Plastic honeycomb building formwork production line

A technology of building formwork and plastic honeycomb, applied in the field of plastic honeycomb building formwork production line, can solve the problems of less turnover, poor water resistance, waste of resources, etc., and achieve the effect of stress relief, uniform distribution and uniform pressure on the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

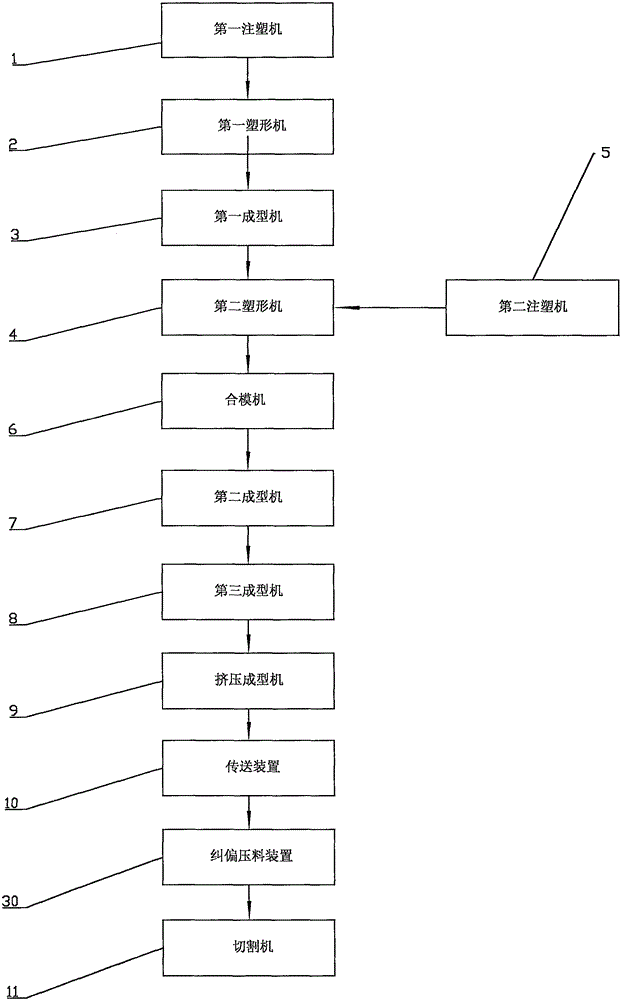

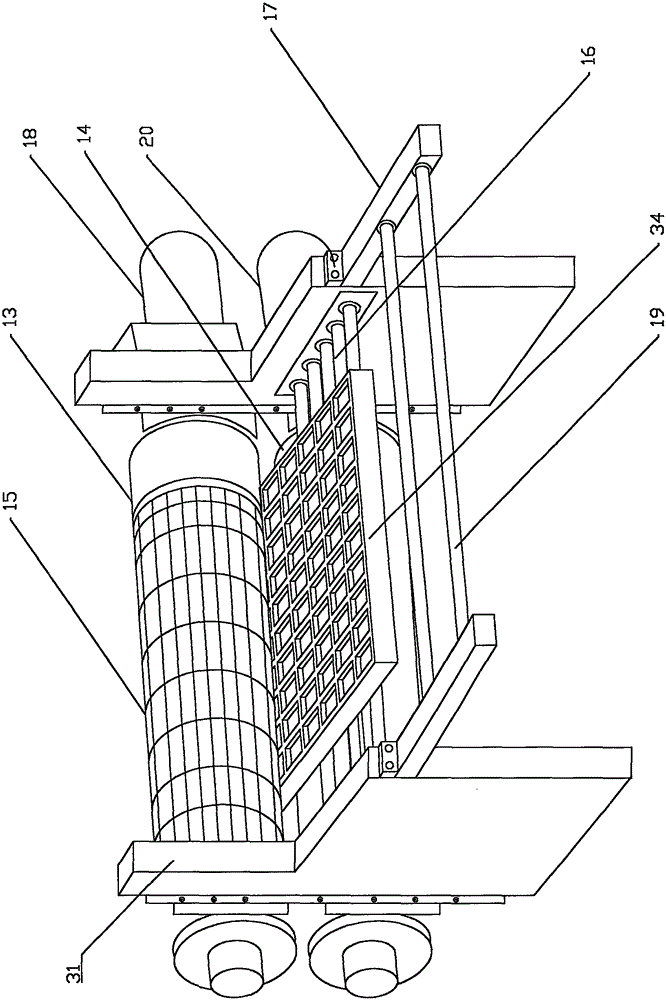

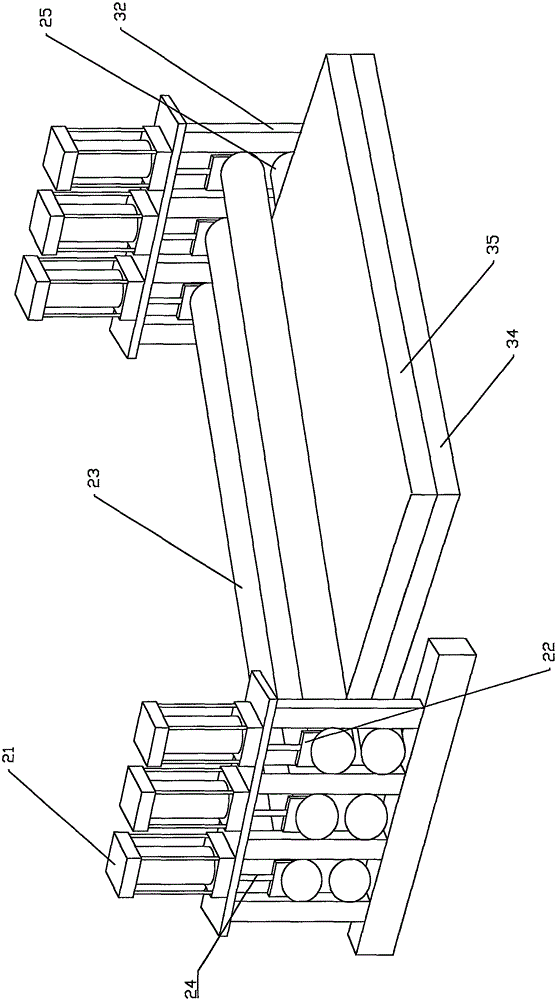

[0031] Such as Figure 1-4 As shown, the plastic honeycomb building formwork production line includes a first injection molding machine 1 and a second injection molding machine 5. The first injection molding machine 1 has a lower template 34 for injection molding, and the second injection molding machine 5 has an upper template 35 for injection molding. The discharge end of the first injection molding machine 1 is connected with the first molding machine 2, the discharge end of the first molding machine 2 is connected with the first molding machine 3, and the discharge end of the first molding machine 3 is connected with The second molding machine 4, the second molding machine 4 is connected with the discharge end of the second injection molding machine 5, the discharge end of the second molding machine 4 is connected with a mold clamping machine 6, and the mold clamping The discharge end of the machine 6 is connected with a second molding machine 7, the discharge end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com