Non-destructive testing method for web bonding area of wind turbine blades

A wind power blade, non-destructive testing technology, applied in the field of wind turbine blade quality testing equipment, can solve the problems of high cost, high transportation cost, affecting the stability and safety of the unit, so as to improve the service life and ensure the bonding Quality and reduction of maintenance costs

Active Publication Date: 2019-10-01

SINOMATECH FUNING WIND POWER BLADE

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a running unit, if there is a quality problem with the blades, it will not only be expensive to repair and replace, but also affect the stability and safety of the entire unit operation, especially for large offshore wind turbine blades, the costs of transportation, hoisting and maintenance are all high. It is very high, so it is very important to find defects at the manufacturing stage through effective inspection methods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

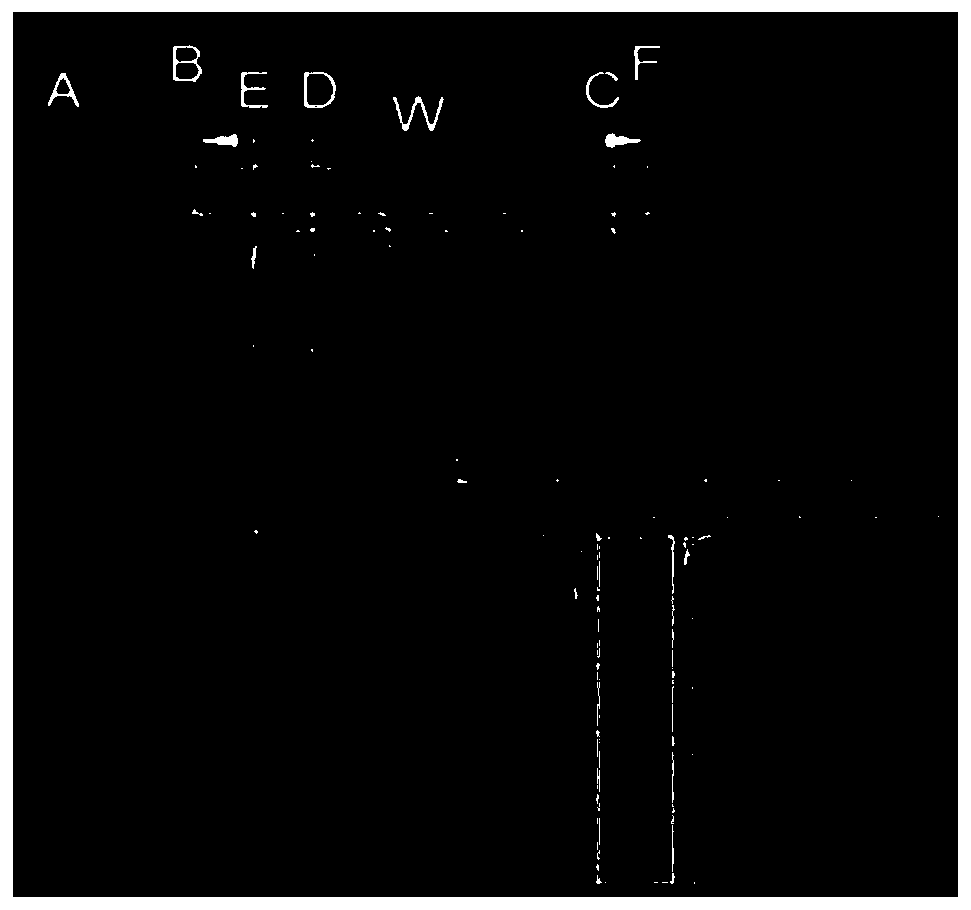

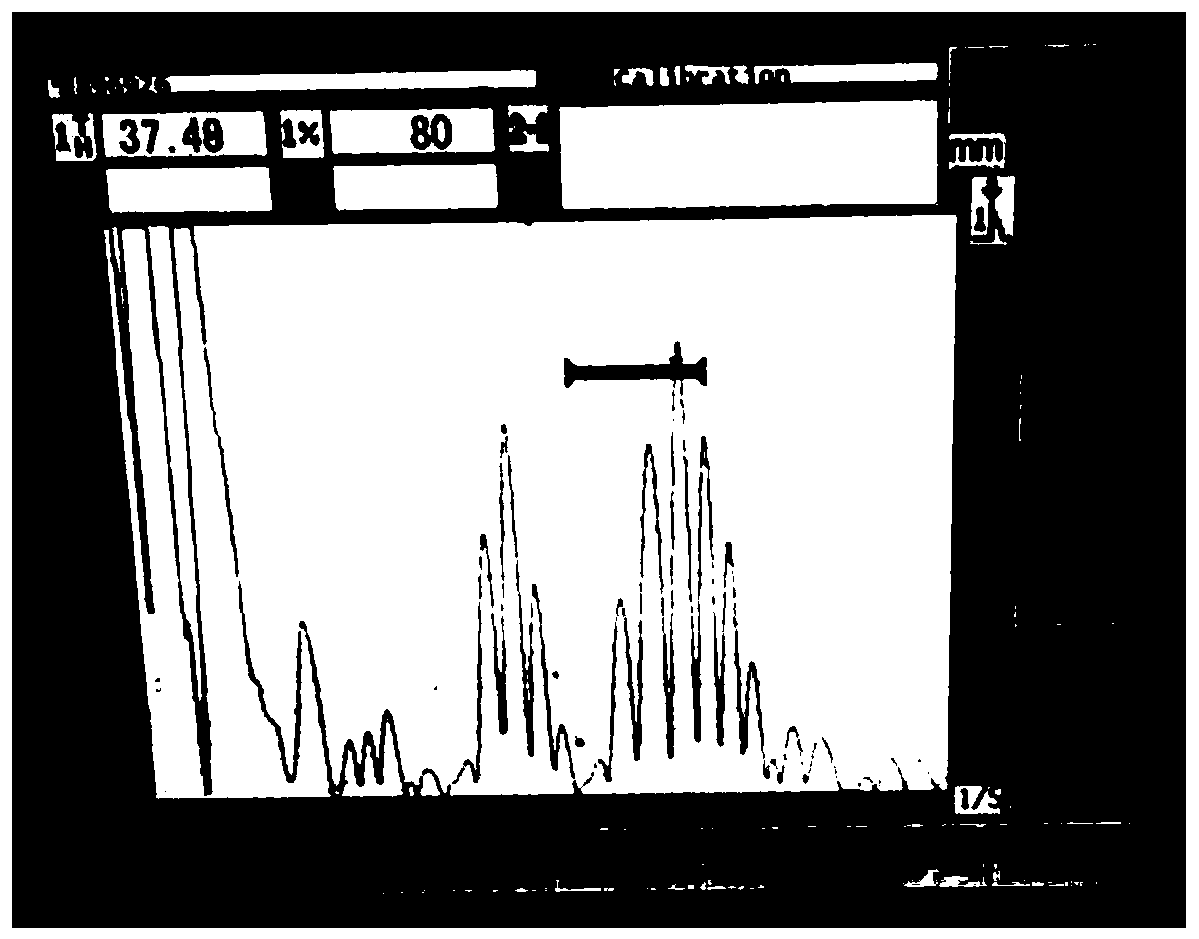

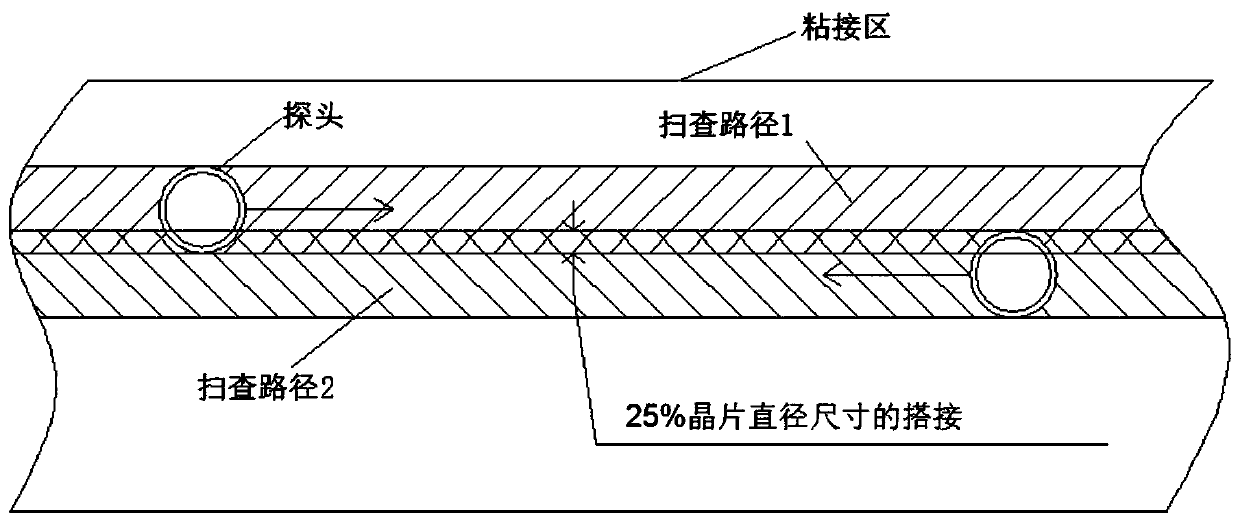

The invention discloses a nondestructive detection method for the web plate bonding area of a wind turbine blade. The nondestructive detection method comprises the following steps: firstly, determining the starting point and the finishing point of the web plate bonding area; and secondly, performing nondestructive detection on the overall web plate bonding adhesive area B-F within the chord direction range by using ultrasonic longitudinal waves. The nondestructive detection method for the web plate bonding area of the wind turbine blade provided by the invention has the benefits as follows: the specific location of web plates in the blade is determined precisely by positioning the web plate core materials, and whether the web plates are dislocated or not can also be determined; moreover, the effective width of the bonding adhesive of the web plates can be detected in the true sense, that is, not only is the width of the bonding adhesive detected, but also the measured bonding width isensured to be consistent with that required by drawings; and besides, through the detection on the defects of the adhesive layer in the bonding area of the web plates, whether the bonding between theweb plates and the main beams meets the drawing and process requirements or not is recognized, and the bonding quality of the blade is ensured.

Description

technical field The invention relates to a quality detection device for a wind turbine blade, in particular to a nondestructive detection method for a web bonding area of a wind power blade. Background technique With the rapid development of the wind power industry, wind turbines continue to develop towards large-scale trends, the length of the blades is also increasing, and the manufacturing cost of the blades is also becoming more and more expensive, which accounts for 10%-15% of the total cost of the whole machine. For a running unit, if there is a quality problem with the blades, it will not only be expensive to repair and replace, but also affect the stability and safety of the entire unit operation, especially for large offshore wind turbine blades, the costs of transportation, hoisting and maintenance are all high. It is very high, so it is very important to find defects at the manufacturing stage through effective inspection methods. Contents of the invention P...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C65/82

Inventor 朱维

Owner SINOMATECH FUNING WIND POWER BLADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com