Patents

Literature

36results about How to "Effective width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

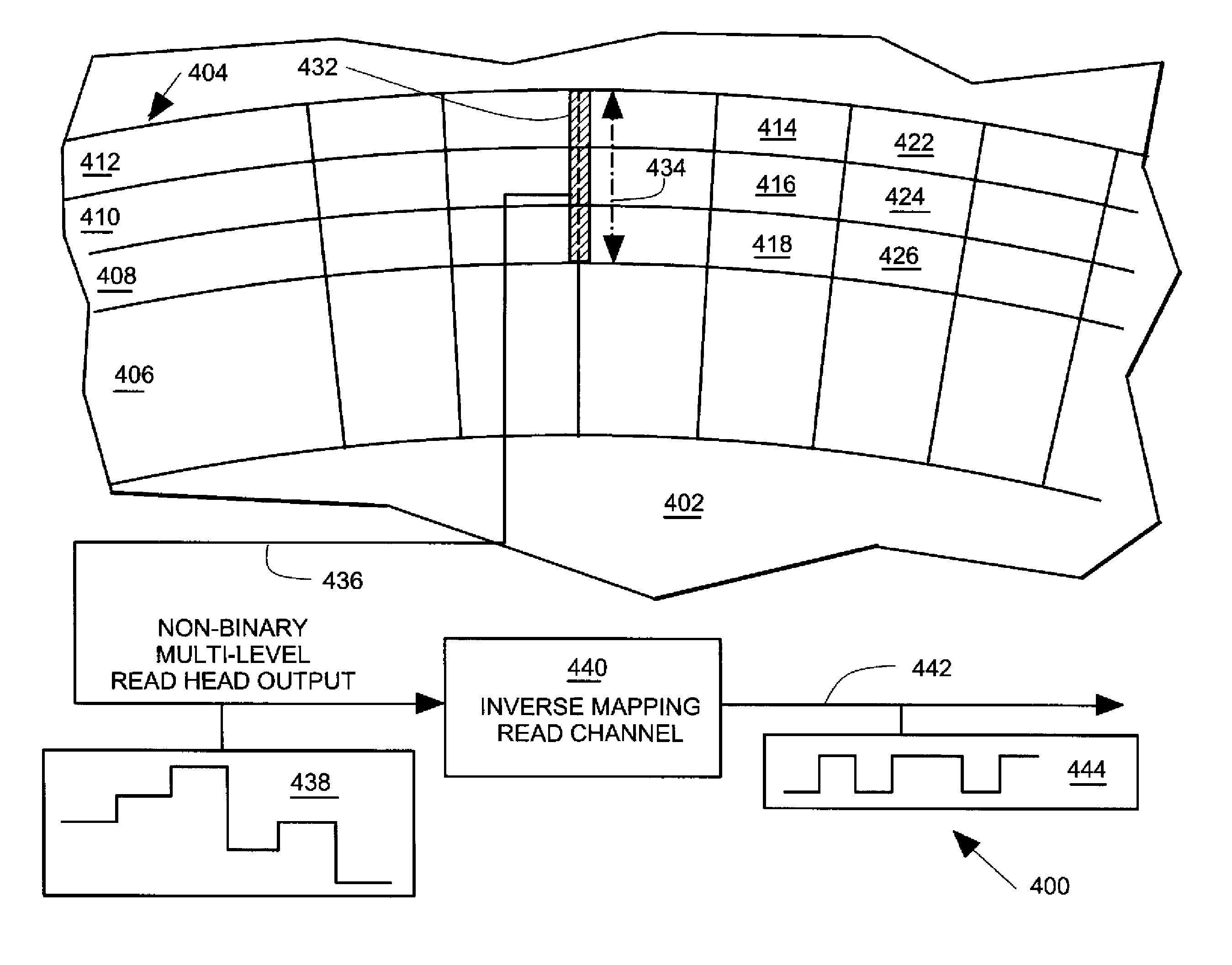

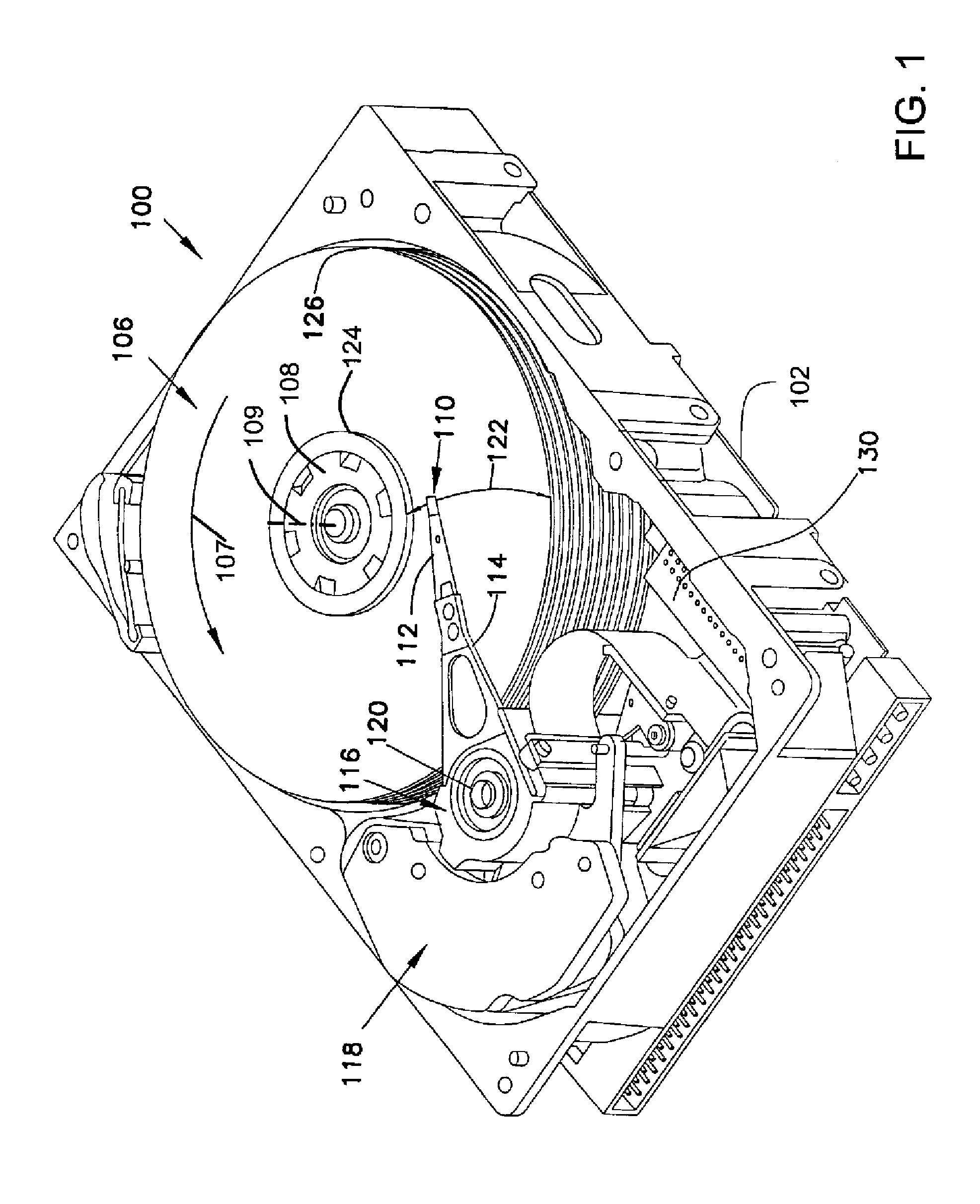

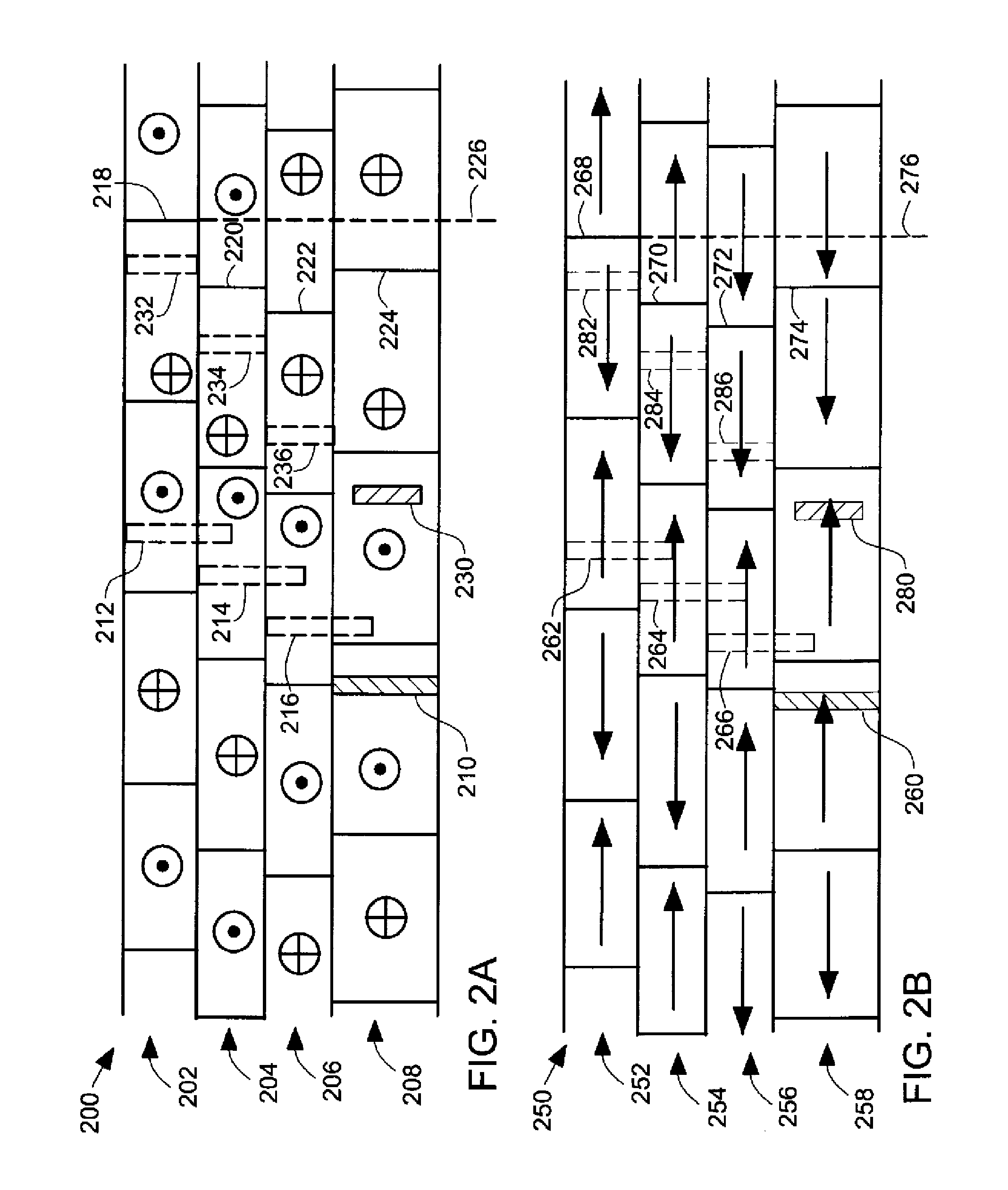

Multi-level recording on shingled coherent magnetic media

InactiveUS7982994B1Effective widthRecord information storageAnalogue recordingMagnetic mediaRecording media

A data storage system includes recording media with a shingled track pattern of multiple data tracks in which mapped data bits are recorded. The mapped data are coherently aligned with one another across the multiple data tracks. A read head has an effective read head width that extends across the multiple data tracks and that is aligned to coherently read the mapped data bits. A read head output includes a non-binary multi-level amplitude summation of the mapped data bits.

Owner:SEAGATE TECH LLC

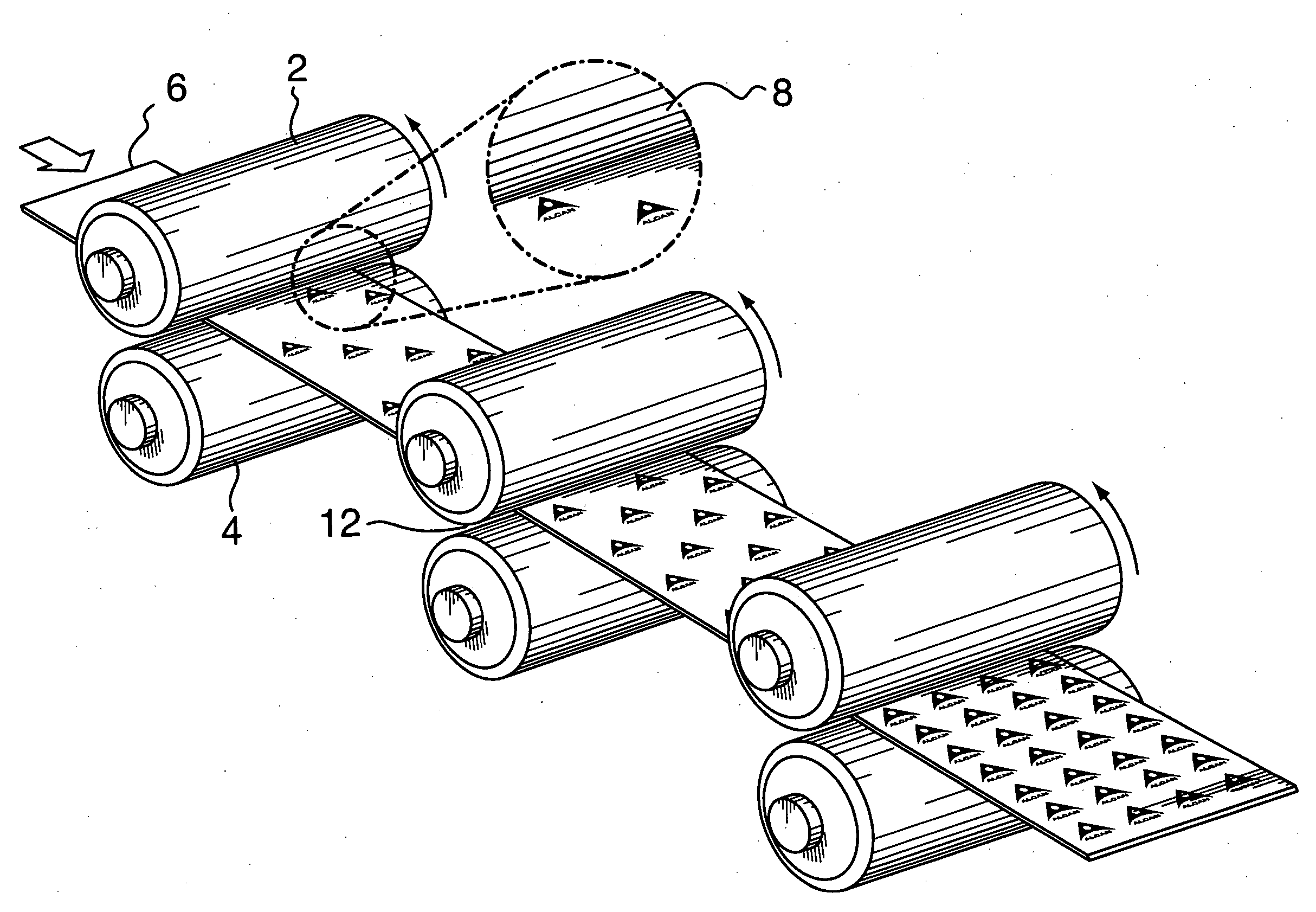

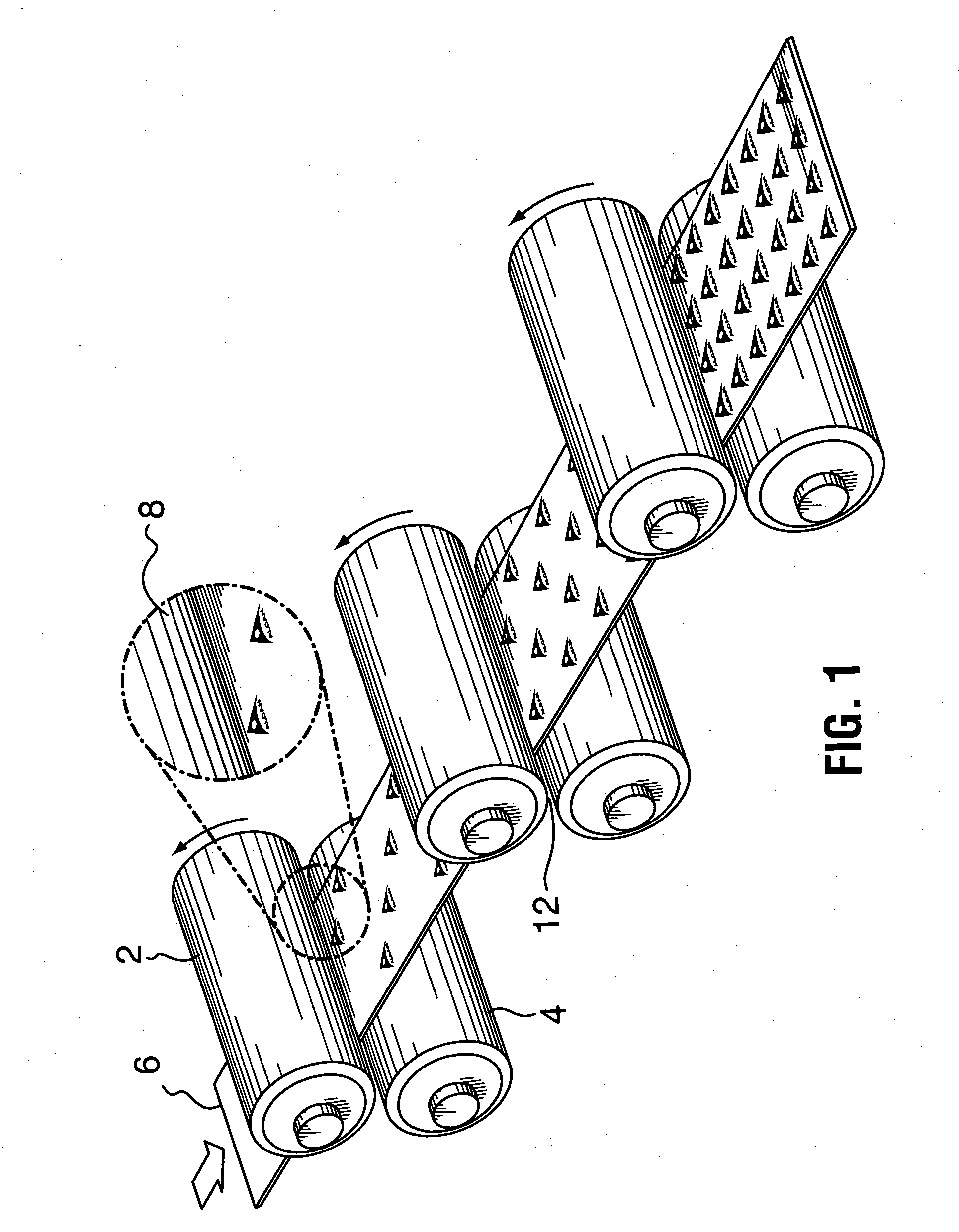

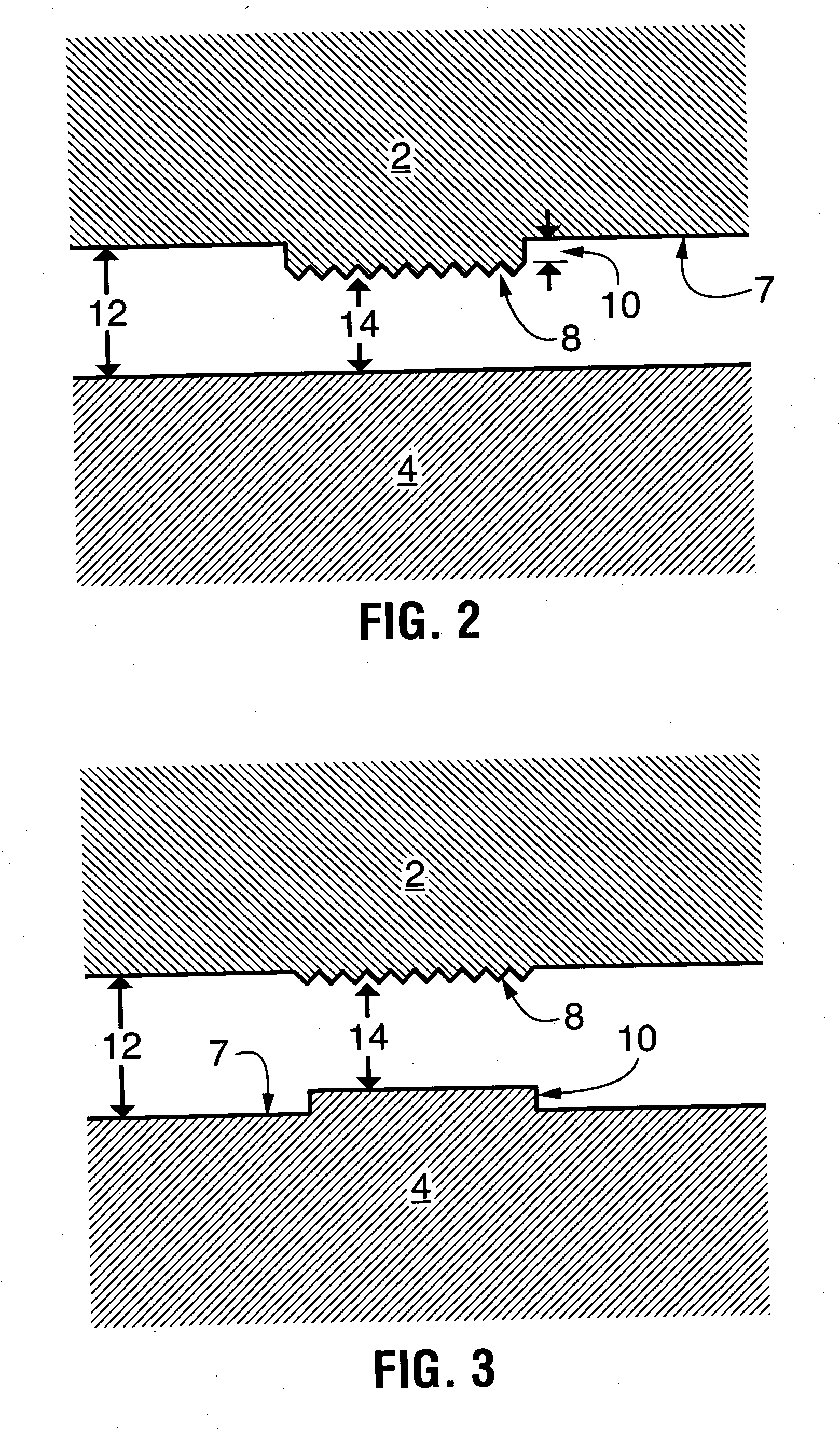

Roll embossing of discrete features

ActiveUS20060123867A1Effective widthReduce compressionShaping toolsDecorative surface effectsUltimate tensile strengthMaterials science

A cold rolling process for impressing a pattern on a surface of a sheet metal article involves passing the sheet article through a pair of rolls and engaging a patterning feature with isolated areas of a surface of the sheet article, at a localized pressure to plastically deform at least the surface of the sheet article. A rolling pressure is maintained on other areas of the sheet article that is less than the bulk elastic yield strength of the metal. A cold rolling apparatus is also described having a pair of rolls, each with partially cylindrical outer surfaces. The rolls have a gap between the cylindrical parts. One of the rolls has a localized surface region that is displaced relative to the surface of the roll. When the localized region is brought near the other roll, a spacing exists that is narrower than the gap. One of the rolls has a localized patterning feature that aligns with the localized surface region to impress a pattern into the sheet article. The gap allows the rolls to engage opposite surfaces of the sheet article while imparting compression less than a bulk elastic yield strength of the metal.

Owner:NOVELIS INC

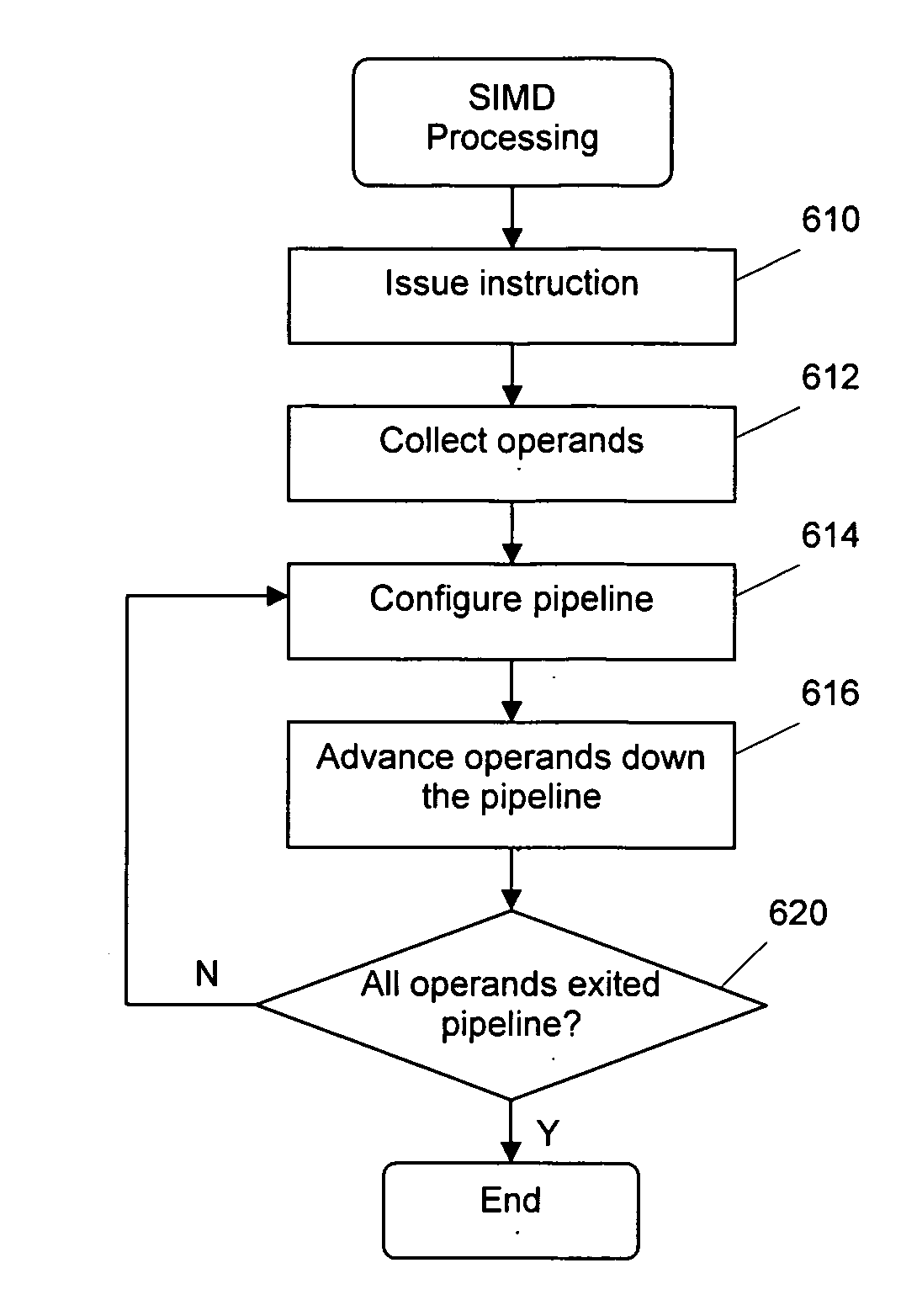

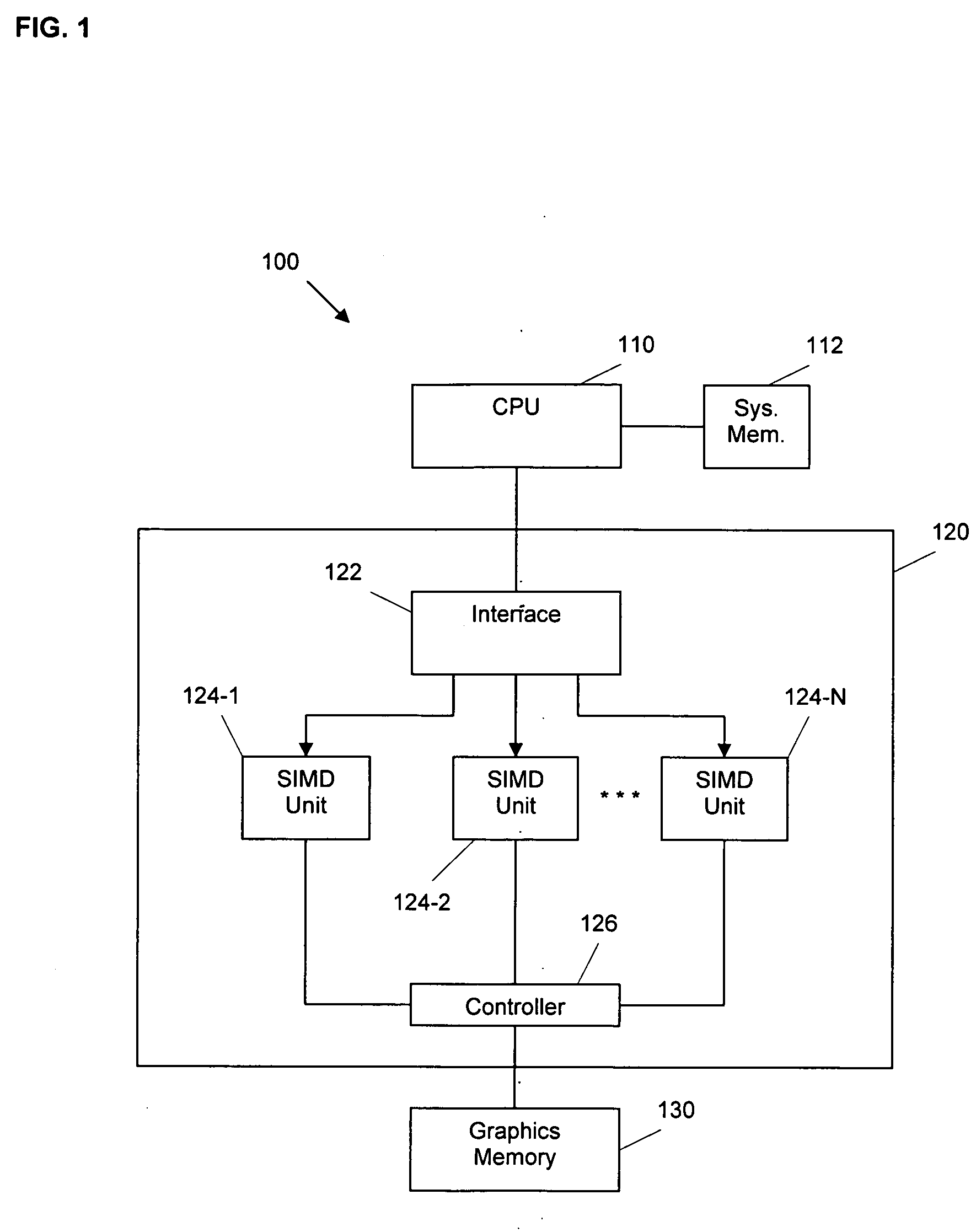

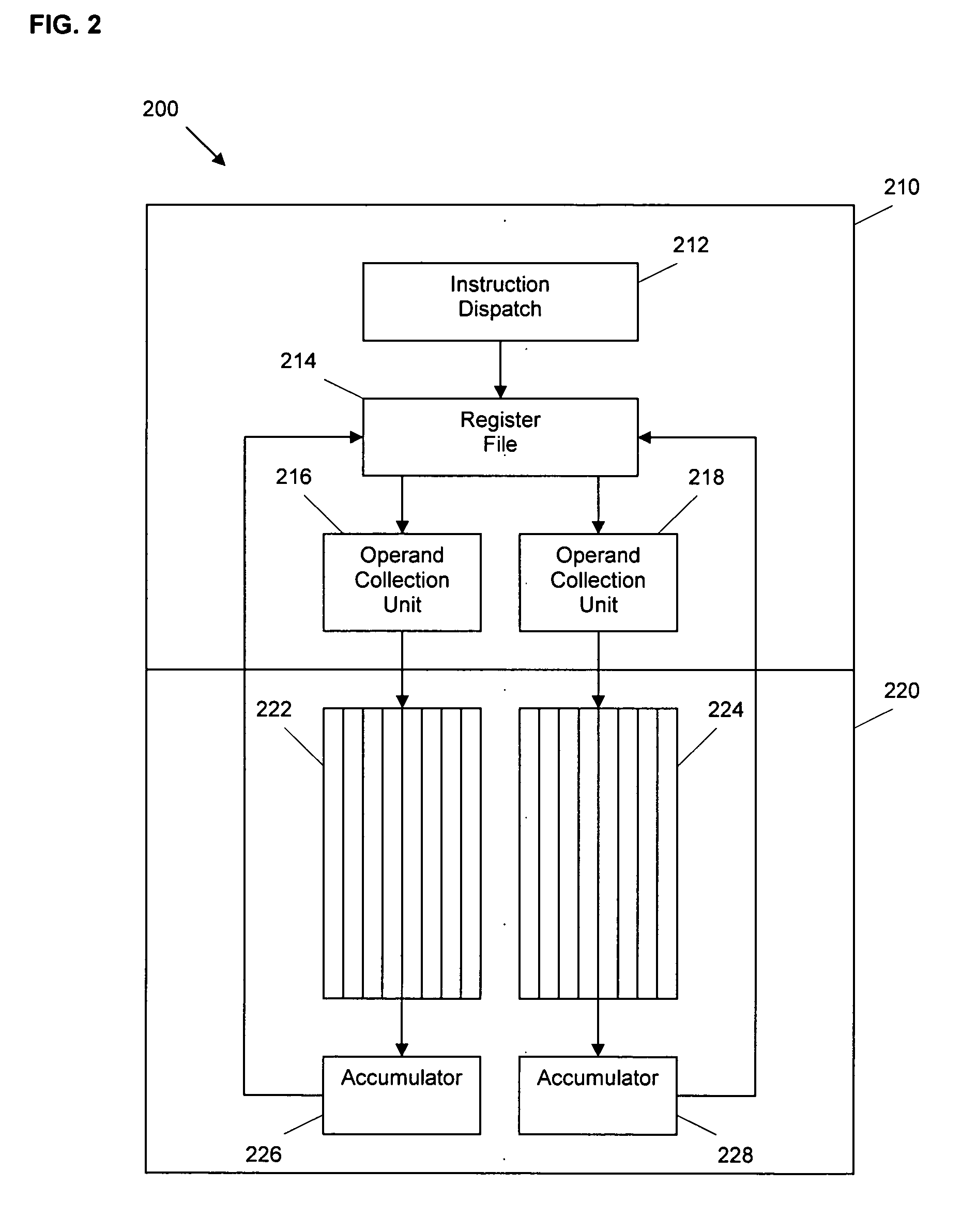

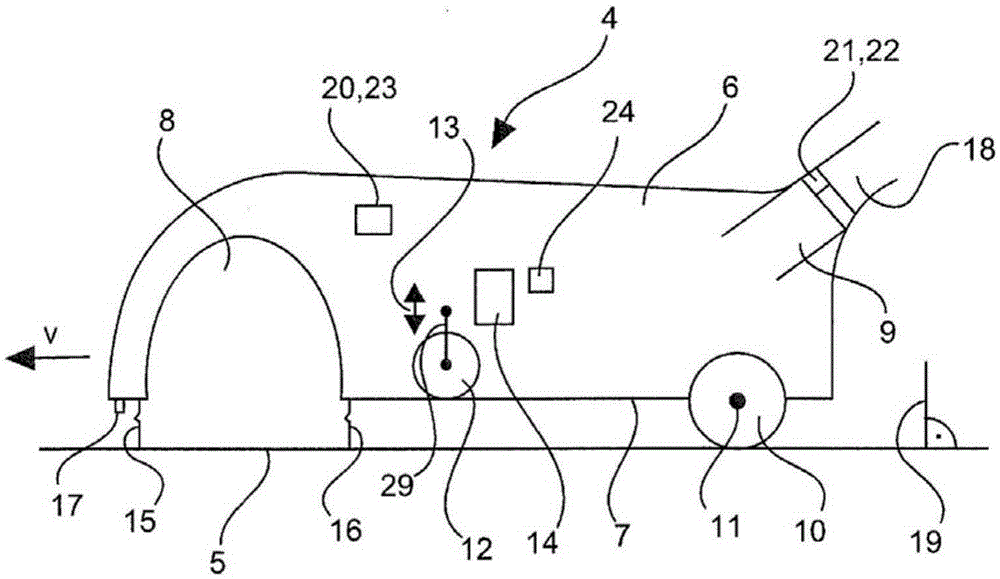

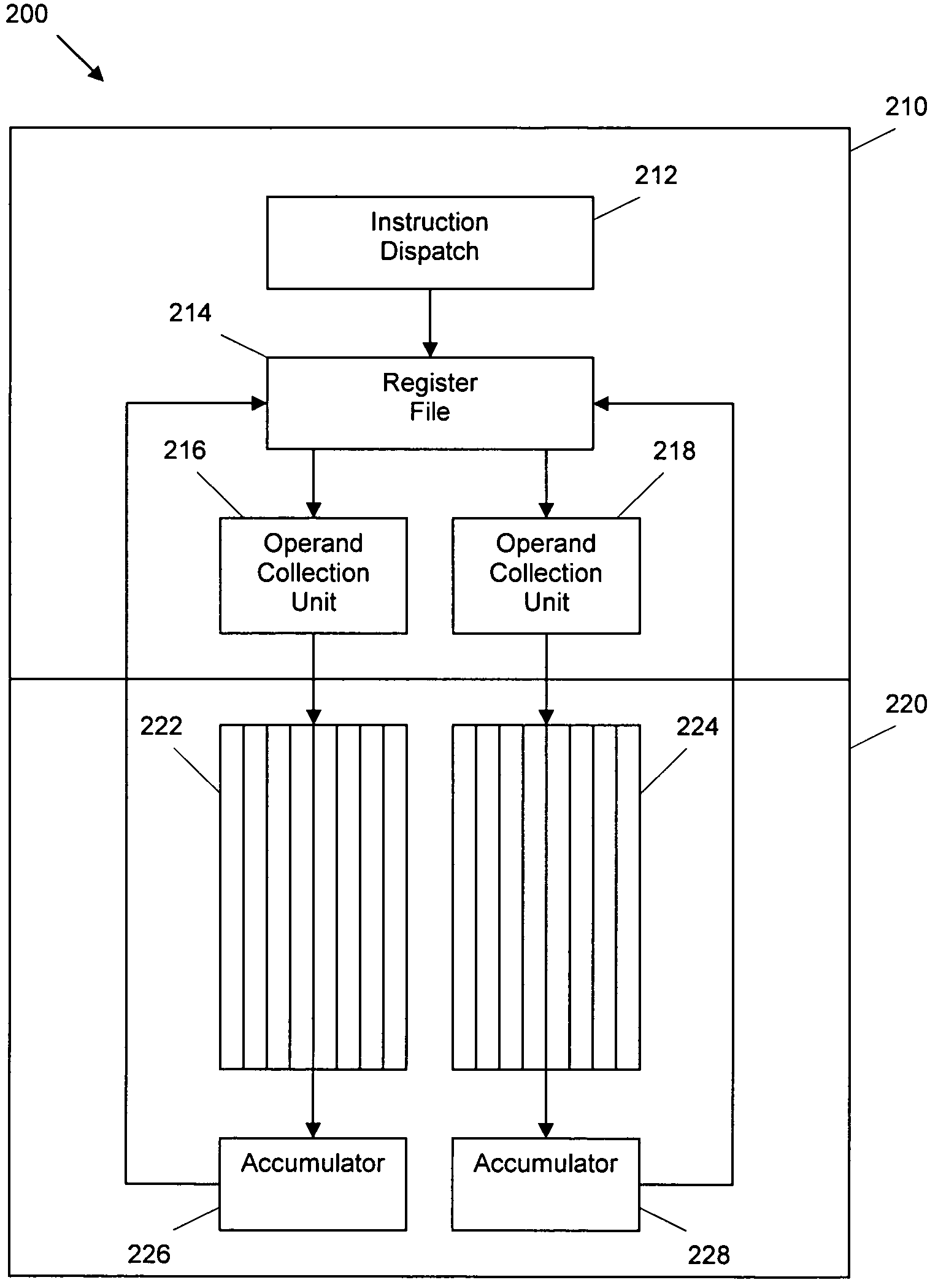

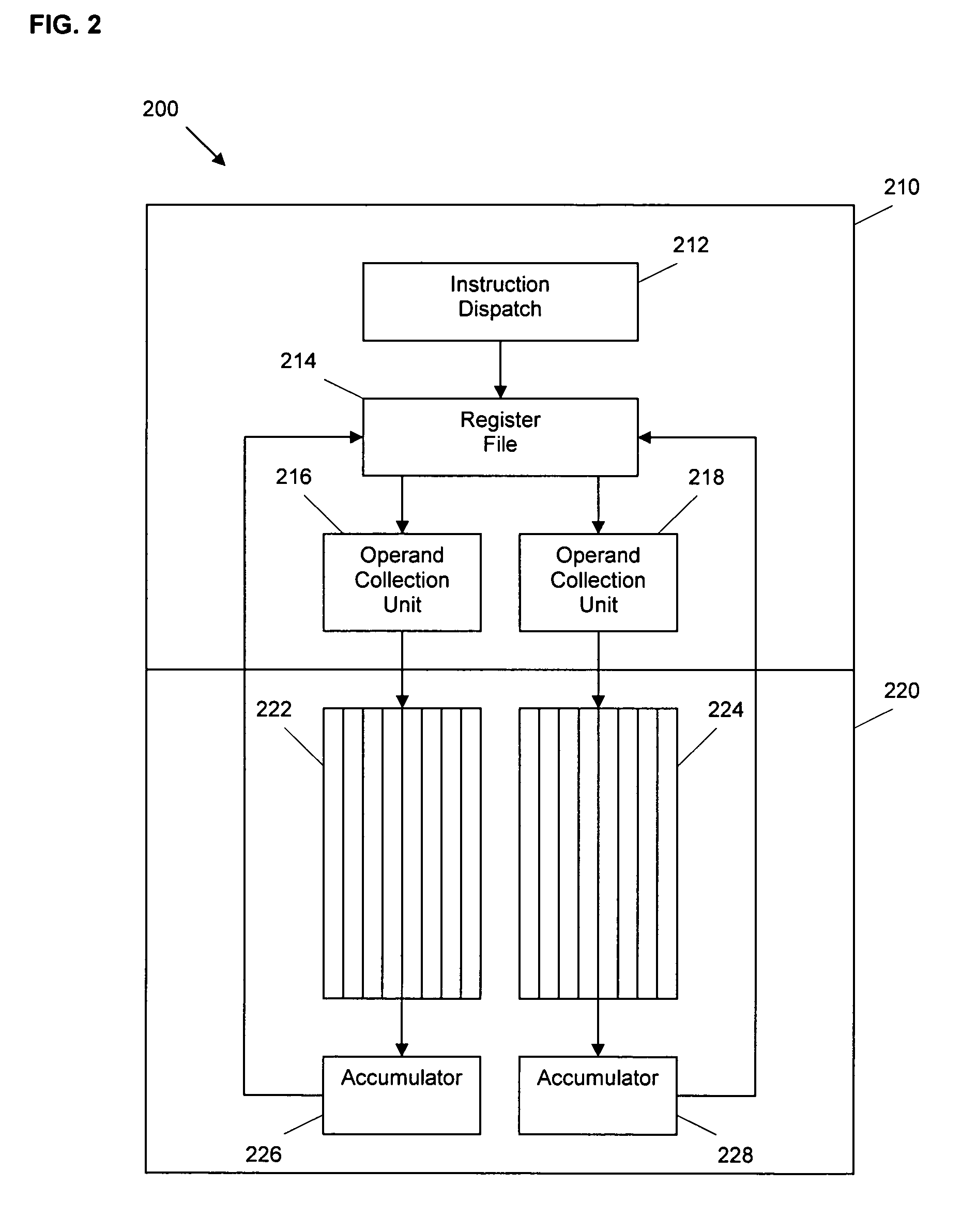

System and method for processing thread groups in a SIMD architecture

ActiveUS20070130447A1Reduce clock frequencyLow hardware requirementsGeneral purpose stored program computerMemory systemsGraphicsDatapath

A SIMD processor efficiently utilizes its hardware resources to achieve higher data processing throughput. The effective width of a SIMD processor is extended by clocking the instruction processing side of the SIMD processor at a fraction of the rate of the data processing side and by providing multiple execution pipelines, each with multiple data paths. As a result, higher data processing throughput is achieved while an instruction is fetched and issued once per clock. This configuration also allows a large group of threads to be clustered and executed together through the SIMD processor so that greater memory efficiency can be achieved for certain types of operations like texture memory accesses performed in connection with graphics processing.

Owner:NVIDIA CORP

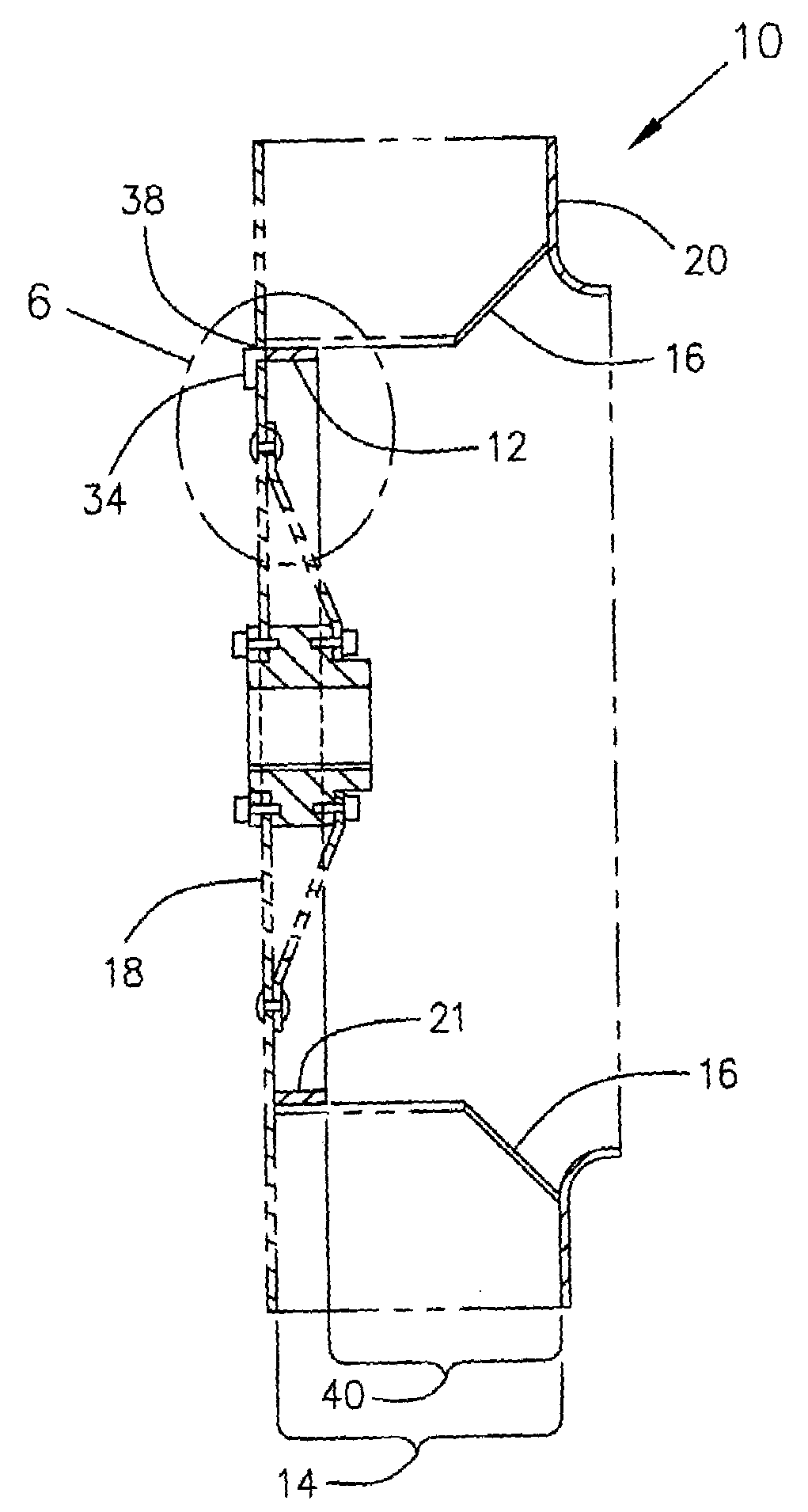

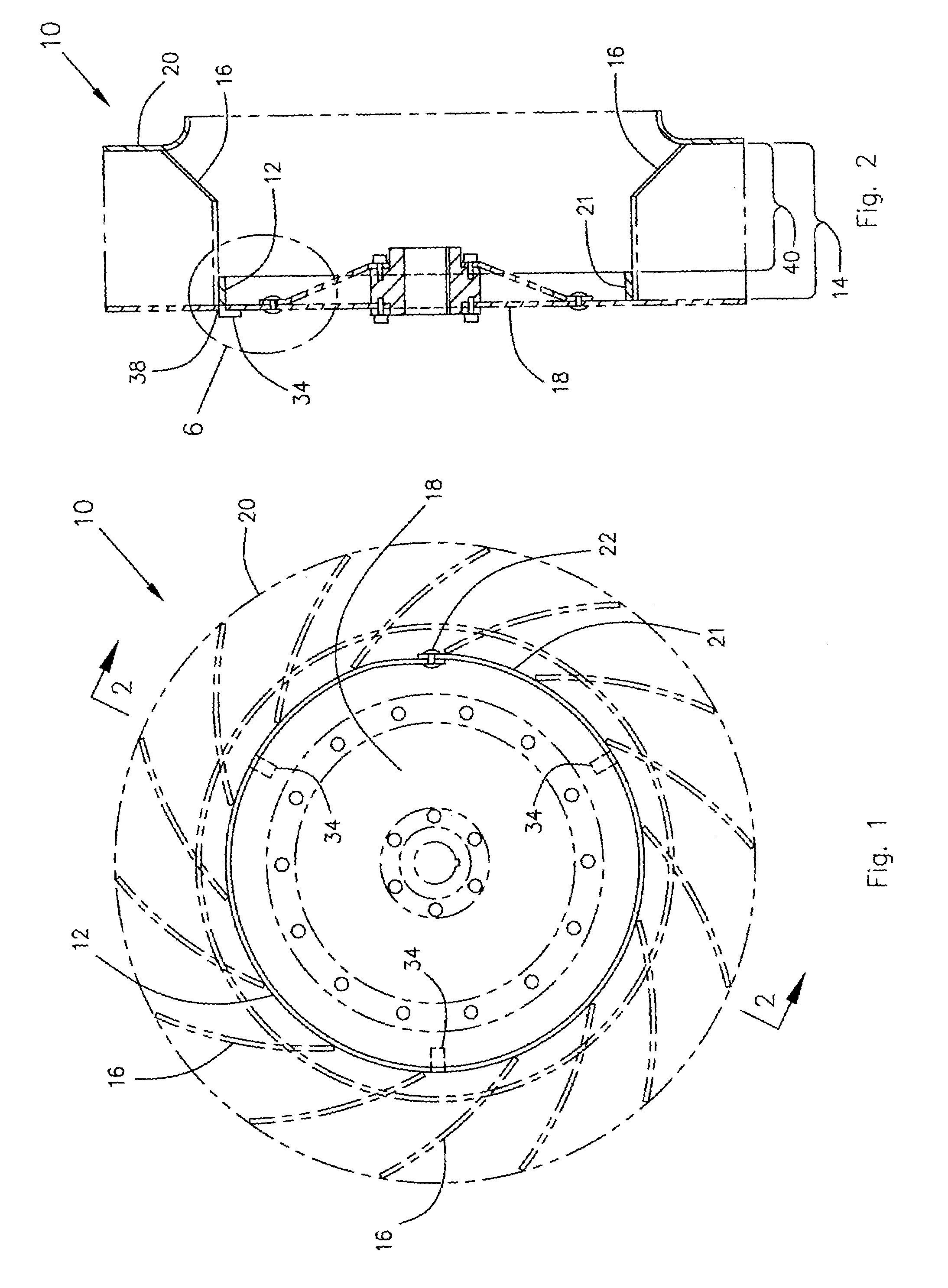

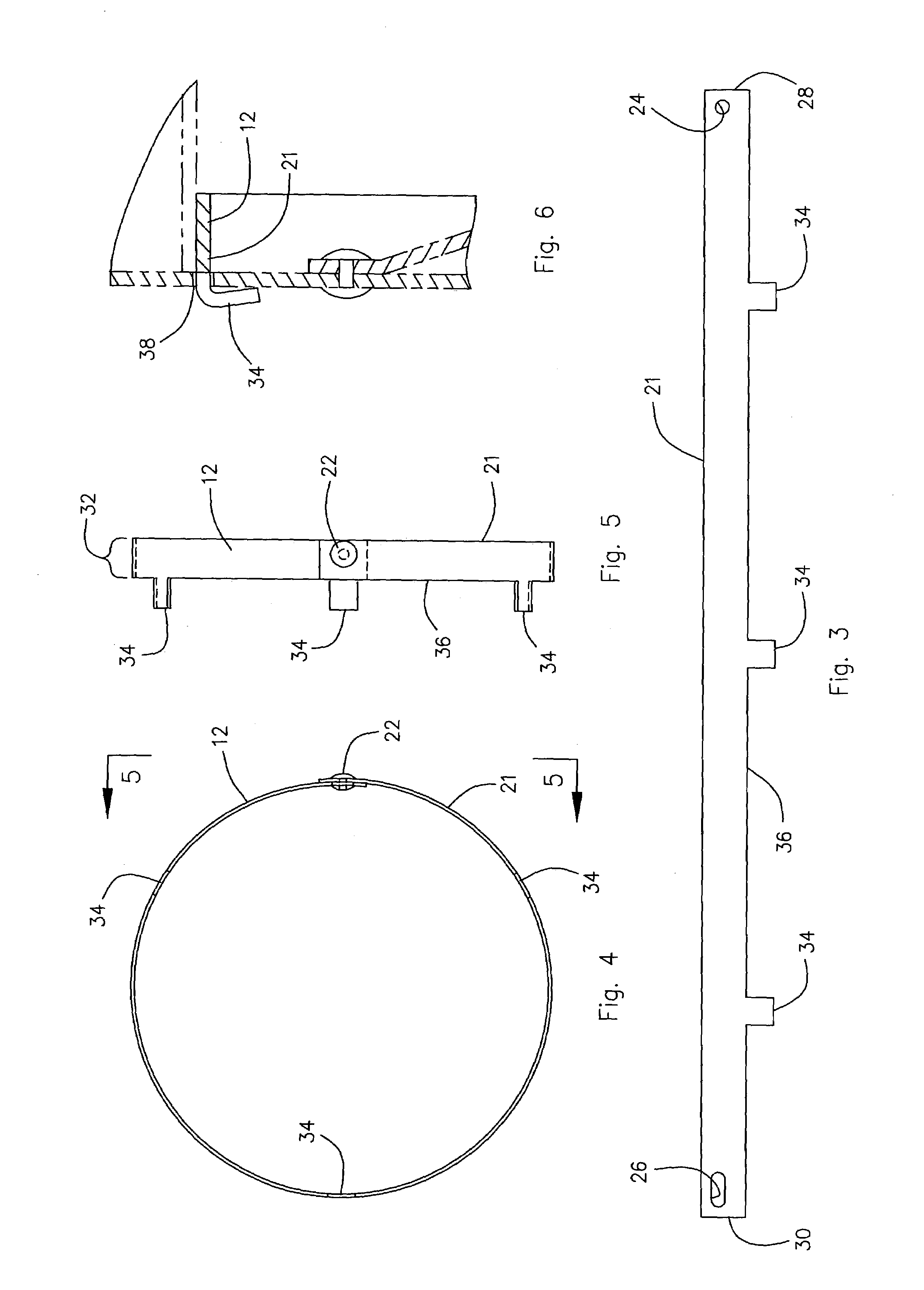

Plenum fan banding

Plenum fan banding that effectively changes the width of the fan blades in a plenum fan for a HVAC unit. A removable and replaceable band attaches to the back of a fan wheel of the plenum fan so that the band is located within the circle of the fan blades and extends outward perpendicular to the back of the wheel. The band is provided with tabs that insert through slots provided in the back of the fan wheel, and the tabs can be bent over as a means of removably securing the band to the fan wheel. The band effective reduces the functional width of the fan blades in proportion to the width of the band.

Owner:AAON

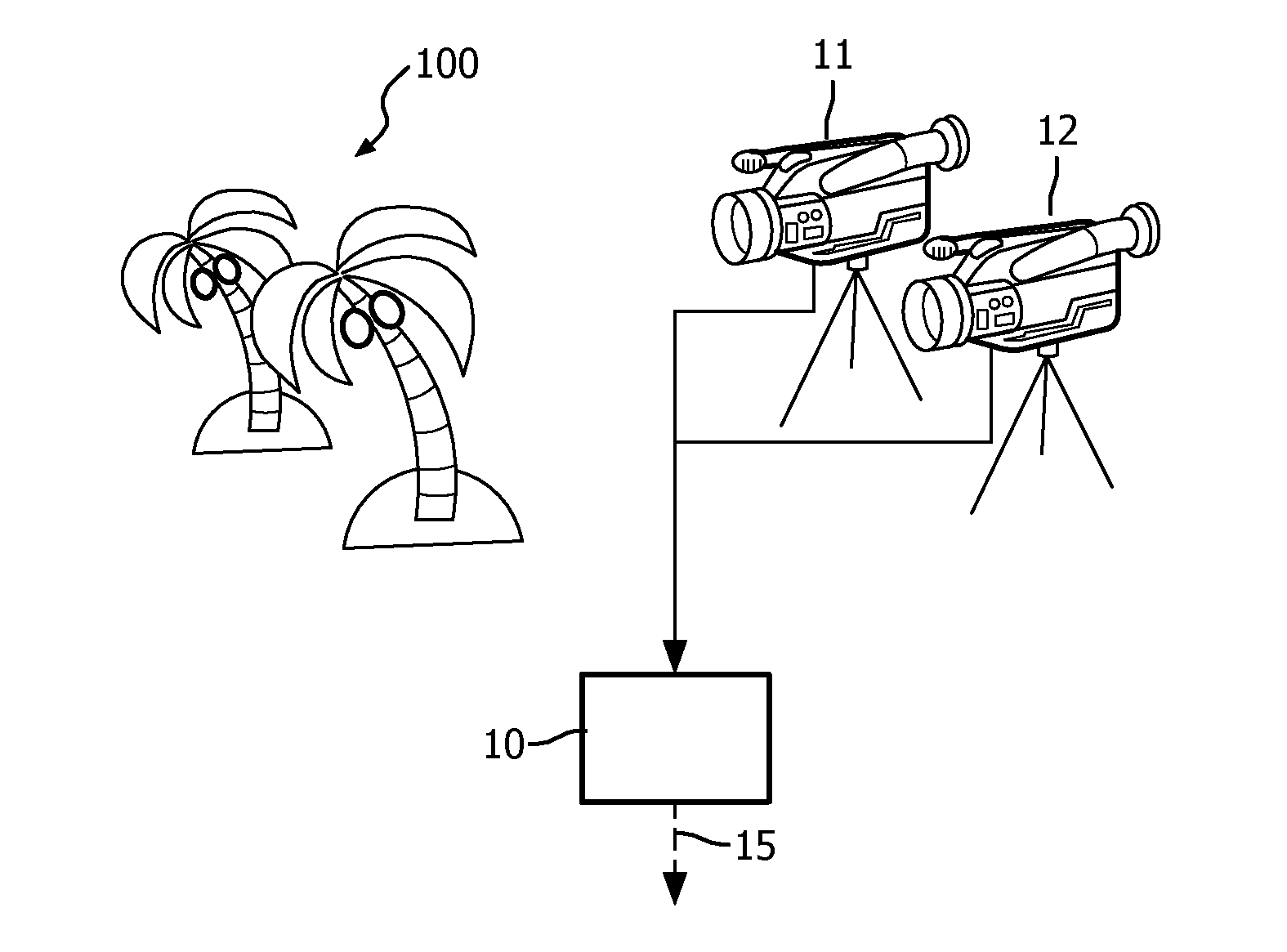

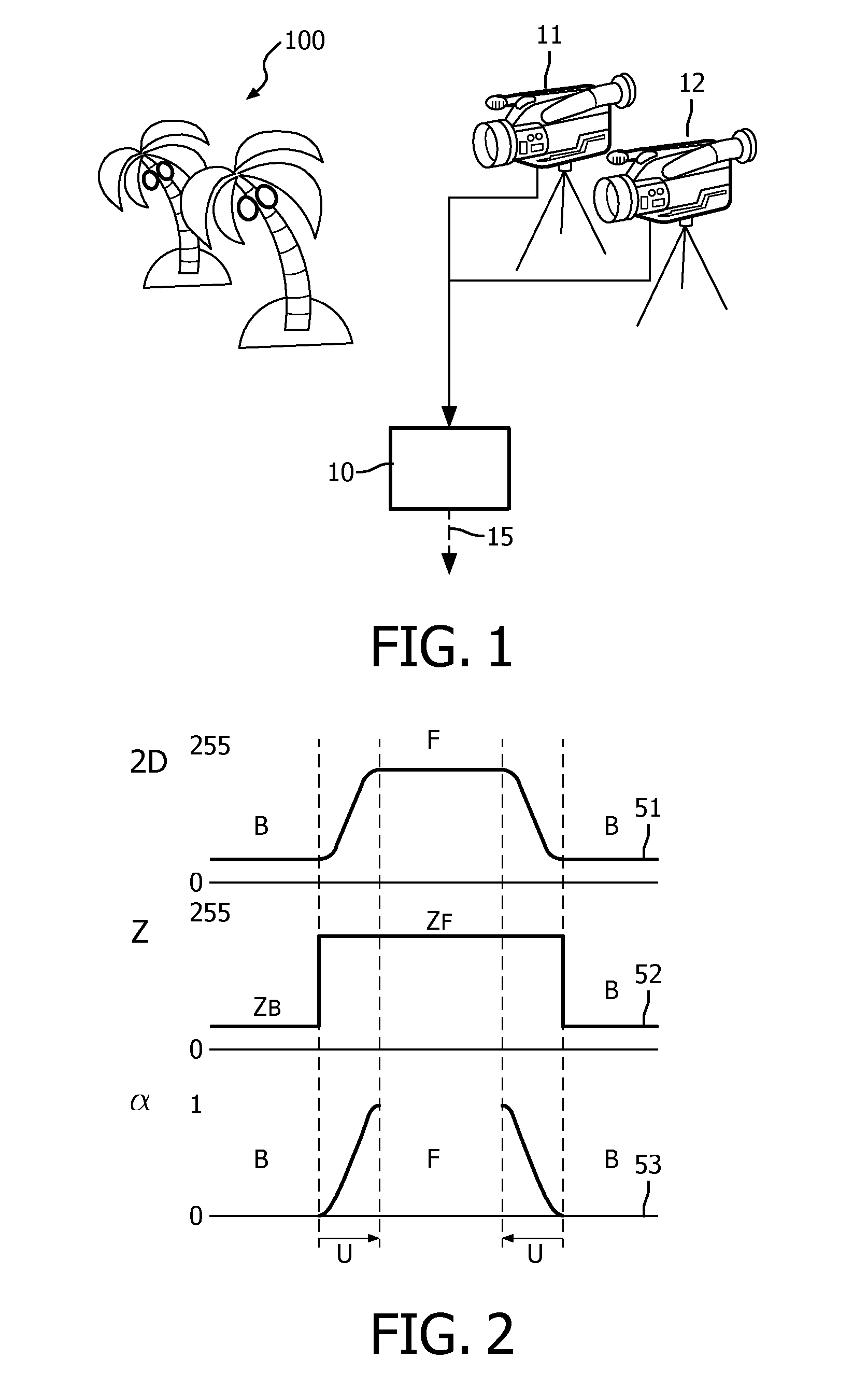

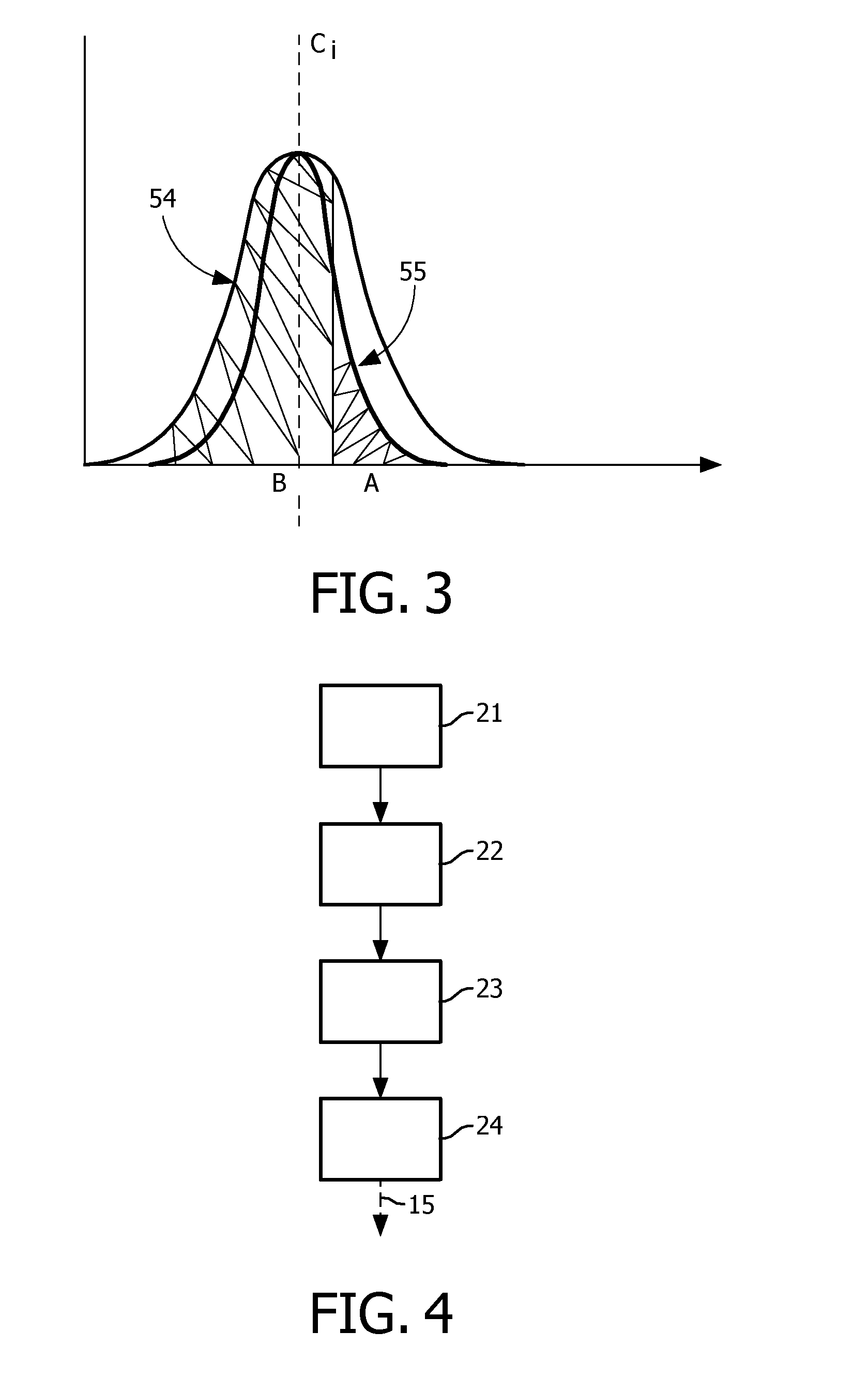

Efficient coding of depth transitions in 3D (VIDEO)

ActiveUS20120229603A1Reduce transmission costsSmooth transitionDigital video signal modificationSteroscopic systemsData signalDepth map

A method of encoding a video data signal (15) is provided, together with a method for decoding. The encoding comprises providing color information (51) for pixels in an image, providing a depth map with depth information (52) for the pixels, providing transition information (56, 57, 60, 70, 71) being representative of a width (63, 73) of a transition region (61, 72) in the image, the transition region (61, 72) comprising a depth transition (62) and blended pixels in which colors of a foreground object and a background object are blended, and generating (24) the video data signal (15) comprising encoded data representing the color information (51), the depth map (52) and the transition information (56, 57, 60, 70, 71). The decoding comprises using the transition information (56, 57, 60, 70, 71) for determining the width (63, 73) of the transition regions (61, 72) and for determining alpha values (53) for pixels inside the transition regions (61, 72). The determined alpha values (53) are used for determining the color of a blended pixel at the transition of a foreground object and a background object.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

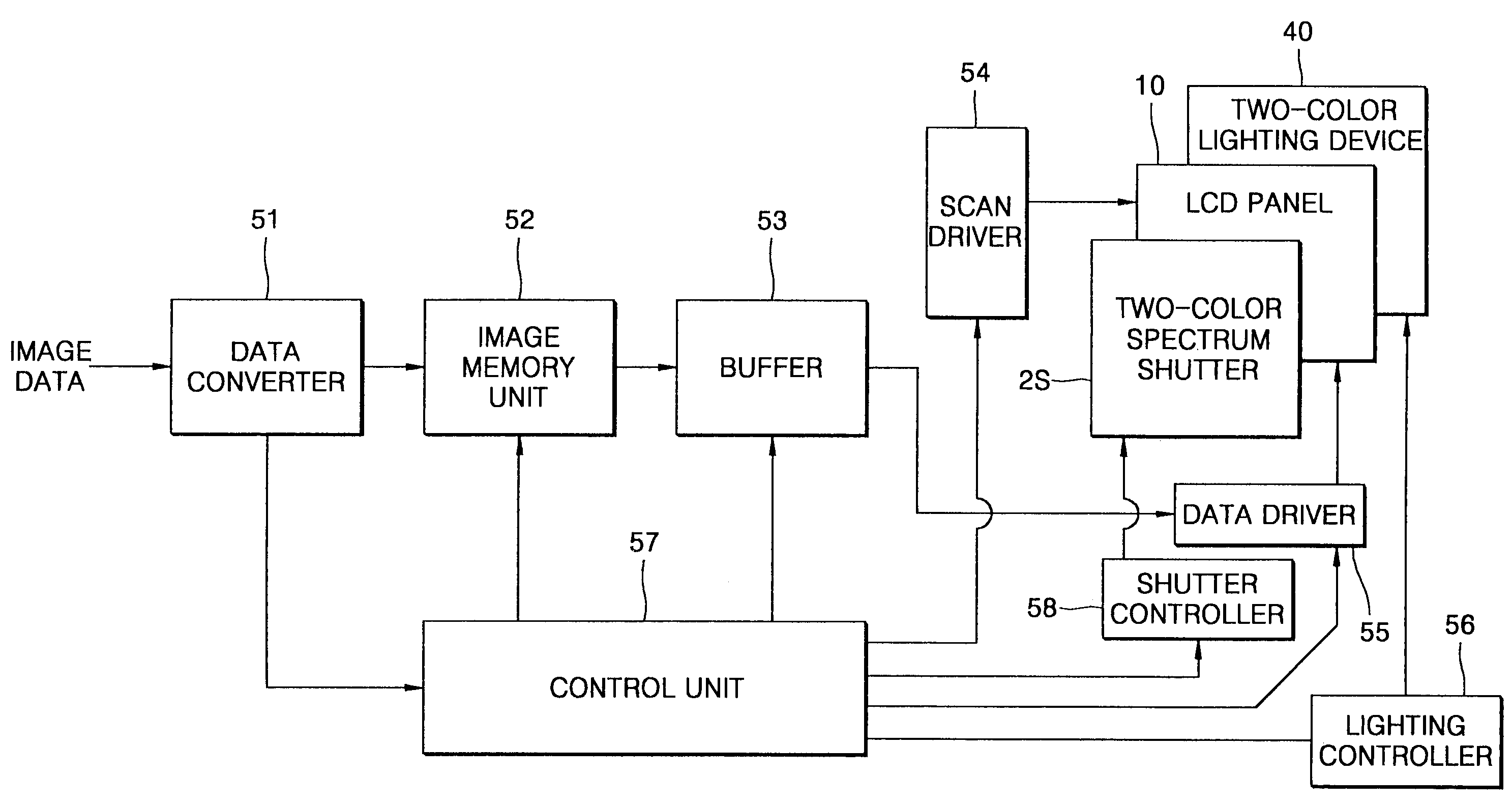

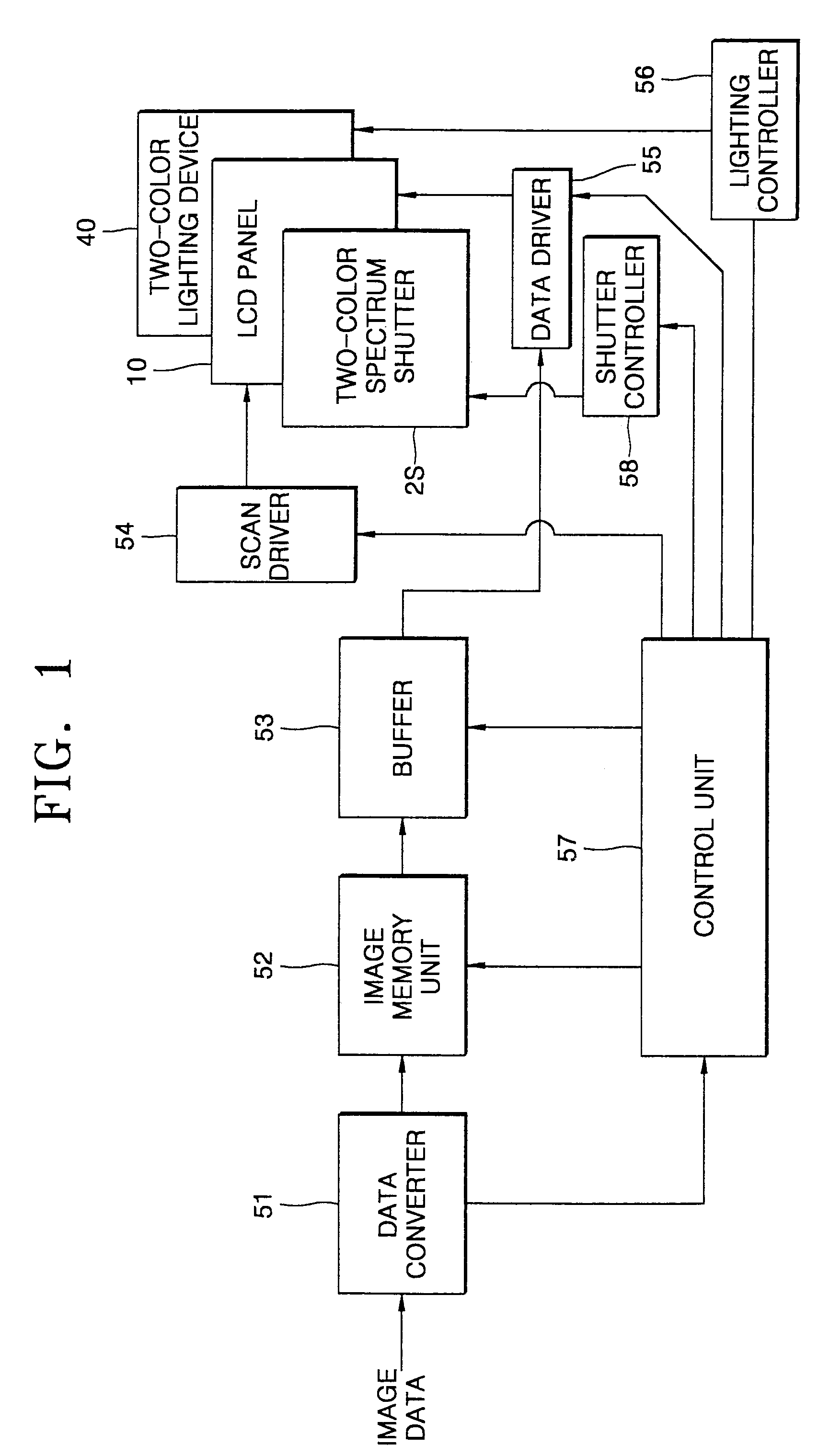

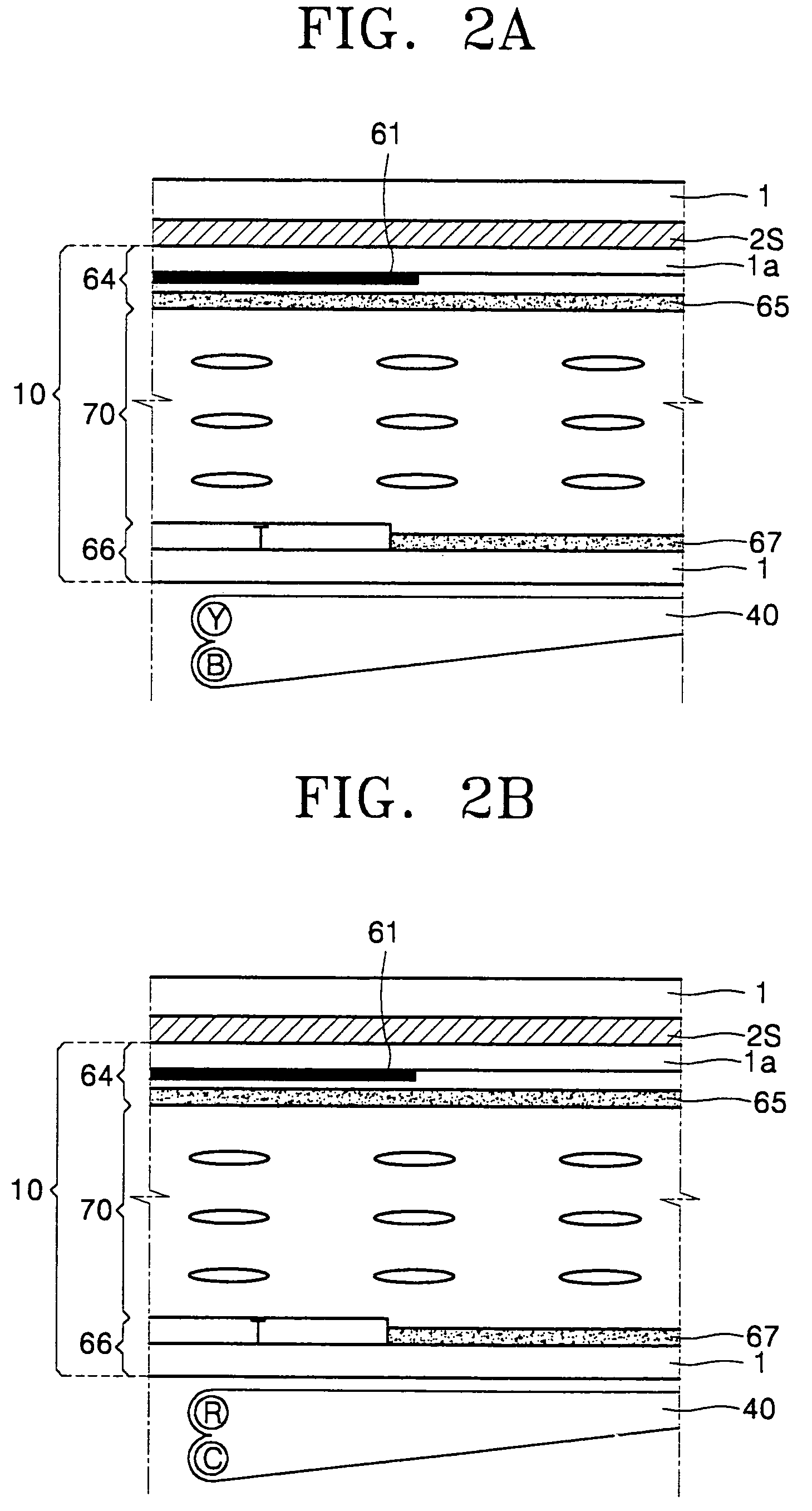

Method of stably driving liquid crystal display apparatus and liquid crystal display apparatus using the method

InactiveUS7289091B2Increase widthDrive stabilityCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayEngineering

A method of stably driving a liquid crystal display apparatus and a liquid crystal display apparatus, the apparatus including a liquid crystal display panel having data electrode lines allocated for three colors and scan electrode lines crossing the data electrode lines and a lighting device installed in the back of the liquid crystal display panel to sequentially generate back lights having different colors, so that a unit driving period is divided into first, second, and third color driving periods. The liquid crystal display apparatus sequentially applies a single scan pulse to the scan electrode lines during a two-color driving period, in which the two color driving periods among the three color driving periods are combined, and activate two colors while the single scan pulse is applied to the scan electrode lines.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

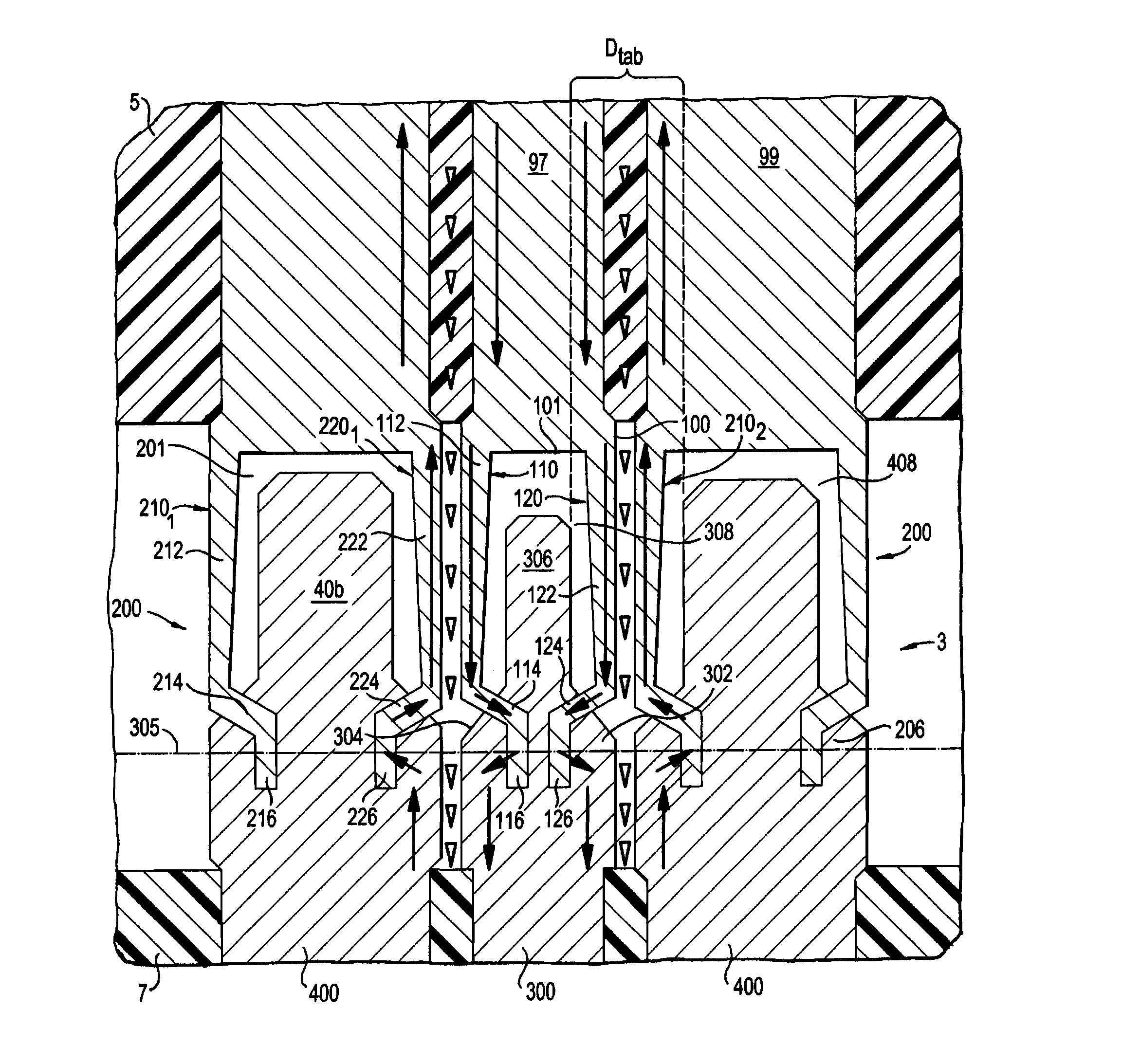

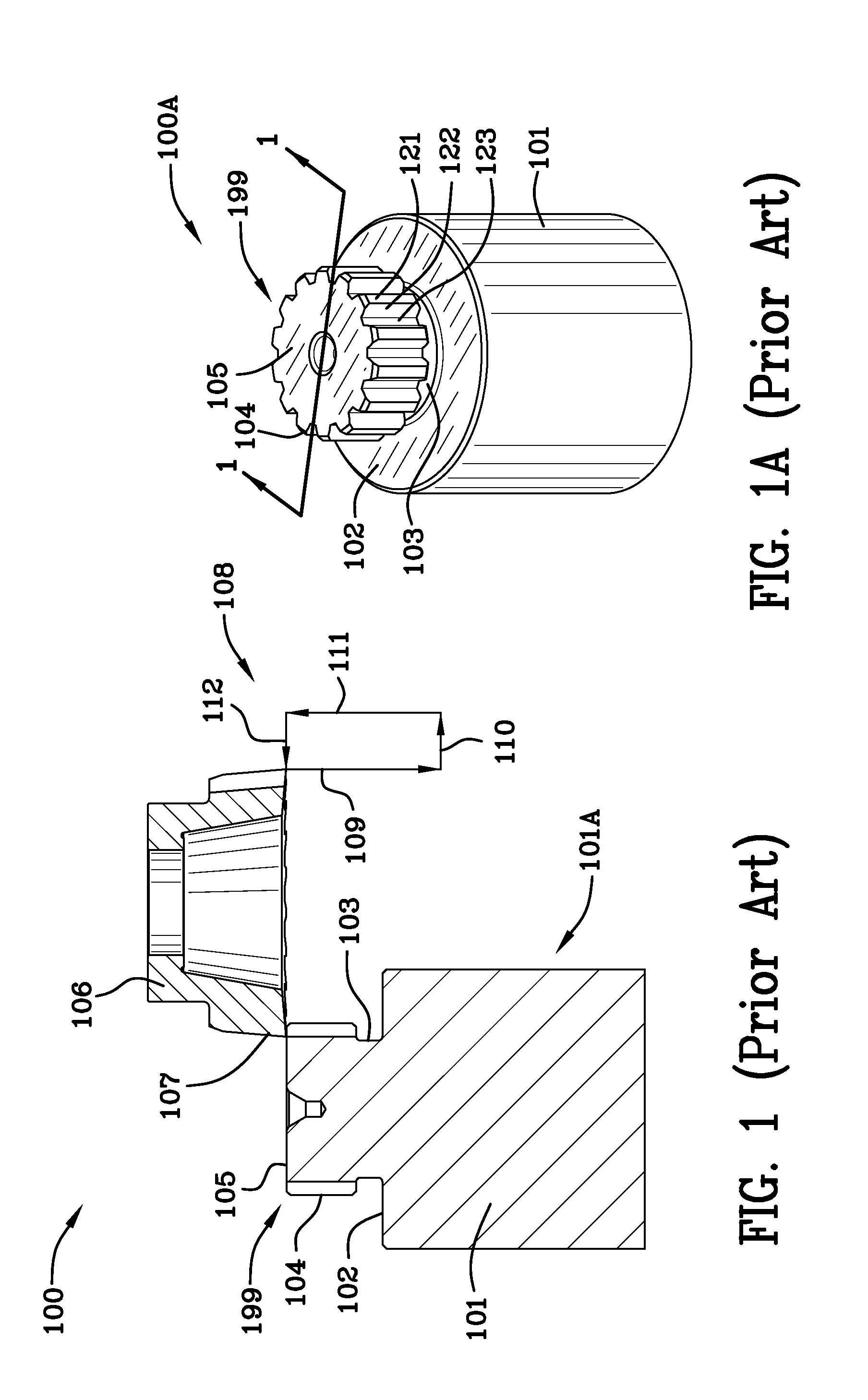

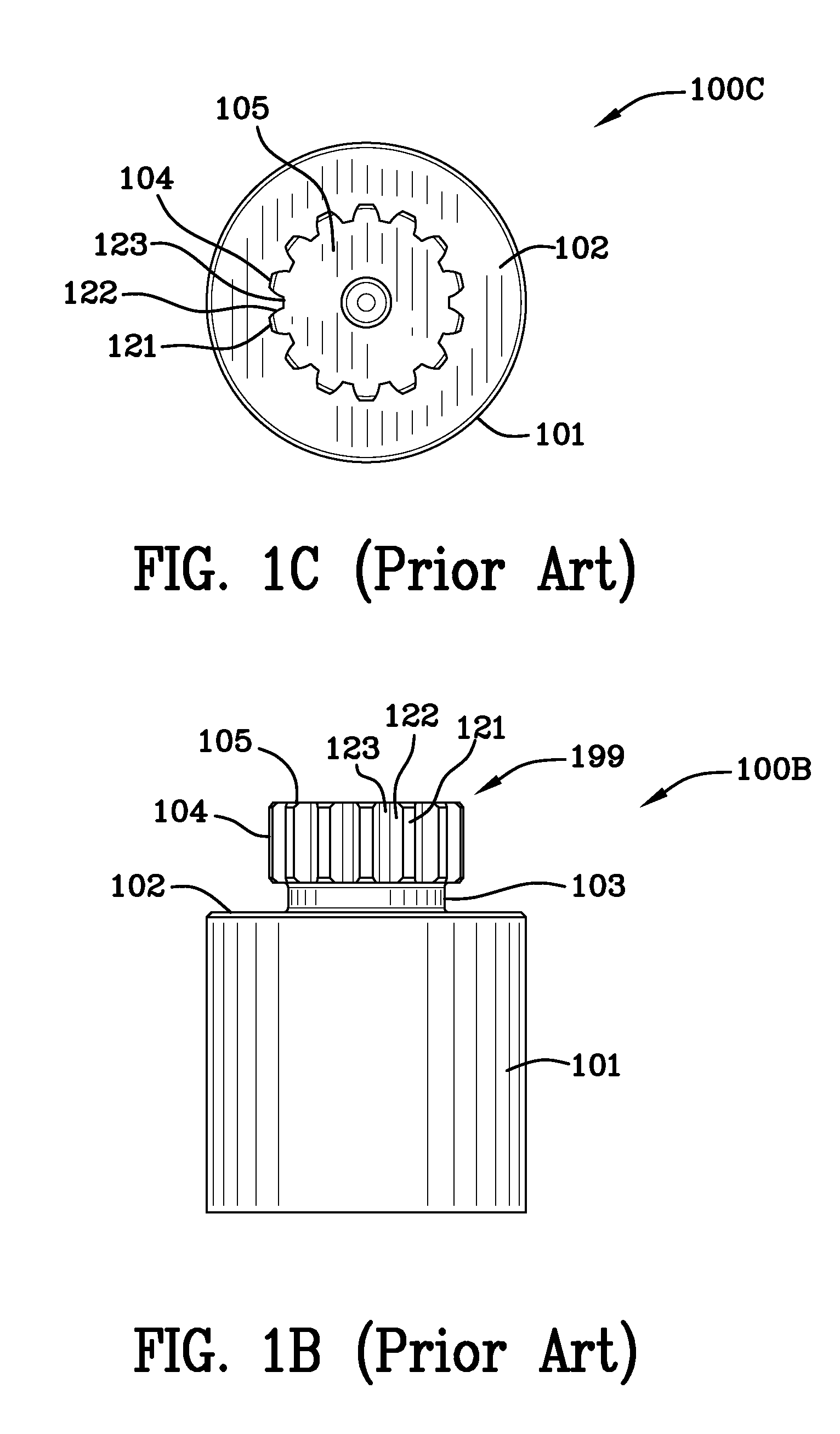

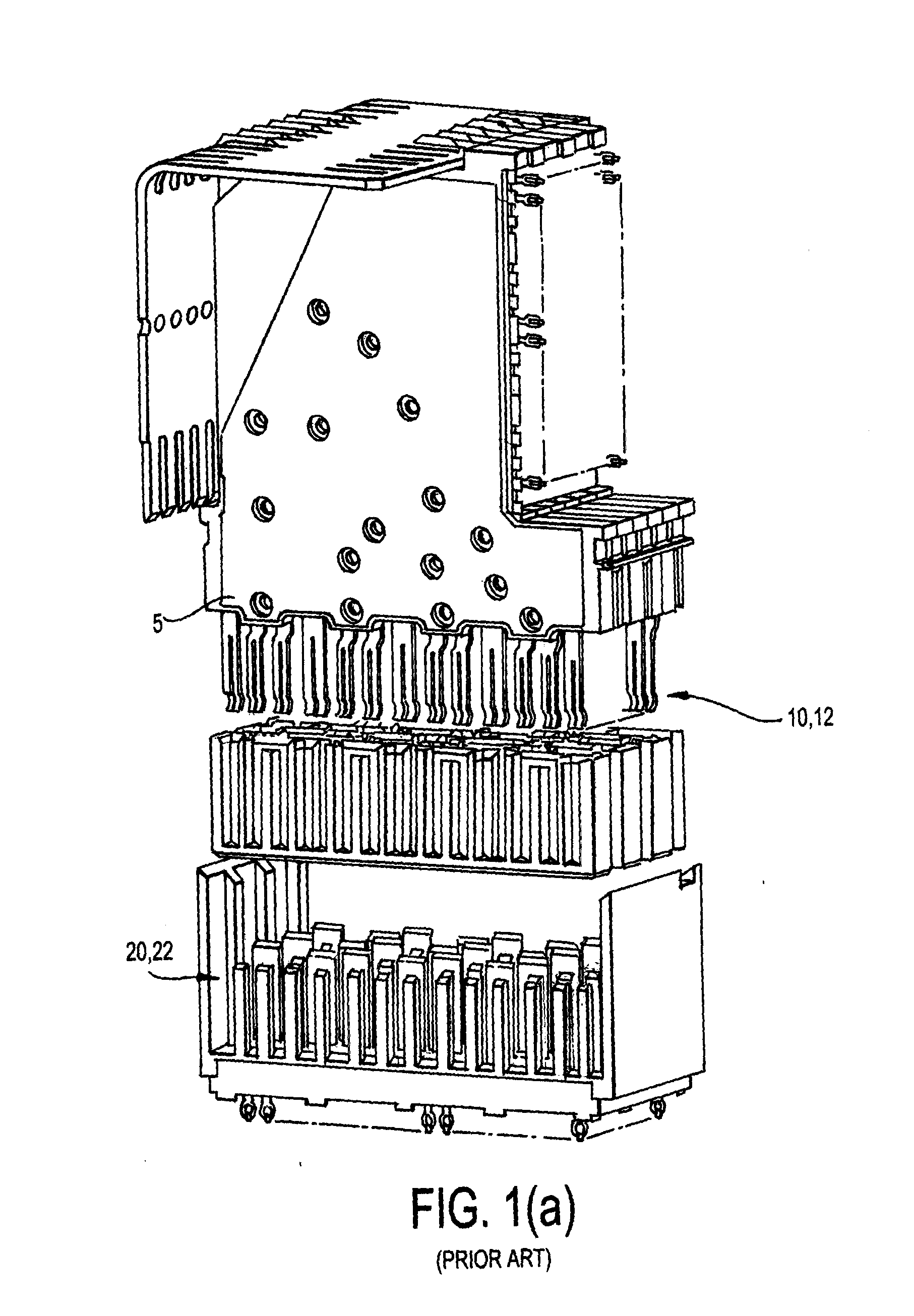

Connector having improved contacts

ActiveUS8961227B2Sufficient flexibilityReduce impactElectrically conductive connectionsCoupling contact membersElectrical conductorEngineering

An electrical connector for connecting a conductor of a daughter card connector wafer with a blade in the housing of a backplane connector. The daughter card conductor has a body with two elongated beams extending outward from the body. The two elongated beams each have an outer edge and an inner edge, whereby an opening is defined between the inner edges. The backplane conductor has a body with a narrowed tab portion extending outward from said second conductor body. The narrowed tab portion having outer opposite edges and is sized so that the narrowed tab portion fits between at least a portion of the outer edges of the two elongated beams, and in some cases between at least a portion of the inner edges of the two elongated beams.

Owner:AMPHENOL CORP

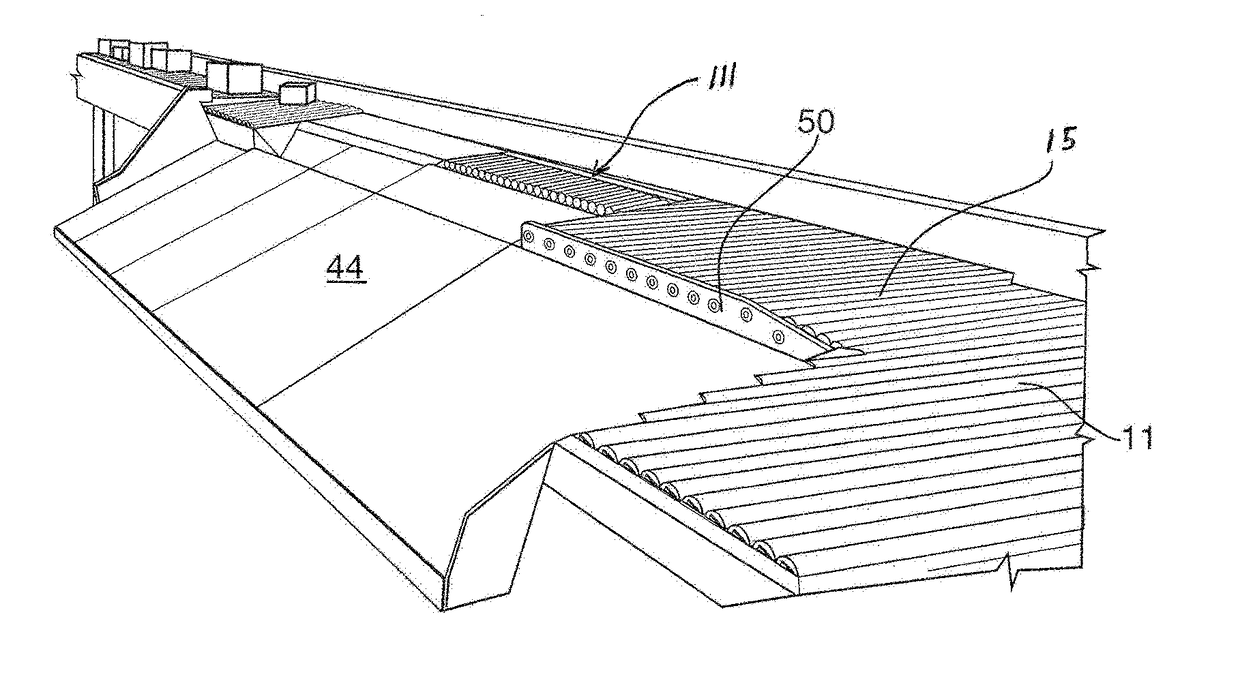

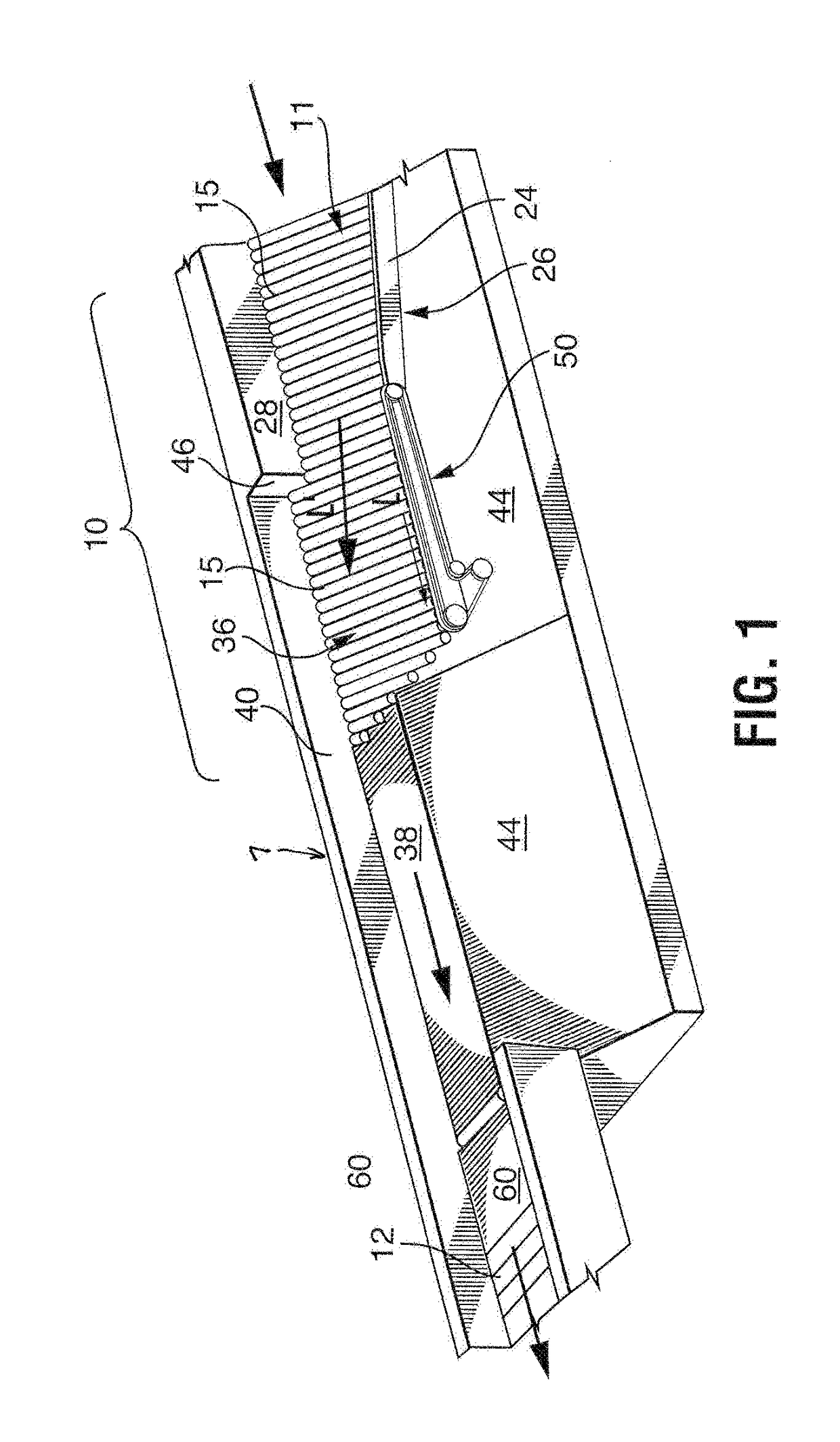

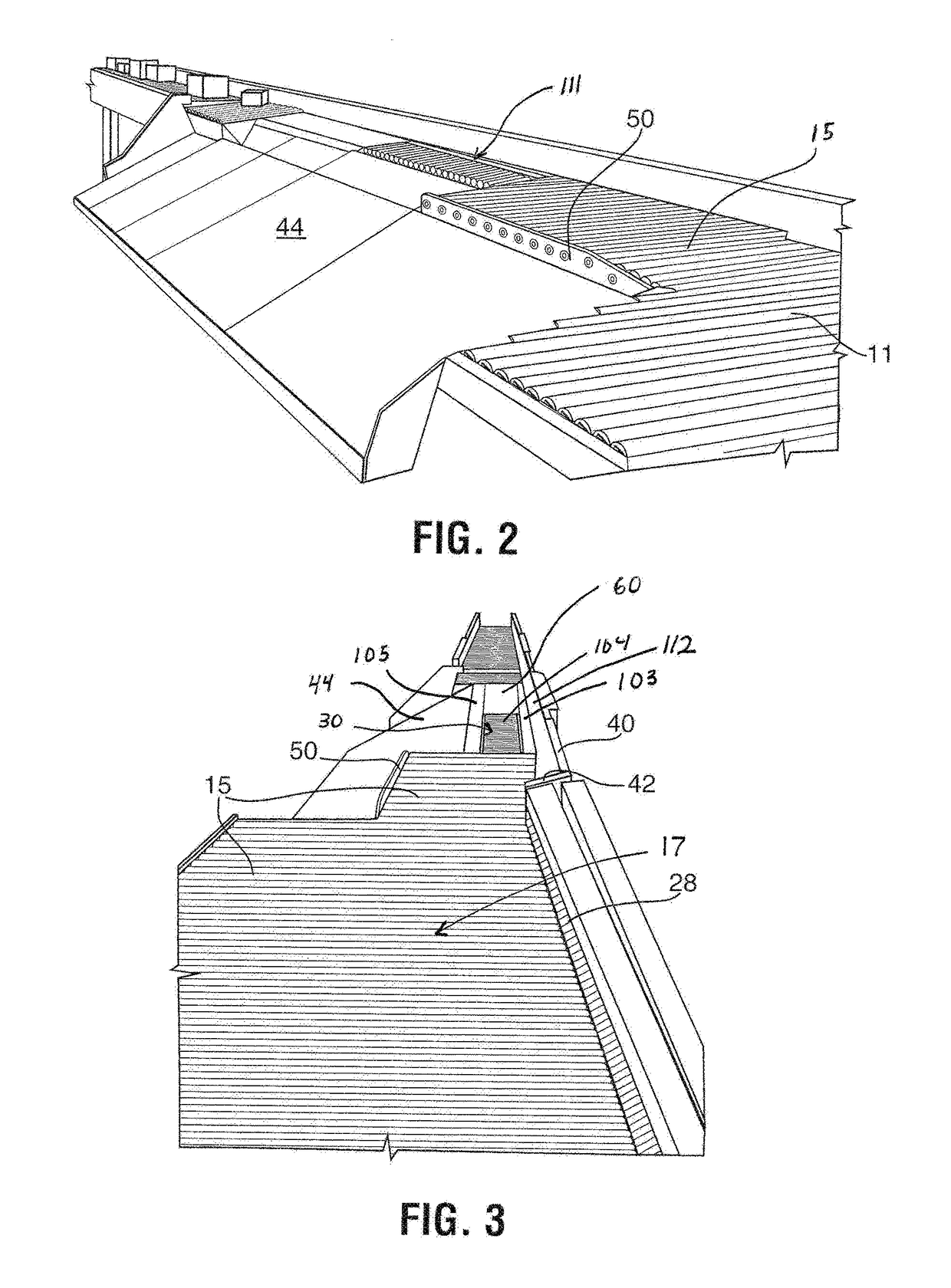

Stepped wall singulator conveyor for oversized item removal

ActiveUS20170173635A1Increase frictionEffective widthConveyorsSortingEngineeringMechanical engineering

This invention relates generally to a conveyor assembly for separating and aligning parcels, packages, bags and other articles prior to processing with a singulator. The stepped wall assembly includes a low friction conveying surface having both forward and lateral conveying forces for moving articles toward a lateral sidewall and a downstream conveyor. A series of offsets disposed between straight and diverging sidewalls force parcels toward the center of the conveyor against the lateral forces of the low friction conveying surface gradually separating and converging the parcels toward a selected sidewall of the conveyor and in line with a singulator apparatus.

Owner:FIVES INTRALOGISTICS SA

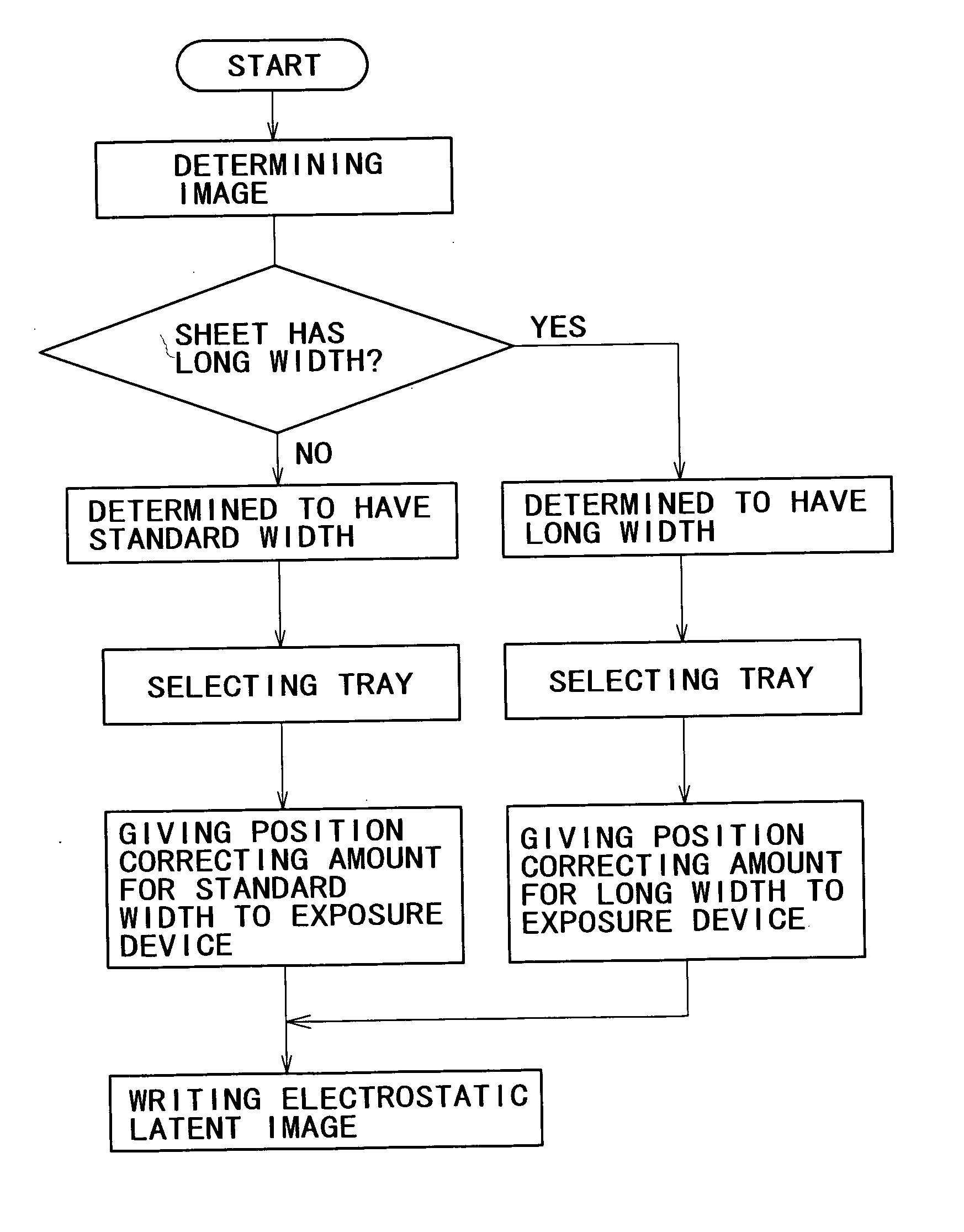

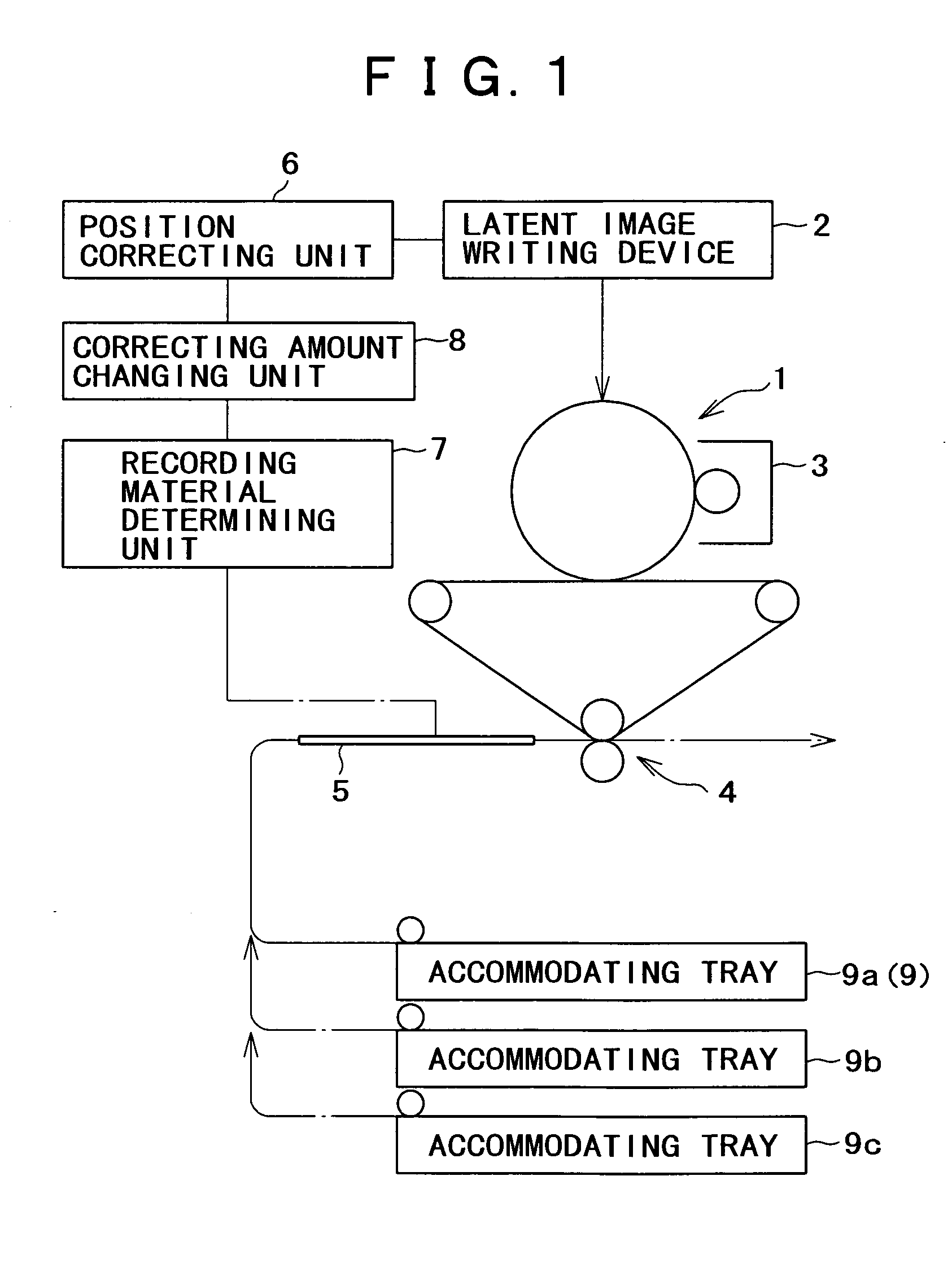

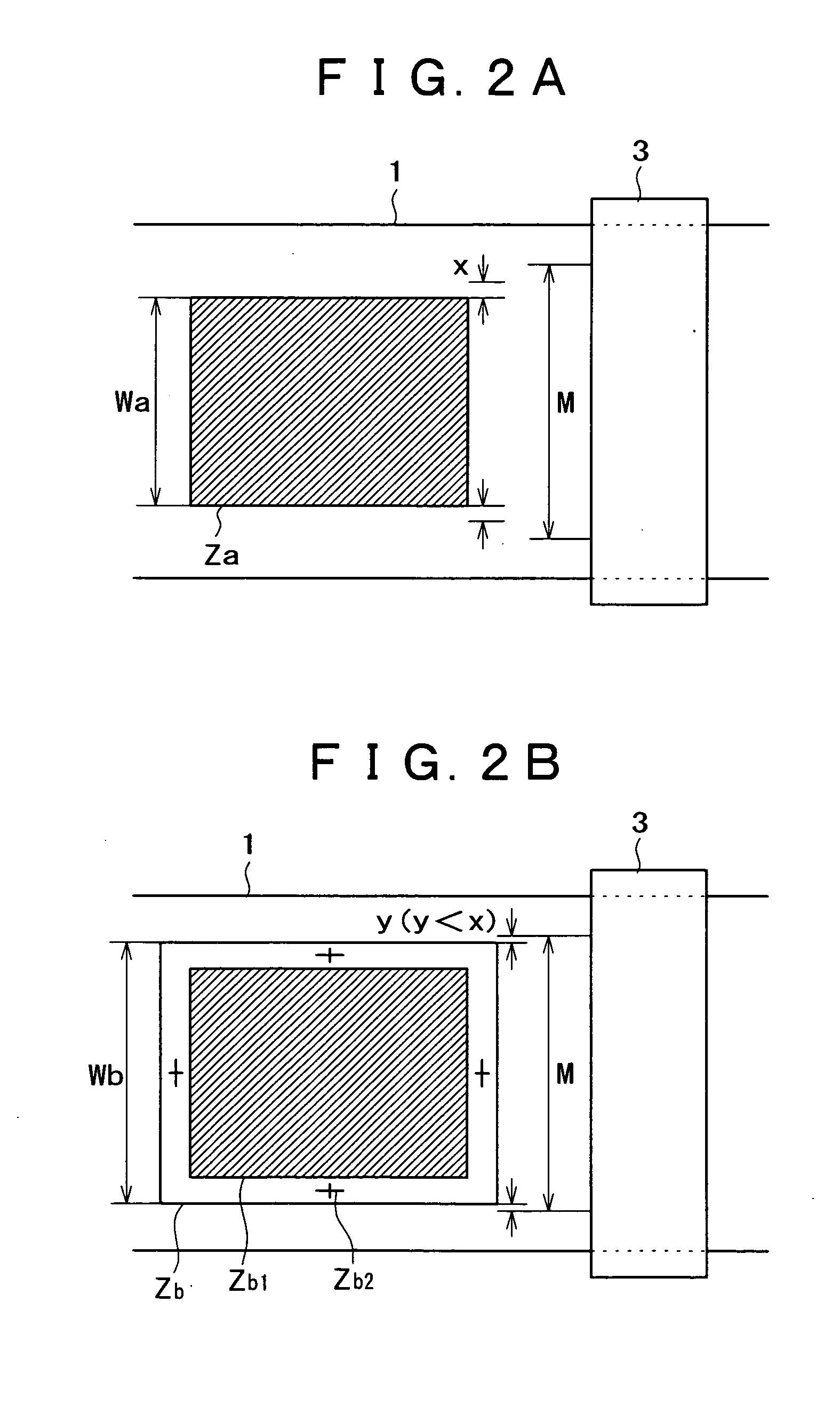

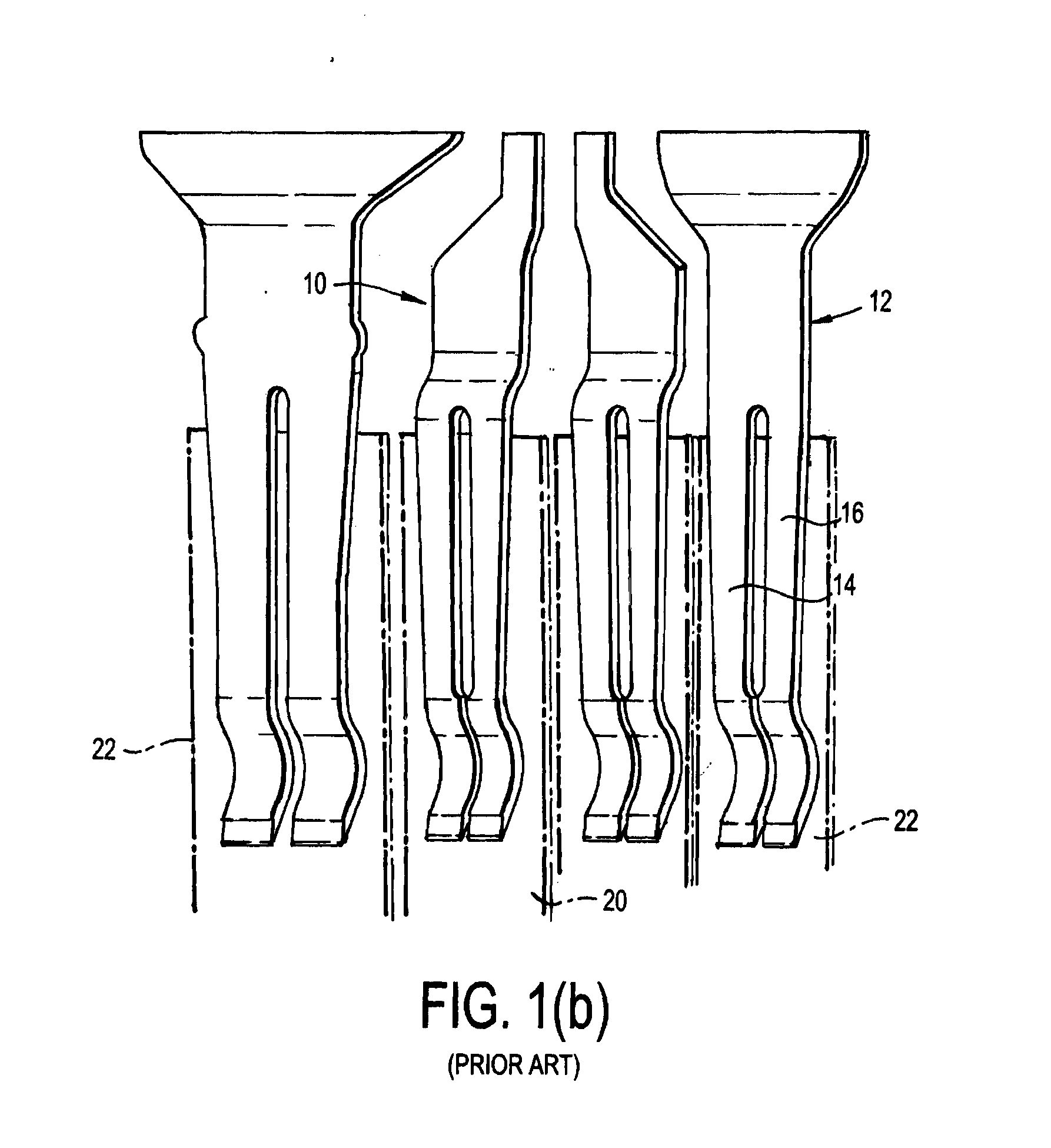

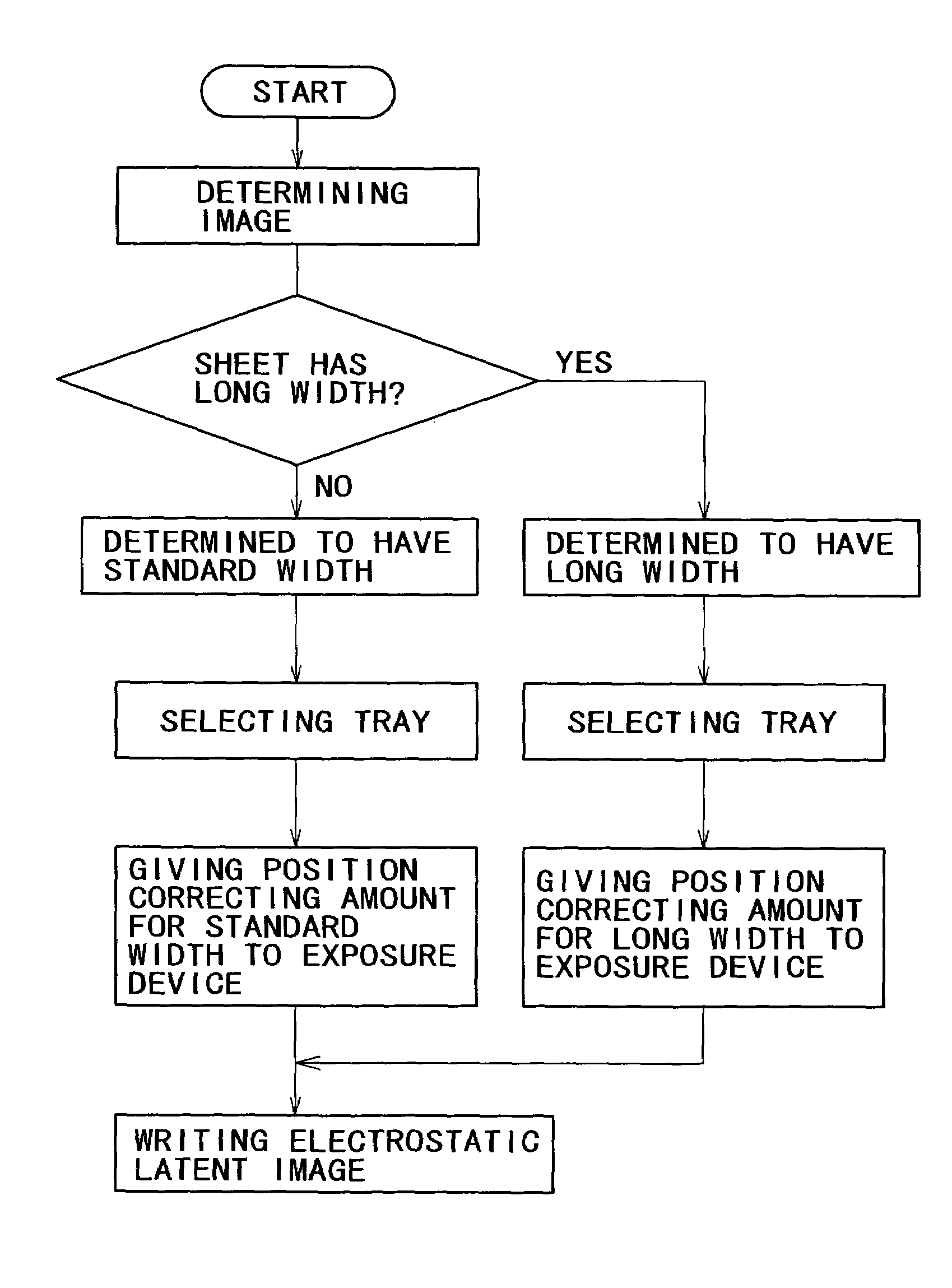

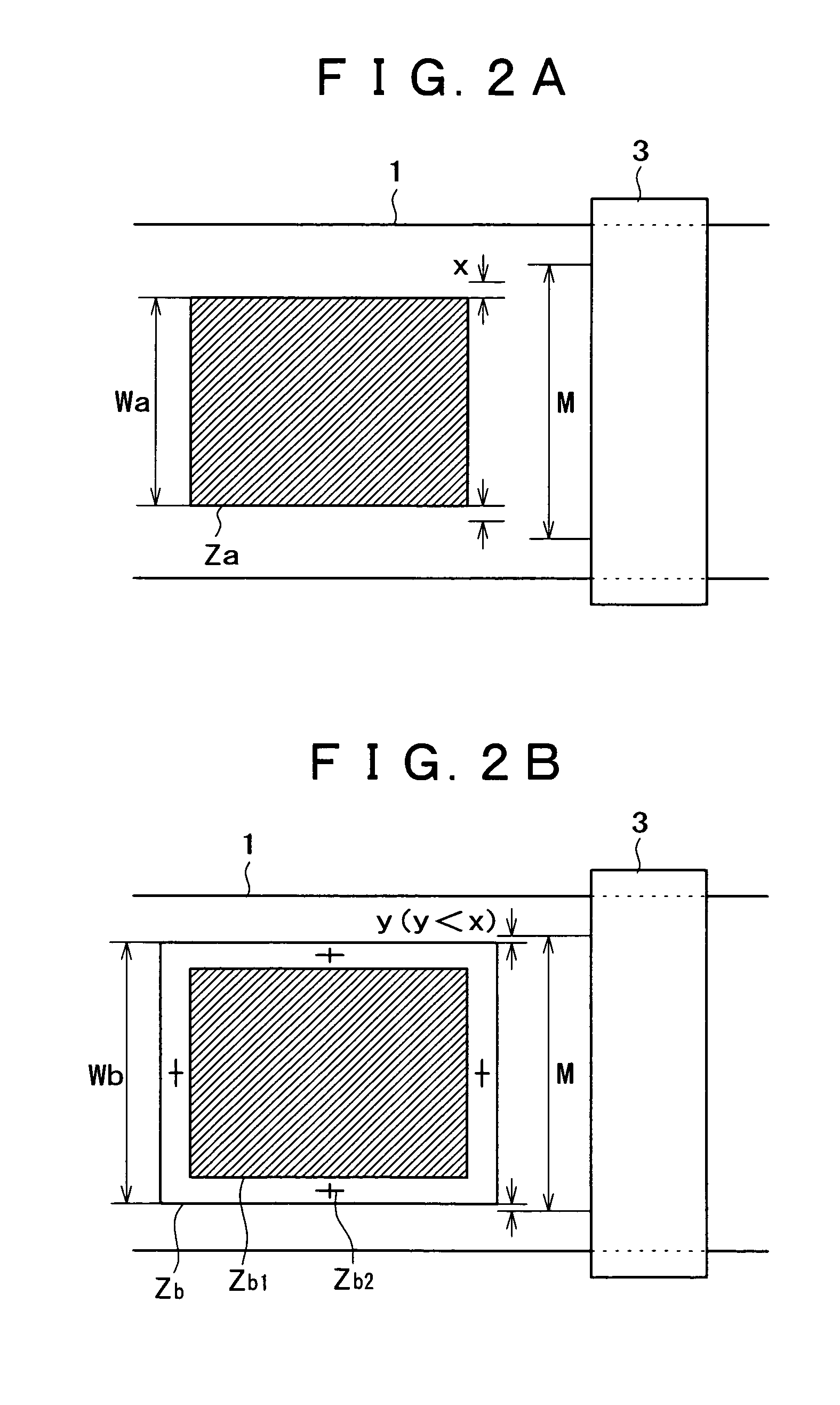

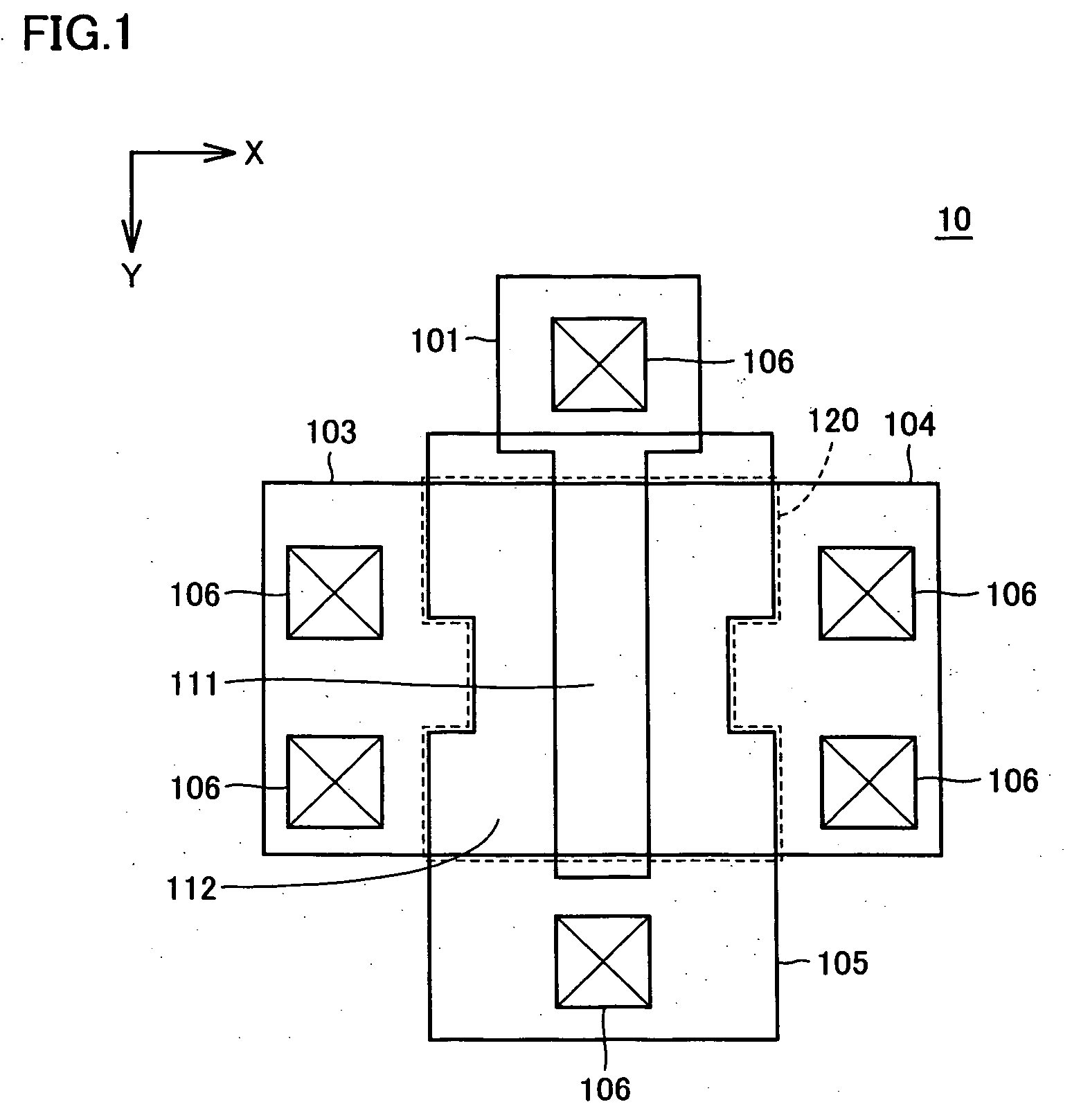

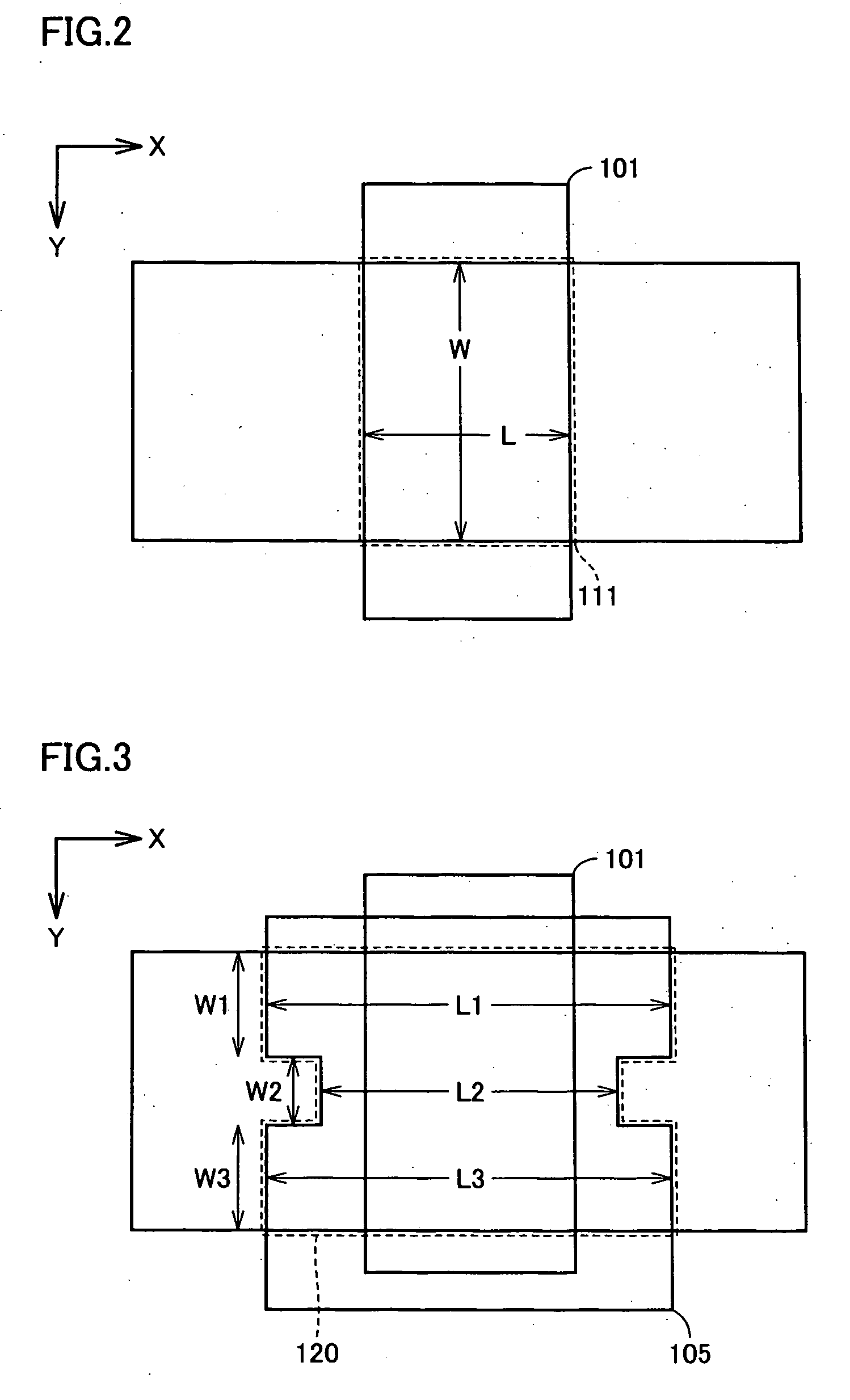

Image forming apparatus

InactiveUS20050041988A1Efficient developmentEffective widthElectrographic process apparatusLatent imageImage formation

An image forming apparatus has a latent image writing device that writes an electrostatic latent image on an image bearing member, a developing device that develops a toner image based on the electrostatic latent image, a transferring device that transfers the toner image onto a recording material, a position correcting unit that corrects a position of the electrostatic latent image written by the latent image writing device, a recording material determining unit that determines whether or not the recording material has a long width, and a corrected amount changing unit that, when the recording material determining unit determines that the recording material has a long width, changes an amount of correcting the position of the electrostatic latent image to a value different from a set value for a recording material having a standard width.

Owner:FUJIFILM BUSINESS INNOVATION CORP

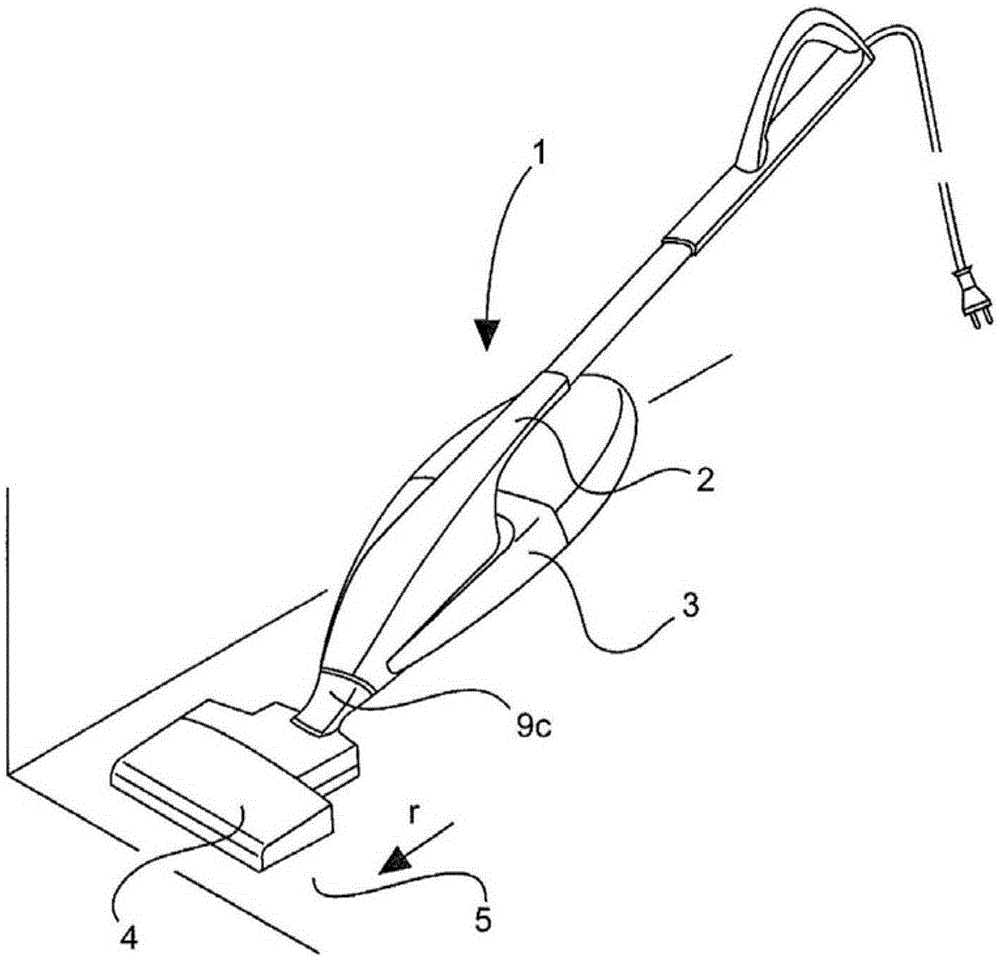

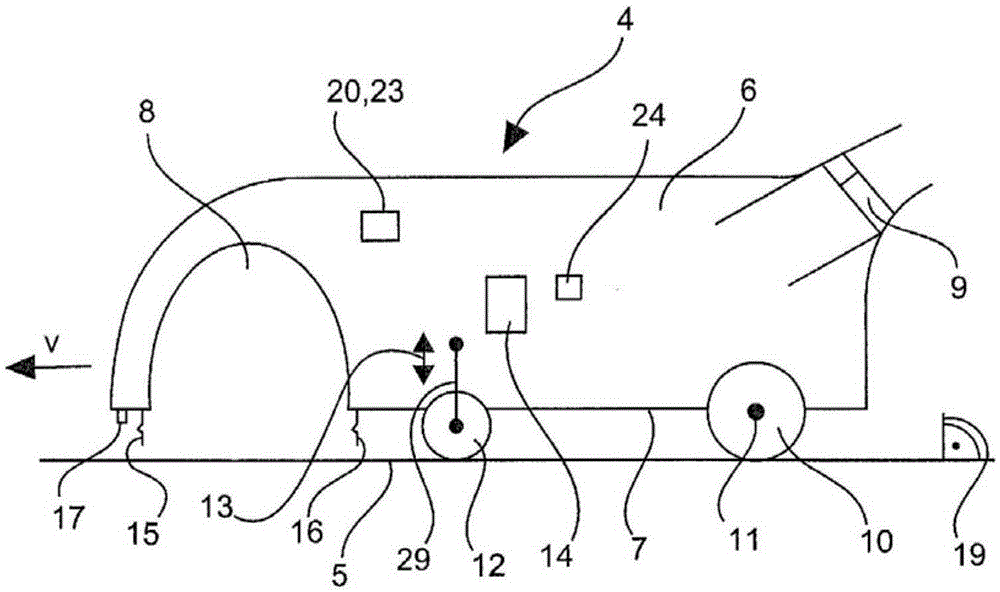

Nozzle of cleaner for caring floors

ActiveCN105595916AEasy to moveSimplify the turning processSuction nozzlesElectric equipment installationControl signalEngineering

The present invention relates to a nozzle (4) of a cleaner (1) for caring floors (5). The bottom (7) of the nozzle (4) is provided with a matrix (3) with a supporting wheel (12) which is used for allowing the flow to turn and allow the nozzle (4) to connect with a connection join (9c), and the supporting wheel (12) is able to lift and sink with respect to the bottom (7). Therefore, the forming nozzle (4) is able to lift the supporting wheel (12) after the connection join (9c) is converted to a stop position, the force of the supporting wheel (12) is too large, and / or the electric power consumed by the air pump motor of the cleaner (1) and the control signals reduced according to a preset value are received.

Owner:VORWERK & CO INTERHOLDING GMBH

System and method for processing thread groups in a SIMD architecture

ActiveUS7836276B2Efficient use ofImprove throughputGeneral purpose stored program computerConcurrent instruction executionGraphicsSimd processor

A SIMD processor efficiently utilizes its hardware resources to achieve higher data processing throughput. The effective width of a SIMD processor is extended by clocking the instruction processing side of the SIMD processor at a fraction of the rate of the data processing side and by providing multiple execution pipelines, each with multiple data paths. As a result, higher data processing throughput is achieved while an instruction is fetched and issued once per clock. This configuration also allows a large group of threads to be clustered and executed together through the SIMD processor so that greater memory efficiency can be achieved for certain types of operations like texture memory accesses performed in connection with graphics processing.

Owner:NVIDIA CORP

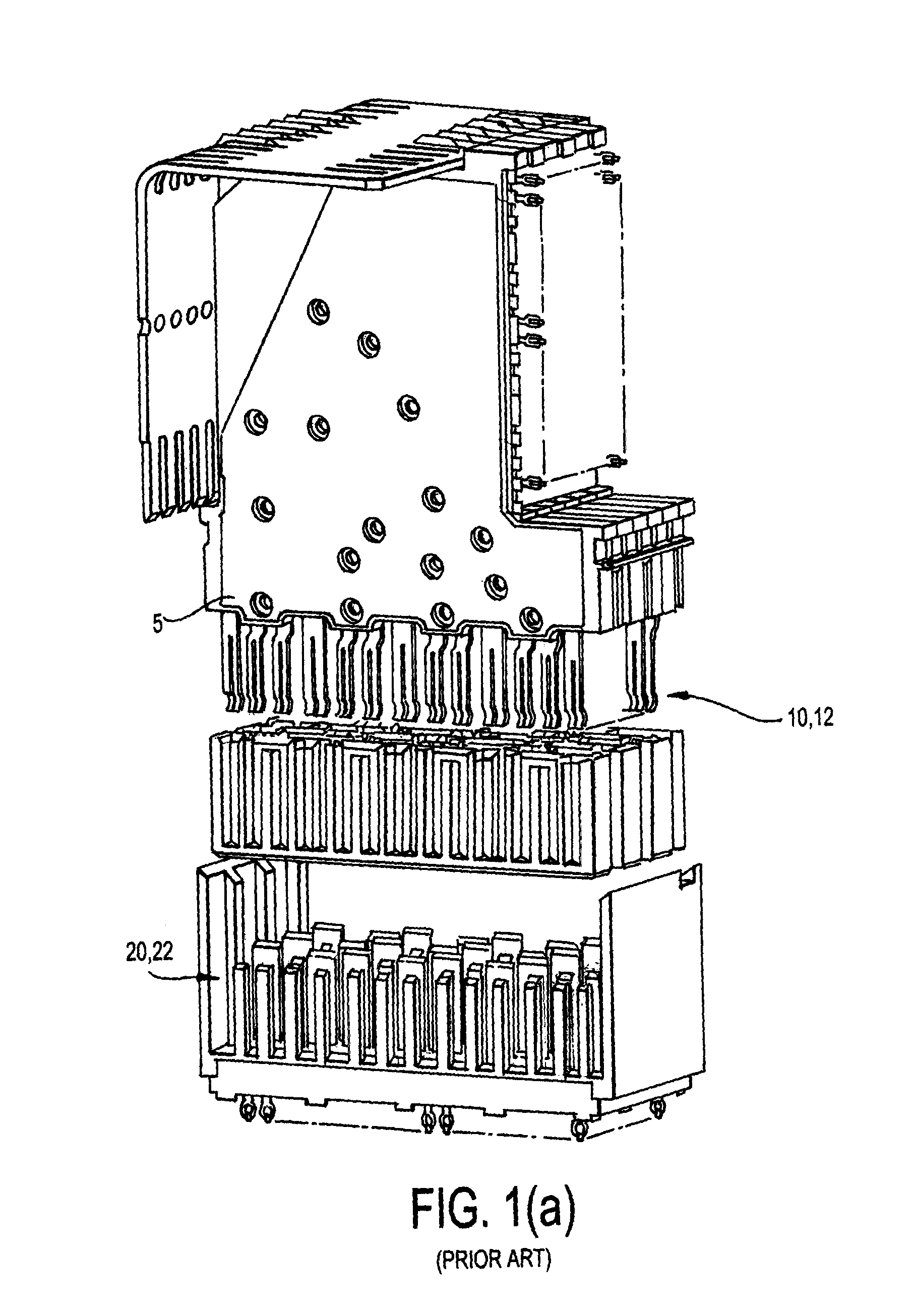

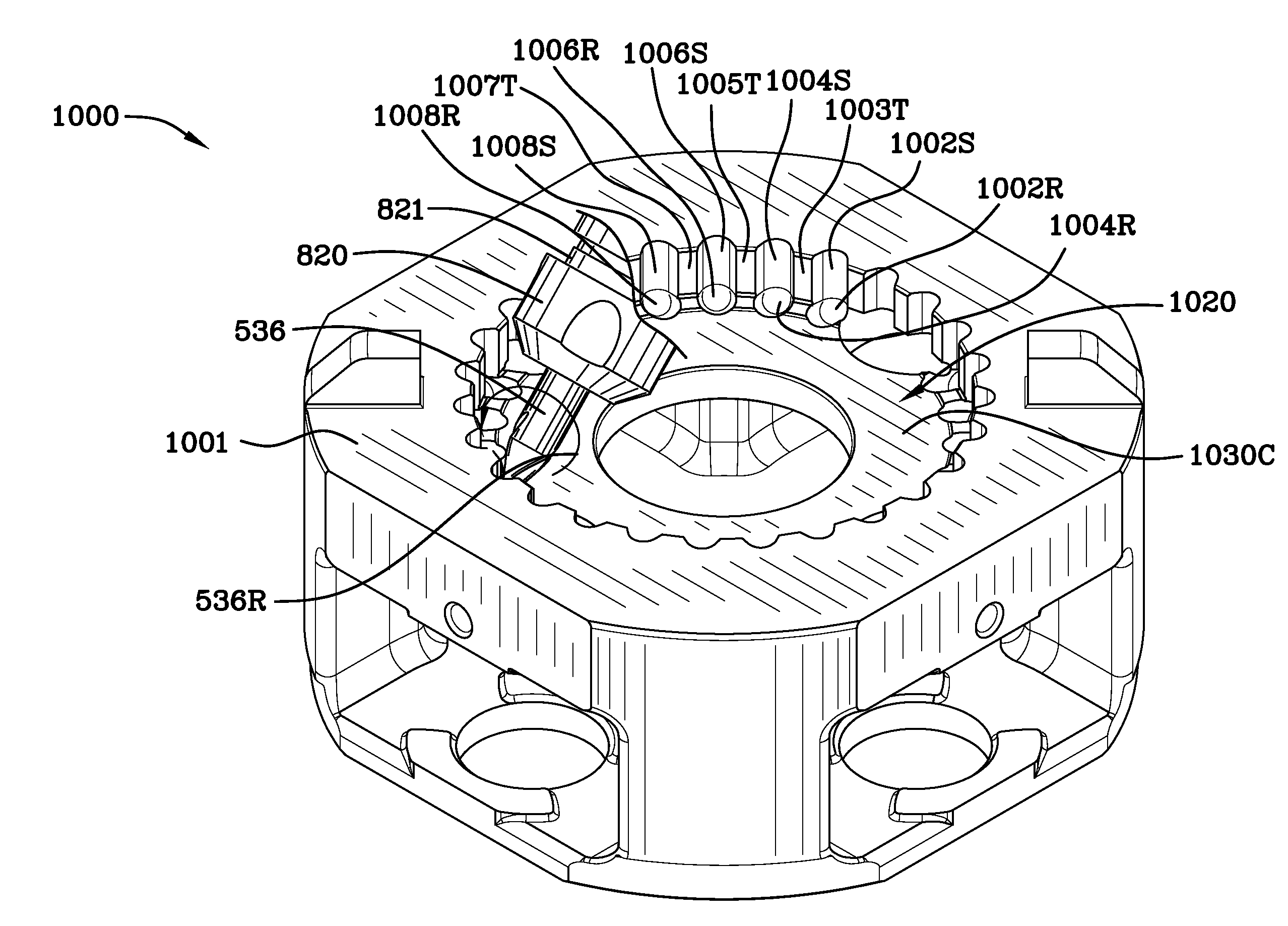

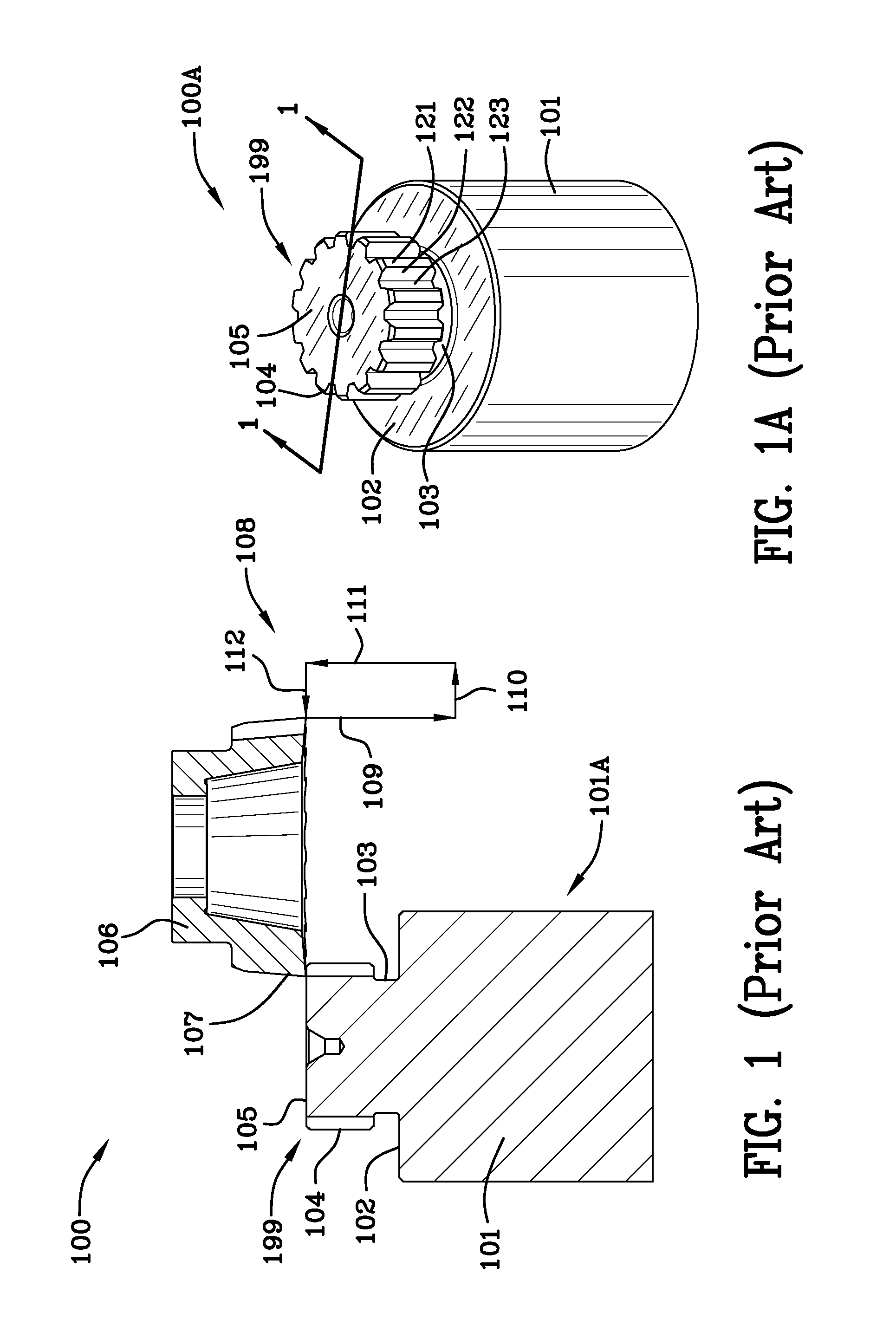

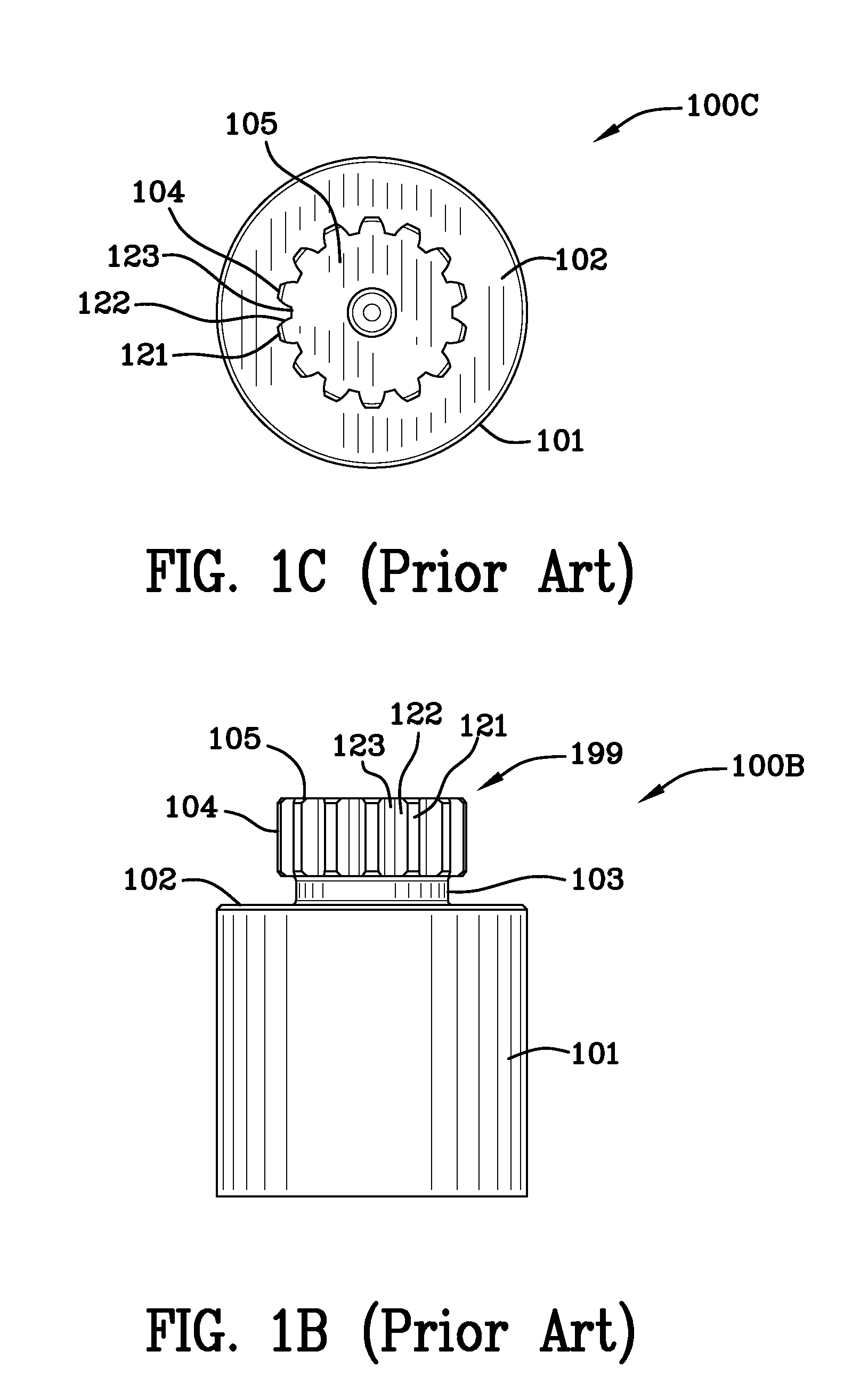

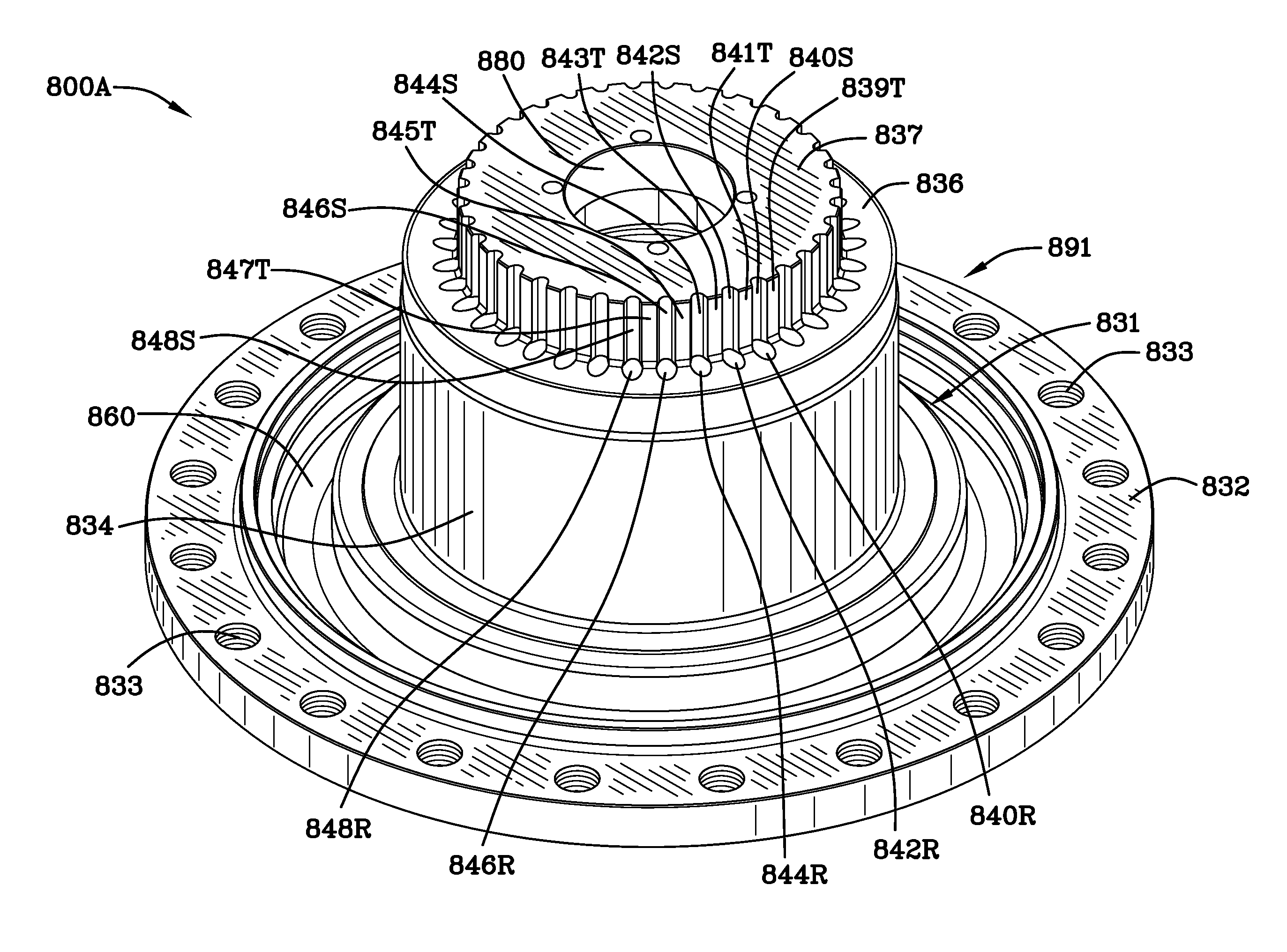

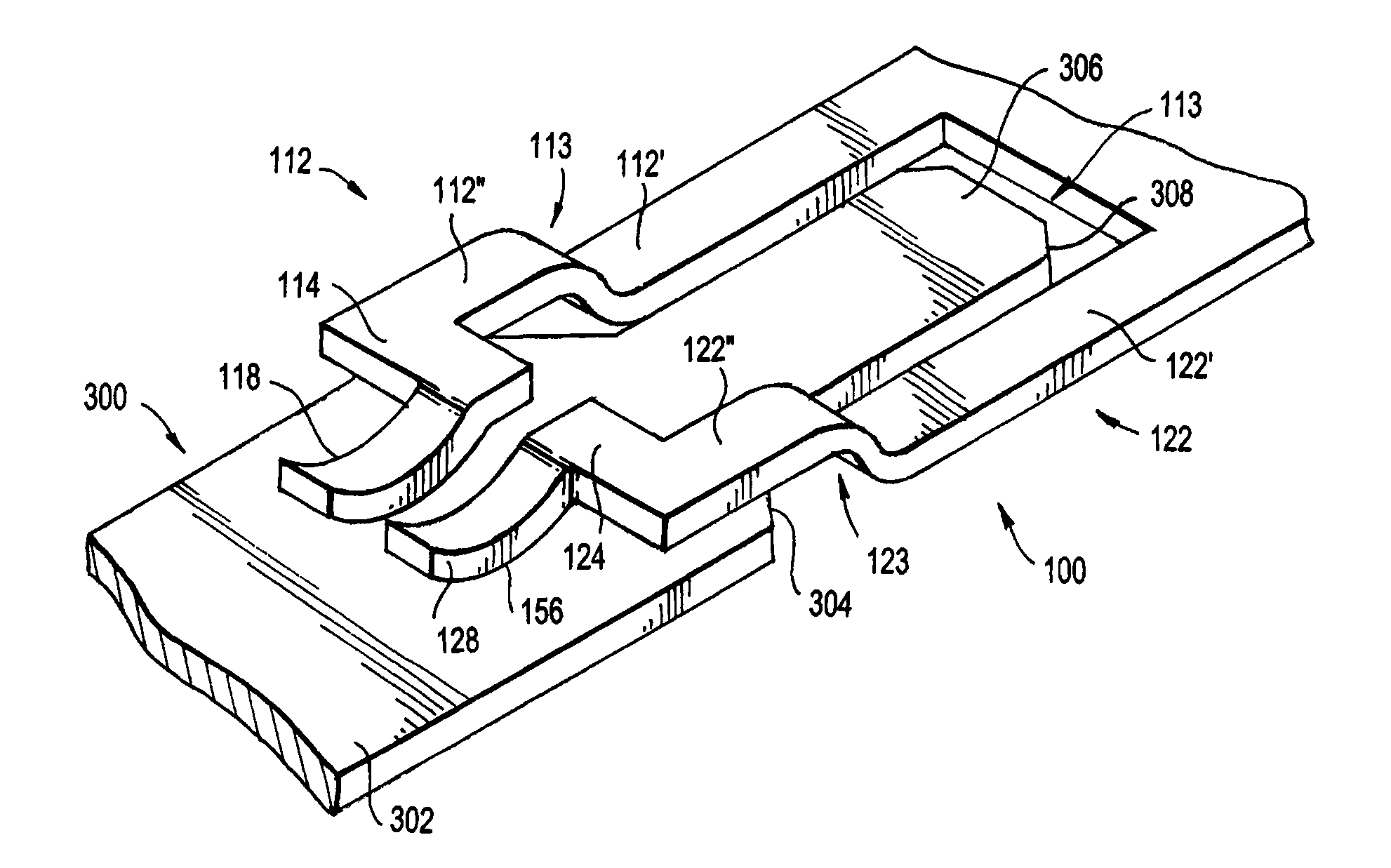

Smilled spline apparatus and smilling process for manufacturing the smilled spline apparatus

ActiveUS20120282022A1Maximize their effective face widthSave spaceMilling cuttersRod connectionsEngineeringMechanical engineering

By combining shaping and milling actions, or smilling, the cutting tool can move through the entire usable portion of the spline and machine a tool relief into the face of the adjacent feature such as a shoulder before retracting, reversing direction, and repeating the cycle. The smilling apparatus and manufacturing method eliminates the need for an annular spline relief and the full length of spline engagement can be utilized for strength. The effective width of the spline connection apparatus manufactured by the smilling process conserves space and increases the load carrying capability of the spline connection.

Owner:FAIRFIELD MFG CO INC

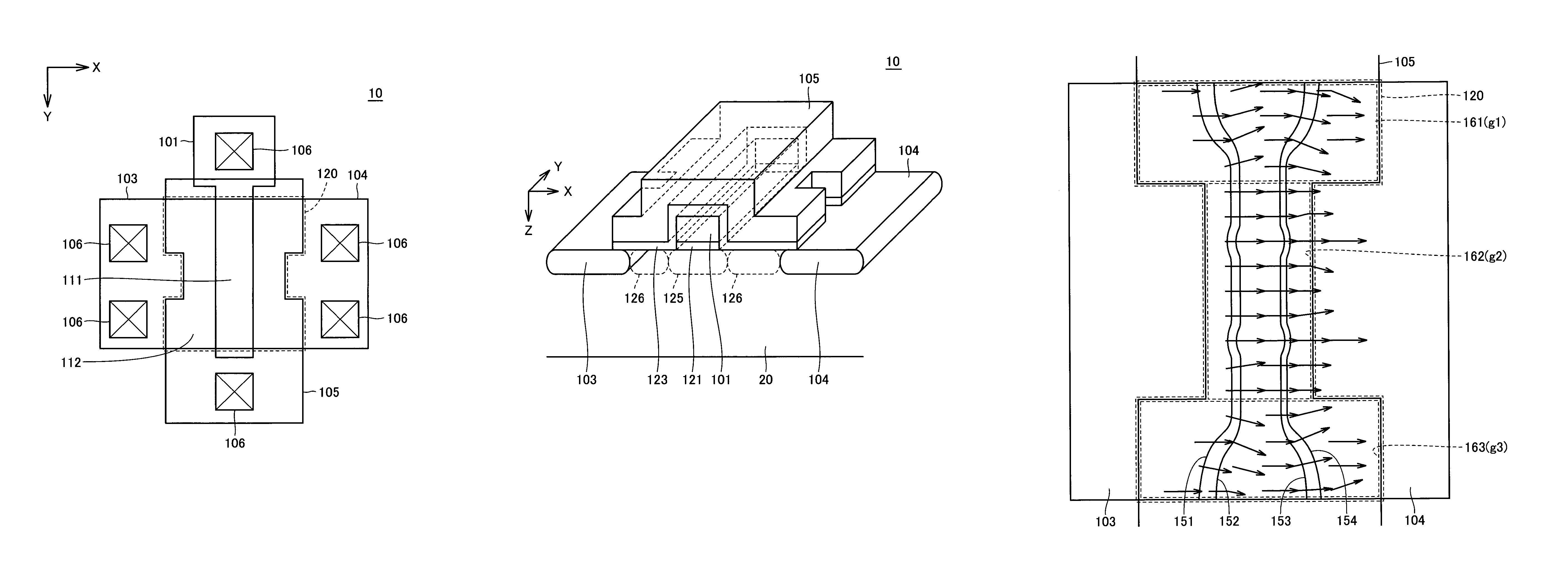

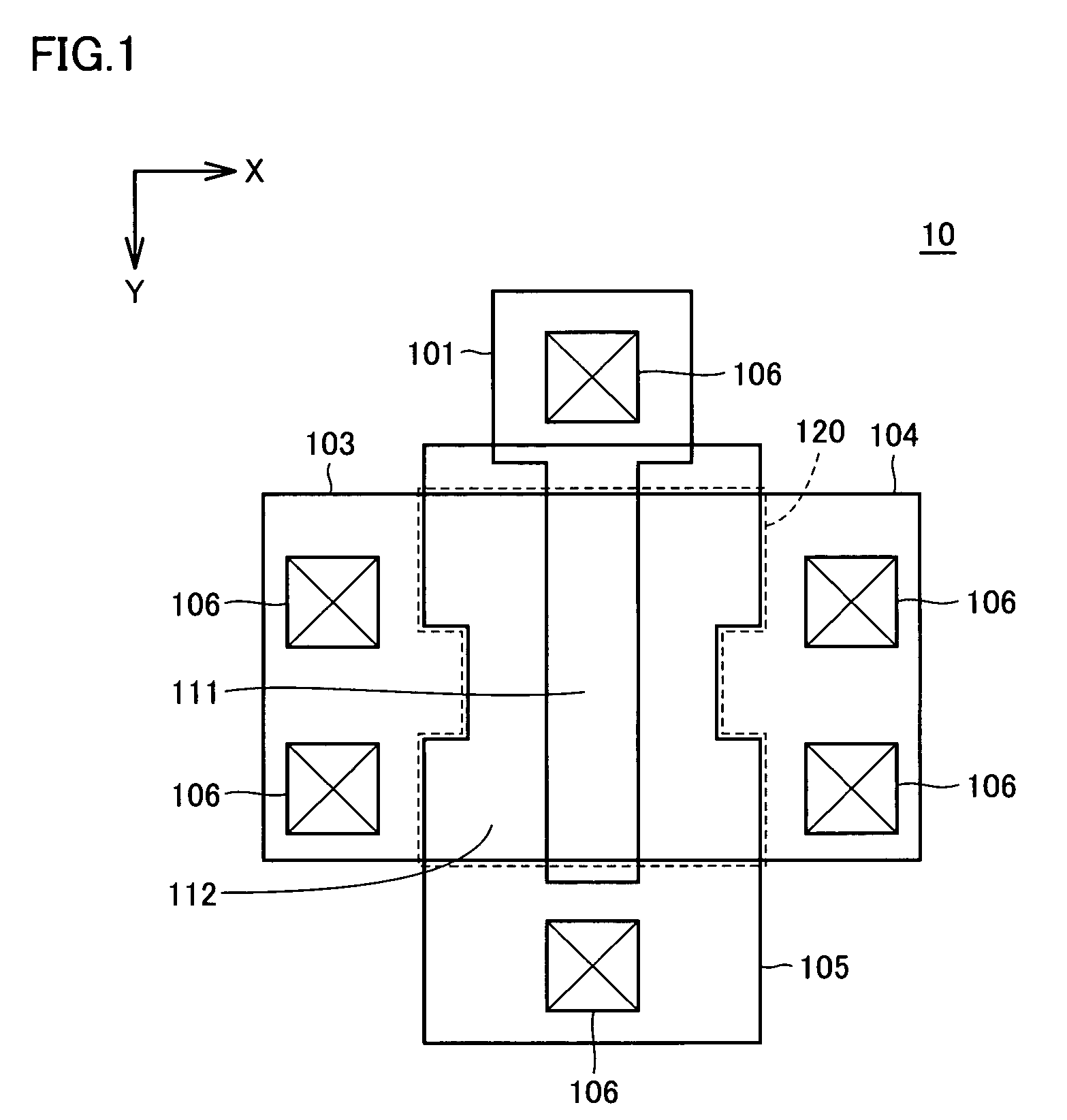

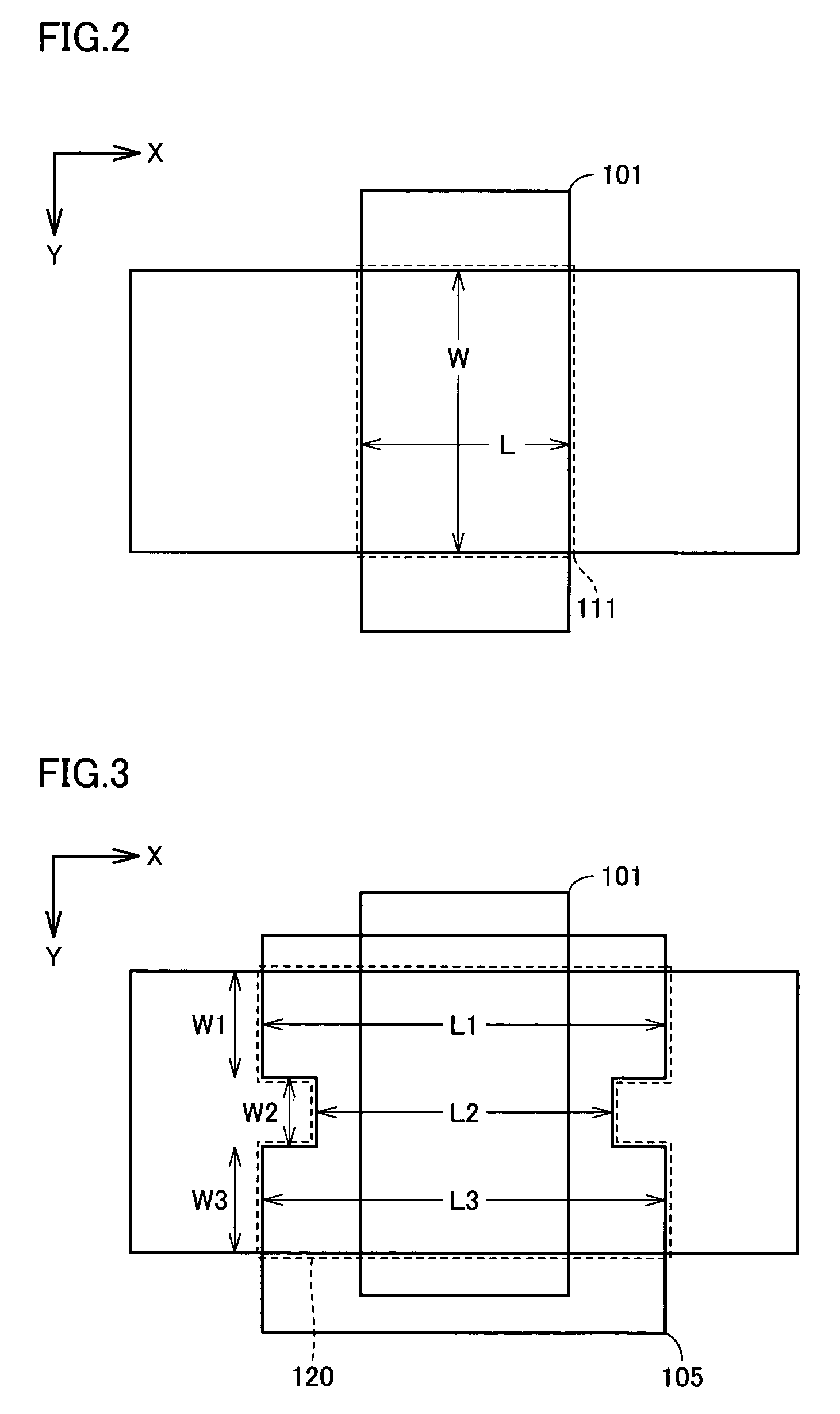

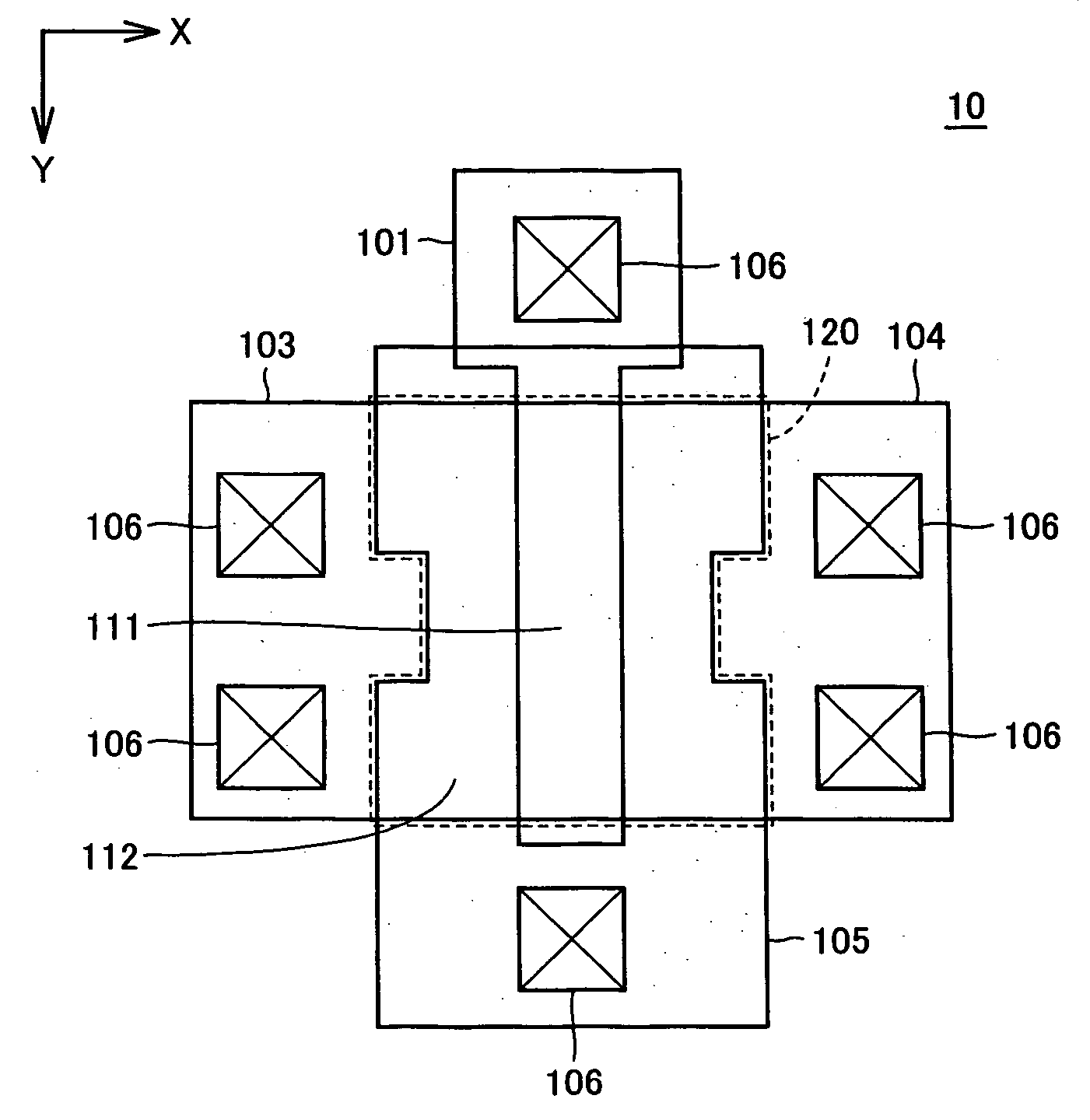

Semiconductor device allowing modulation of a gain coefficient and a logic circuit provided with the same

InactiveUS7057239B2Improve accuracyEasy to produceTransistorSemiconductor/solid-state device manufacturingGain coefficientEngineering

In addition to ordinary MOS gate, drain and source, a semiconductor element includes a control gate having geometry, which is defined only by a group of straight lines along a rectangular form of the MOS gate, is not defined by an oblique line and provides a nonuniform gate length at least in one of regions aligned in a direction of a gate width. A channel region formed by the control gate provides a region of strong electric fields and a region of weak electric fields. Consequently, a conductance of a whole channel region formed by the MOS gate and the control gate, i.e., a gain coefficient β of the semiconductor element can be modulated in accordance with voltages applied to the MOS gate and the control gate.

Owner:FUSAYOSHI HIROTSU +1

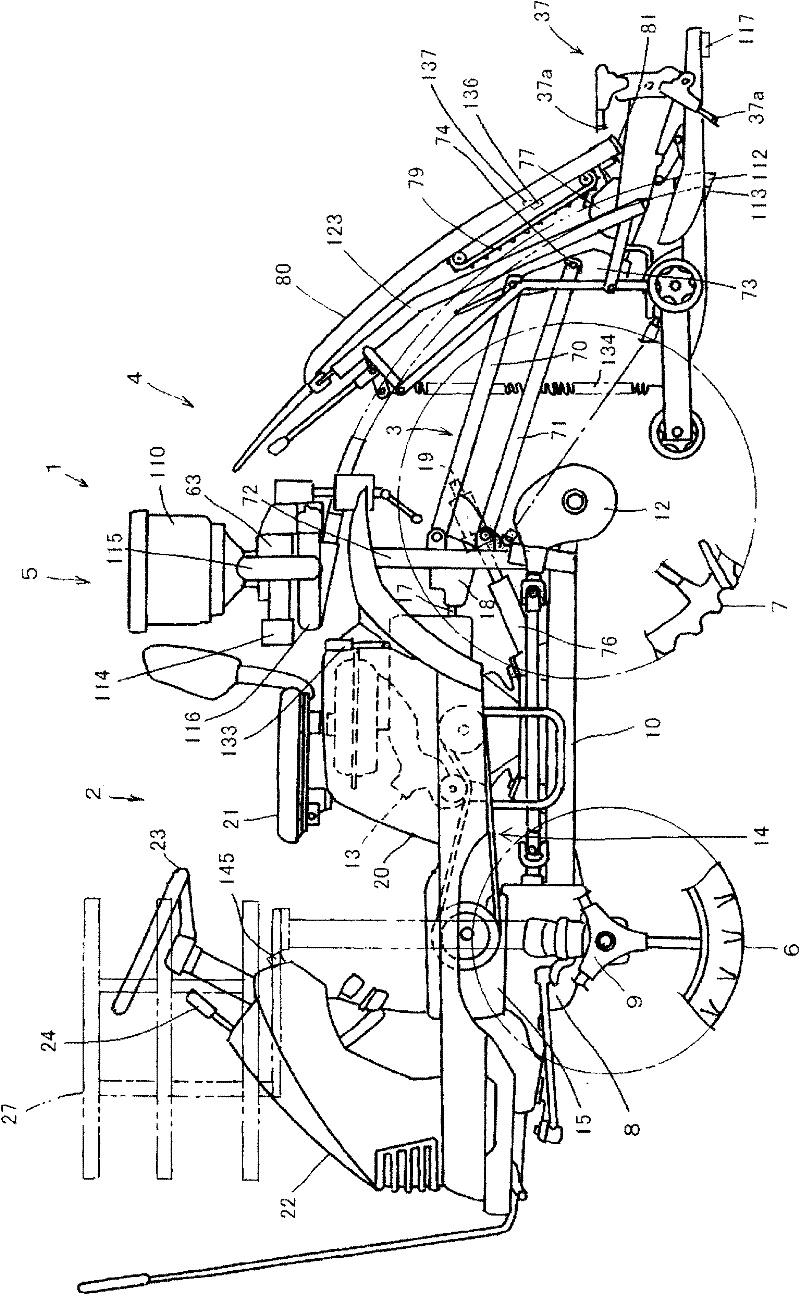

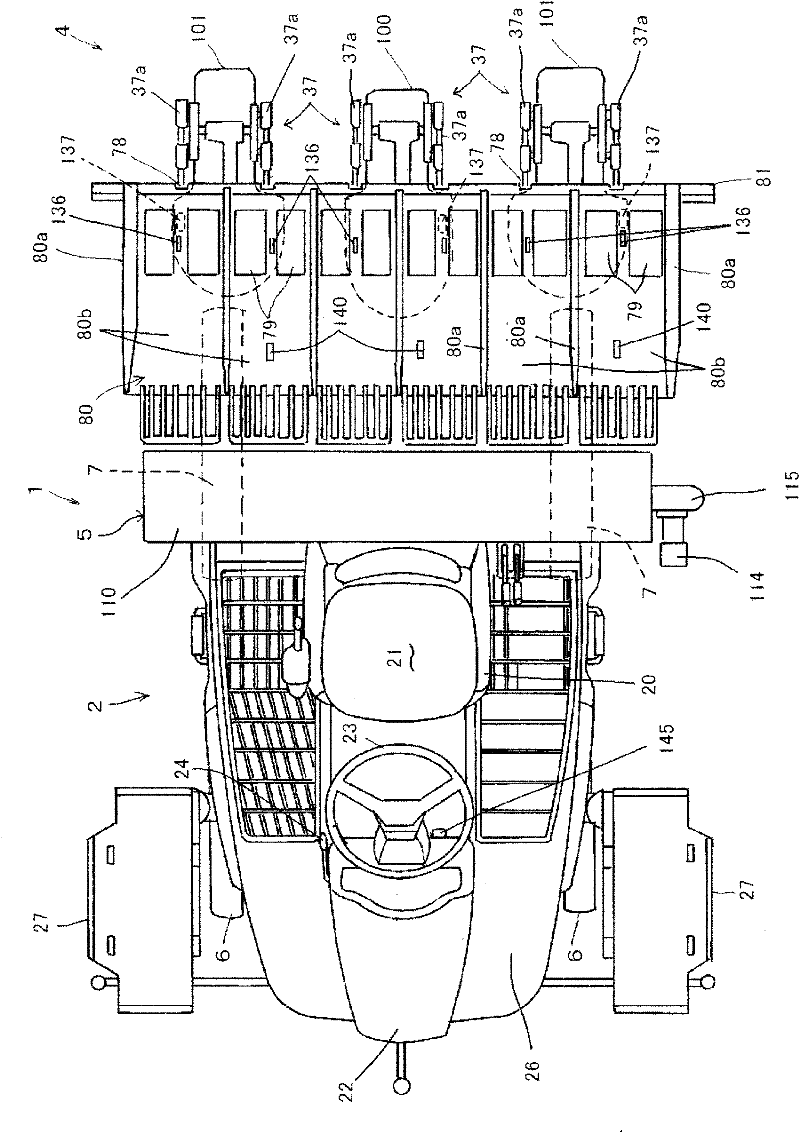

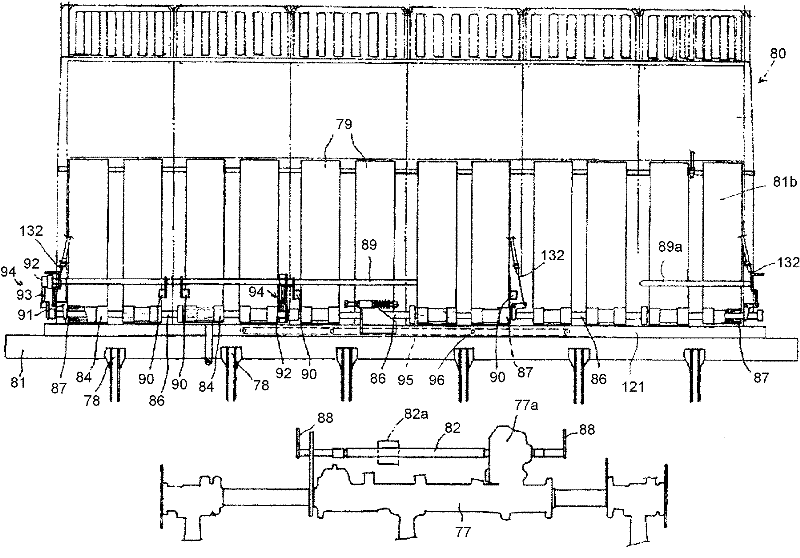

Seedling transplanting machine

The invention provides a seedling transplanting machine, wherein the maintenance work of a seedling loading table is easily performed even when a seeding delivering device and a seedling transplanting device are arranged to be complex. According to the seedling transplanting machine, a running body is equipped with a seedling transplanting portion via a lifting link device. The seedling transplanting portion is equipped with a transmission case, a seedling loading table (80) for loading seedlings, a seeding carrier (81) arranged at the lower part of the seedling loading table (80) along a right and left direction, a seedling sending device for sending the seedlings on the seedling loading table (80) and a guide path cam for the left and right movement of the seedling loading table (80). The seedling transplanting machine is characterized by comprising a connection mechanism (40) for connecting the seedling loading table (80) with the guide path cam. The connection mechanism (40) is formed by a rising guide member (43) for forming a moving groove and a rising support shaft (46) freely arranged inside the moving groove. The rising support shaft (46) is fixed on the rising support shaft (46).

Owner:ISEKI & CO LTD

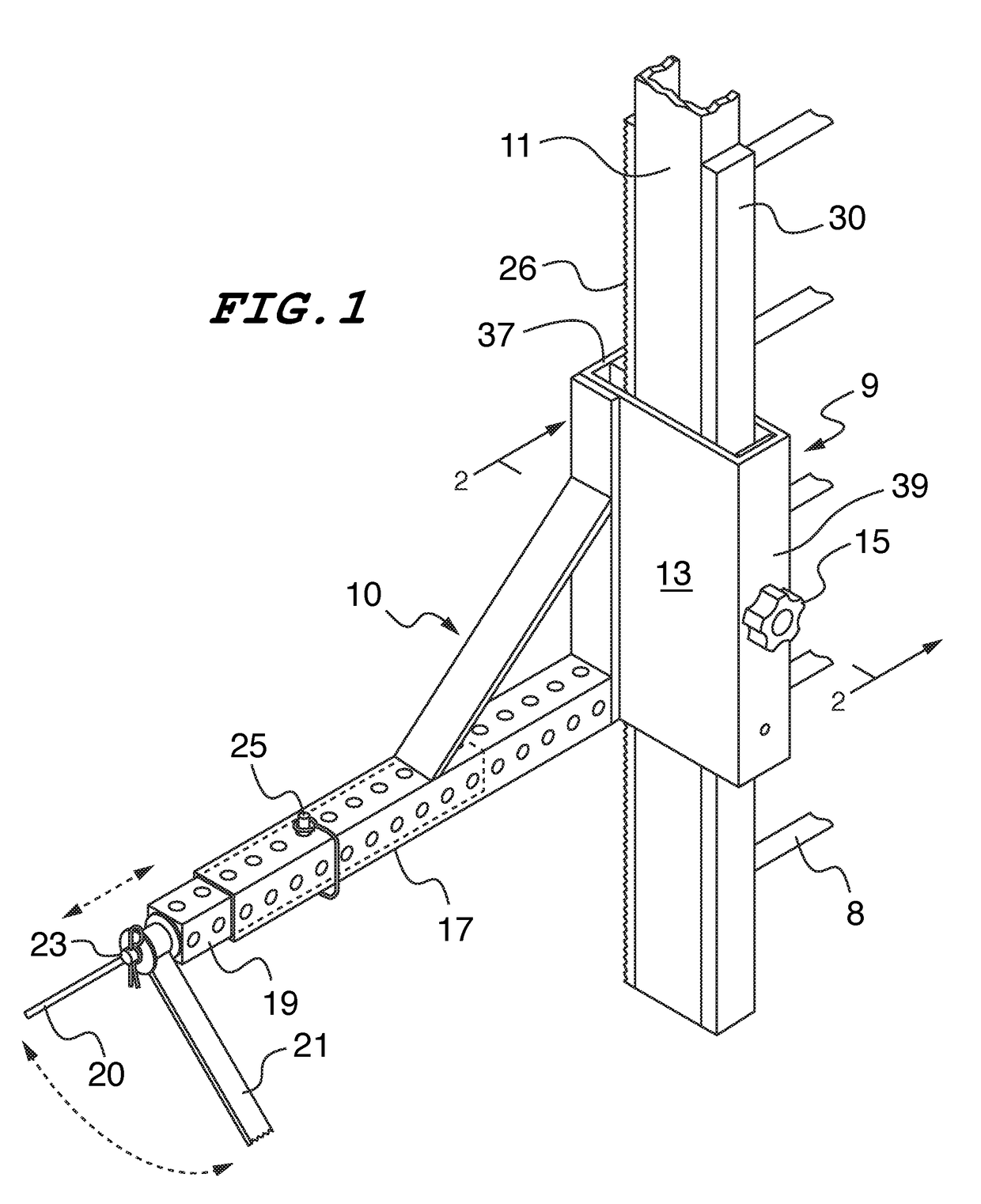

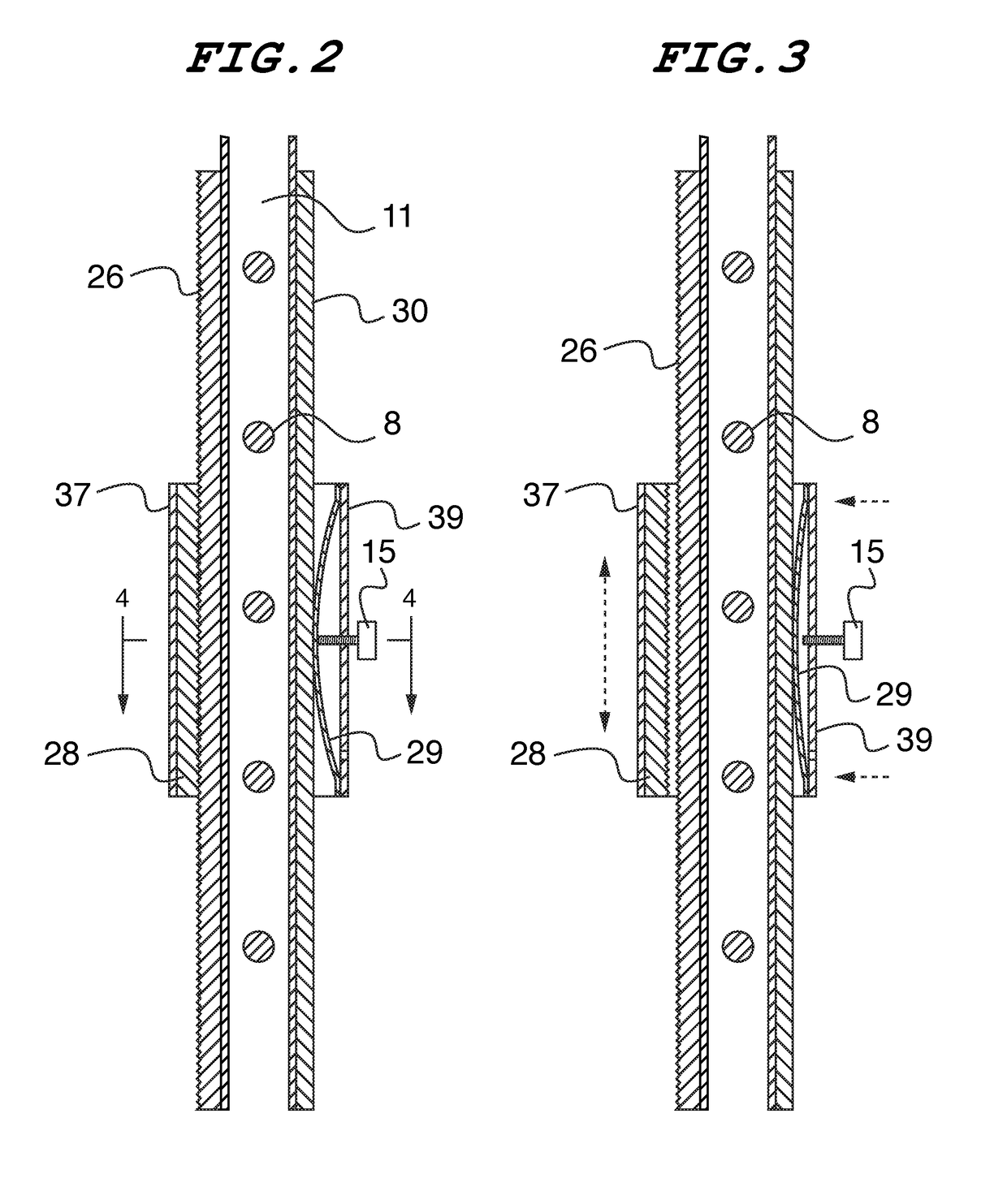

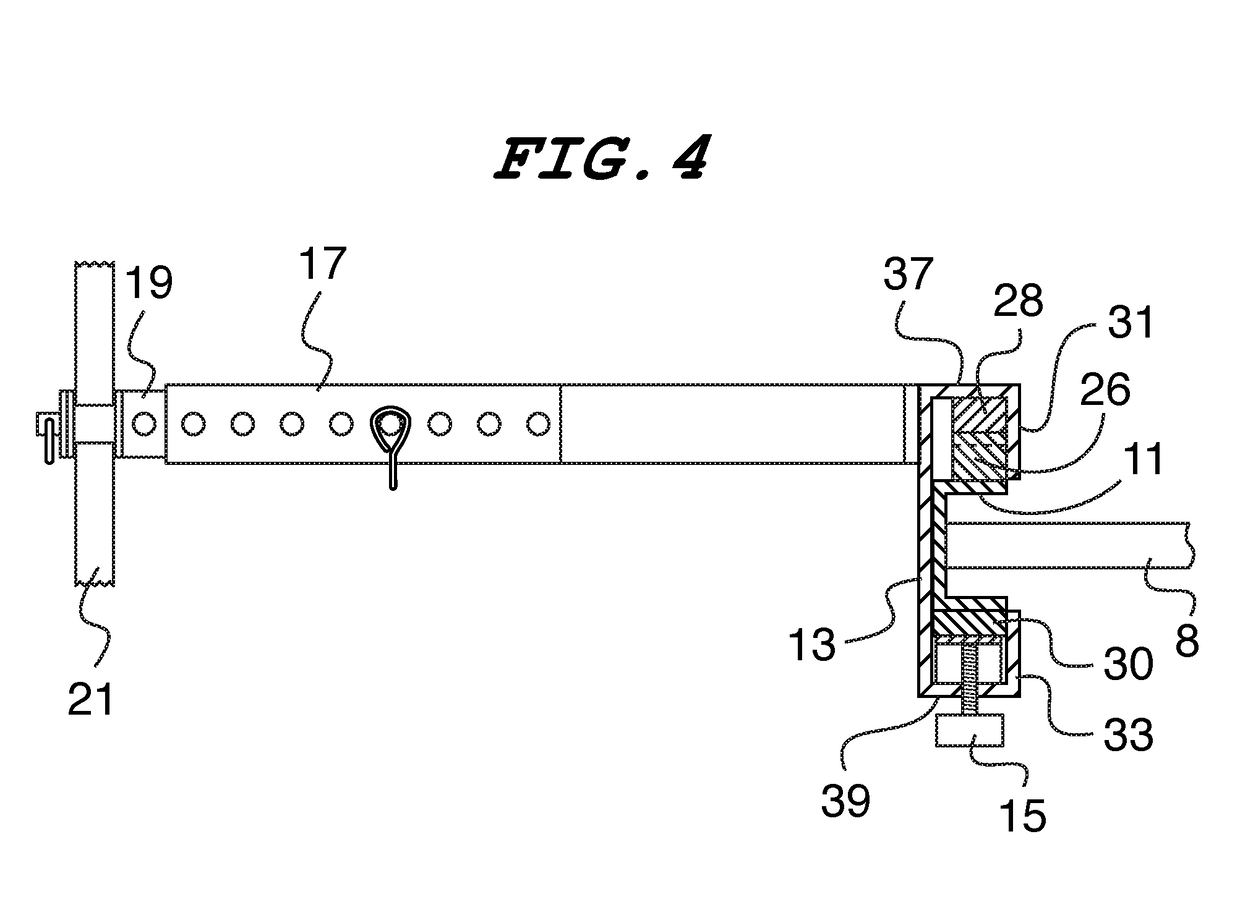

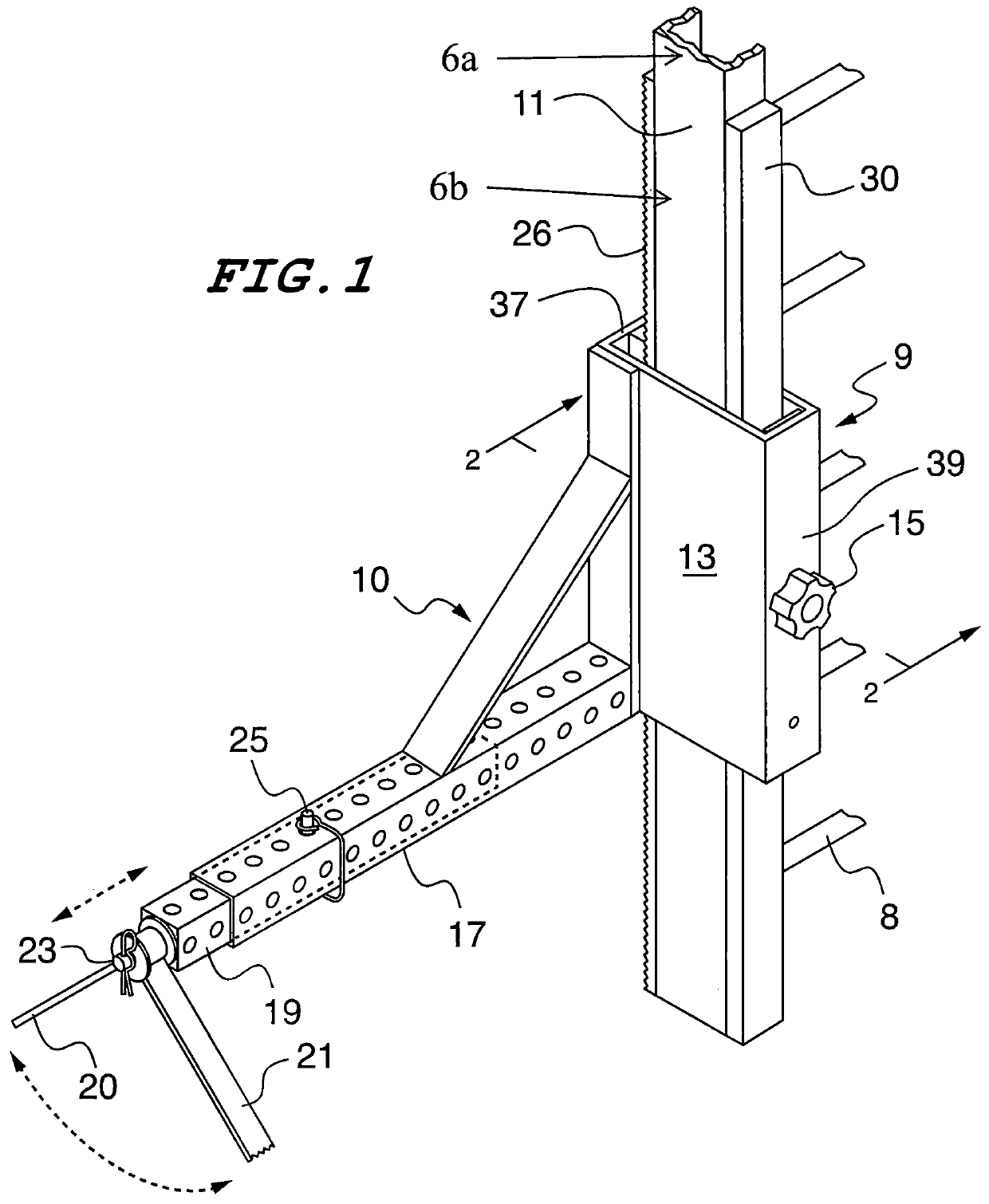

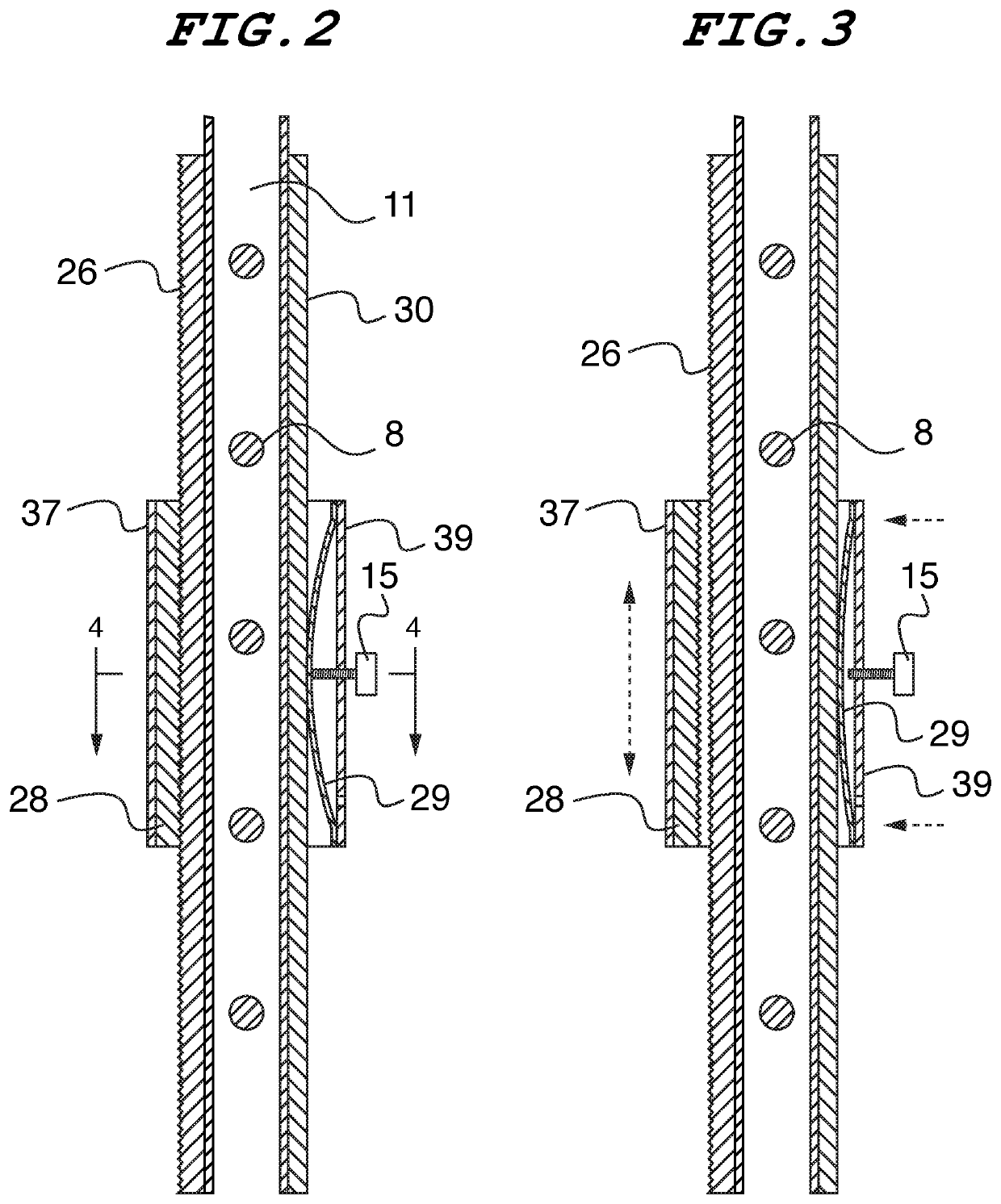

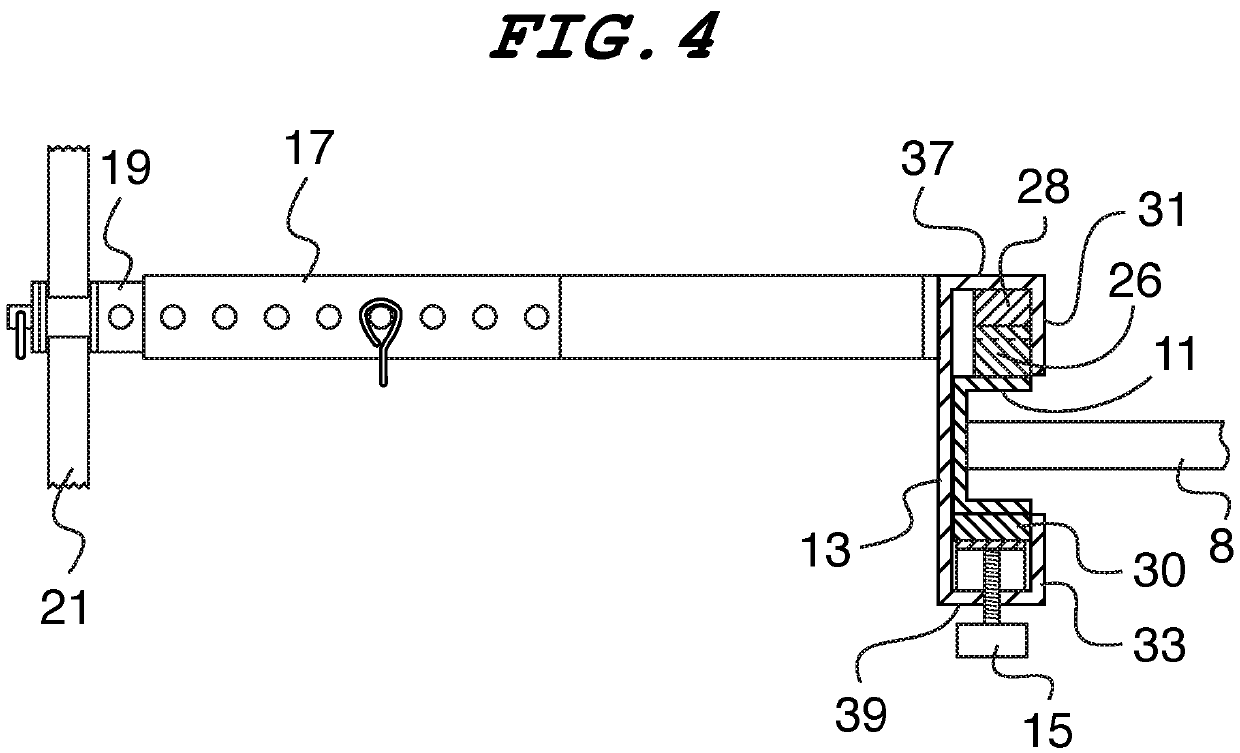

Ladder Stabilizer and Leveler

ActiveUS20190055784A1Overcome deficienciesEasily adjust to any sloping or uneven terrainLaddersTerrainSelf adjusting

A ladder stabilizer comprises a pair of stabilizer brackets attached to the ladder side rails at the bottom on either side. Each bracket has a C-shaped clamping mechanism that utilizes a toothed gear rack which engages / disengages with mating teeth of a corresponding gear rack on the ladder rail. The gear-like engagement of the teeth provides a positive locking of the attachment member to the ladder. A spring and locking screw allow ease of adjustment and a positive lock at the desired location along the ladder side rail. The rack is attached longitudinally along the length of each rail to provide a range of length adjustment to the feet. This permits one side to be longer than the other to accommodate a laterally sloping terrain. The brackets have rotatable, laterally extending A-frames with ground-engaging feet which self-adjust to a terrain which is sloping from front-to-back or vice versa.

Owner:KAZANJIAN DAVID

Smilled spline apparatus and smilling process for manufacturing the smilled spline apparatus

By combining shaping and milling actions, or smilling, the cutting tool can move through the entire usable portion of the spline and machine a tool relief into the face of the adjacent feature such as a shoulder before retracting, reversing direction, and repeating the cycle. The smilling apparatus and manufacturing method eliminates the need for an annular spline relief and the full length of spline engagement can be utilized for strength. The effective width of the spline connection apparatus manufactured by the smilling process conserves space and increases the load carrying capability of the spline connection.

Owner:FAIRFIELD MFG CO INC

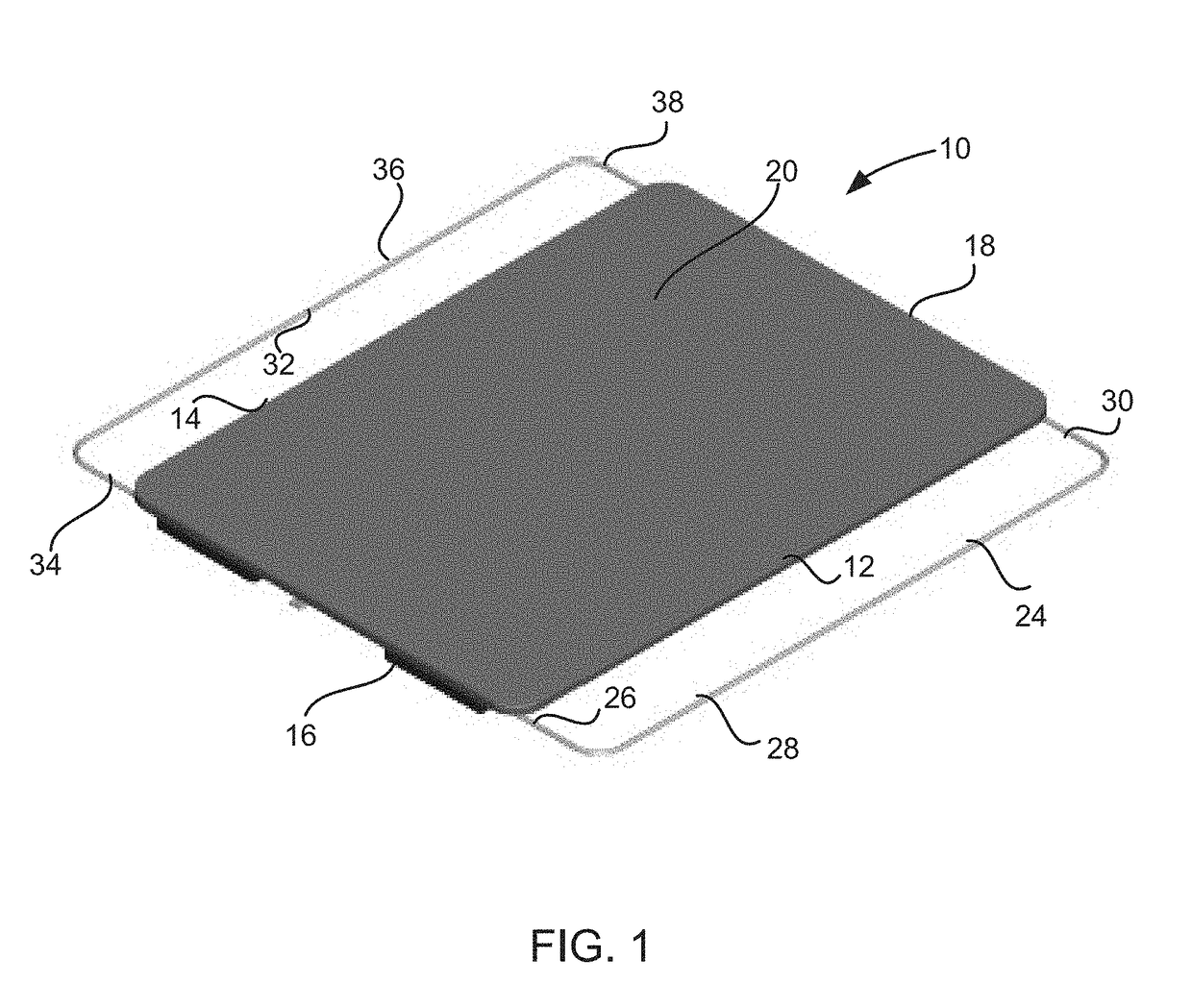

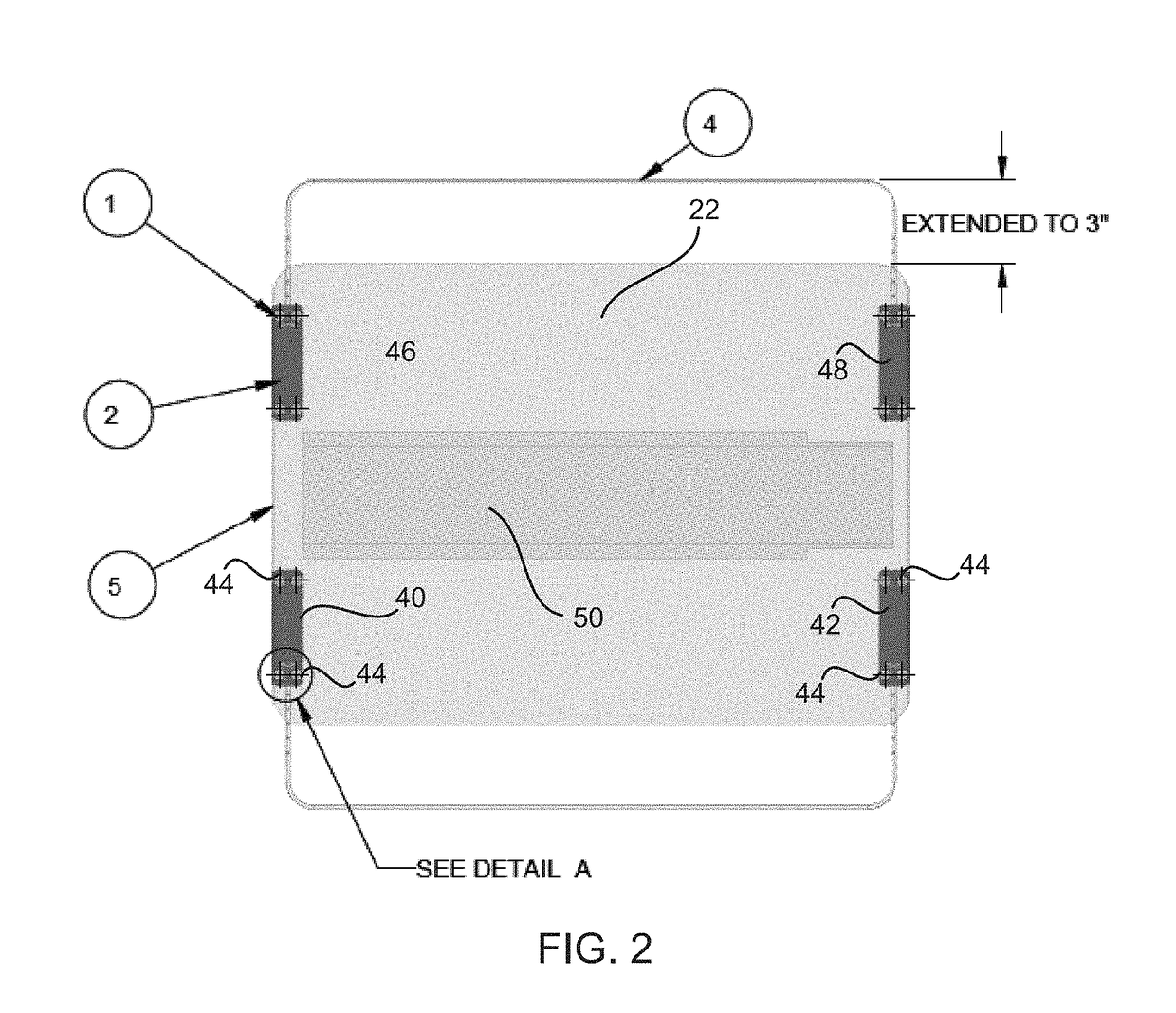

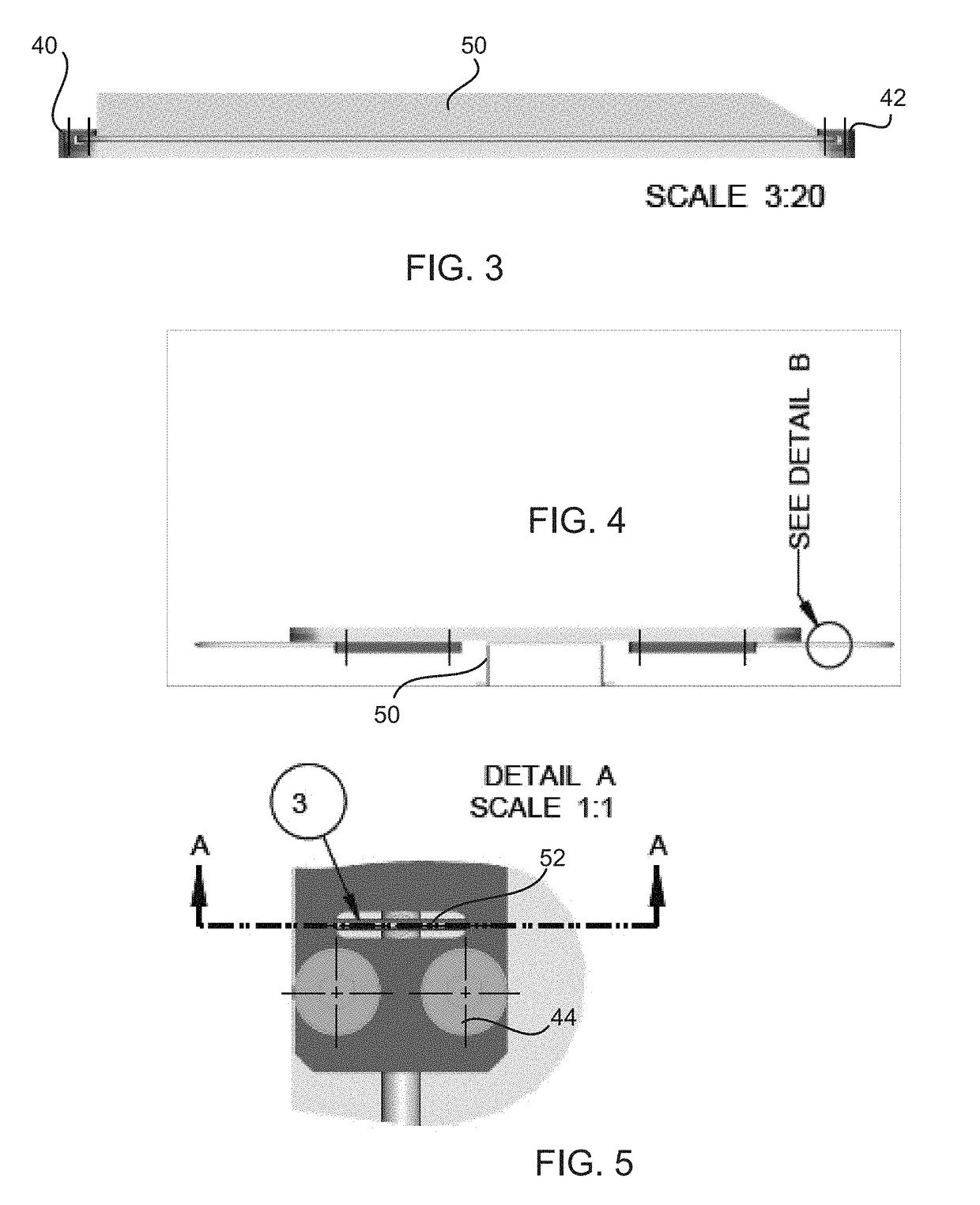

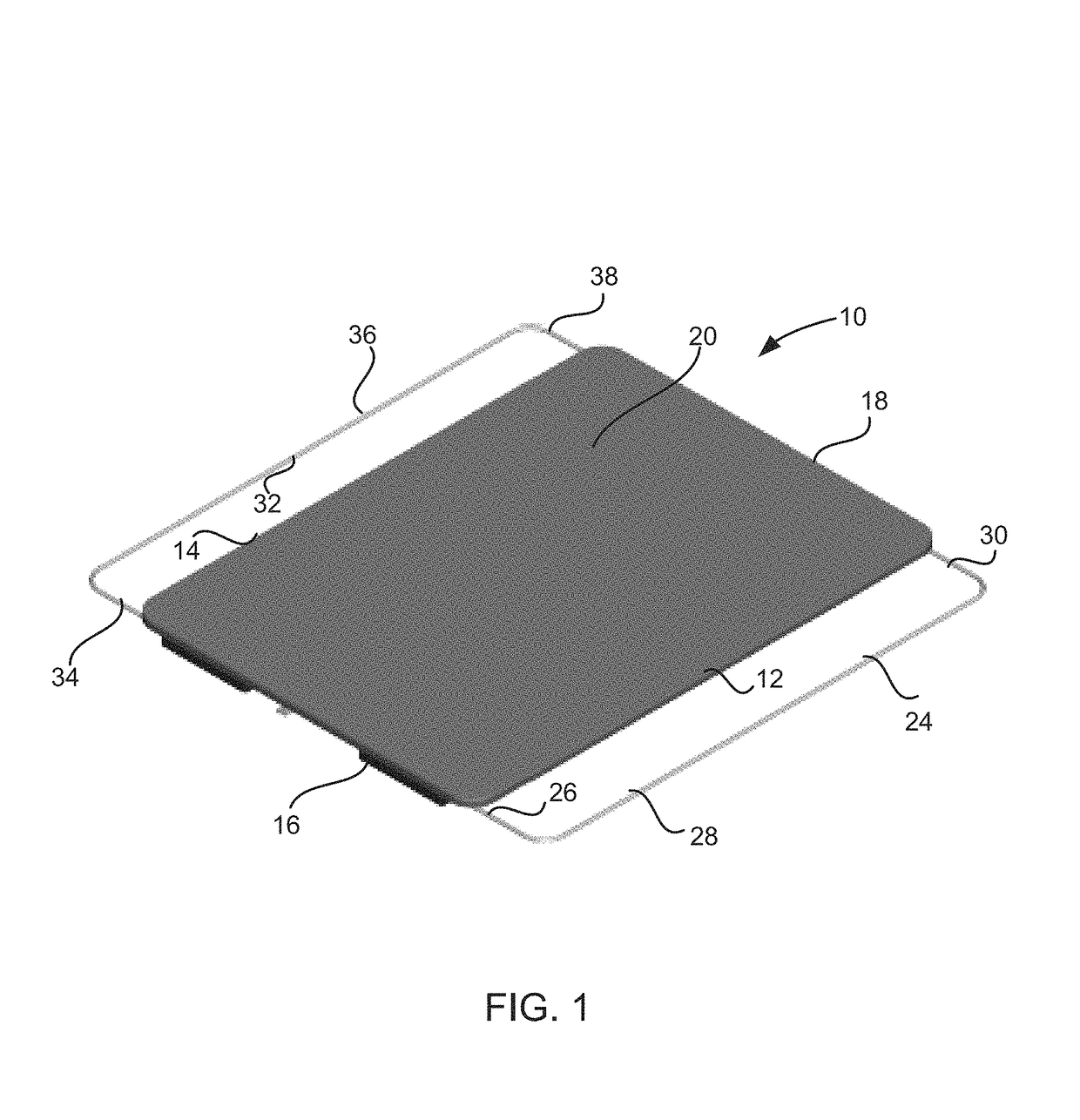

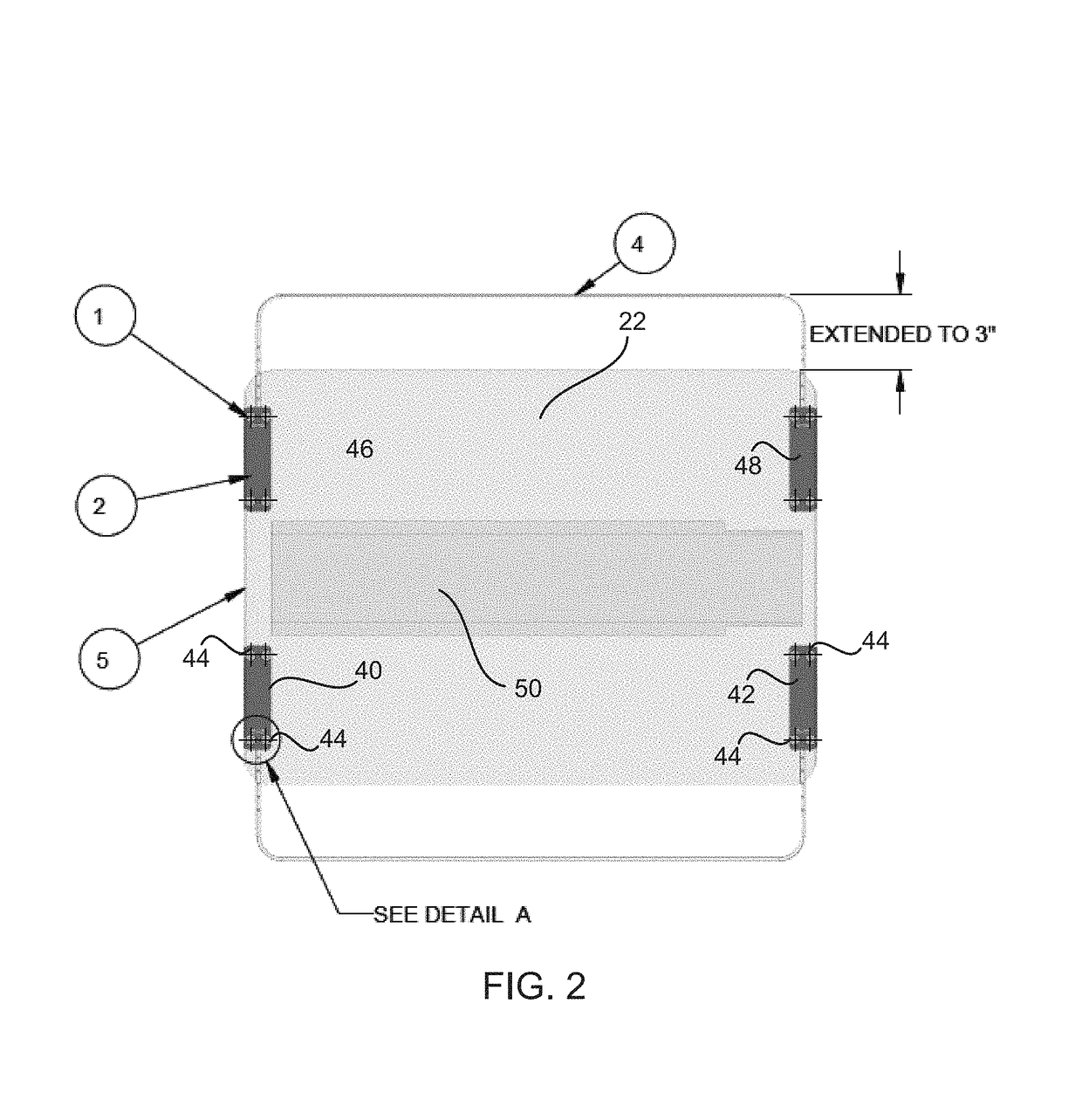

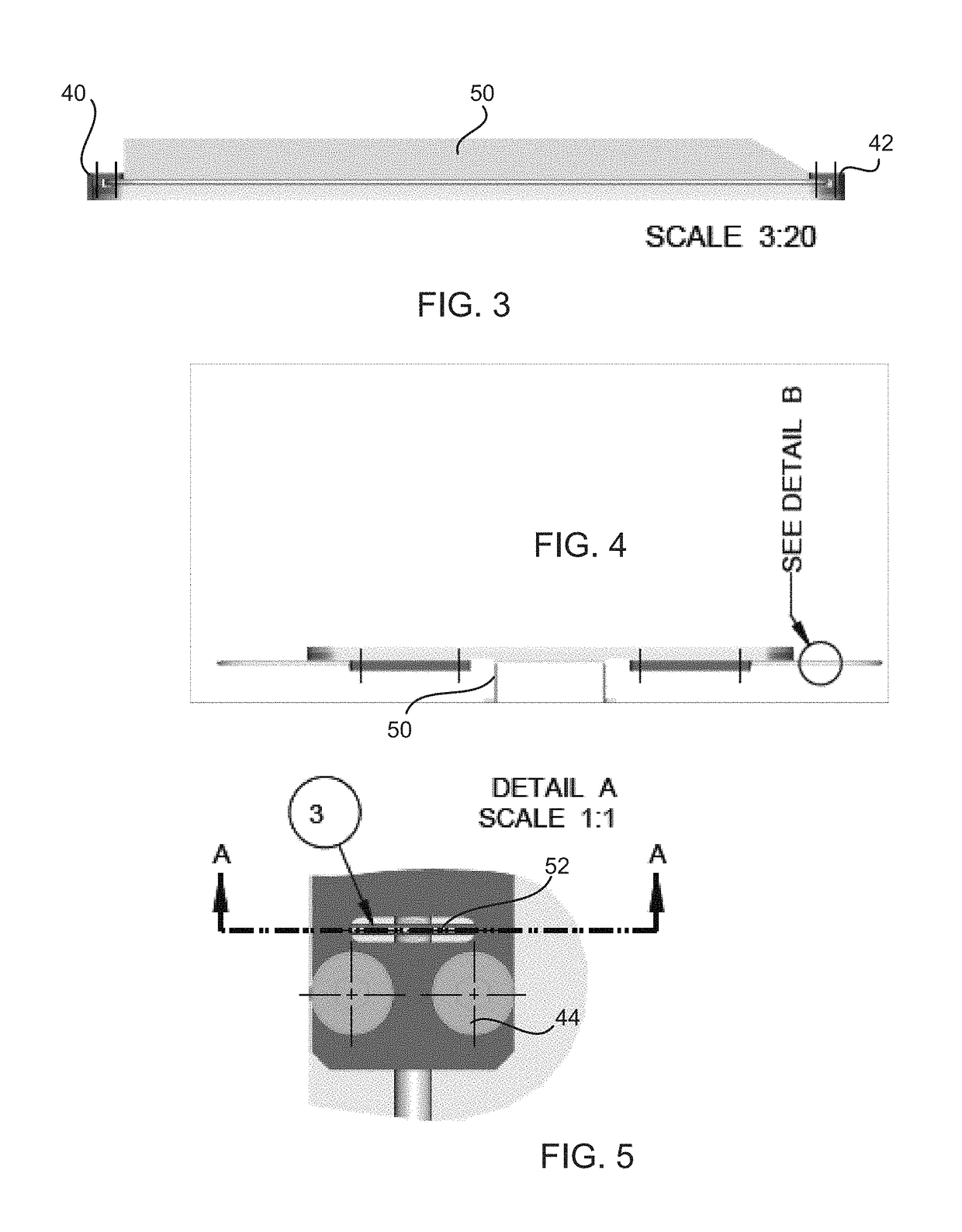

Textile pallet with adjustable frame

InactiveUS20180370258A1Improve scalabilityQuick alignmentScreen printersTypewritersPalletElectrical and Electronics engineering

A textile holder having adjustable side extensions is provided. The side extensions can be generally U-shaped metal rods or wires having a plurality of spaced notches for adjusting the spacing of the wires from a central pallet portion. Alternatively, other structures, such as plates can be used for the side extensions. The plates can include one or more slots. Screws or posts on the central pallet portion can be used to align the plates at appropriate extension distances and hold the plates in place.

Owner:M&R PRINTING EQUIP

Connector having improved contacts

ActiveUS20120202395A1Strong couplingSufficient flexibilityElectrically conductive connectionsCoupling contact membersElectrical conductorEngineering

An electrical connector for connecting a conductor of a daughter card connector wafer with a blade in the housing of a backplane connector. The daughter card conductor has a body with two elongated beams extending outward from the body. The two elongated beams each have an outer edge and an inner edge, whereby an opening is defined between the inner edges. The backplane conductor has a body with a narrowed tab portion extending outward from said second conductor body. The narrowed tab portion having outer opposite edges and is sized so that the narrowed tab portion fits between at least a portion of the outer edges of the two elongated beams, and in some cases between at least a portion of the inner edges of the two elongated beams.

Owner:AMPHENOL CORP

Image forming apparatus

InactiveUS7412177B2Efficient developmentEffective widthElectrographic process apparatusLatent imageImage formation

An image forming apparatus has a latent image writing device that writes an electrostatic latent image on an image bearing member, a developing device that develops a toner image based on the electrostatic latent image, a transferring device that transfers the toner image onto a recording material, a position correcting unit that corrects a position of the electrostatic latent image written by the latent image writing device, a recording material determining unit that determines whether or not the recording material has a long width, and a corrected amount changing unit that, when the recording material determining unit determines that the recording material has a long width, changes an amount of correcting the position of the electrostatic latent image to a value different from a set value for a recording material having a standard width.

Owner:FUJIFILM BUSINESS INNOVATION CORP

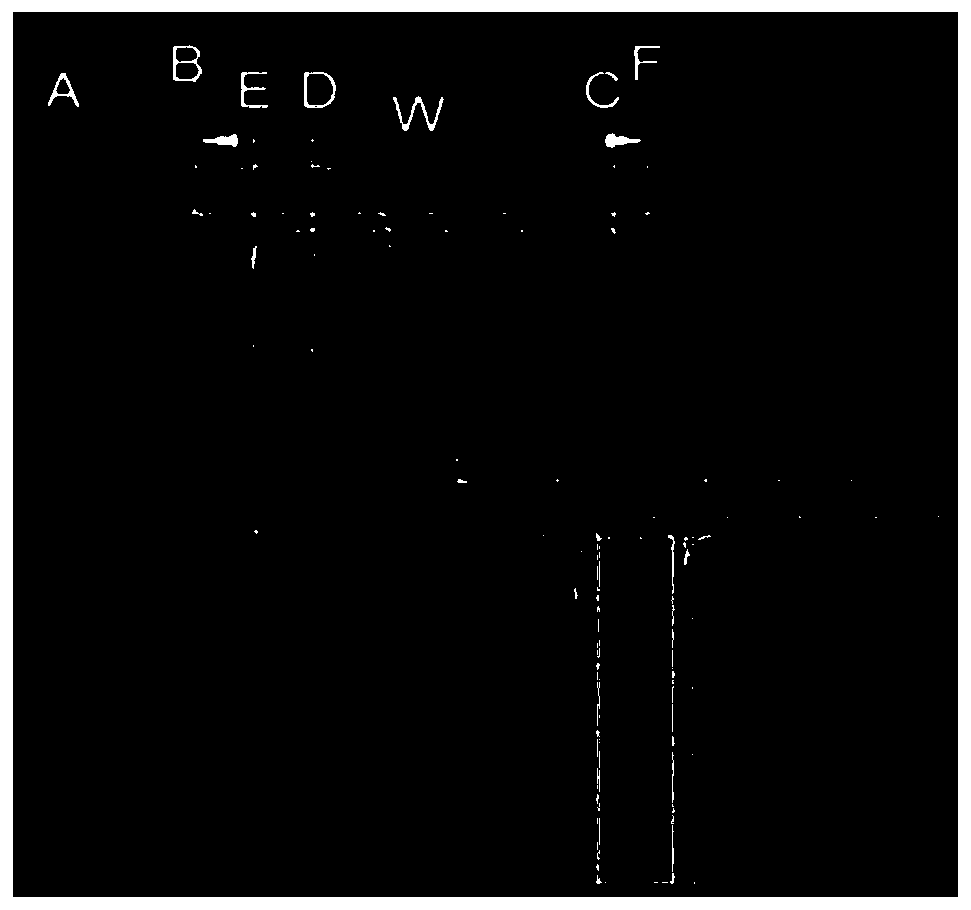

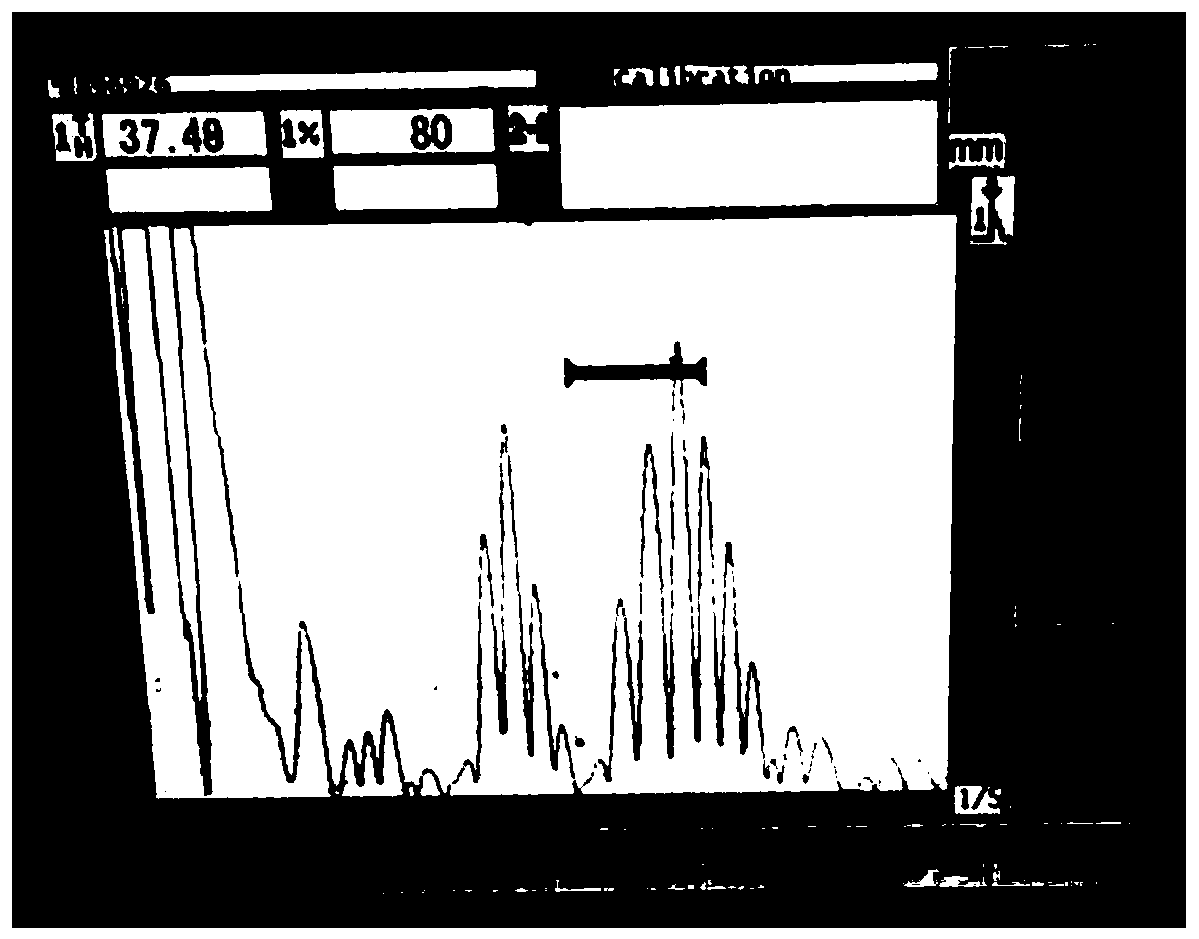

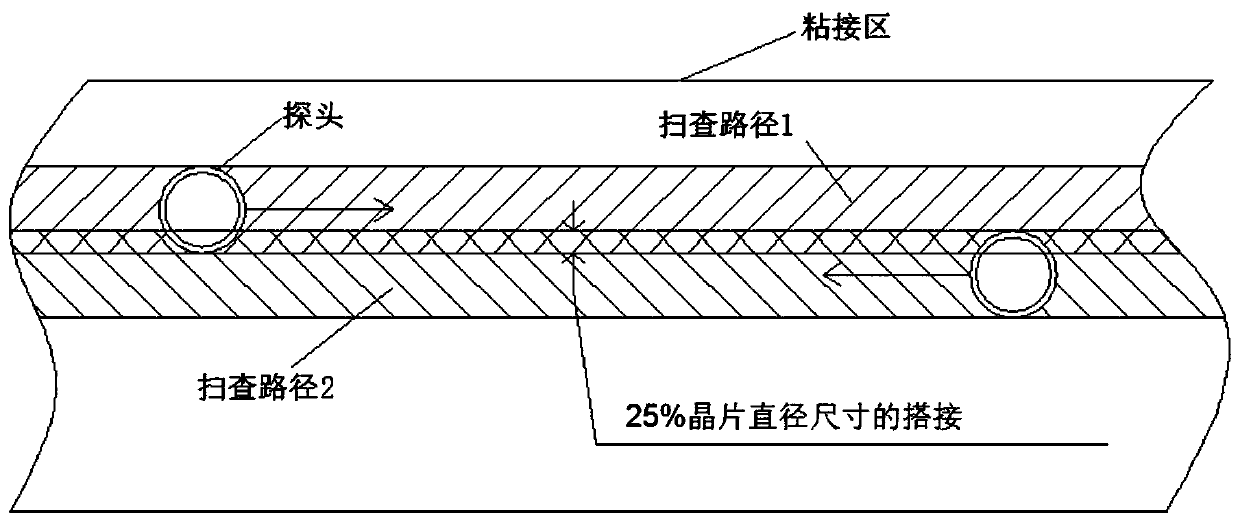

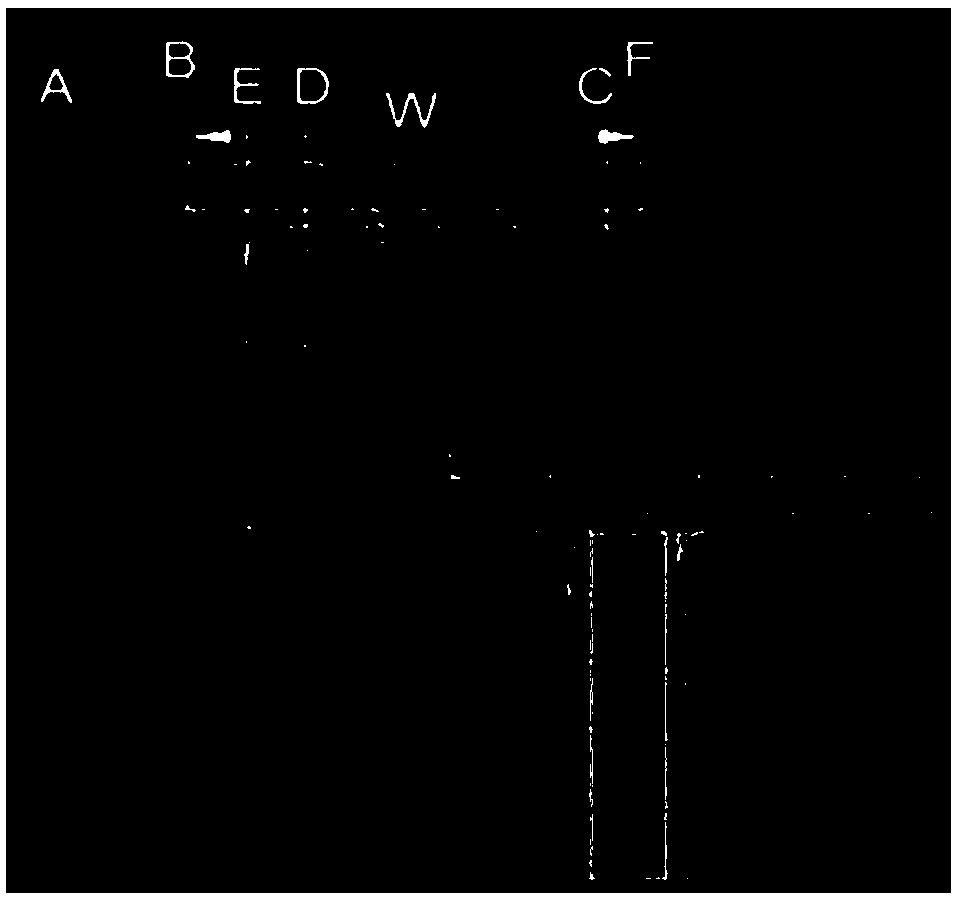

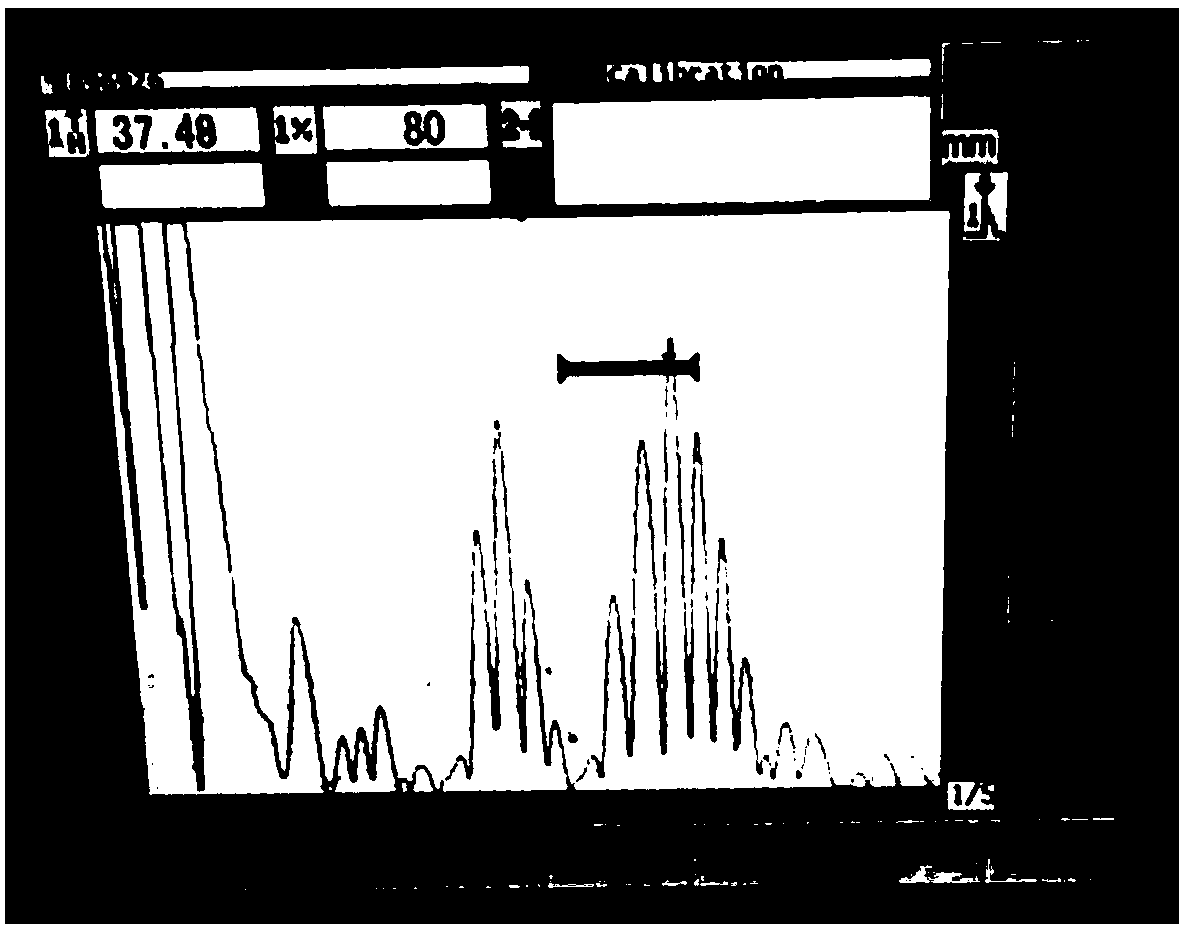

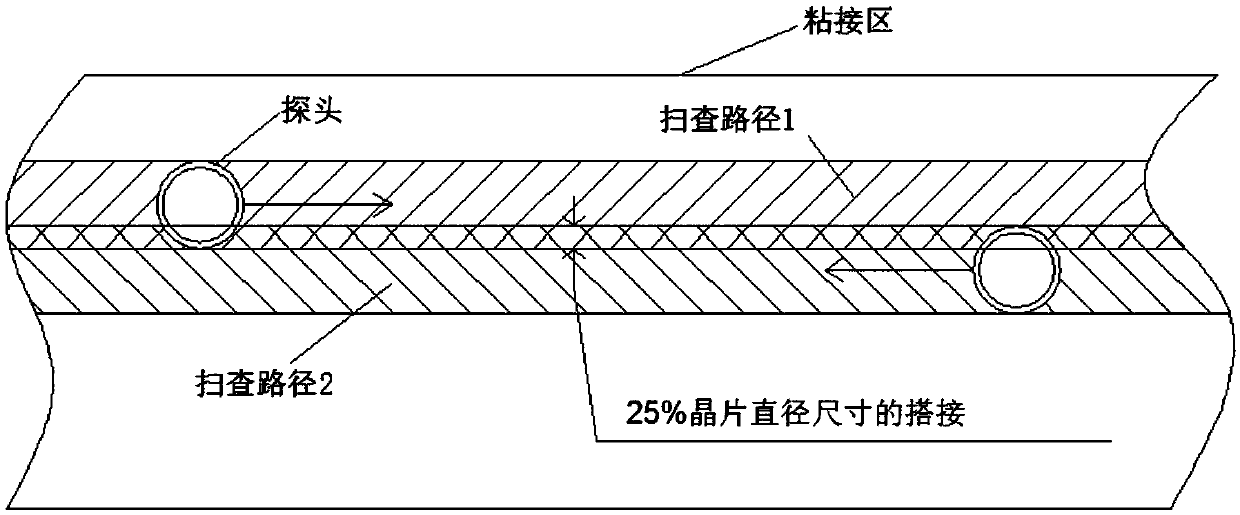

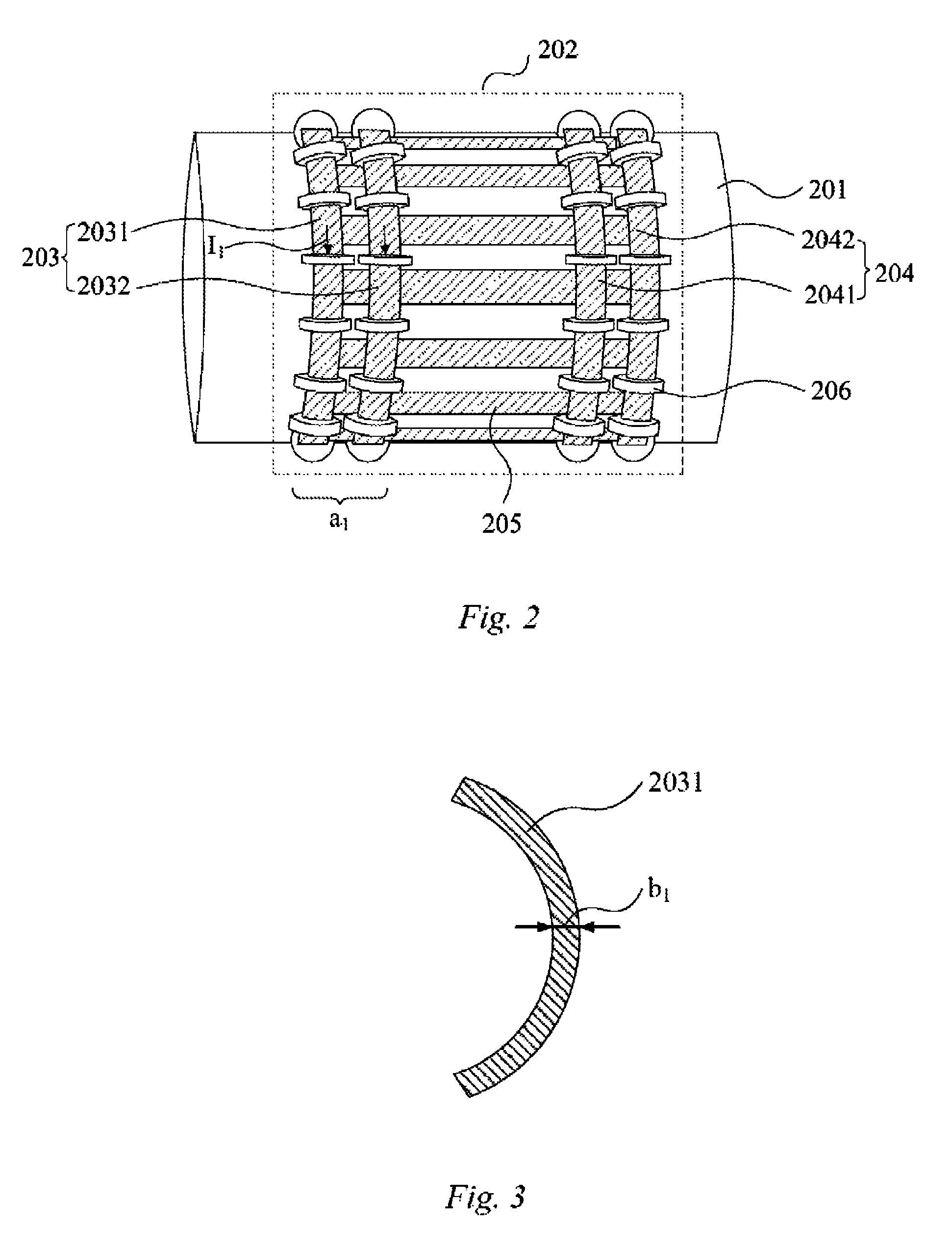

Non-destructive testing method for web bonding area of wind turbine blades

The invention discloses a nondestructive detection method for the web plate bonding area of a wind turbine blade. The nondestructive detection method comprises the following steps: firstly, determining the starting point and the finishing point of the web plate bonding area; and secondly, performing nondestructive detection on the overall web plate bonding adhesive area B-F within the chord direction range by using ultrasonic longitudinal waves. The nondestructive detection method for the web plate bonding area of the wind turbine blade provided by the invention has the benefits as follows: the specific location of web plates in the blade is determined precisely by positioning the web plate core materials, and whether the web plates are dislocated or not can also be determined; moreover, the effective width of the bonding adhesive of the web plates can be detected in the true sense, that is, not only is the width of the bonding adhesive detected, but also the measured bonding width isensured to be consistent with that required by drawings; and besides, through the detection on the defects of the adhesive layer in the bonding area of the web plates, whether the bonding between theweb plates and the main beams meets the drawing and process requirements or not is recognized, and the bonding quality of the blade is ensured.

Owner:SINOMATECH FUNING WIND POWER BLADE

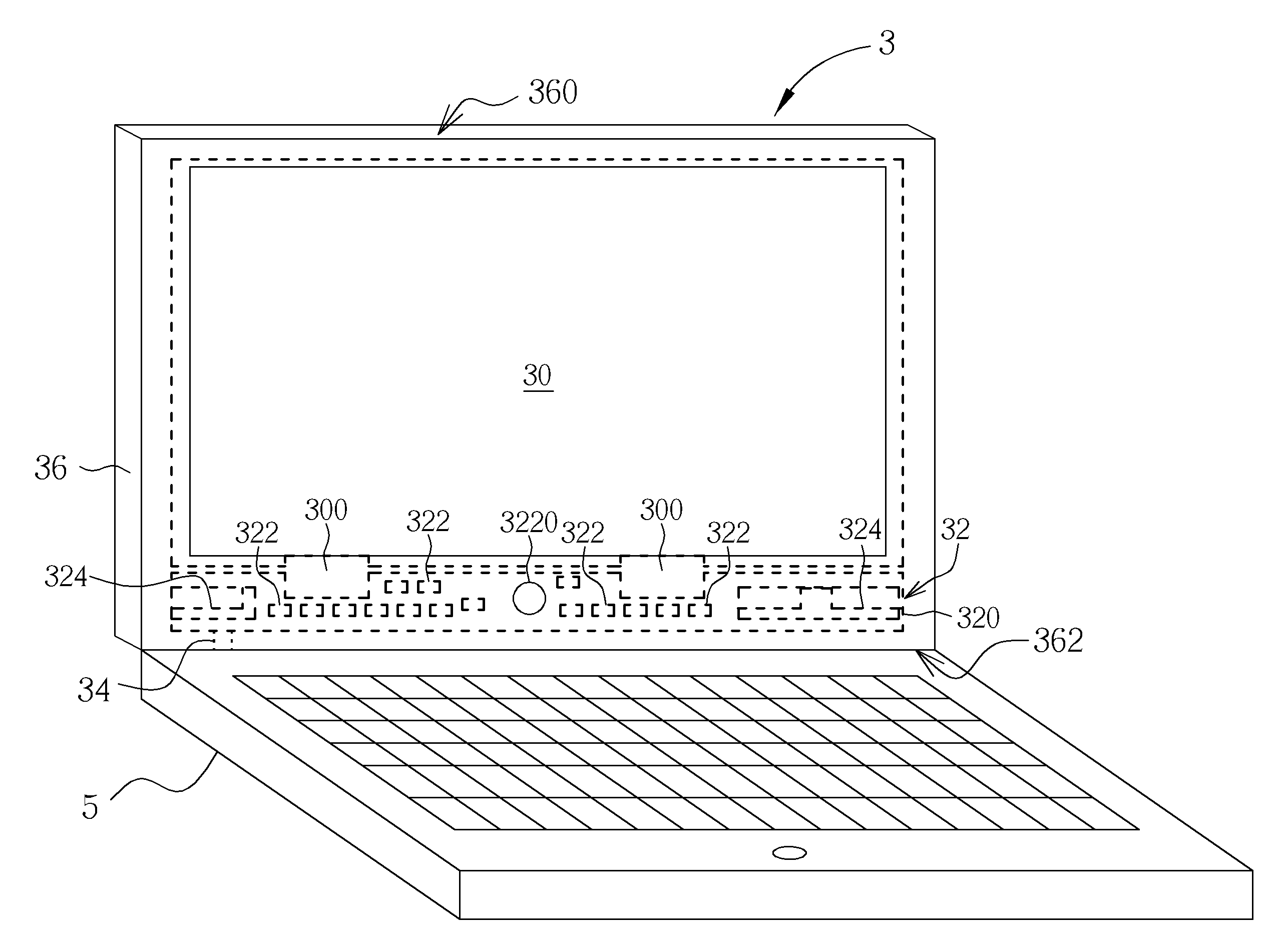

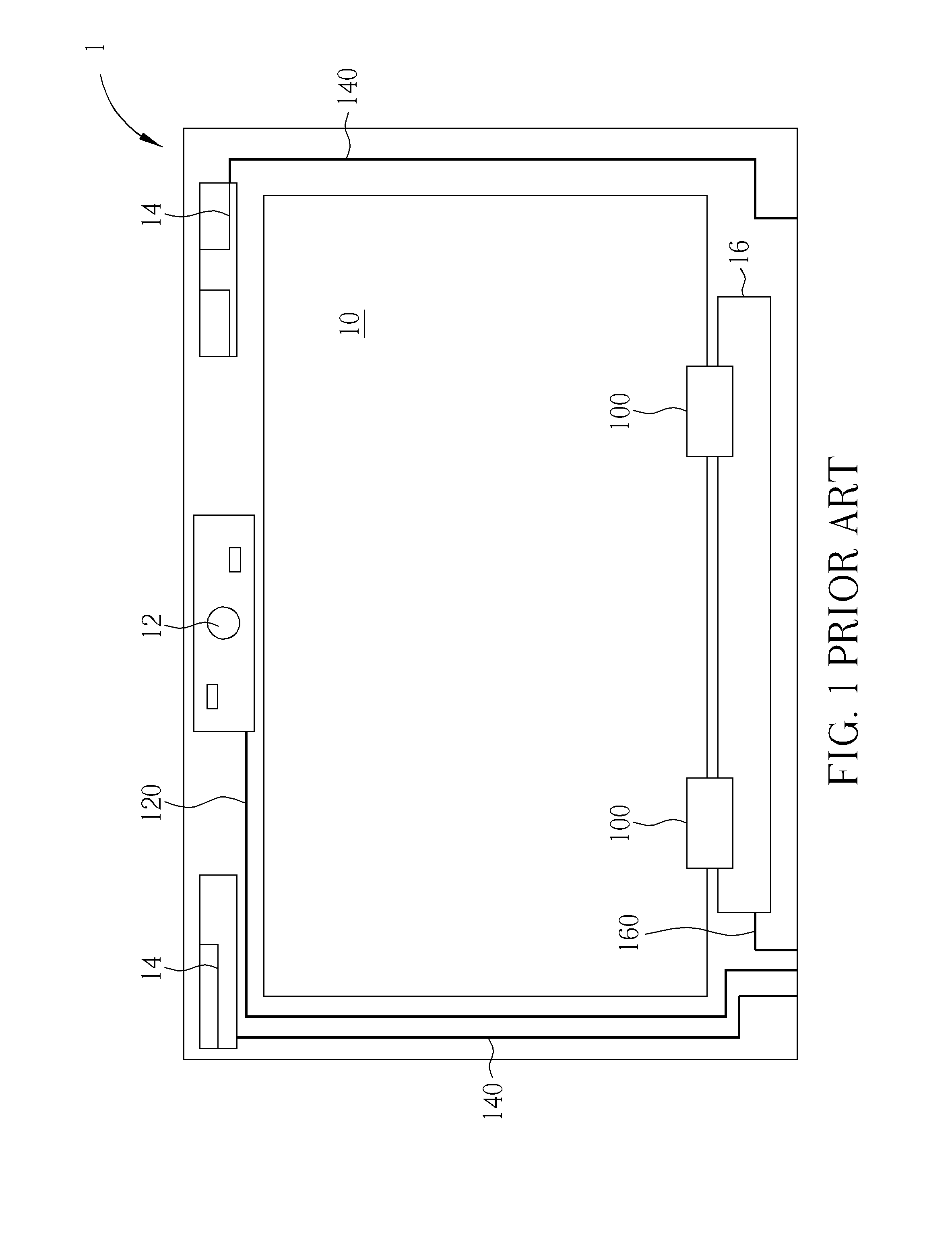

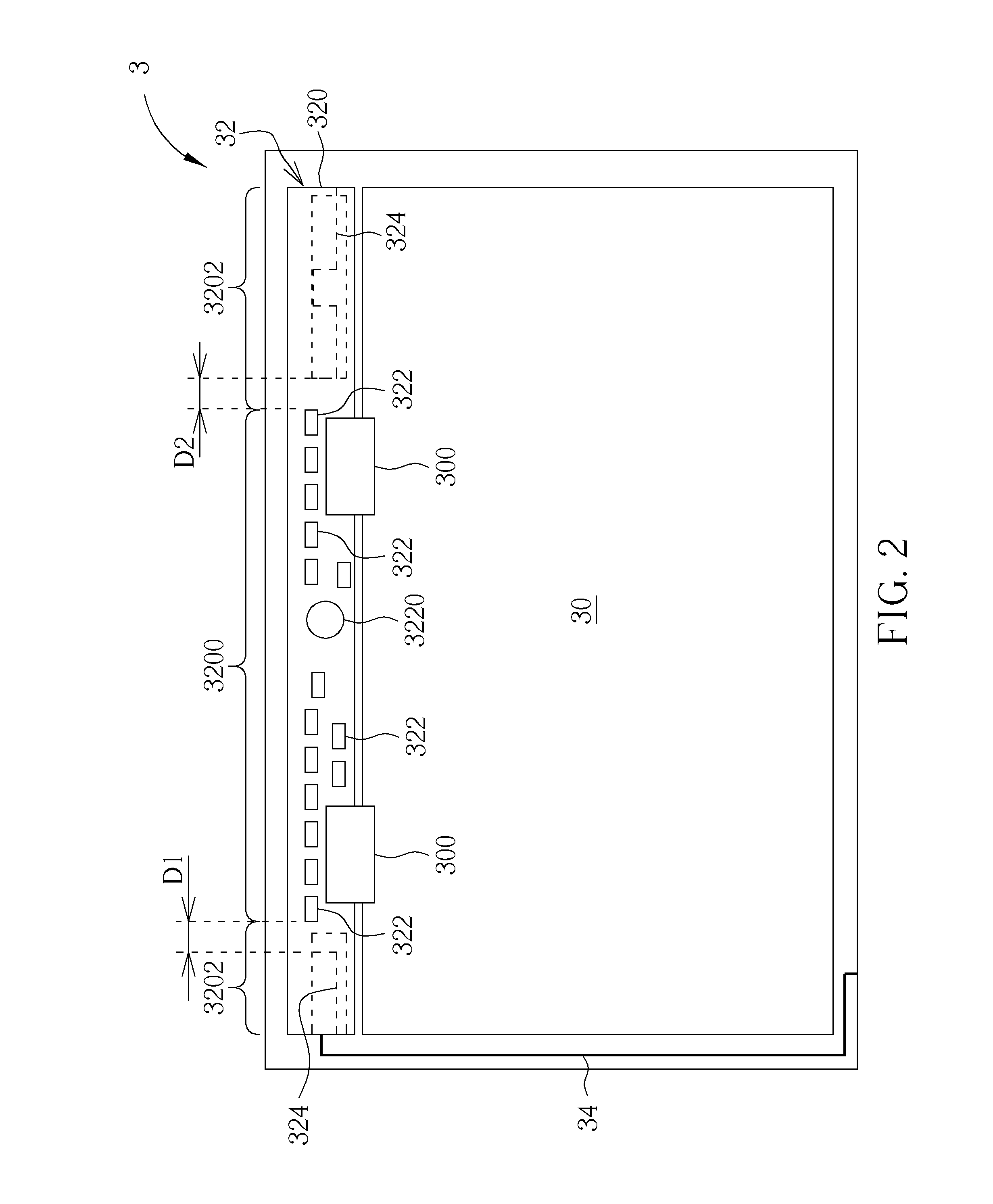

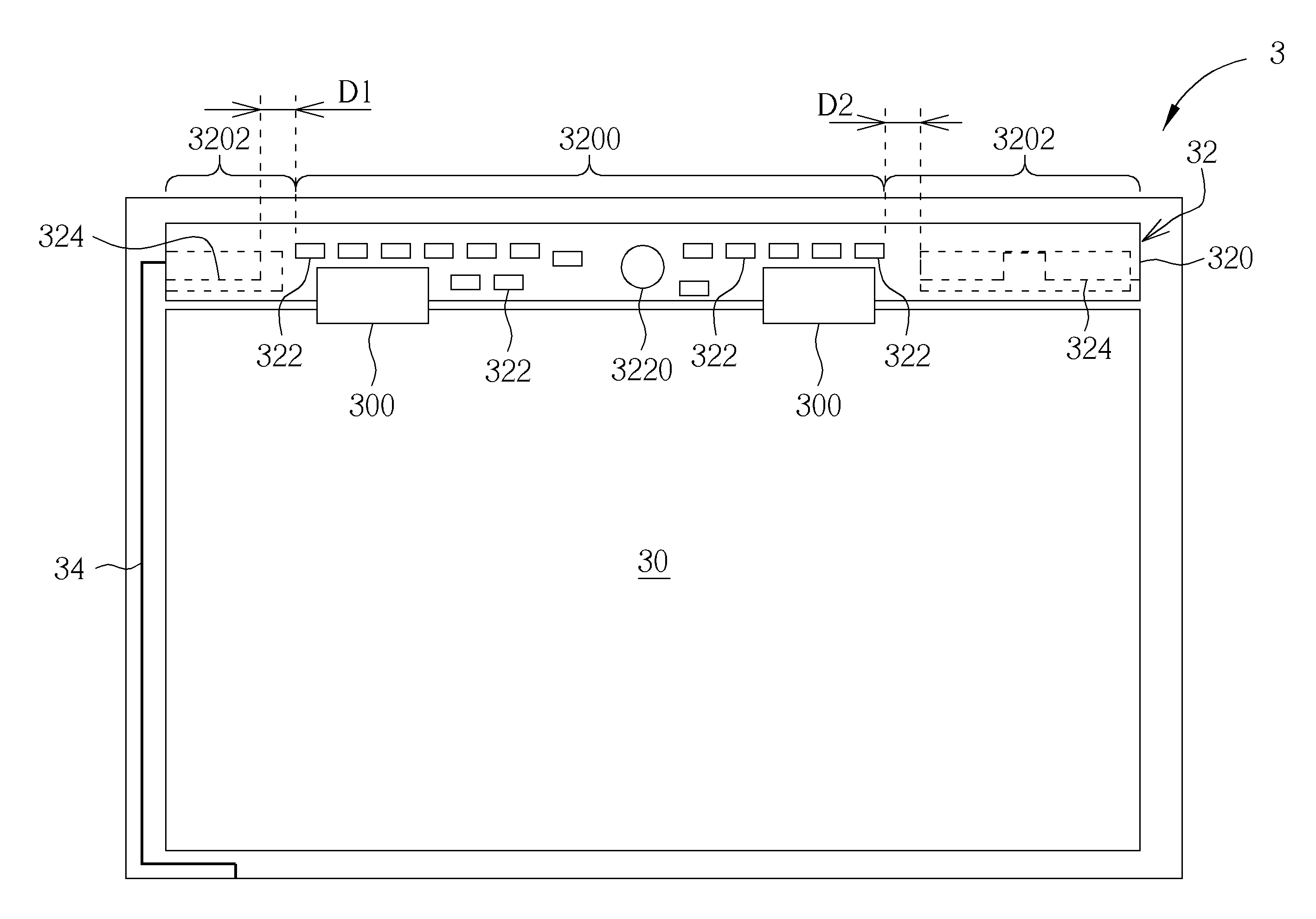

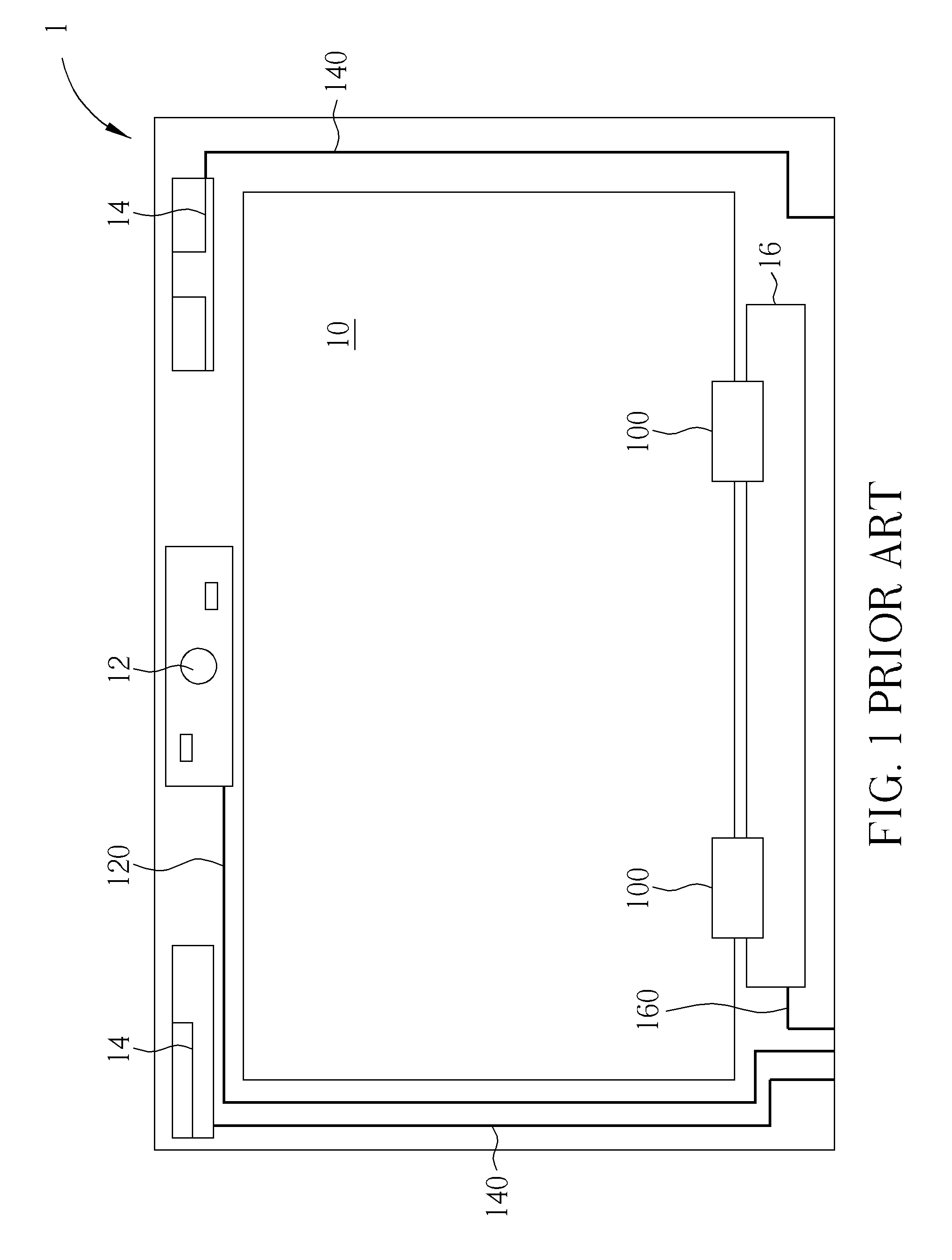

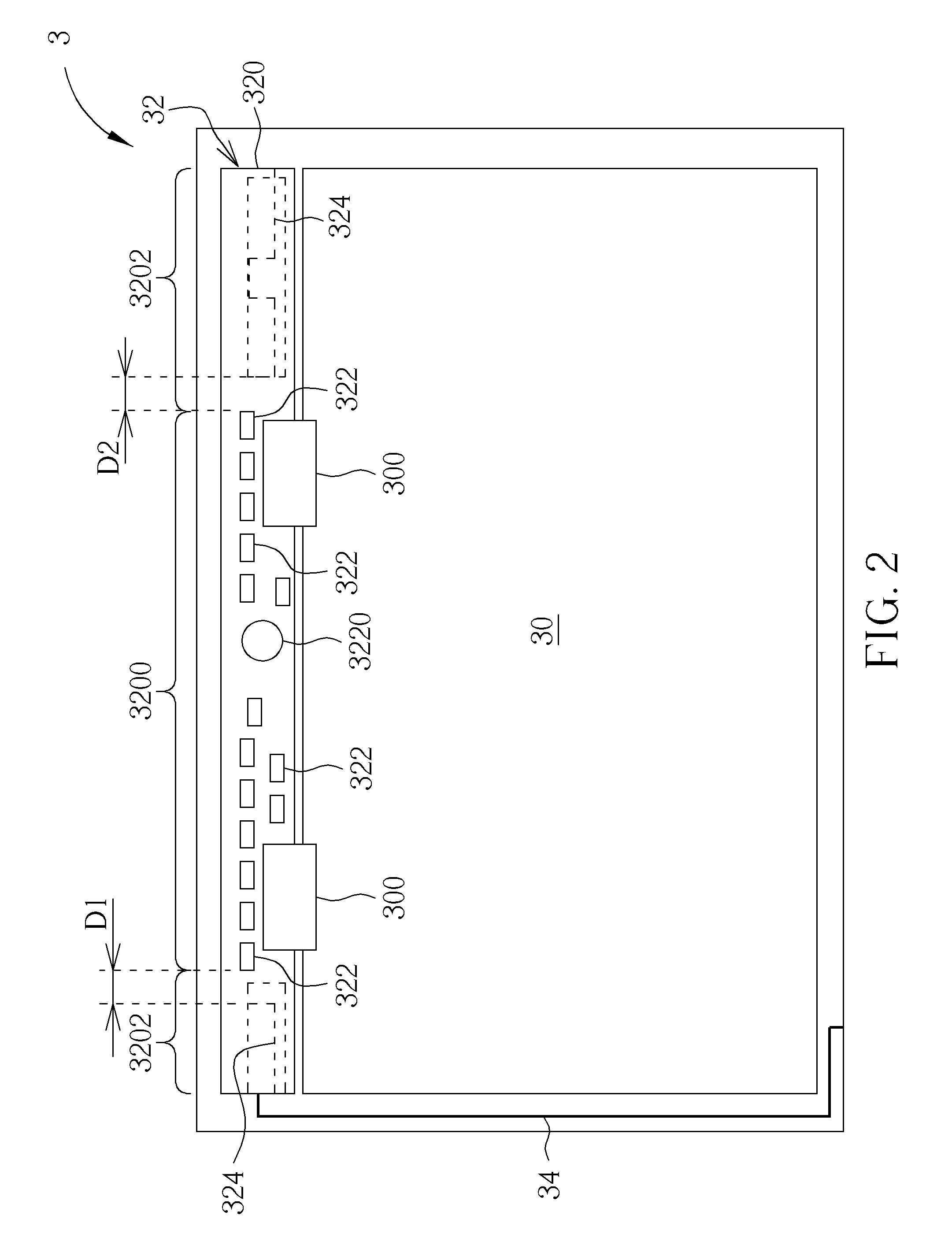

Integrated circuit board and display system

ActiveUS20130083497A1Effective widthReduce widthPrinted electric component incorporationPrinted circuit aspectsEngineeringElectronic component

An integrated circuit board includes a substrate, a plurality of electronic components and at least one antenna. The substrate has a central area and two edge areas, wherein the central area is between the two edge areas. The electronic components are disposed on the central area. The antenna is disposed on at least one of the two edge areas, wherein there is predetermined distance between the antenna and the electronic components.

Owner:AU OPTRONICS CORP

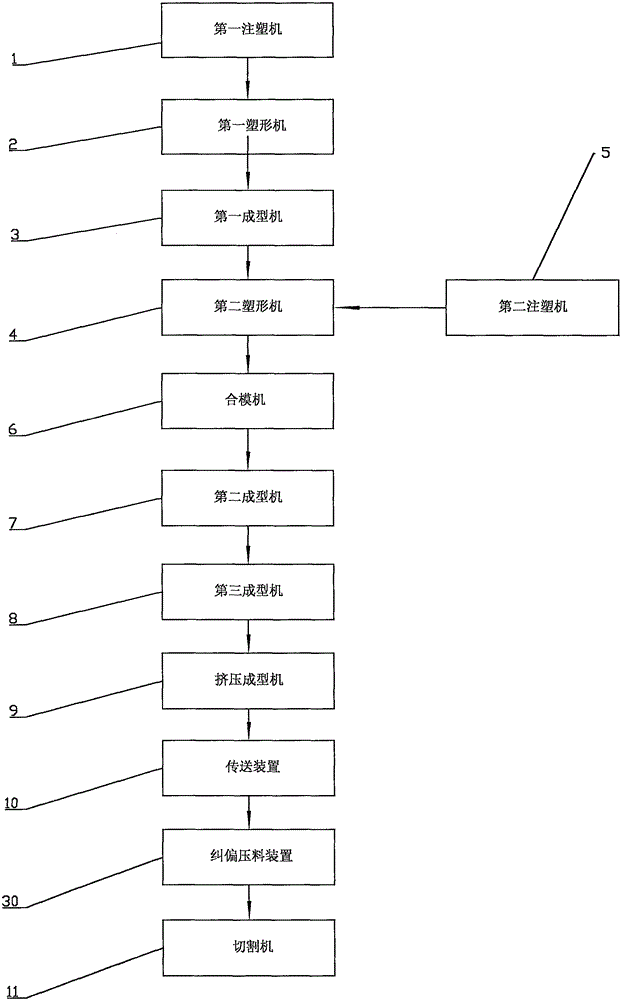

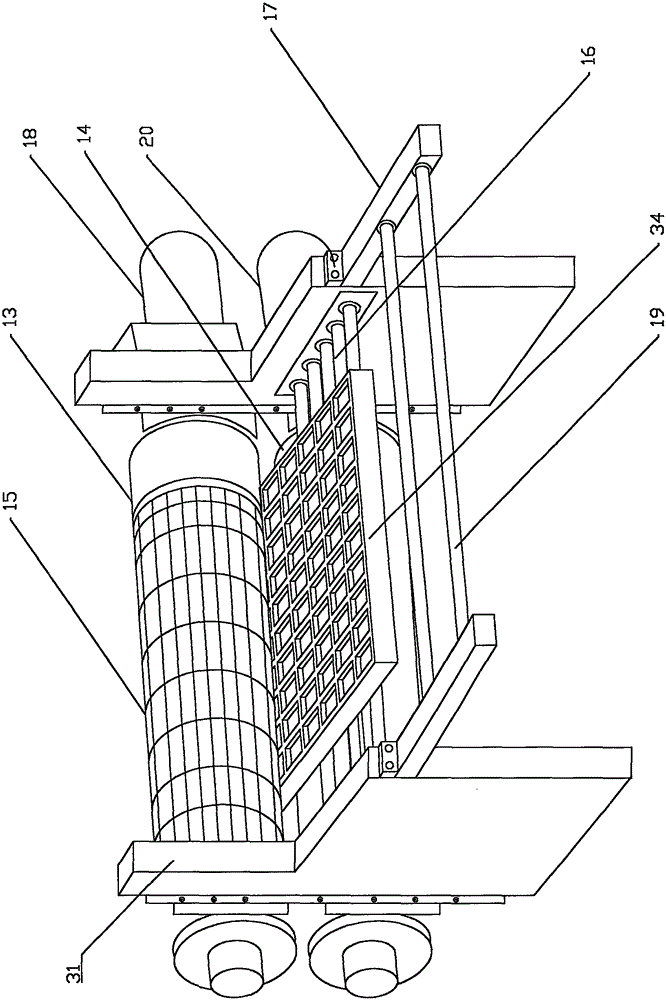

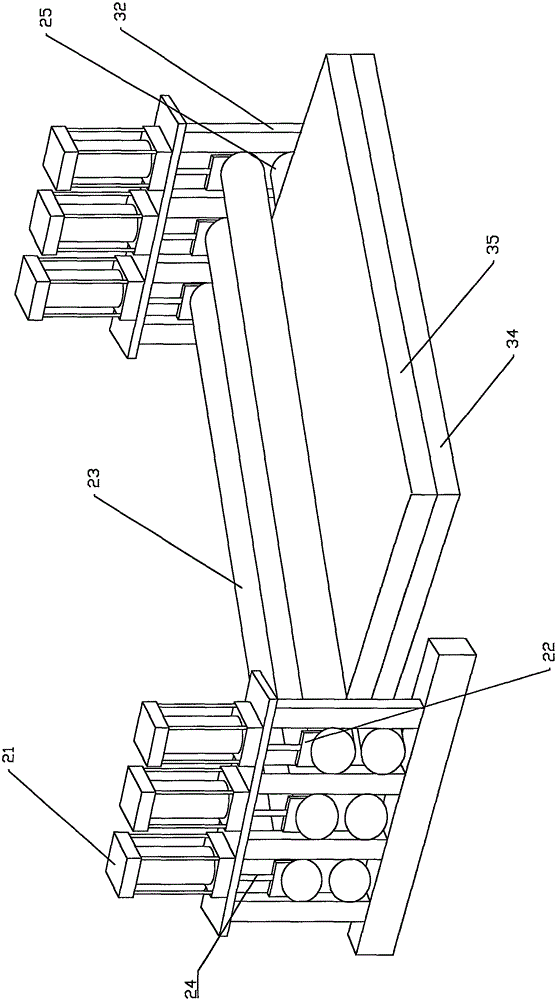

Plastic honeycomb building formwork production line

The invention discloses a plastic honeycomb building formwork production line. The plastic honeycomb building formwork production line comprises a first injection molding machine and a second injection molding machine. A lower formwork is formed on the first injection molding machine in an injection molding manner. An upper formwork is formed on the second injection molding machine in an injection molding manner. The discharging end of the first injection molding machine is connected with a first molding machine. The discharging end of the first molding machine is connected with a first forming machine. The discharging end of the first forming machine is connected with a second molding machine. The second molding machine is connected with the discharging end of the second injection molding machine. The discharging end of the second molding machine is connected with a mold combining machine. The discharging end of the mold combining machine is connected with the second forming machine. The discharging end of the second forming machine is connected with a third forming machine. The discharging end of the third forming machine is connected with an extrusion forming machine. A conveying roller is arranged at the discharging end of the extrusion forming machine. A deviation correcting material pressing device is arranged at the discharging end of the conveying roller, and the discharging end of the deviation correcting material pressing device is connected with a cutter. A combined type production assembly line is adopted, injection molding, forming, mold combining, cutting and other procedures are carried out on a double-layer plastic building formwork in the production and machining process, and the plastic formwork needed for construction is produced.

Owner:高超

Nondestructive detection method for web plate bonding area of a wind turbine blade

The invention discloses a nondestructive detection method for the web plate bonding area of a wind turbine blade. The nondestructive detection method comprises the following steps: firstly, determining the starting point and the finishing point of the web plate bonding area; and secondly, performing nondestructive detection on the overall web plate bonding adhesive area B-F within the chord direction range by using ultrasonic longitudinal waves. The nondestructive detection method for the web plate bonding area of the wind turbine blade provided by the invention has the benefits as follows: the specific location of web plates in the blade is determined precisely by positioning the web plate core materials, and whether the web plates are dislocated or not can also be determined; moreover, the effective width of the bonding adhesive of the web plates can be detected in the true sense, that is, not only is the width of the bonding adhesive detected, but also the measured bonding width isensured to be consistent with that required by drawings; and besides, through the detection on the defects of the adhesive layer in the bonding area of the web plates, whether the bonding between theweb plates and the main beams meets the drawing and process requirements or not is recognized, and the bonding quality of the blade is ensured.

Owner:SINOMATECH FUNING WIND POWER BLADE

Ladder stabilizer and leveler

ActiveUS11492848B2Overcome deficienciesEasily adjust to any sloping or uneven terrainLaddersGear wheelClassical mechanics

Owner:KAZANJIAN DAVID

Textile pallet with adjustable frame

InactiveUS10214033B2Improve scalabilityQuick alignmentScreen printersTypewritersPalletElectrical and Electronics engineering

A textile holder having adjustable side extensions is provided. The side extensions can be generally U-shaped metal rods or wires having a plurality of spaced notches for adjusting the spacing of the wires from a central pallet portion. Alternatively, other structures, such as plates can be used for the side extensions. The plates can include one or more slots. Screws or posts on the central pallet portion can be used to align the plates at appropriate extension distances and hold the plates in place.

Owner:M&R PRINTING EQUIP

Semiconductor device allowing modulation of a gain coefficient and a logic circuit provided with the same

InactiveUS20060192252A1Effective lengthEffective widthTransistorSemiconductor/solid-state device manufacturingDevice materialGain coefficient

In addition to ordinary MOS gate, drain and source, a semiconductor element includes a control gate having geometry, which is defined only by a group of straight lines along a rectangular form of the MOS gate, is not defined by an oblique line and provides a nonuniform gate length at least in one of regions aligned in a direction of a gate width. A channel region formed by the control gate provides a region of strong electric fields and a region of weak electric fields. Consequently, a conductance of a whole channel region formed by the MOS gate and the control gate, i.e., a gain coefficient β of the semiconductor element can be modulated in accordance with voltages applied to the MOS gate and the control gate.

Owner:KENZAN

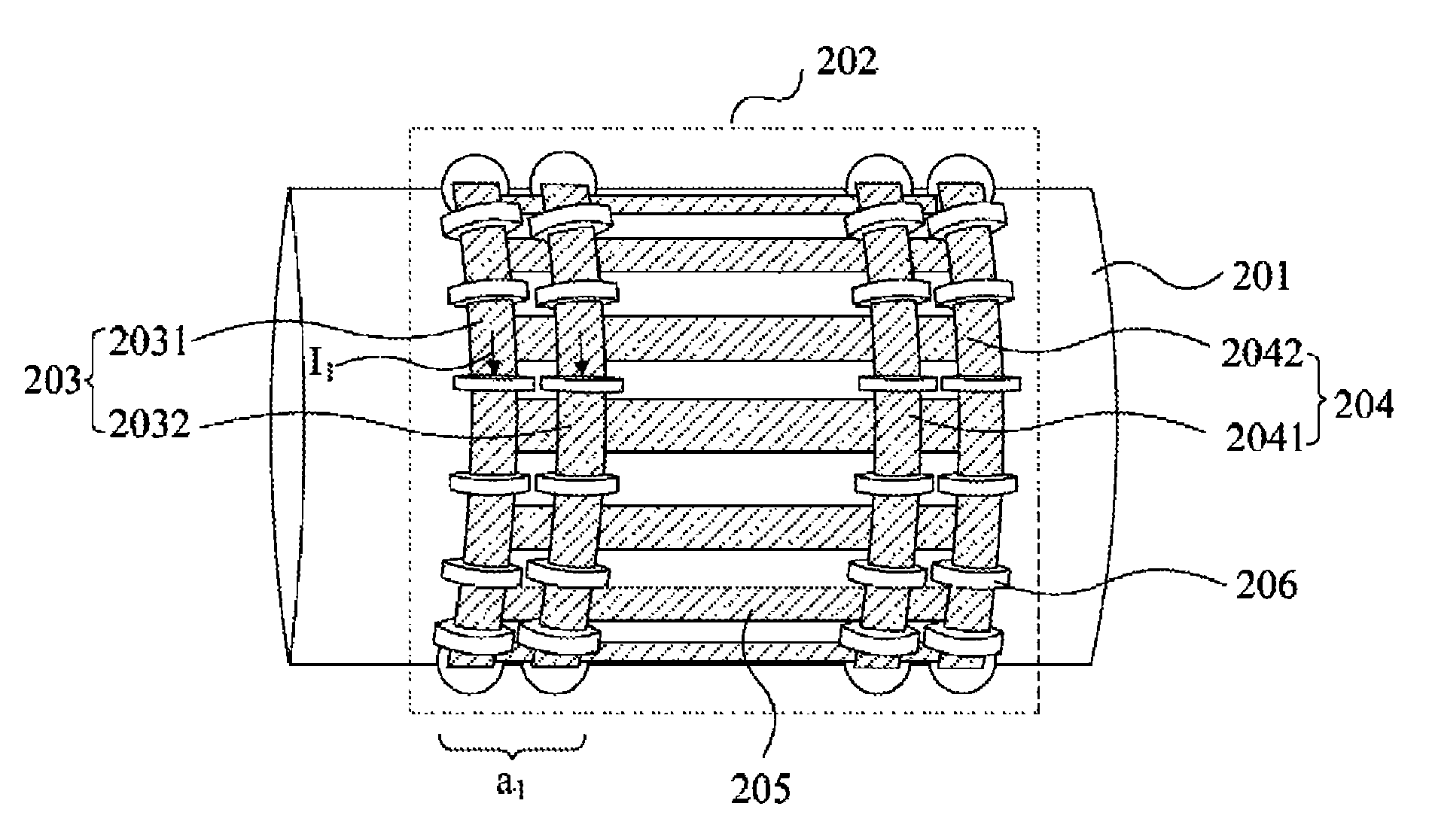

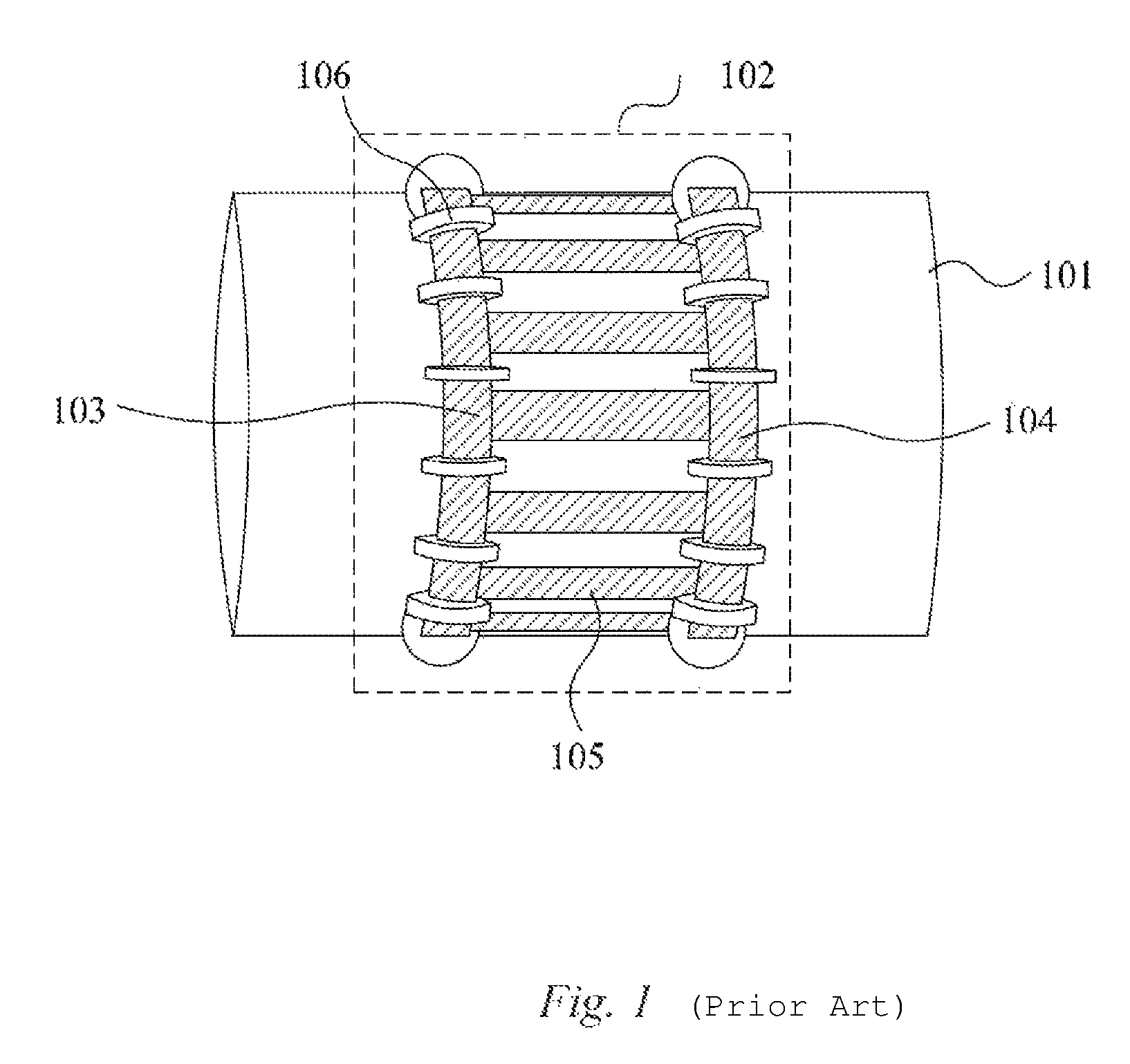

Body coil for magnetic resonance imaging

ActiveUS9568570B2Efficient actionCentralized flowDiagnostic recording/measuringSensorsEffective actionRadio frequency

A body coil includes a first end ring and a second end ring provided at two ends thereof. The first end ring and the second end ring are connected to each other with a plurality of legs. The first end ring or the second end ring has a structure with the current flow width in a direction parallel to the axis thereof being greater than that in a direction perpendicular to the axis thereof. Since the effective action width of the current is increased in the axial direction and the centralized flow of the current in the end ring is reduced, the local specific absorption rate of radio frequency induced by the magnetic field is therefore reduced.

Owner:SIEMENS HEALTHCARE GMBH

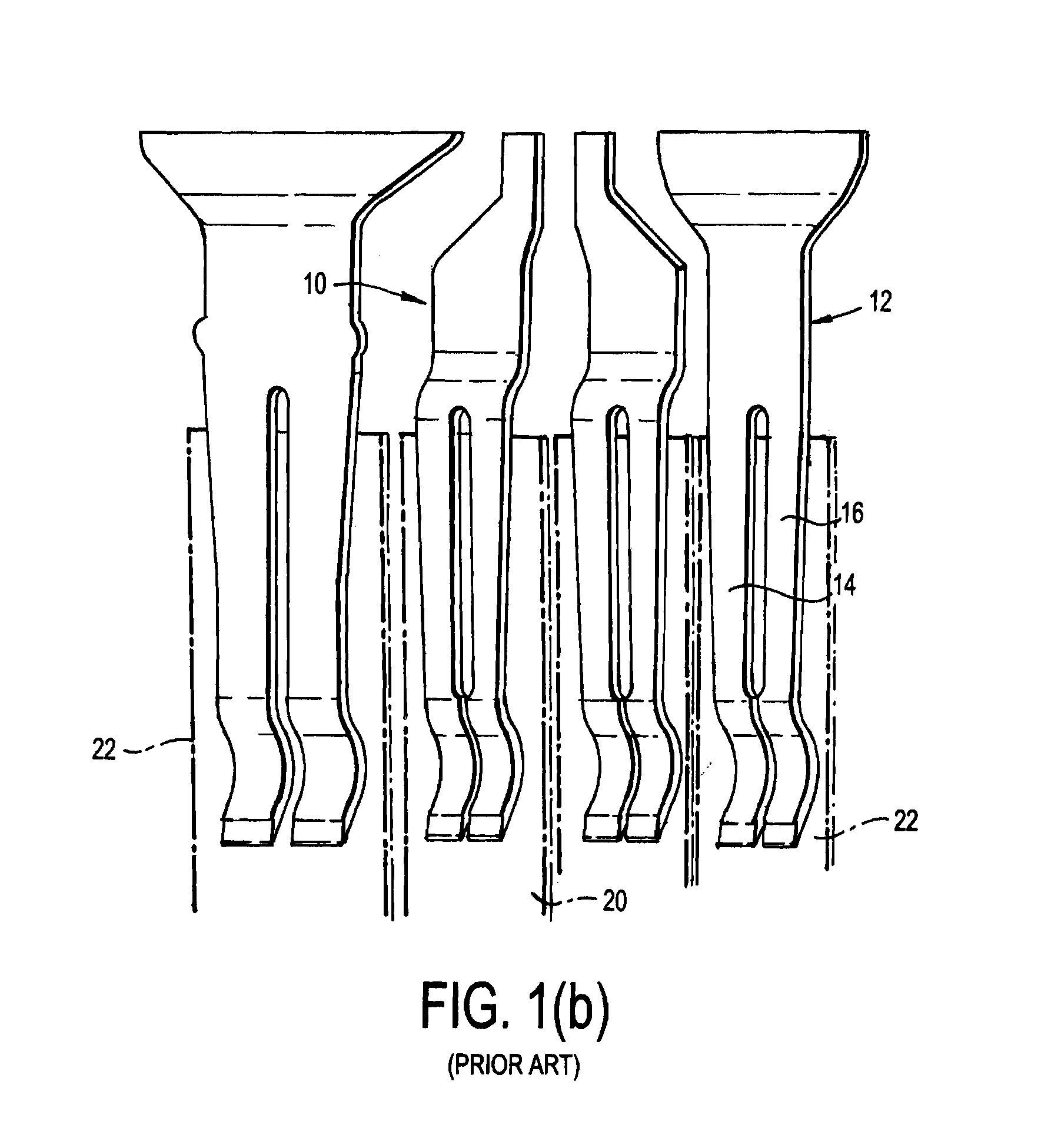

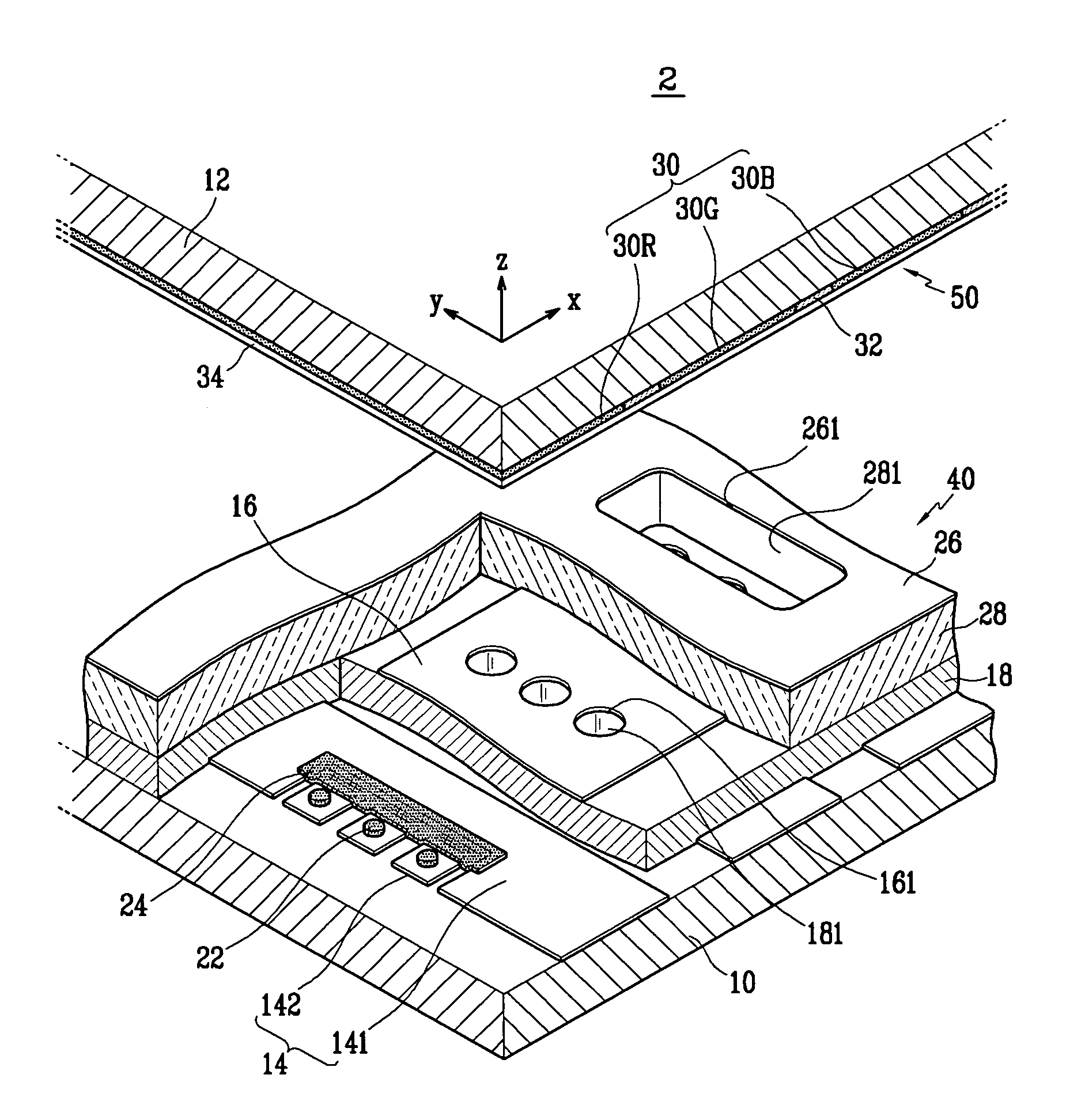

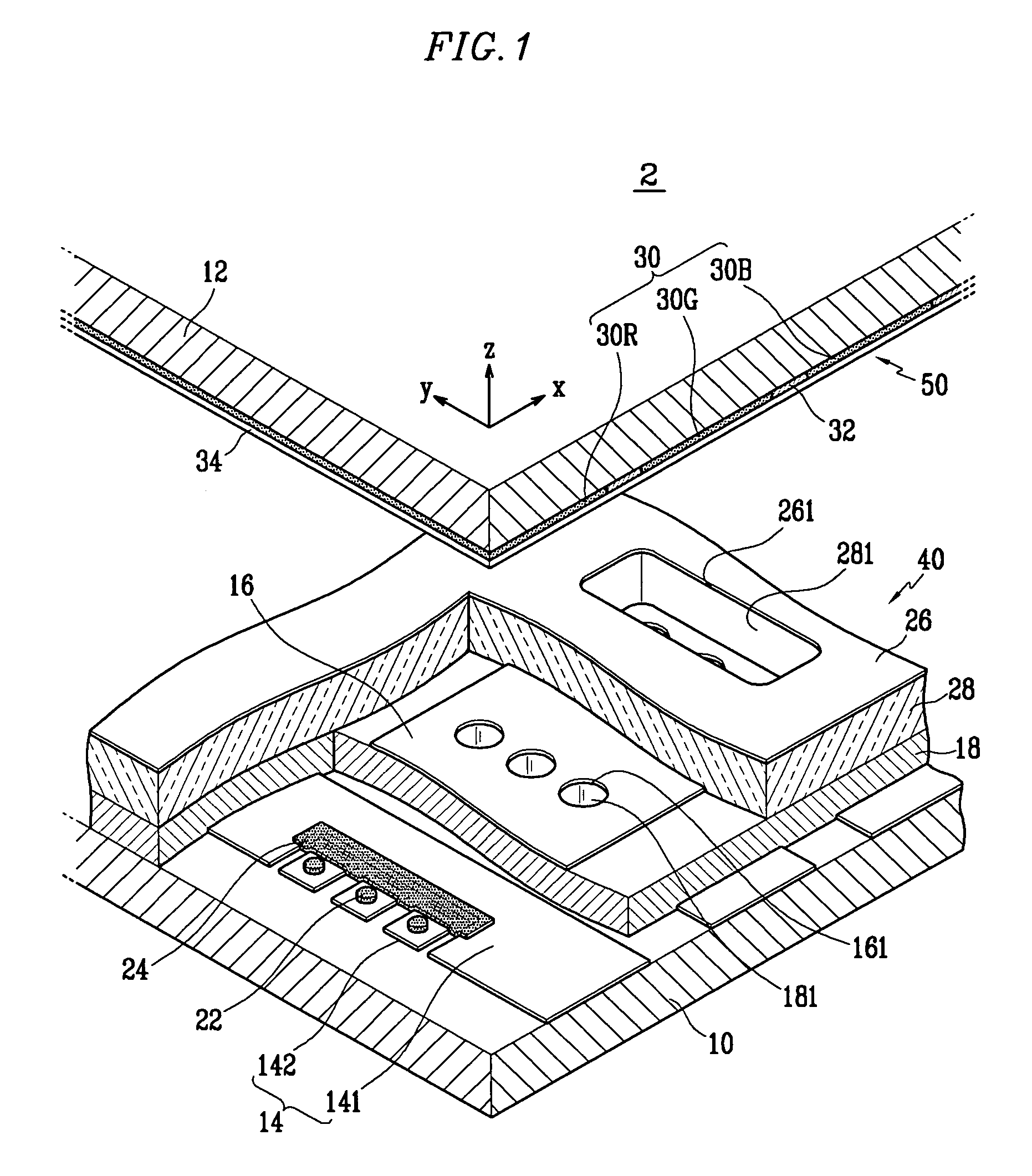

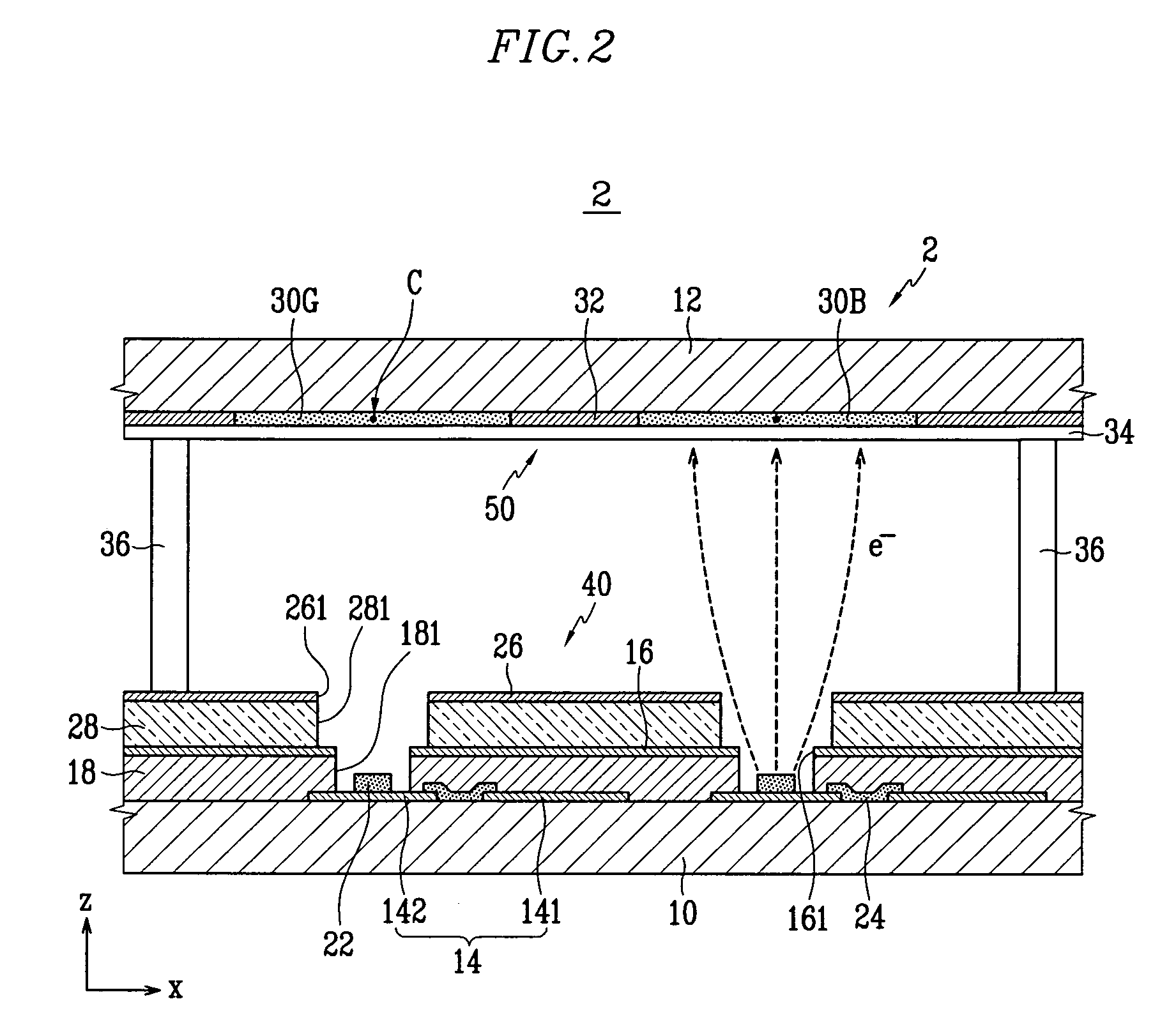

Electron emission display including a cathode having resistance layer electrically connecting isolation electrodes having electron emission regions to a line electrode

InactiveUS7541725B2Effective widthUniform emissionDischarge tube luminescnet screensCathode ray tubes/electron beam tubesDisplay deviceElectron

An electron emission device includes a substrate, cathode and gate electrodes placed on the substrate in an insulated manner, and electron emission regions electrically connected to the cathode electrodes. Each of the cathode electrodes includes a line electrode having a groove at one lateral side surface thereof, and isolation electrodes formed on the substrate exposed through the groove such that the isolation electrodes are isolated from the line electrode. The electron emission regions are placed on the isolation electrodes and a resistance layer electrically connects the isolation electrodes to the line electrode.

Owner:SAMSUNG SDI CO LTD

Integrated circuit board and display system

ActiveUS8811029B2Effective widthReduce widthPrinted electric component incorporationPrinted circuit aspectsEngineeringElectronic component

An integrated circuit board includes a substrate, a plurality of electronic components and at least one antenna. The substrate has a central area and two edge areas, wherein the central area is between the two edge areas. The electronic components are disposed on the central area. The antenna is disposed on at least one of the two edge areas, wherein there is predetermined distance between the antenna and the electronic components.

Owner:AU OPTRONICS CORP

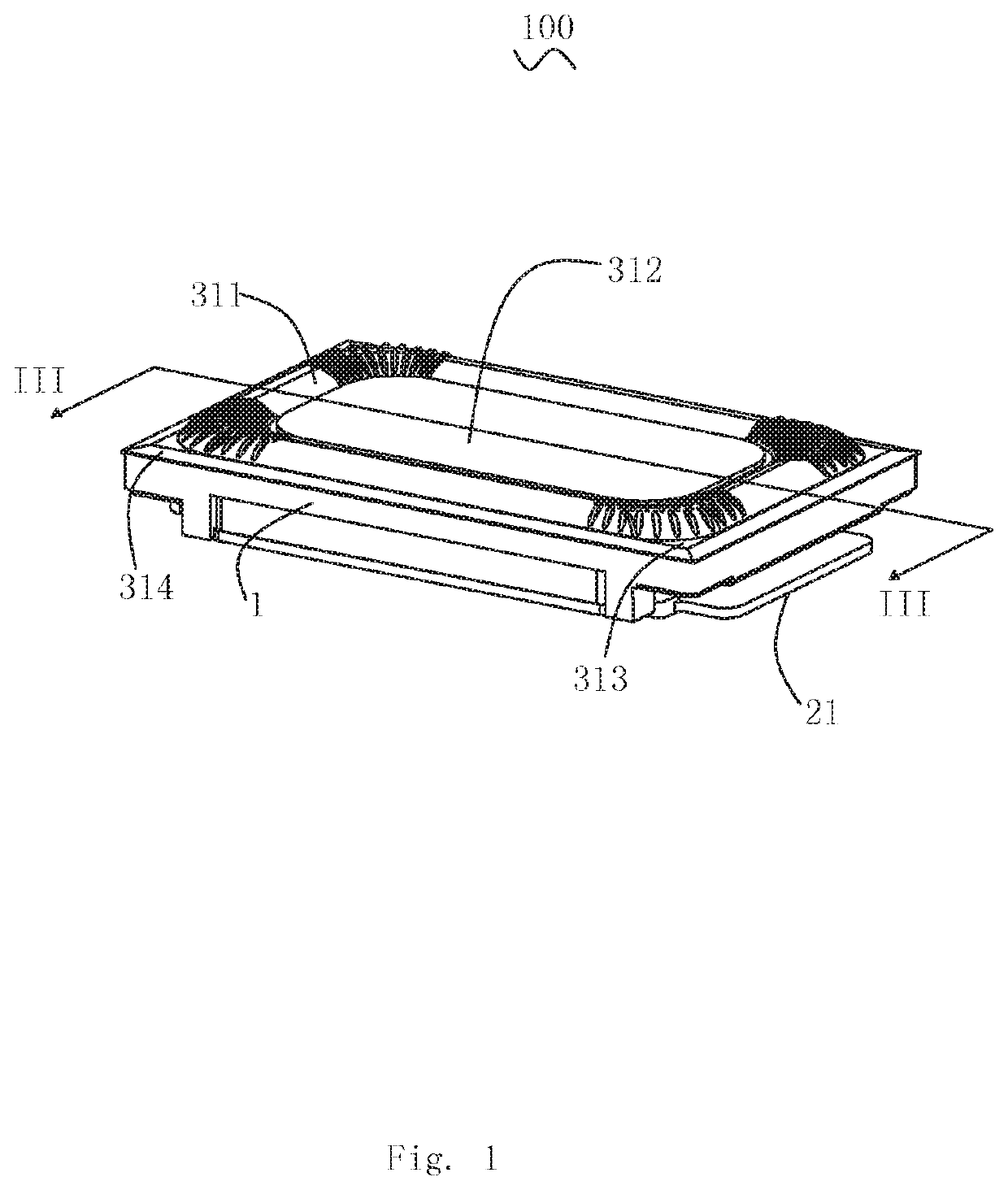

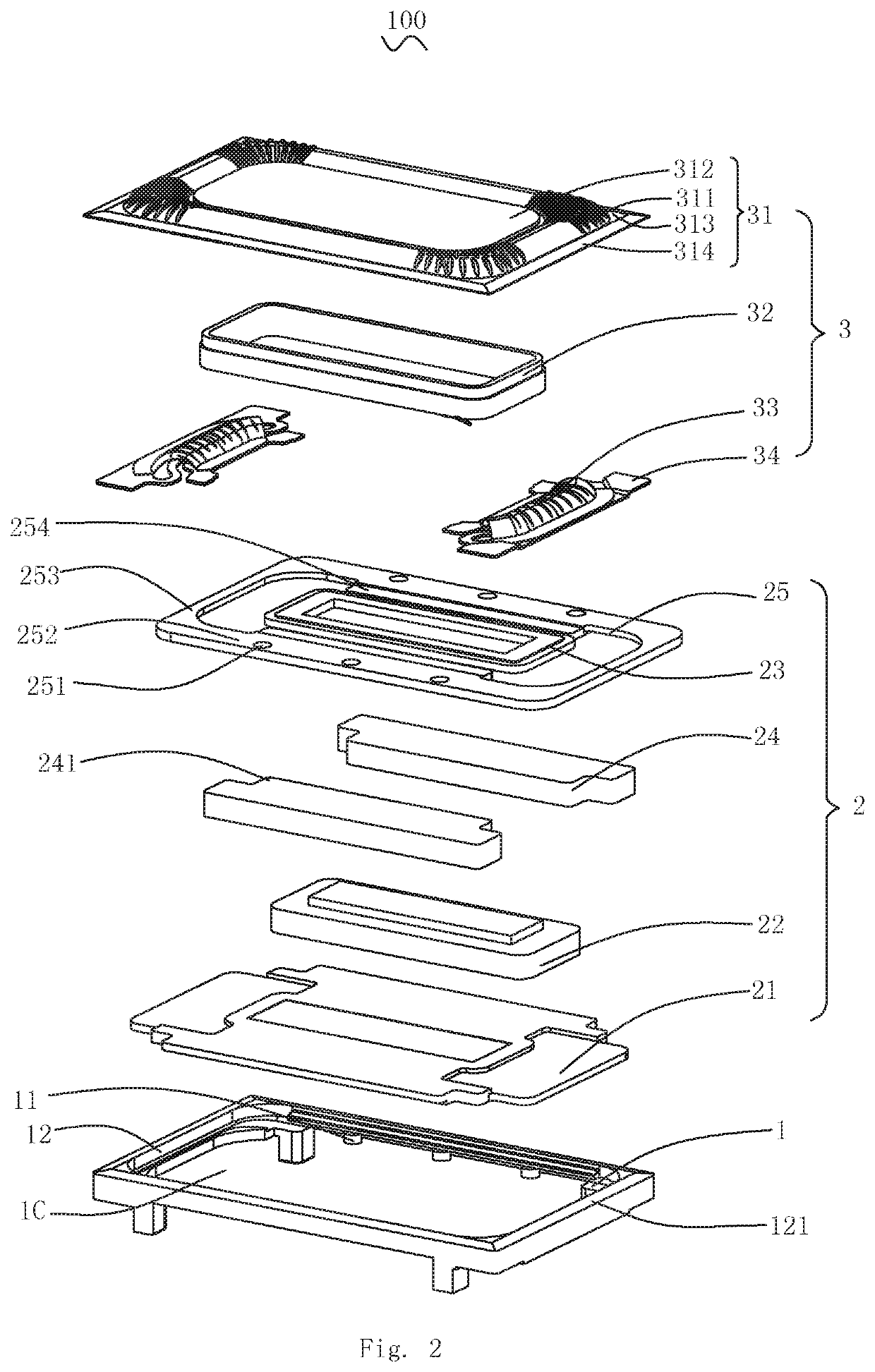

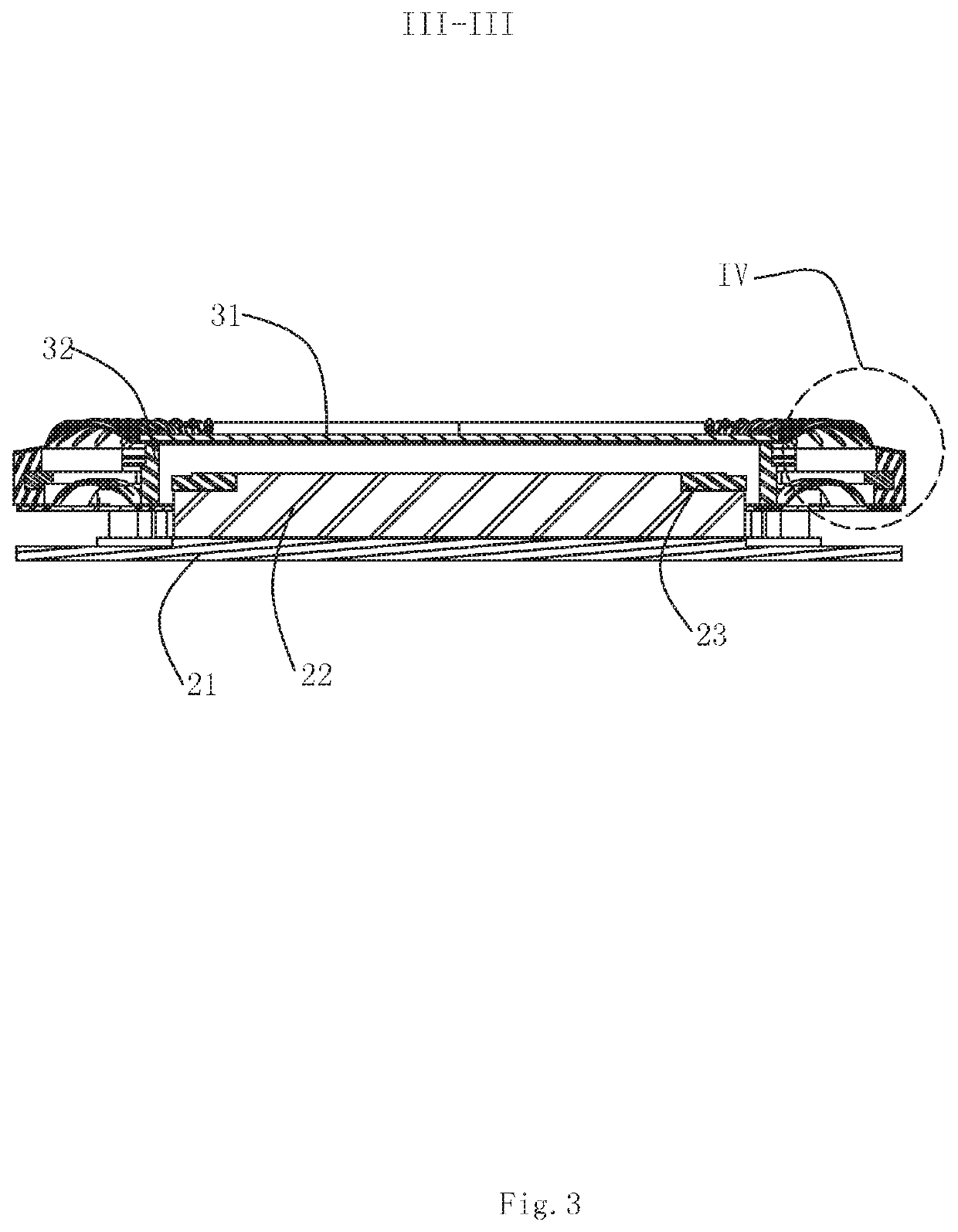

Speaker

InactiveUS20200314549A1Improve reliabilityImprove stabilityLoudspeakersNon-planar diaphragms/conesAcute angleEngineering

The present invention discloses a speaker having a frame, a vibrating system and a magnetic circuit system both fixed on the frame. The vibrating system having a diaphragm fixed on the frame and a voice coil for driving the diaphragm to vibrate and produce sound. The frame has a side wall for forming a receiving space, and the side wall includes a top plane fixedly connected with the diaphragm. An angle between the top plane and a vibrating direction of the vibrating system close to both the receiving space and the diaphragm is an obtuse angle or an acute angle. Compared with the related art, the speaker of the present invention has advantages of excellent acoustic performance and better reliability.

Owner:AAC TECH PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com