system, for detecting water content information of the lubricating oil in the target roll 1, and sending the water content i...

Embodiment 3

[0079] The liquid level of lubricating oil in the roll bearing housing is too high, the amount of lubricating oil is too large, and the resistance is large, which reduces the efficiency of the rolling mill and is prone to lubricating oil leakage, which affects the quality of the rolling emulsion, thereby affecting product quality and polluting the environment; while the roll The liquid level of the lubricating oil in the bearing seat is too low, the amount of lubricating oil is too small, the temperature of the lubricating oil rises, the lubrication effect is poor, the bearing is easily damaged, and the life of the rolling mill is reduced.

[0080] Therefore, on the basis of embodiment one, see figure 1 A first flow control valve 134 is arranged on the pipeline connected between the constant temperature oil storage system and the lubricating oil inlet 101 of the target roll 1, and the constant temperature oil storage system is connected with the lubricating oil outlet 102 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com