Patents

Literature

60results about How to "Effective traction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power generation pad using wasted energy

InactiveUS20070257495A1Effective tractionUnlimited potentialFrom muscle energyMachines/enginesElectricityElectrical connection

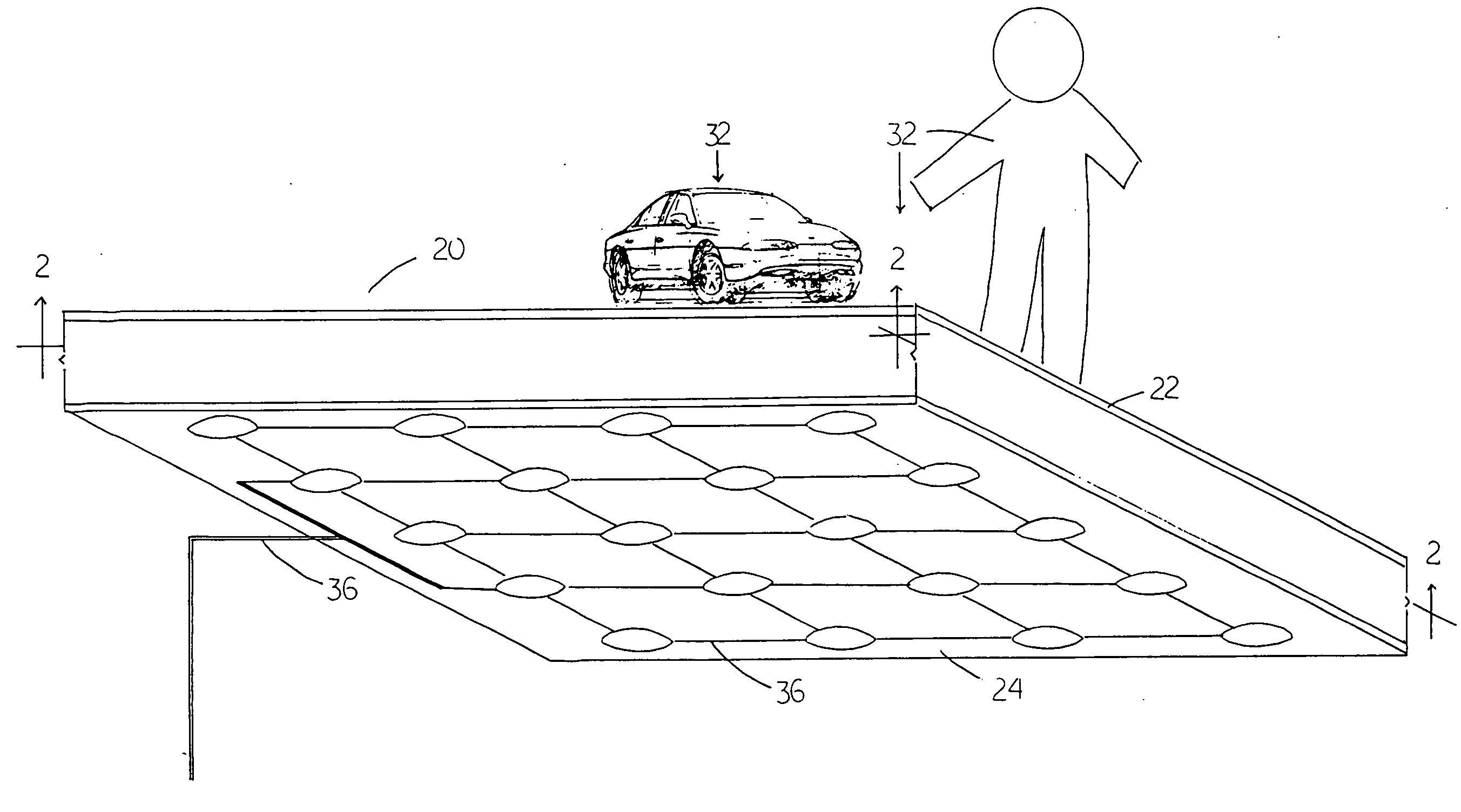

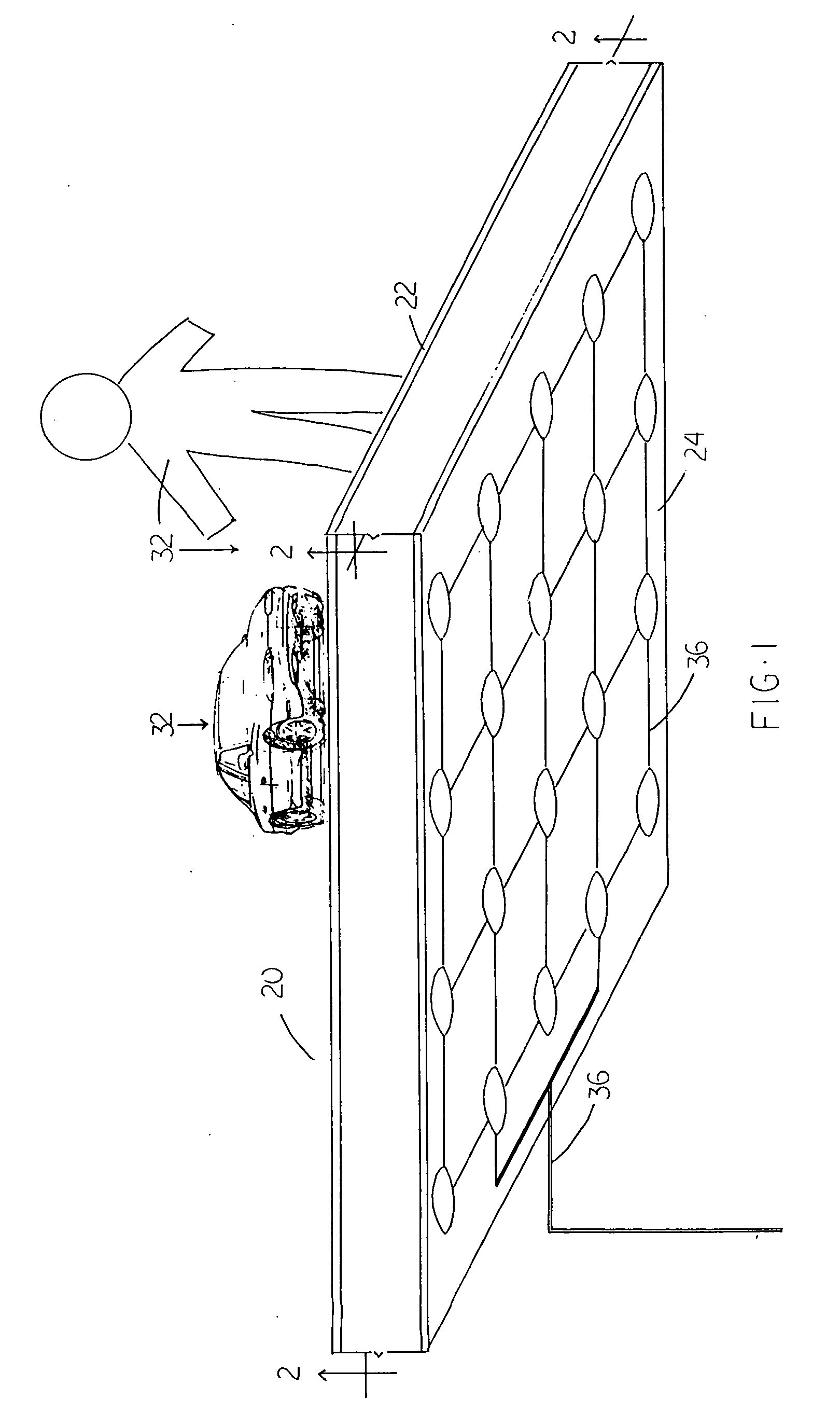

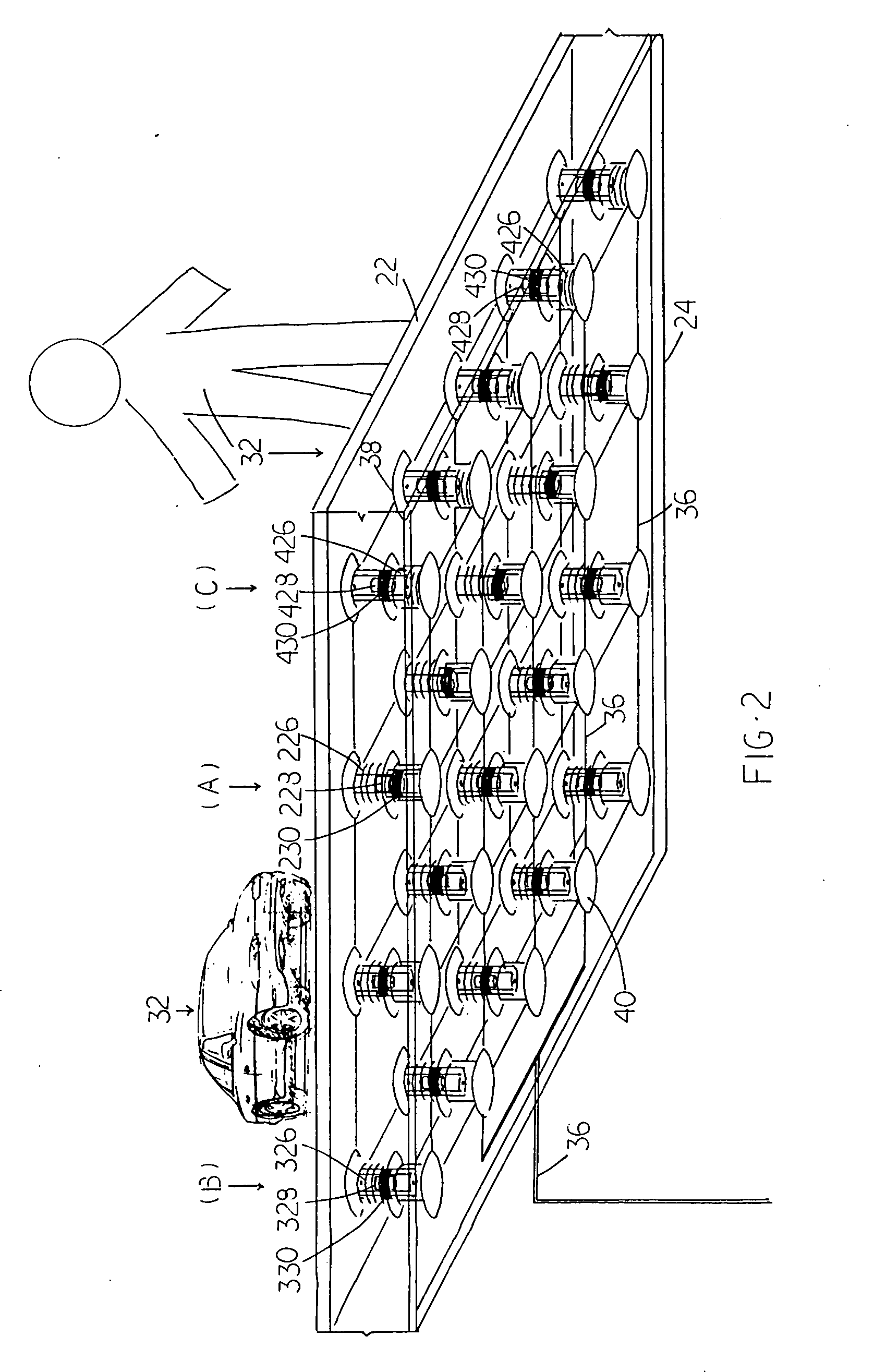

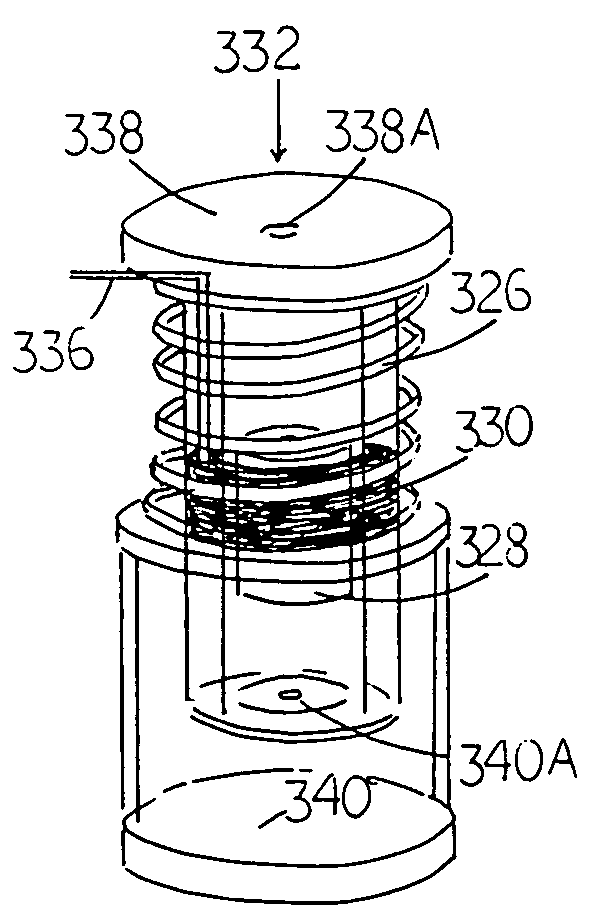

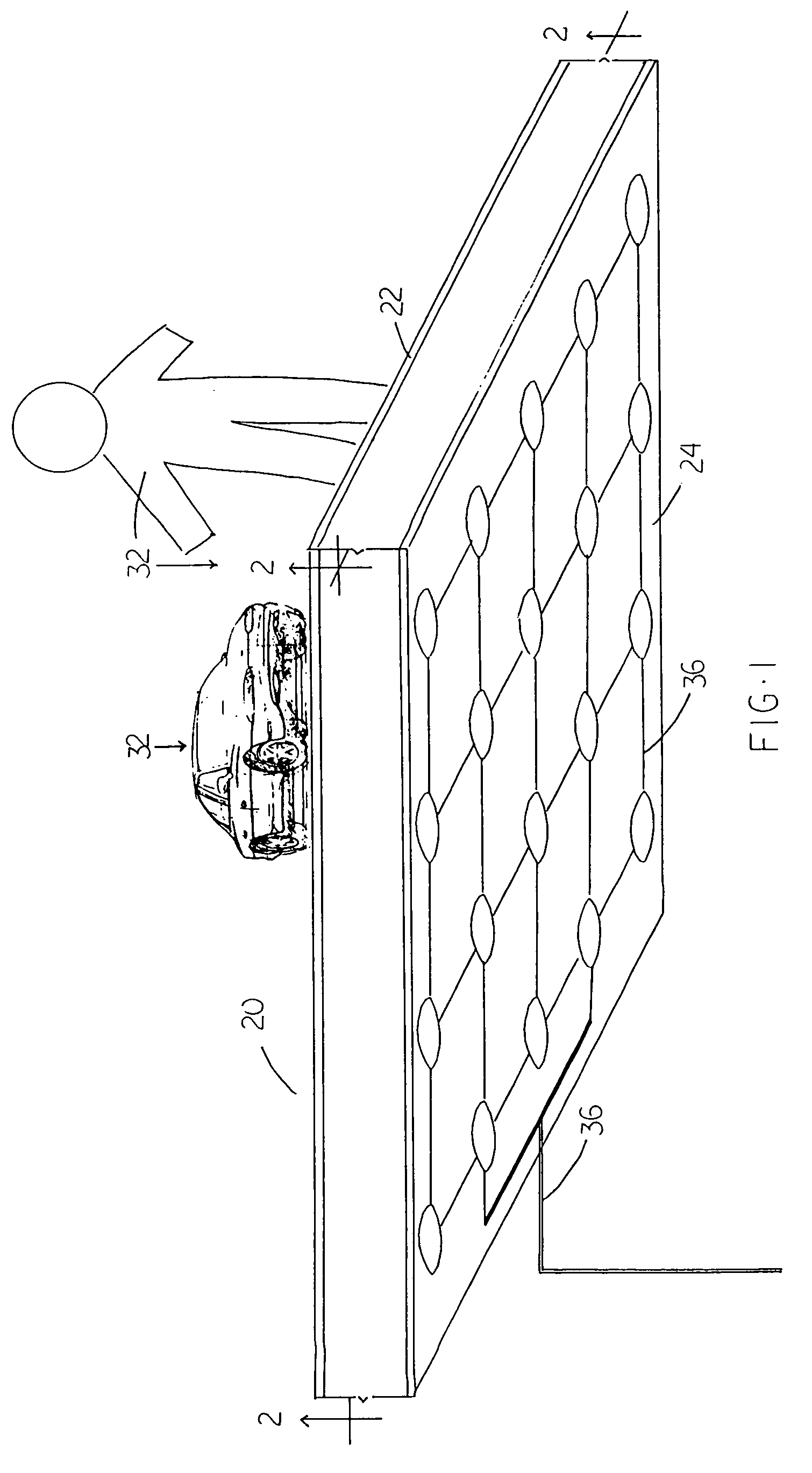

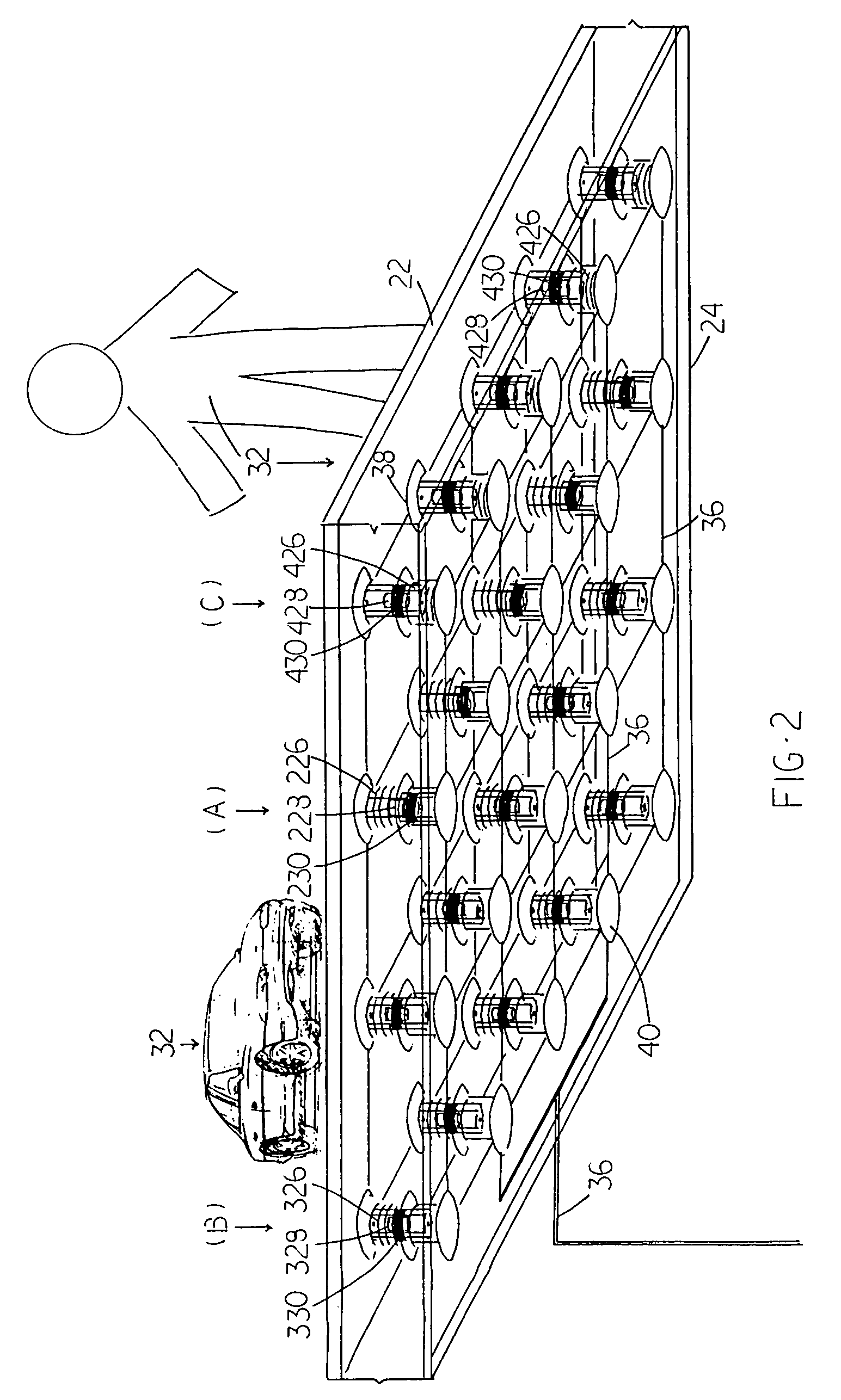

The present invention teaches an energy generator comprising a generally flat and partially flexible traffic surface on which pedestrians and traffic may pass. Underneath the traffic surface, a plurality of dynamo cells each have a dynamo therein, each dynamo having two electricity generating elements (magnets, coils, etc) and an operative electrical connection to an electrical load such as a battery, capacitor, light, an electrical network or the like. A first electrical generating element in each dynamo may be disposed so that it moves downward when weight from traffic is applied to the traffic surface, while a second electricity generating element remains stationary supported. by the bottom surface of the energy generator. A spring and bottom support may urge the first (moving) element back upwards when the imposed force is released.

Owner:KIM RICHARD H +3

Power generation pad using wasted energy

InactiveUS7432607B2Effective tractionUnlimited potentialFrom muscle energyMachines/enginesElectricityElectrical connection

Owner:KIM RICHARD H +3

Driving system of electric motor coach and driving control method thereof

ActiveCN103895524AAddress lack of motivationImprove driving efficiencySpeed controllerElectric devicesPower batteryElectric machine

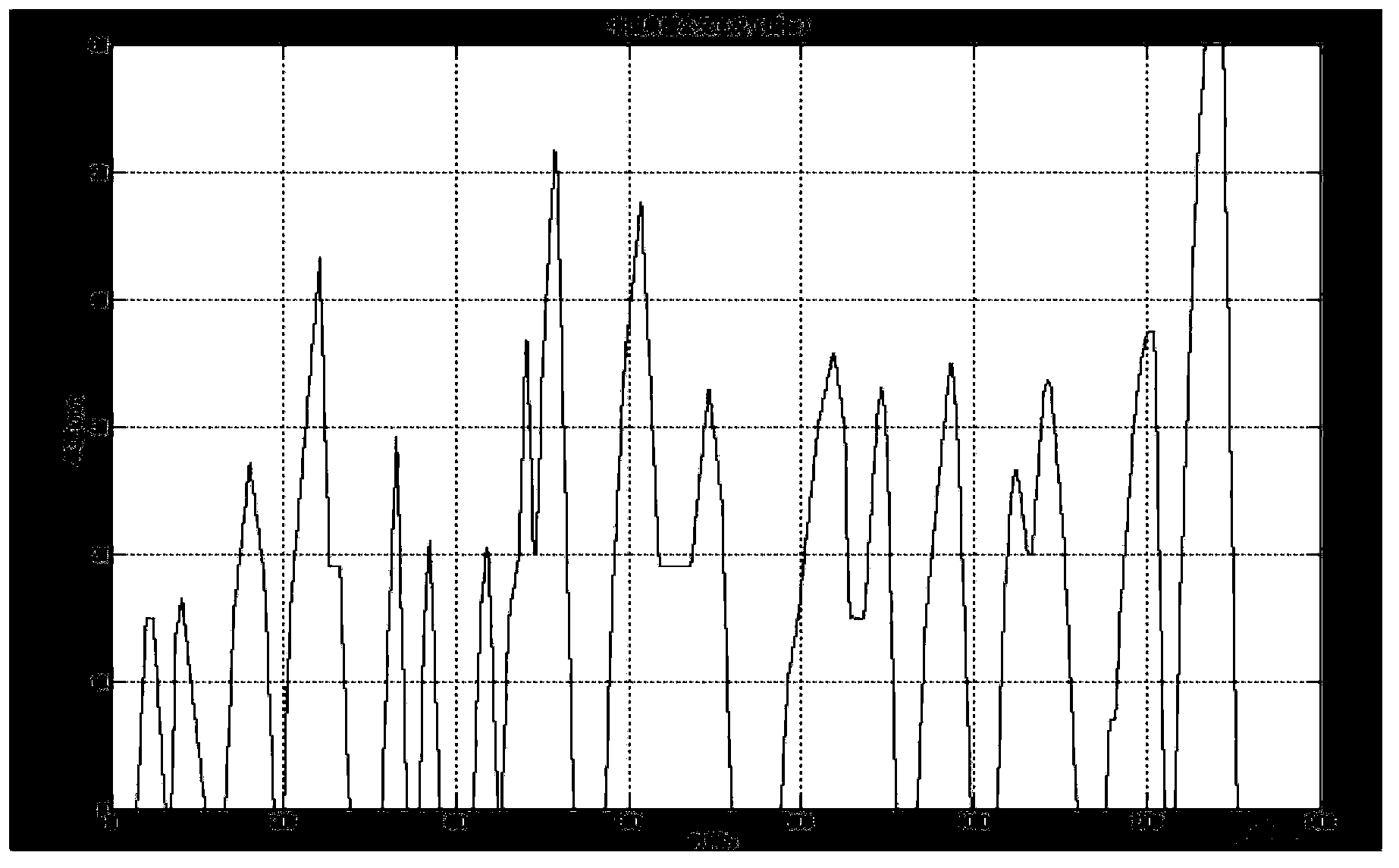

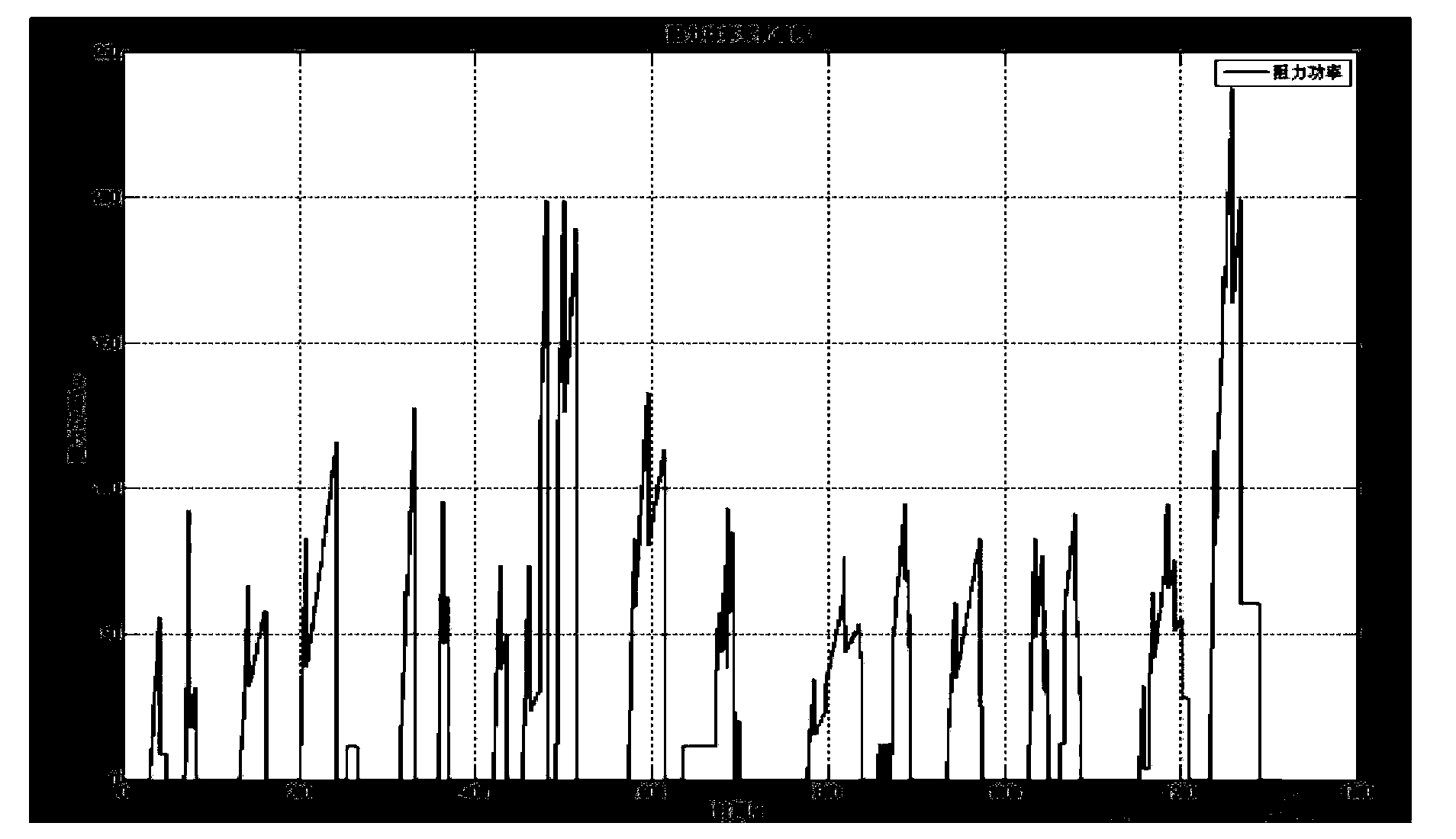

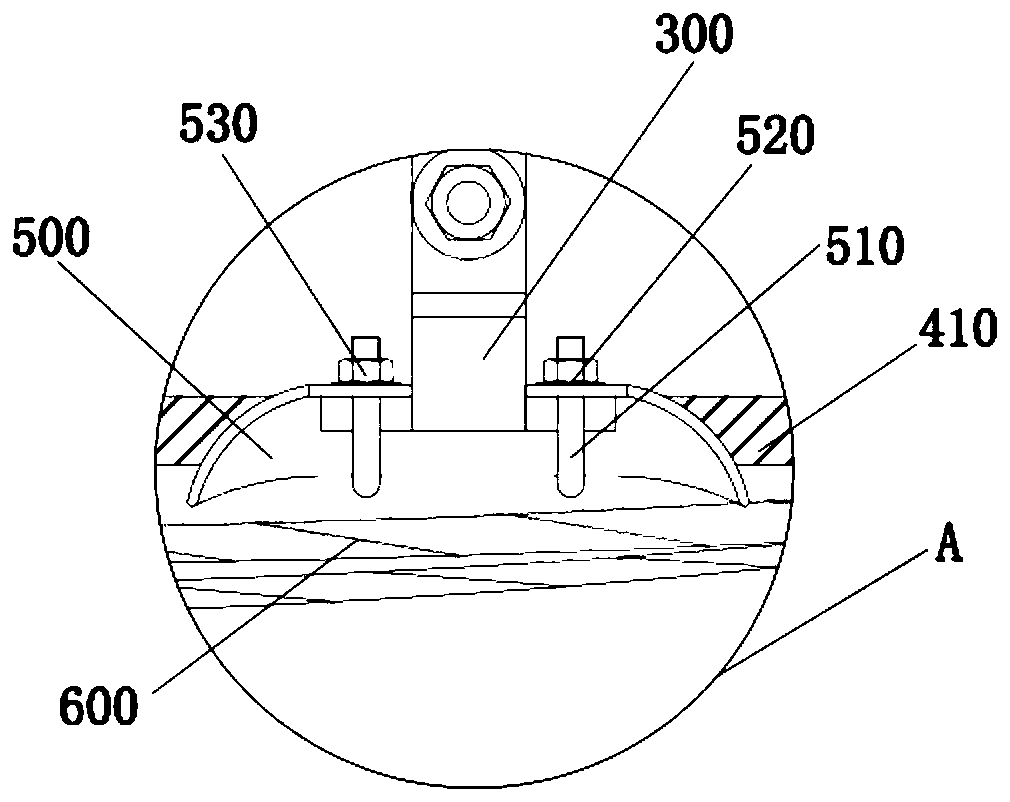

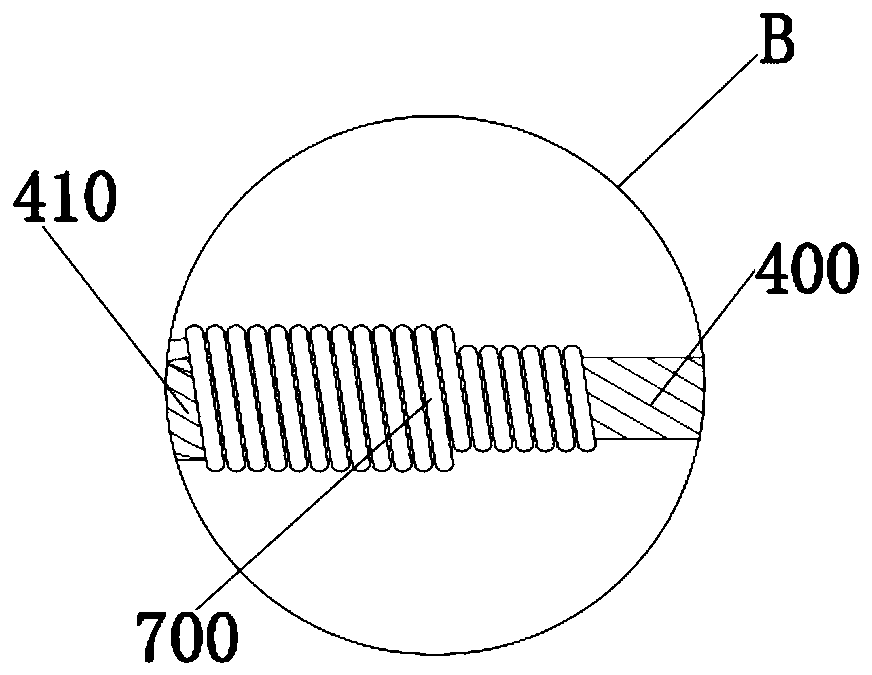

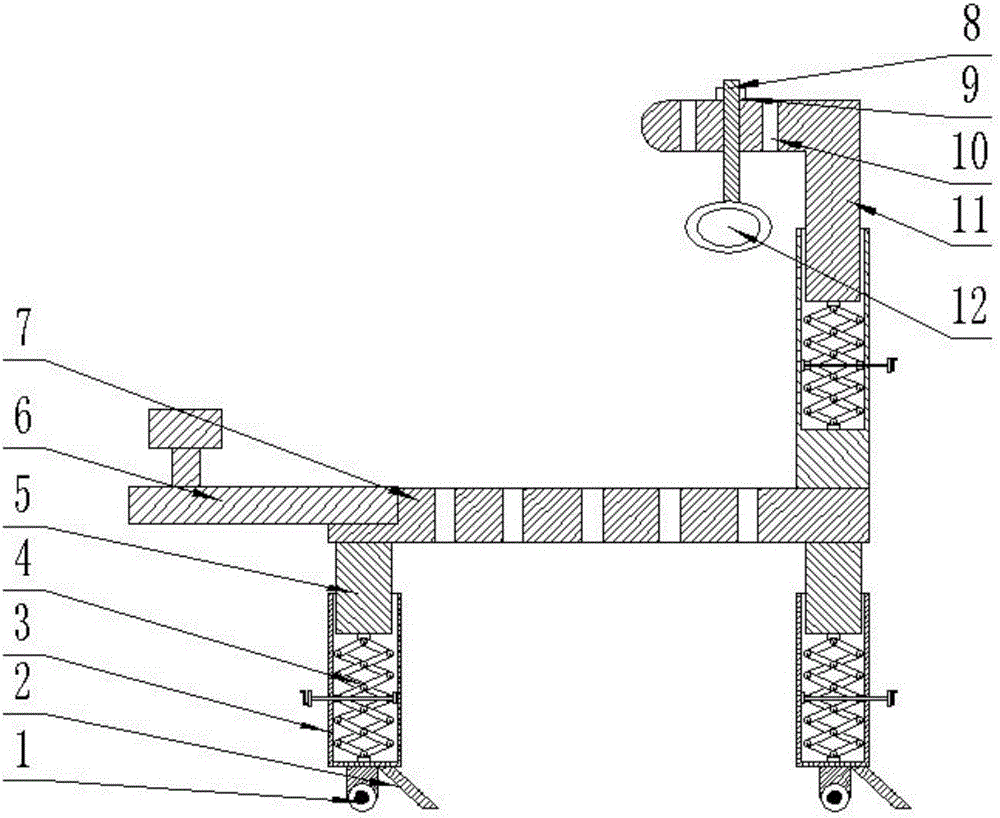

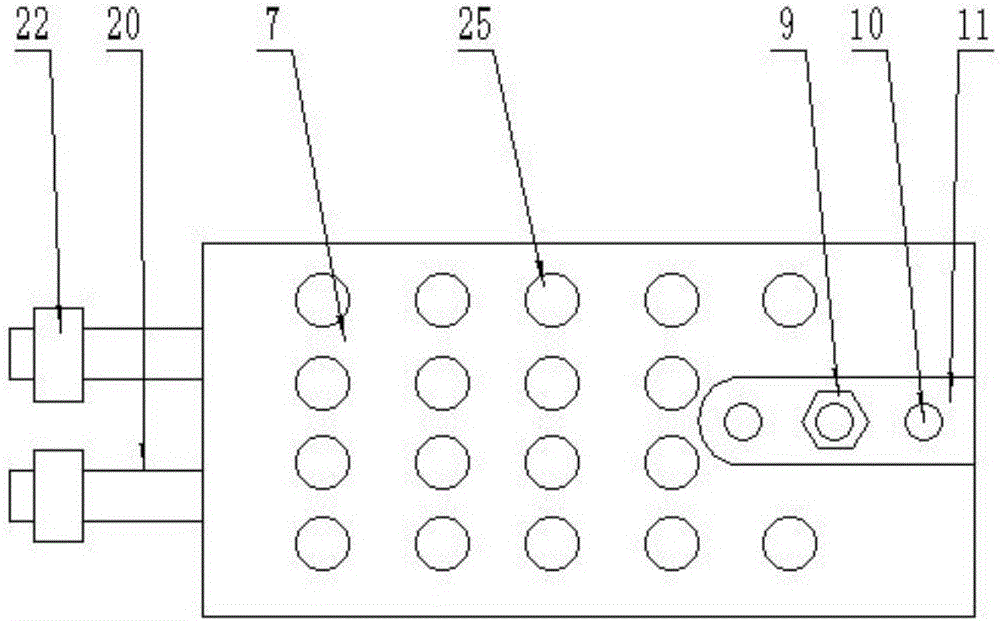

A driving system of an electric vehicle and a method for controlling the same are provided. The driving system comprises: a power battery (100); a plurality of first in-wheel motors (200) connected with the power battery (100); a plurality of first motor controllers (300) controlling the plurality of first in-wheel motors (200) respectively; a plurality of second in-wheel motors (400) connected with the power battery (100); a plurality of second motor controllers (500) controlling the plurality of second in-wheel motors (400) respectively; and a vehicle management system controller (600) connected with the plurality of first motor controllers (300) and the plurality of second motor controllers (500) respectively, and configured to control the plurality of first in-wheel motors (200) and the plurality of second in-wheel motors (400) to start or stop during a running of the electric vehicle.

Owner:BYD CO LTD

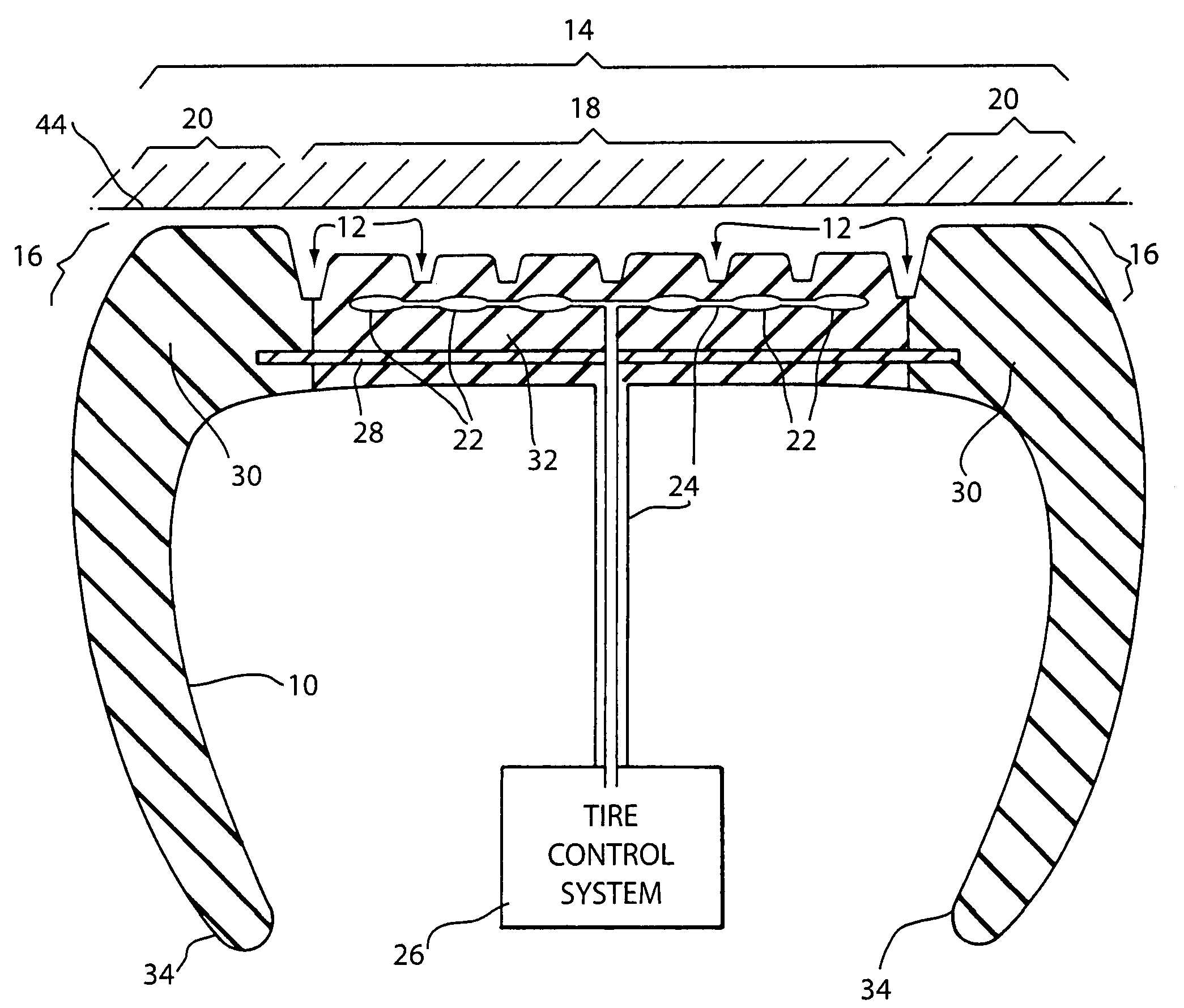

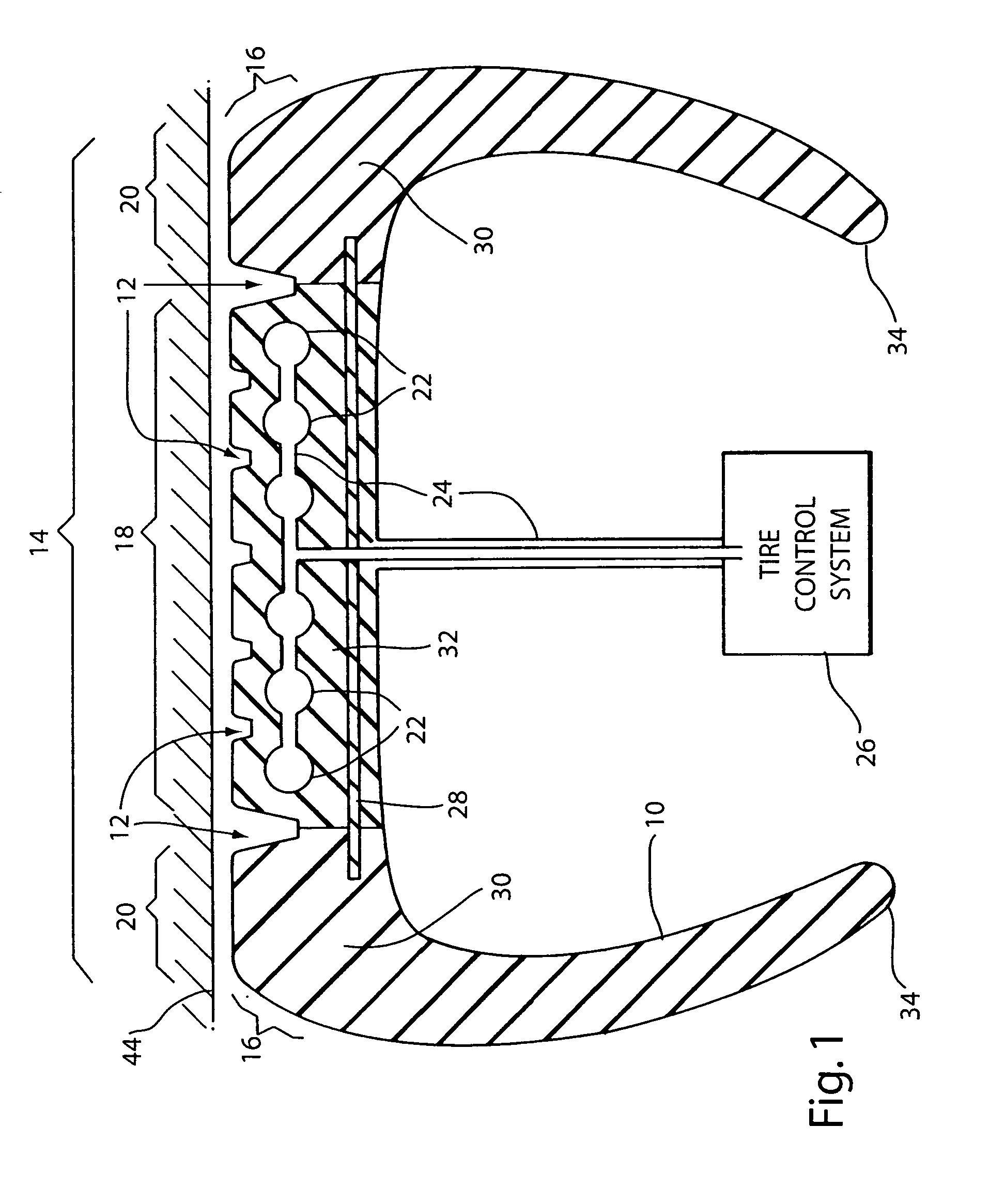

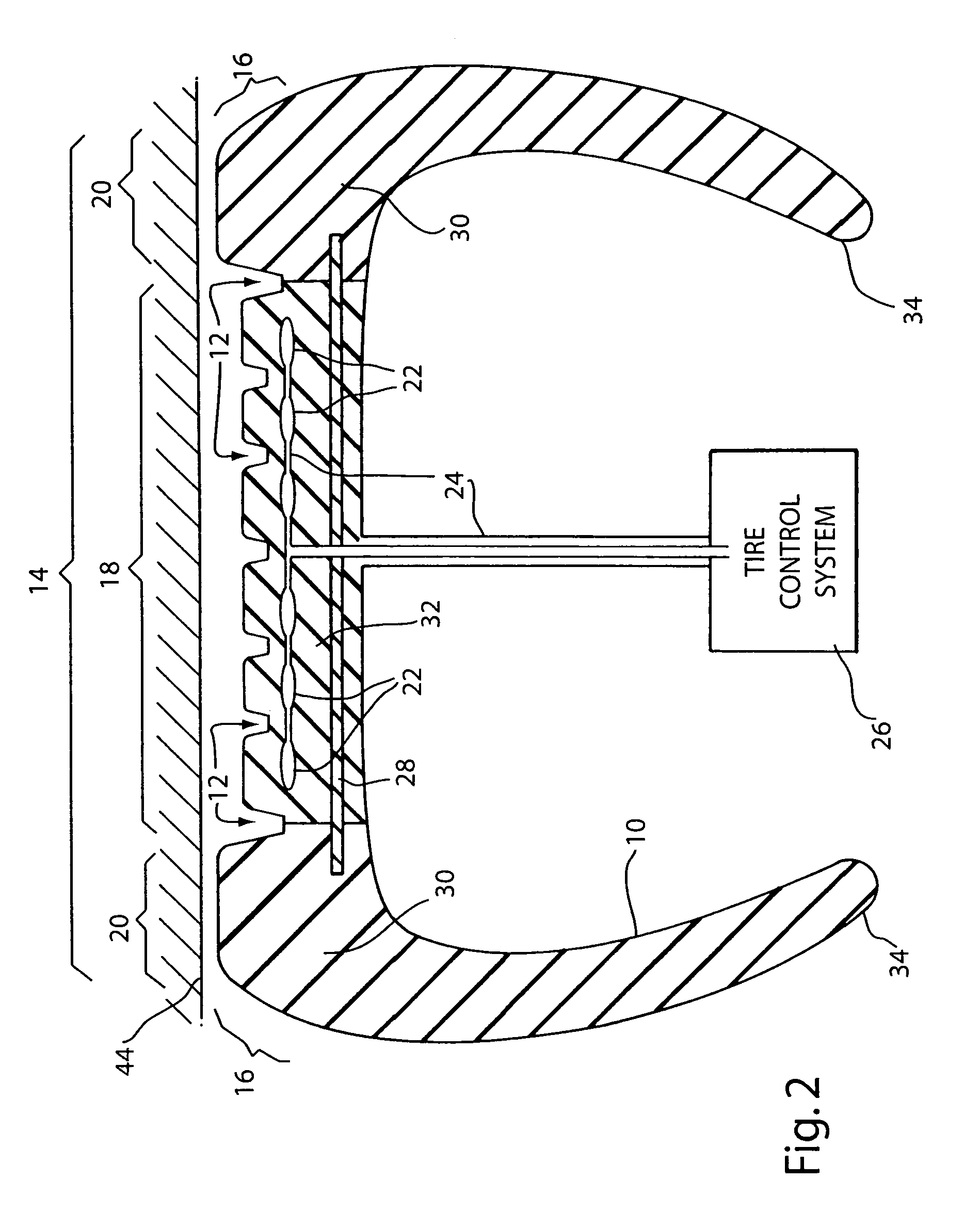

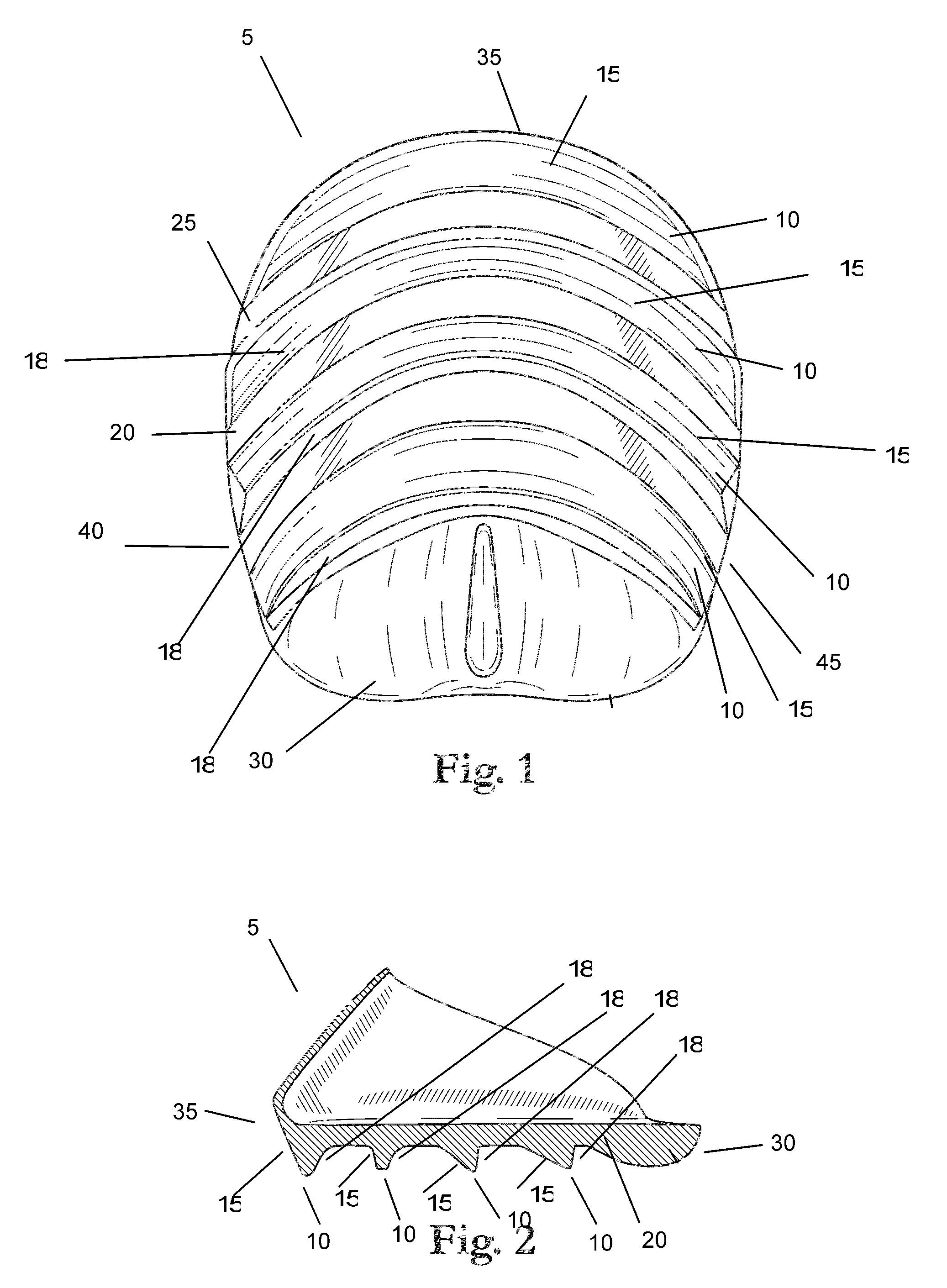

Fuel efficient vehicle tire having a variable footprint and low rolling resistance

InactiveUS7066226B1Low gas consumptionEffective dry tractionSpecial tyresTyre tread bands/patternsGround contactMicrocomputer

A tire for vehicles offering low rolling resistance wherein the ground-contact surface area is variable as a portion of the tread part can be retracted and / or extended using pneumatic, mechanical or hydraulic force to withdraw from, or come into contact with the road surface before, during or after operation permitting more efficient operation wherein the material used within the tread part that retains contact with the road may generally have a smaller internal friction loss than the material used in conventional tires and the rolling resistance is thereby reduced when the retractable portion of the tread is selectively withdrawn from contact with the road surface furthermore achieving a smaller ground-contact patch footprint. The achieved object of a tire with a lower rolling resistance yields improved fuel consumption efficiency. Improvements in exterior and interior noise levels and a reduced tendency to exhibit hydroplaning action are also attained with a variable groove volume to tread surface-contact ratio. Within one embodiment of the present invention, an automated microcomputer-based tire control system is disclosed useable to command the motion of the moveable tread portion of the said tire in response to various operational scenarios.

Owner:FIORE ROBERT ANGELO

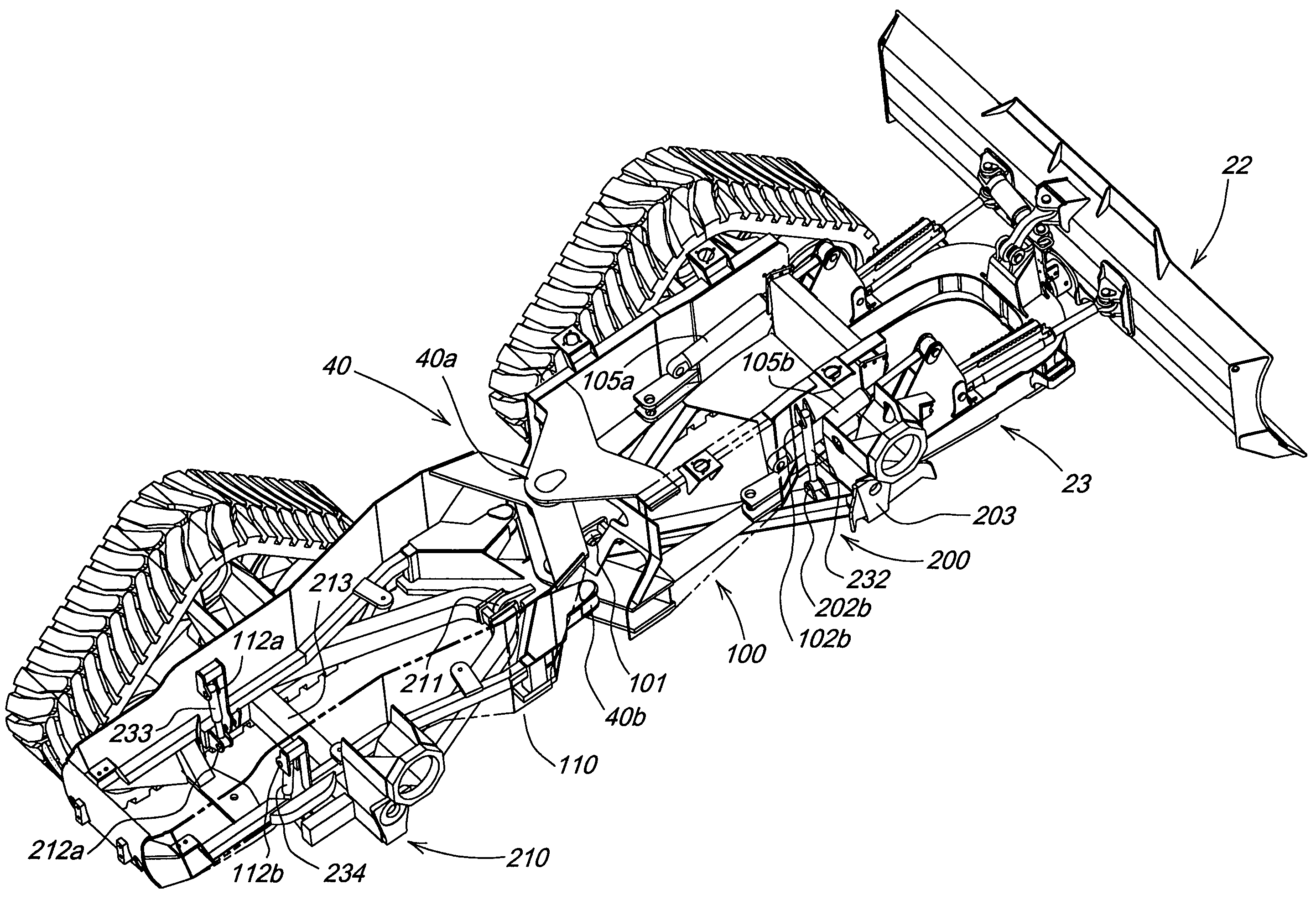

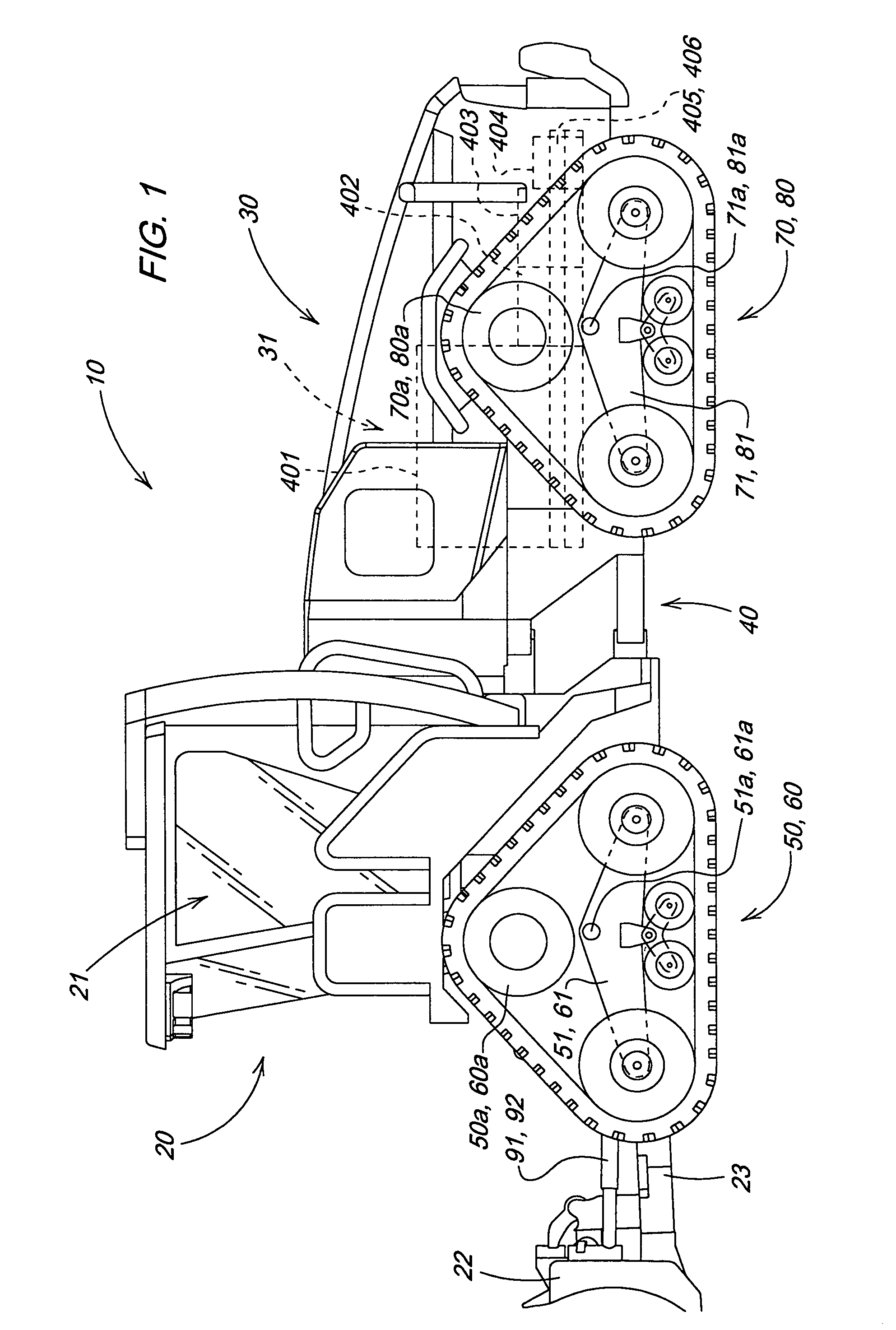

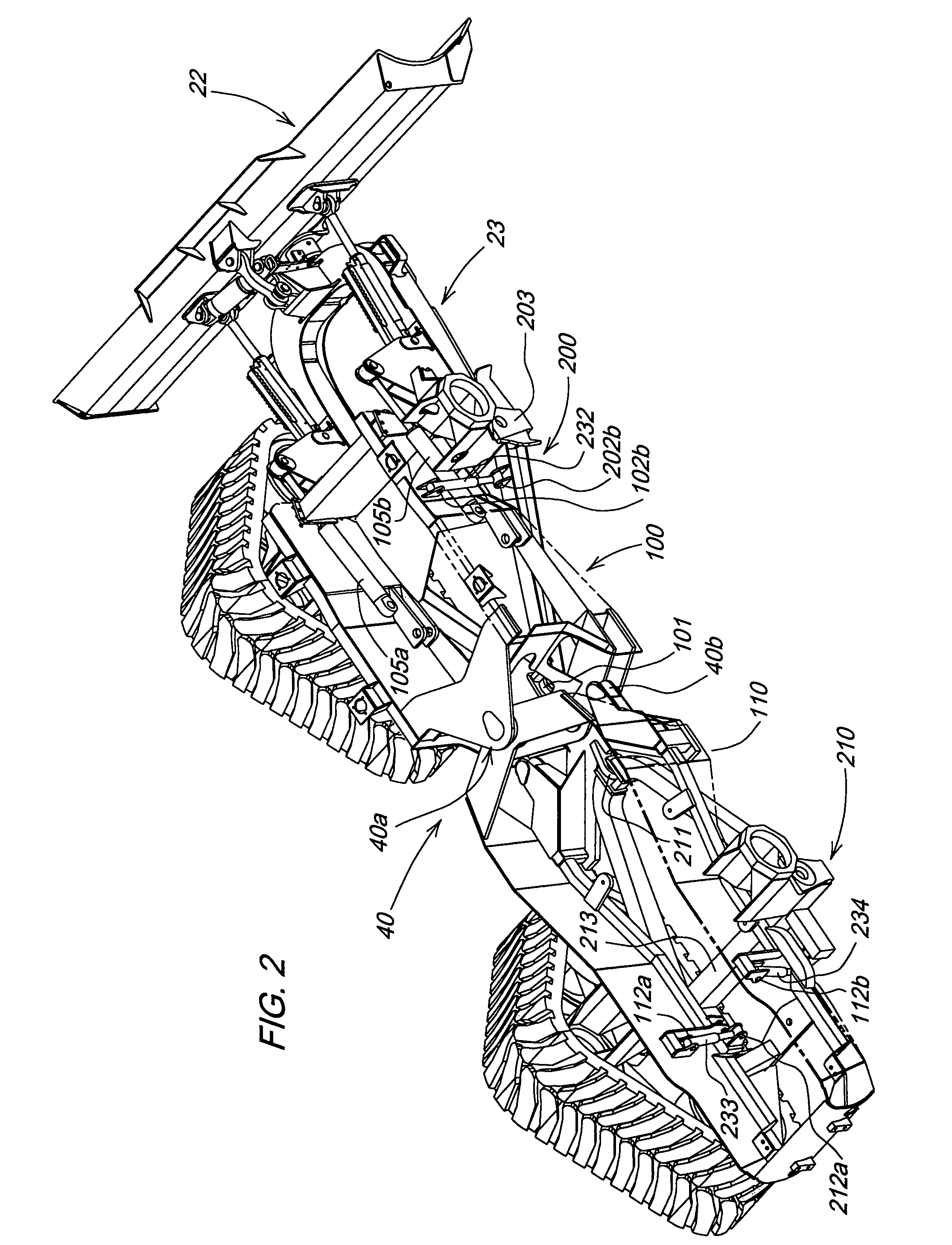

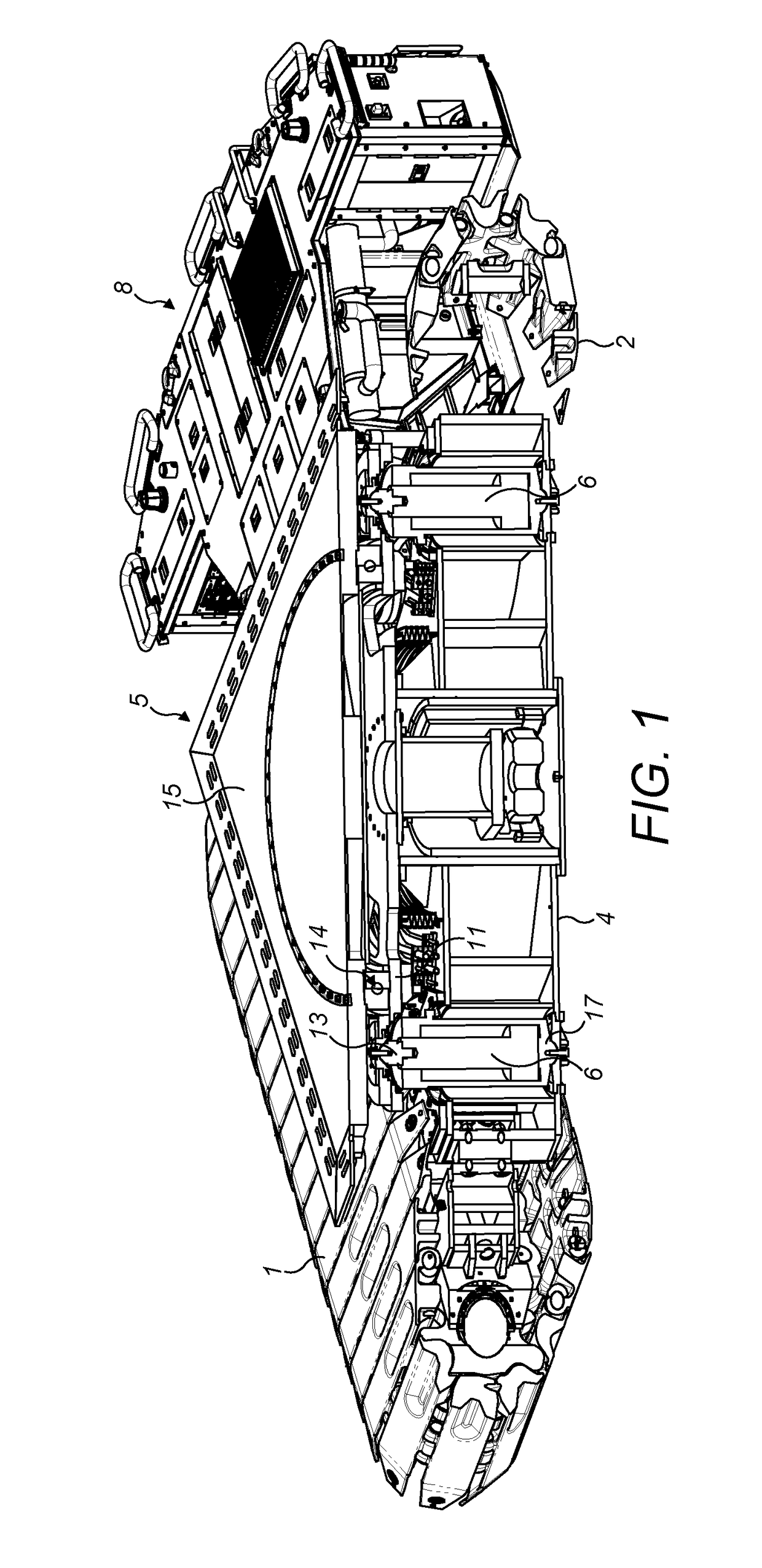

Articulated crawler tractor

InactiveUS7617881B2High effortPower Loss MinimizationAgricultural machinesVehicle cleaning apparatusVisibilityBraced frame

An articulated dozer with a four point independent suspension system between a chassis and two support frames is described. The chassis includes a front chassis portion and a rear chassis portion connected by an articulation joint. The vehicle is compactly arrange so that the chassis and the two support frames fit between the track systems supporting and propelling the vehicle. Additionally, the engine is arranged near the articulation joint and lower than the top of the track systems for improved view and visibility. The cab is arranged over the track systems at the front of the vehicle for an optimal view of the blade.

Owner:DEERE & CO

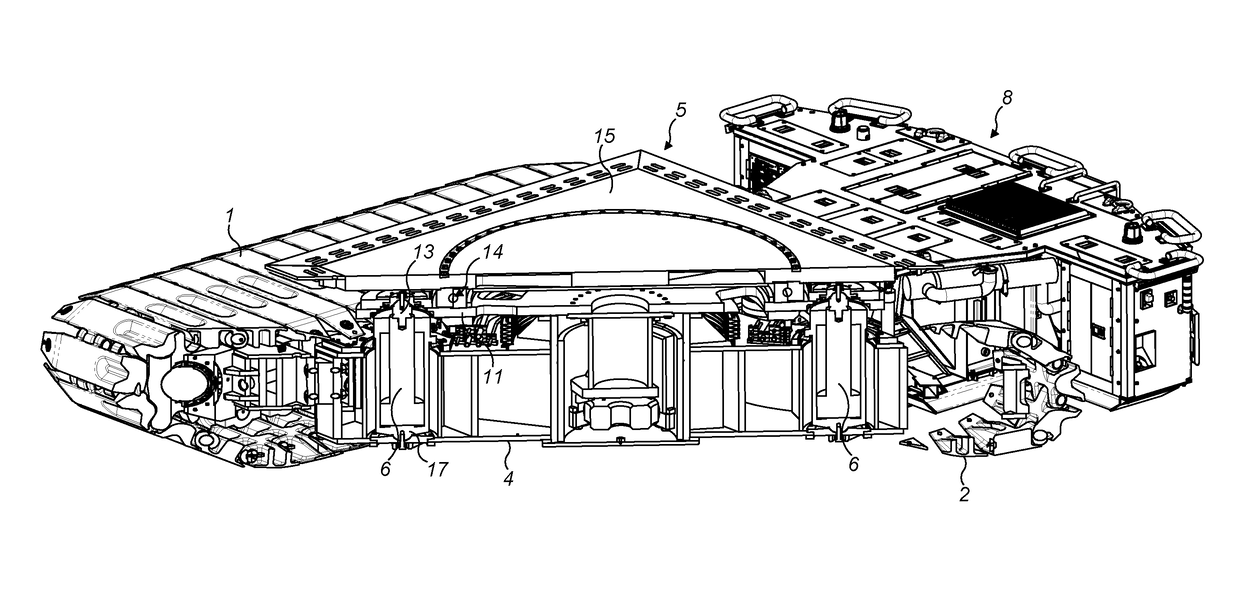

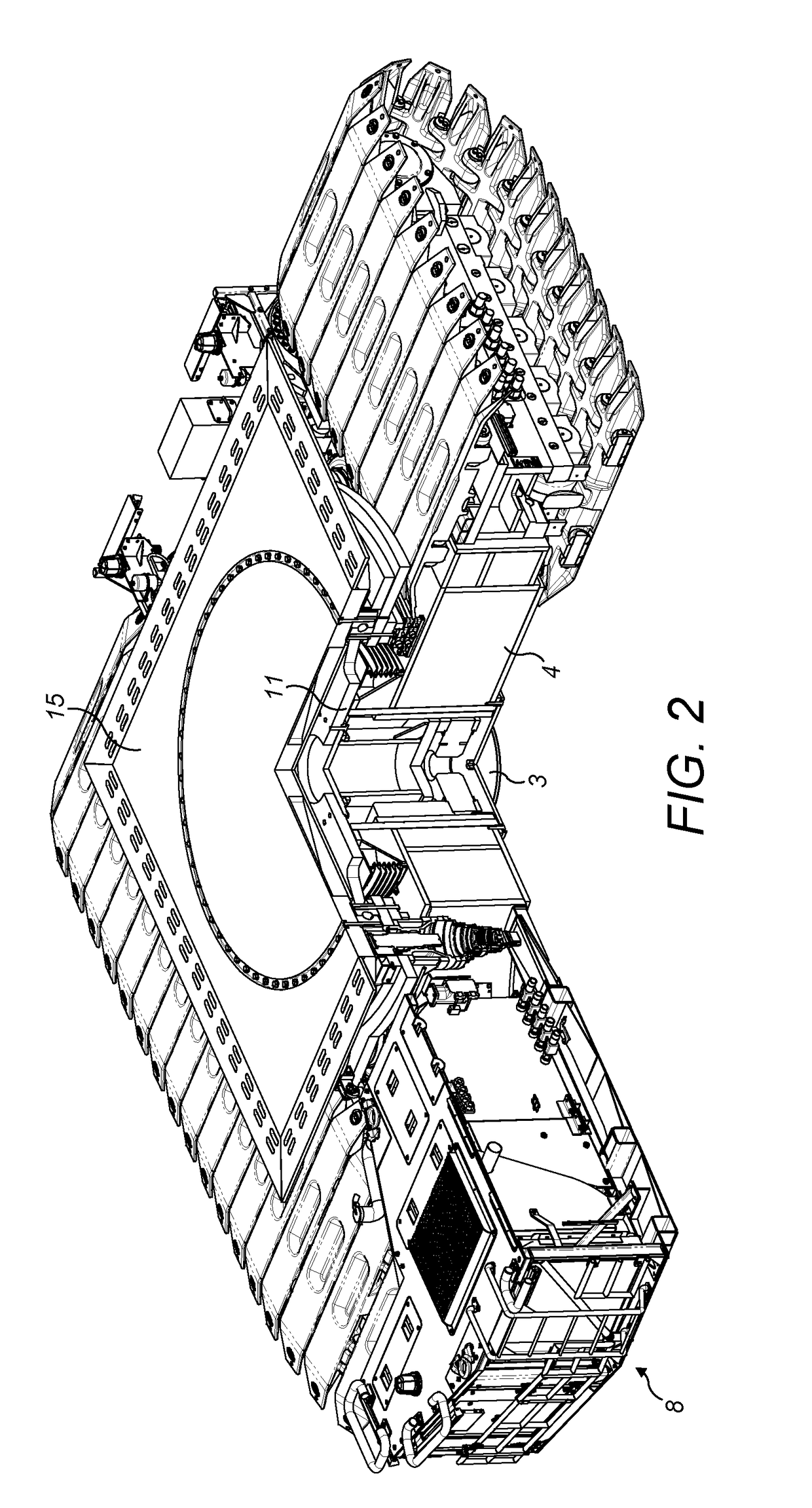

Transporter

ActiveUS9682645B2Control freedomConvenient to accommodateItem transportation vehiclesVehicle with parallel load movementGround contactPayload

A transporter for the transport of a large payload across an uneven ground surface is described. The transporter has a body (4); ground contacting transport means below the body, provided with drive means (1,2) to move the body across a ground surface in use; a payload support module (5) to support a payload above the body in use; and a plurality of elongate extendable elevators (6) each having a first articulated joint (17) with the body at a first end and a second articulated joint (13) with the payload support module at a second end. It is characterised in that each of the plurality of elongate extendable elevators is independently operable so as to enable the elongate extendable elevators (6) together to vary both the height and the attitude of the payload relative to the body; and in that at least one of each of the first (17) or second (13) articulated joints comprises a rotationally restricted joint that allows the elongate extendable elevator (6) to pivot relative to an axis orthogonal to its elongate direction but acts to prevent its rotation about an axis parallel to its elongate direction. The elongate extendable elevators are the means both by which the payload is lifted and by which the attitude of the payload is adjusted to enable it to balance.

Owner:MMD DESIGN & CONSULTANCY LTD

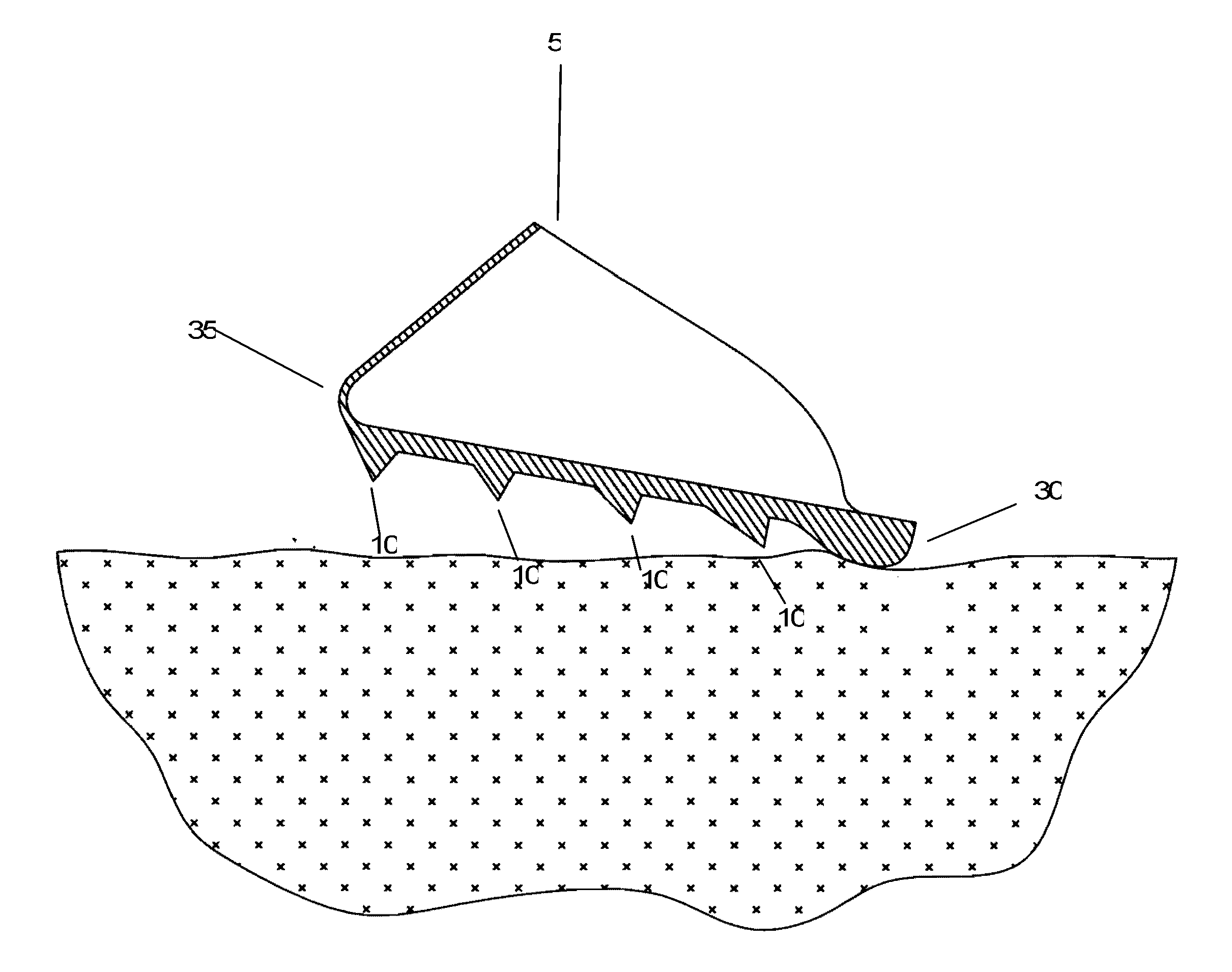

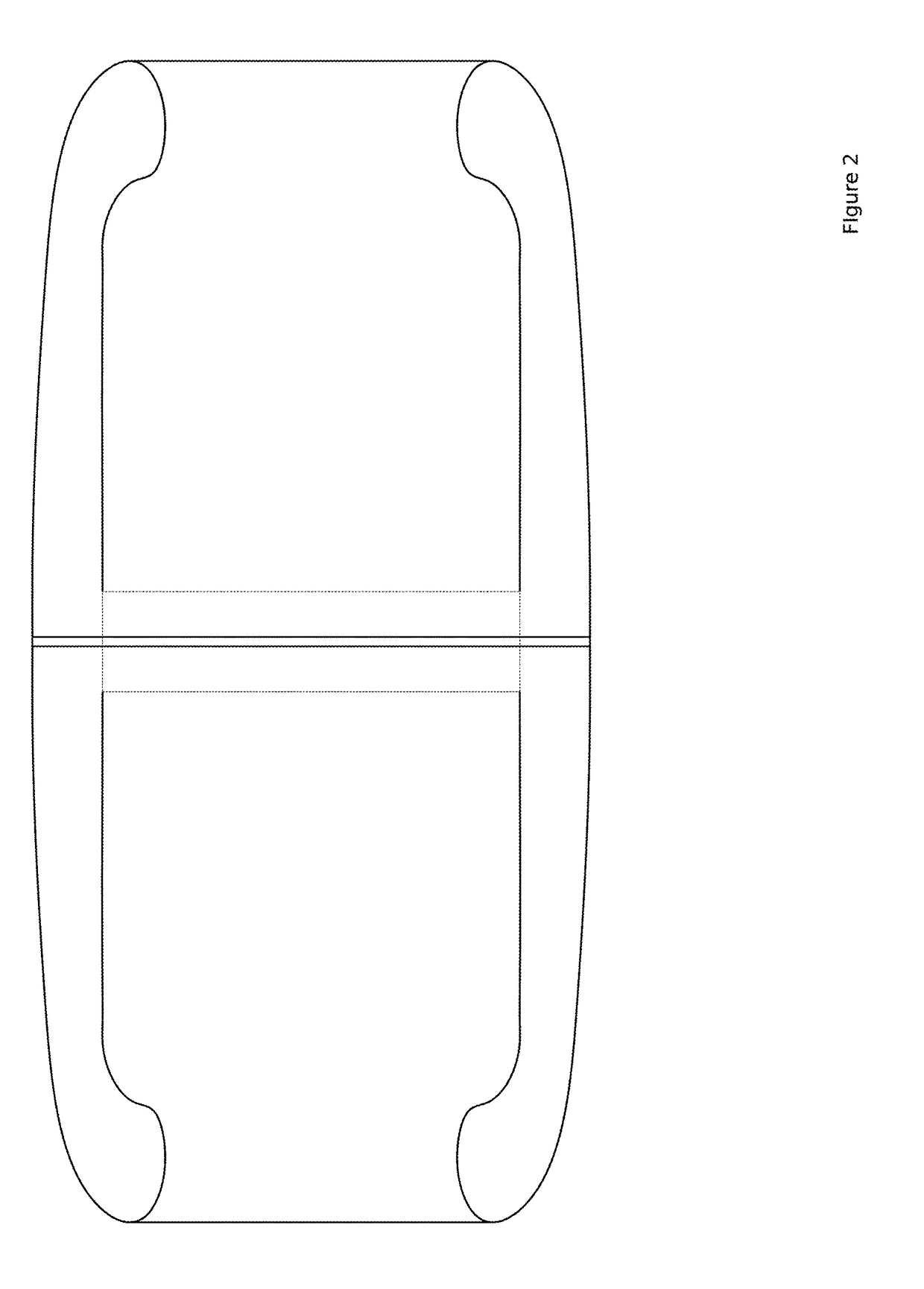

Lumbar recovery bed back support having three curved surfaces matching natural physiological curvature

InactiveUS20130213407A1Effective supportRestore the natural curvature of the lumbar vertebrae effectivelyOperating chairsSofasThoracic vertebraeCushion

A bed-cushion back-support (1) for lumbar recovery having three curved surfaces matching natural physiological curvature matches the natural curvature of the lower backbone of the human body and includes a convex surface (3) for the lumbar vertebrae, and reverse concave surfaces (2,4) for the sacral and lower thoracic vertebrae. The curved bed-surface formed by fixing the bed-cushion back-support on the bed board exactly matches the natural curvature of the backbone of a patient, and provides effective support to the backbone below the midportion of the thoracic vertebrae. With the effect of gravity on the human body, long-term use of the bed-cushion back-support provides long-term traction for an injured backbone, correcting deformities and restoring the functions of the lumbar vertebrae and surrounding tissues.

Owner:YANG DEZHAO

Hoof Boot

InactiveUS20120180441A1Great tractionEfficient locomotionProtection coversHorse protectorsEngineeringHoof

Owner:LANDER KIRT

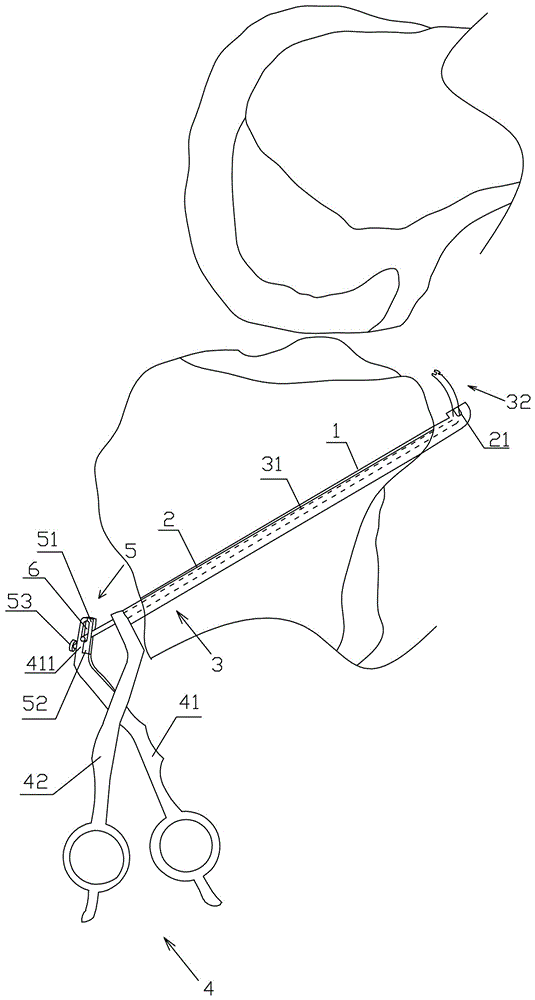

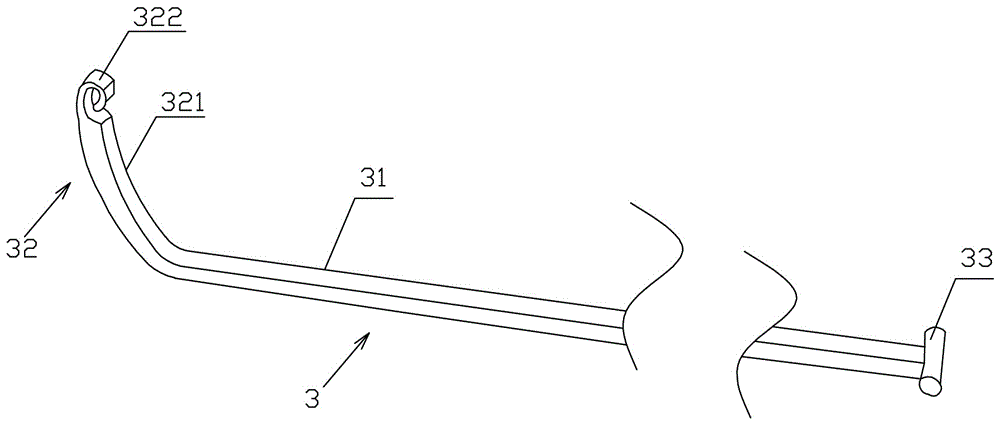

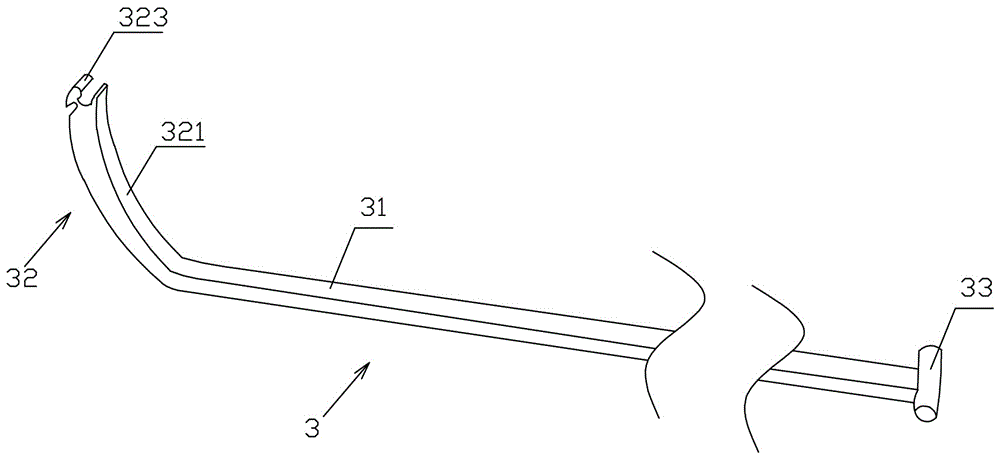

Tibial tunnel pass thread dragging, pushing and pulling device special for orthopedic surgery

The invention discloses a tibial tunnel pass thread dragging, pushing and pulling device special for orthopedic surgery. The device comprises a stretching-in pipe capable of penetrating through a tibial tunnel in adaptive mode. A movable push-pull rod is arranged in the pipe in a matched mode. The bending radian of the front working end of the movable push-pull rod can deform after force is borne and be automatically and elastically restored. When the device penetrates through the tunnel, the front end of the device can be sent to a position of which the height is 1-2 cm higher than the tunnel plane, a dragged thread is convenient to grasp or push out, the front end of the movable push-pull rod can be customized according to different thread pushing and dragging functions, and the bending radian of the movable push-pull rod can be customized to meet different strength requirements. Medical staff can more conveniently drag, push and eject the pass thread passing through the tibial tunnel, the push-pull rod can be rapidly replaced according to different surgical requirements, a doctor can conveniently perform surgical operation, pain of a patient is relieved, and the success rate of the surgery is increased.

Owner:吕宏升

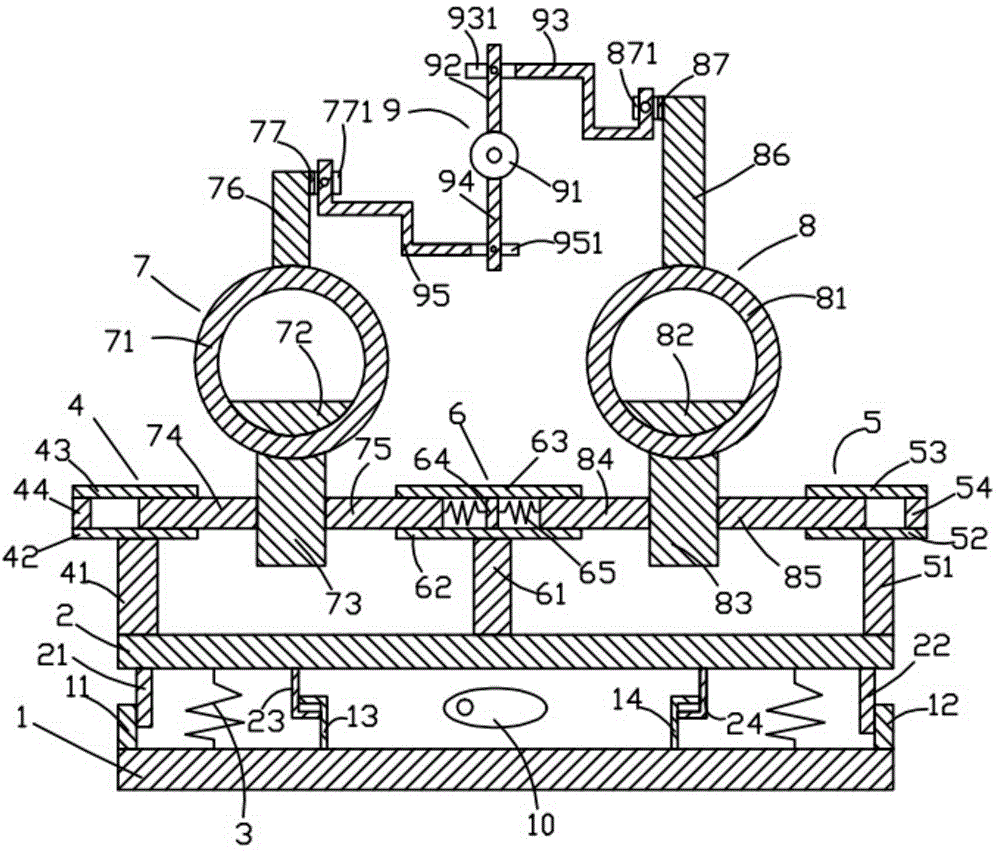

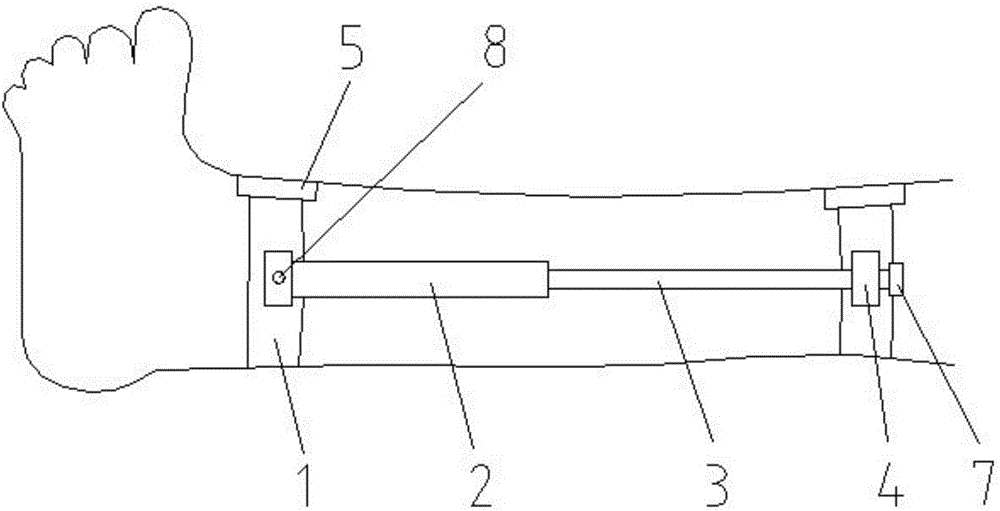

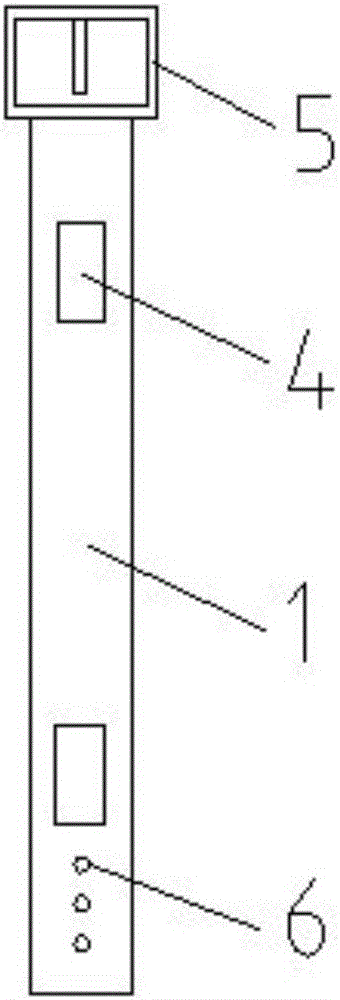

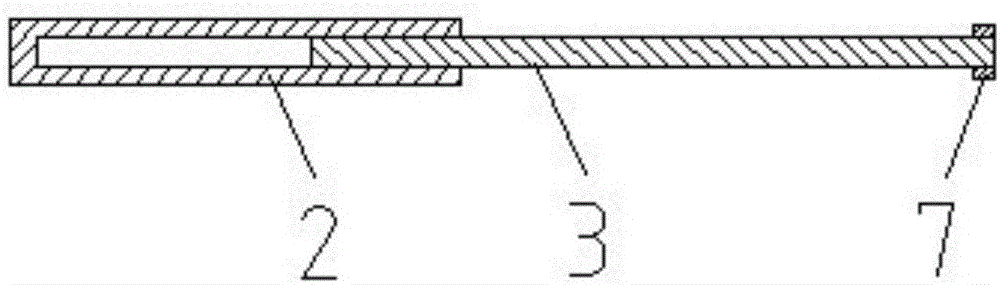

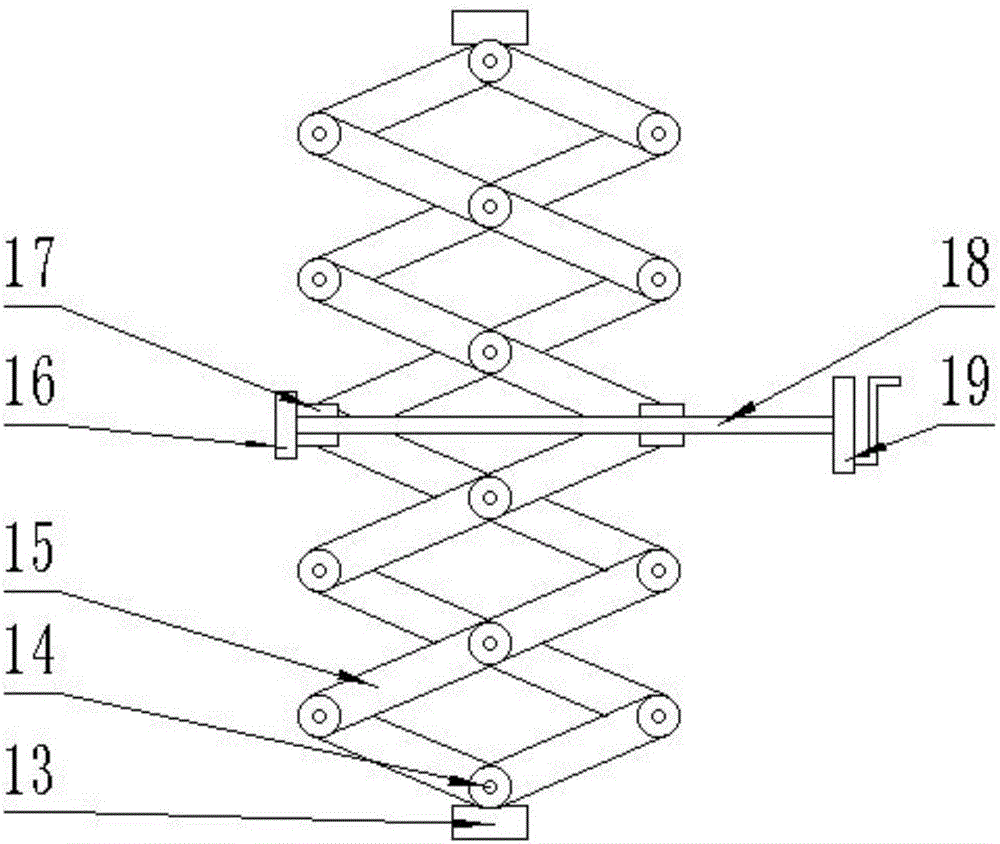

Traction frame for leg rehabilitation activities

A traction frame for leg rehabilitation activities comprises a base, a supporting plate, a first spring, a cam, a first positioning device, a second positioning device, a third positioning device, a first traction device, a second traction device and a driving device. The base is provided with a first positioning rod, a second positioning rod, a first buckling rod and a second buckling rod. The supporting plate is provided with a third positioning rod, a fourth positioning rod, a third buckling rod and a fourth buckling rod. The first positioning device comprises a first supporting post, a first positioning plate, a first connecting block and a second positioning plate. The second positioning device comprises a second supporting post, a third positioning plate, a fourth positioning plate, a second connecting block and a second spring. The third positioning device comprises a third supporting post, a fifth positioning plate, a sixth positioning plate and a third connecting block. The first traction device comprises a first traction framework, a first sponge pad, a first supporting rod, a first horizontal rod, a second horizontal rod, a second supporting rod and a first lug. Through the traction frame, health rehabilitation of legs can be rapid.

Owner:任永恒

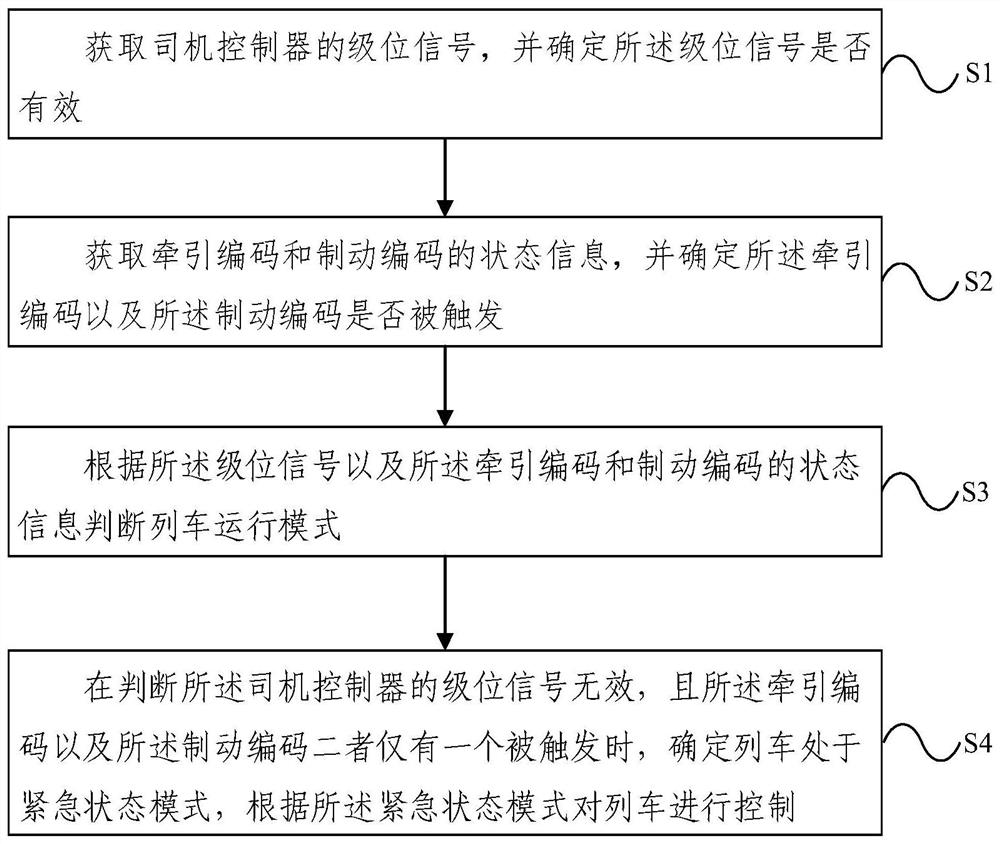

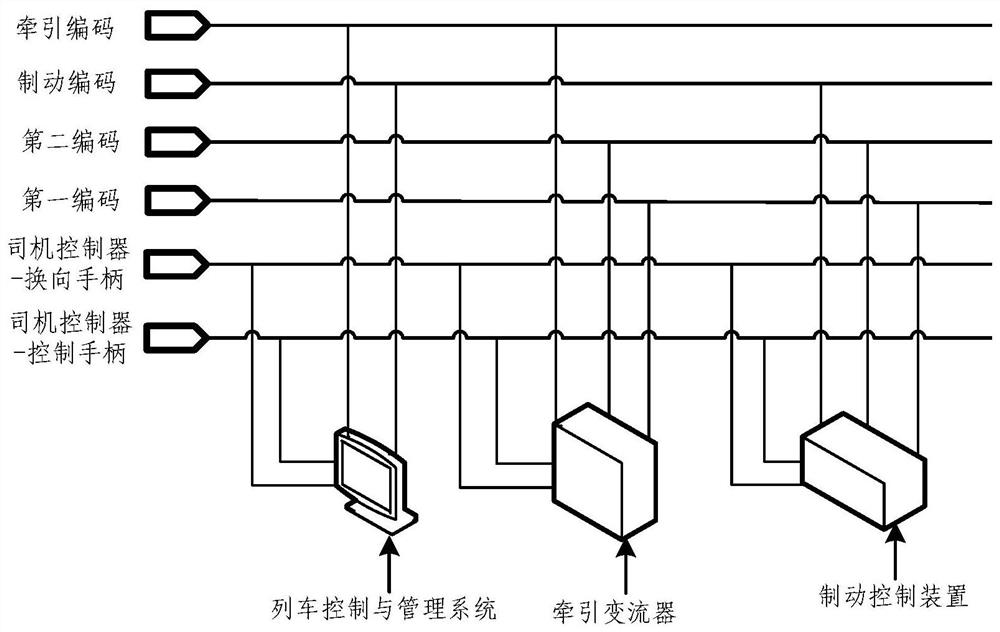

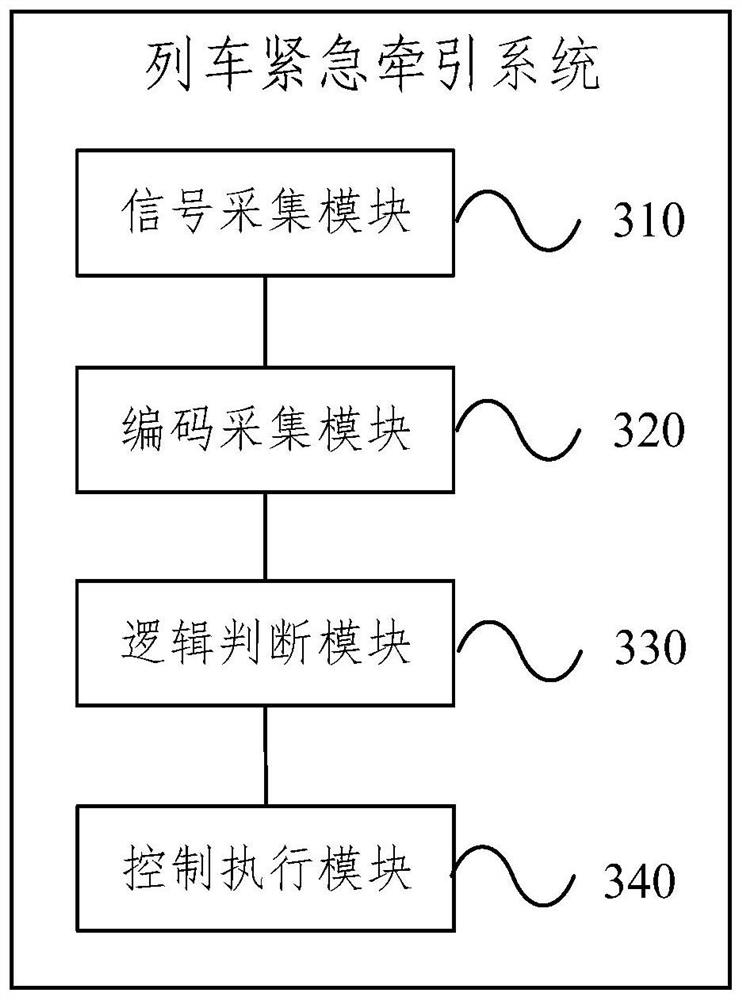

Train control method and system in emergency state, electronic equipment and storage medium

ActiveCN112092866AReduce the probability of parking and waiting for rescueImprove operational efficiencyRailway traffic control systemsReliability engineeringReal-time computing

Embodiments of the invention provide a train control method and system in an emergency state, electronic equipment and a storage medium. The train control method in the emergency state comprises the steps that a level signal of a driver controller is obtained, and whether the level signal is valid or not is determined; state information of a traction code and a brake code are obtained, and whetherthe traction code and the brake code are triggered or not is determined; a train operation mode is judged according to the level signal and the state information of the traction code and the brake code; and when it is judged that the level signal of the driver controller is invalid and only one of the traction code and the brake code is triggered, it is determined that a train is in an emergencystate mode, and the train is controlled according to the emergency state mode. When the driver controller breaks down, traction or braking can be effectively conducted, the probability that a train stops and waits for rescue is reduced, and the running efficiency of the train is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

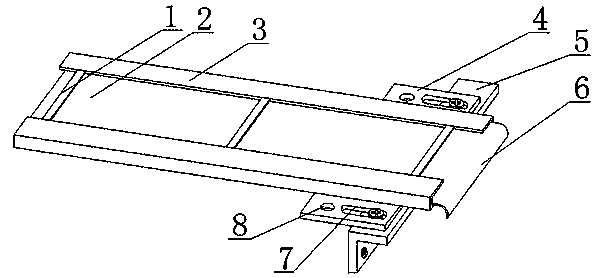

Leather traction device for shoemaking leather

InactiveCN104342504AEasy to cascadeResolve intertwining fromLeather manufacturingSkins/hides/leather/fur manufacturing apparatusEngineering

A leather traction device for shoemaking leather is disclosed. The leather traction device comprises a traction plate (2). Two sides of the traction plate (2) are bended upward and then bended horizontally to form pressing plates (3). Connecting plates (1) are disposed between the two pressing plates (3). Positioning plates (4) are connected to two sides of the lower end of the traction plate (2) and are connected to a right-angle bending plate (4) through bolts. The leather traction device is simple in structure and low in cost, can effectively tract leather, and can avoid the problems of laminating and twining during leather levelling.

Owner:陈小波

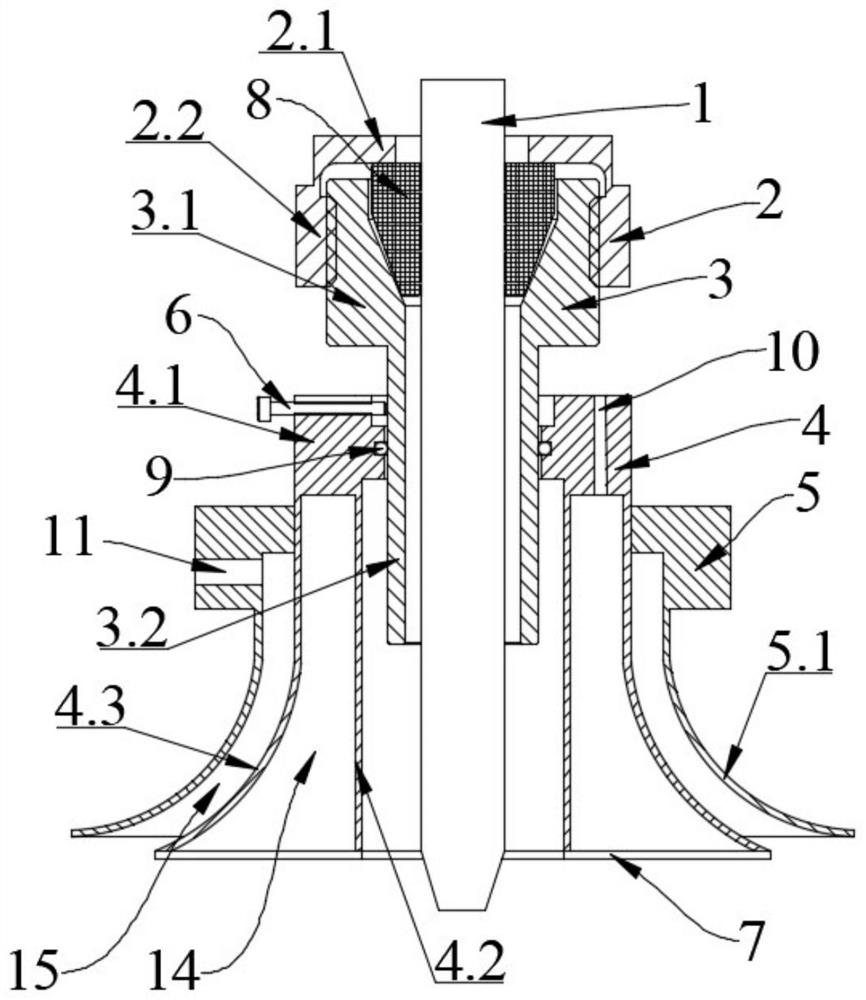

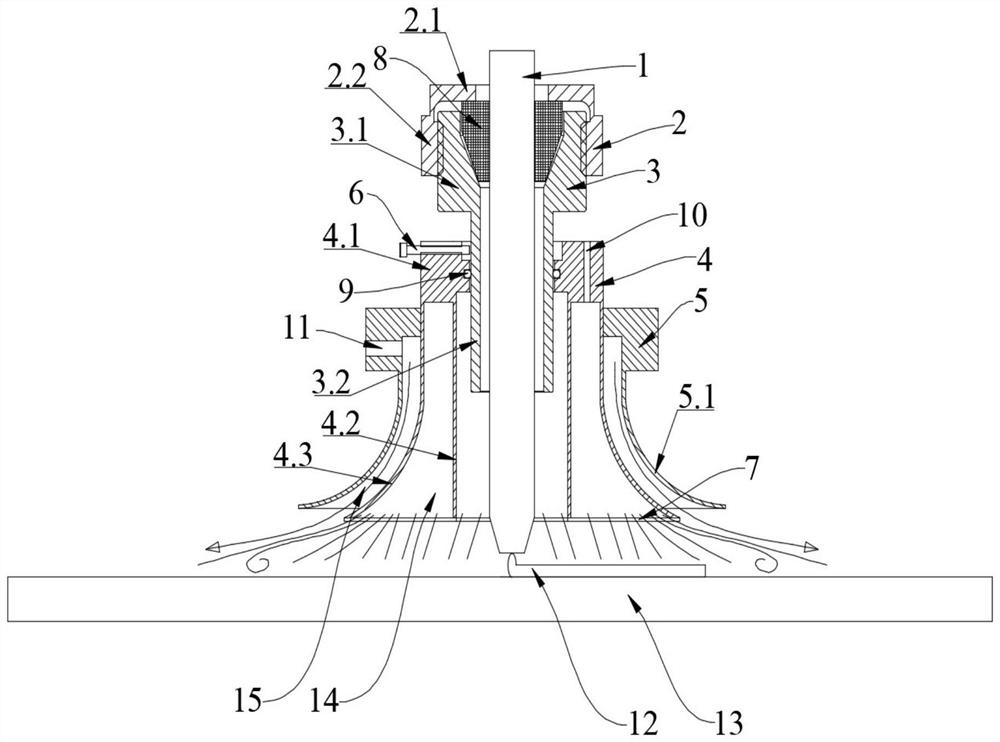

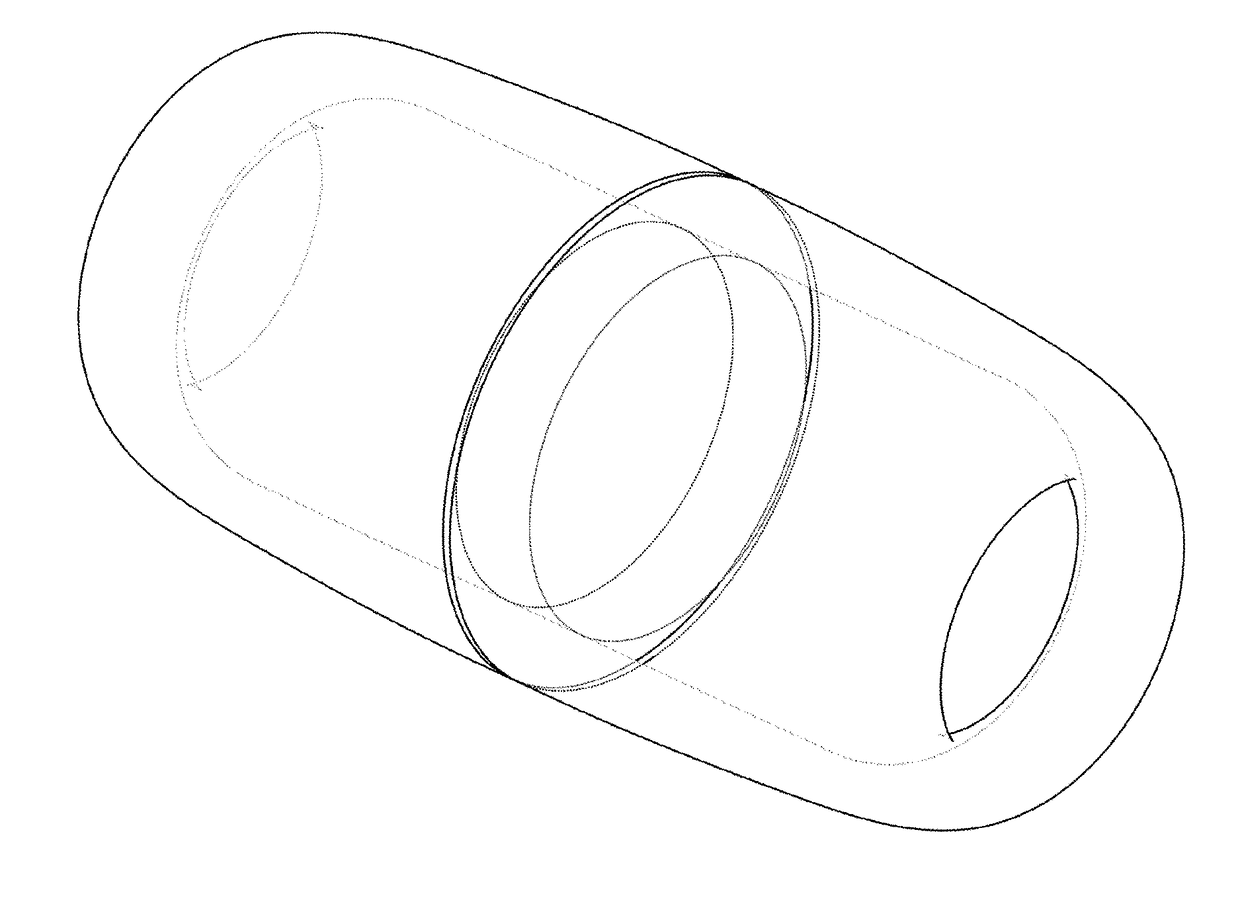

Synchronous air cooling device for gas protective additive

PendingCN112059380AIncrease flow rateEffective tractionShielding gas supply/evacuation devicesAdditive manufacturing apparatusShielding gasEngineering

The invention provides a synchronous air cooling device for a gas protective additive. The synchronous air cooling device comprises an inner cover body and an outer cover body, wherein the inner coverbody is installed on a welding gun in a sleeving mode, an annular sealing plate is installed at the bottom end of the inner cover body, the annular sealing plate is connected with the inner wall andthe outer wall of the inner cover body to form a first accommodating chamber, a protective gas inlet is formed in the top end of the inner cover body and used for injecting protective gas, and a plurality of fine holes are formed in the annular sealing plate and used for allowing the protective gas to flow out; and the outer cover body is installed on the outer wall of the inner cover body in a sleeving manner, a second accommodating chamber is formed by the outer cover body and the outer wall of the inner cover body, a compressed gas inlet is formed in the top end of the outer cover body andused for injecting compressed gas, and a compressed gas outlet is formed in the bottom end of the outer cover body and used for allowing the compressed gas to flow out. According to the synchronous air cooling device for the gas protective additive, the problems that the metal welding cooling speed is low, synchronous cooling is difficult and strength and grain size grade are obviously reduced inthe prior art are solved.

Owner:佛山宇仁智能科技有限公司

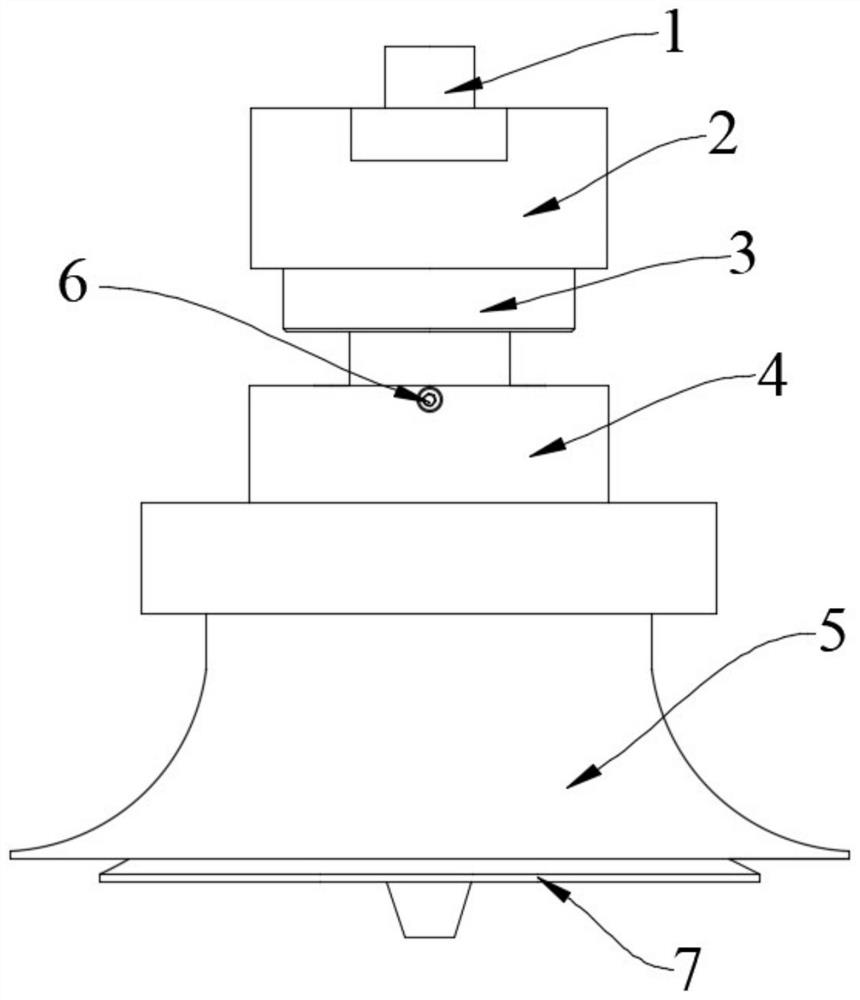

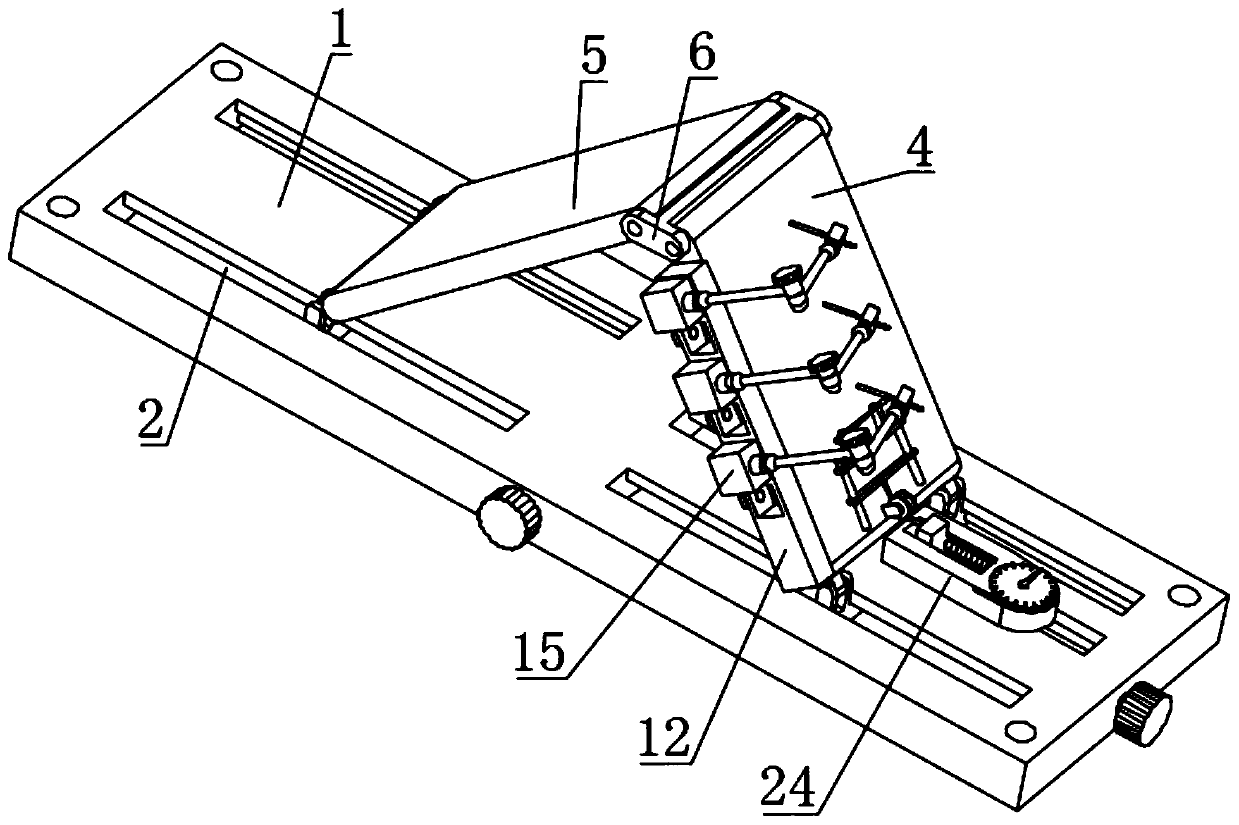

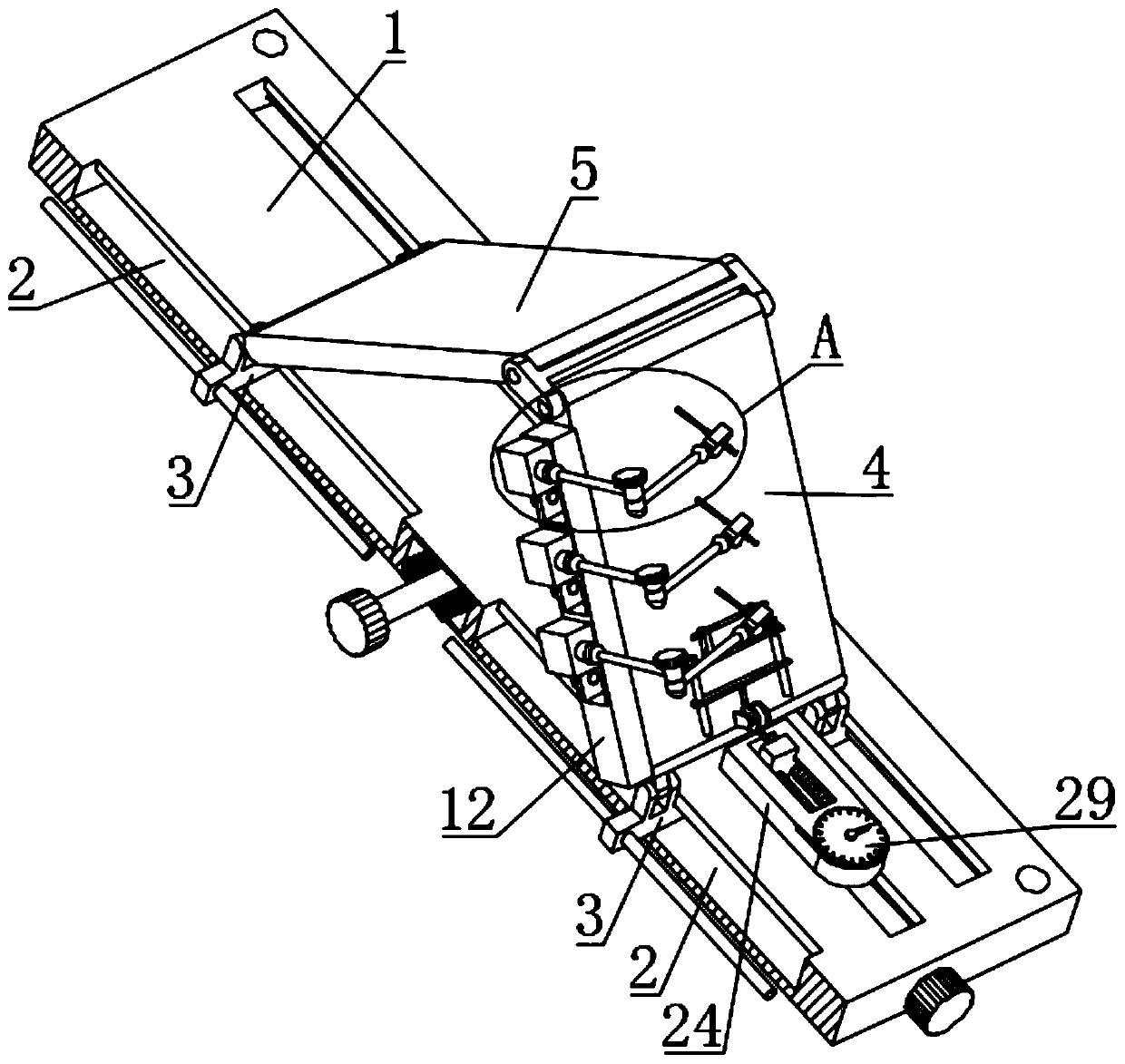

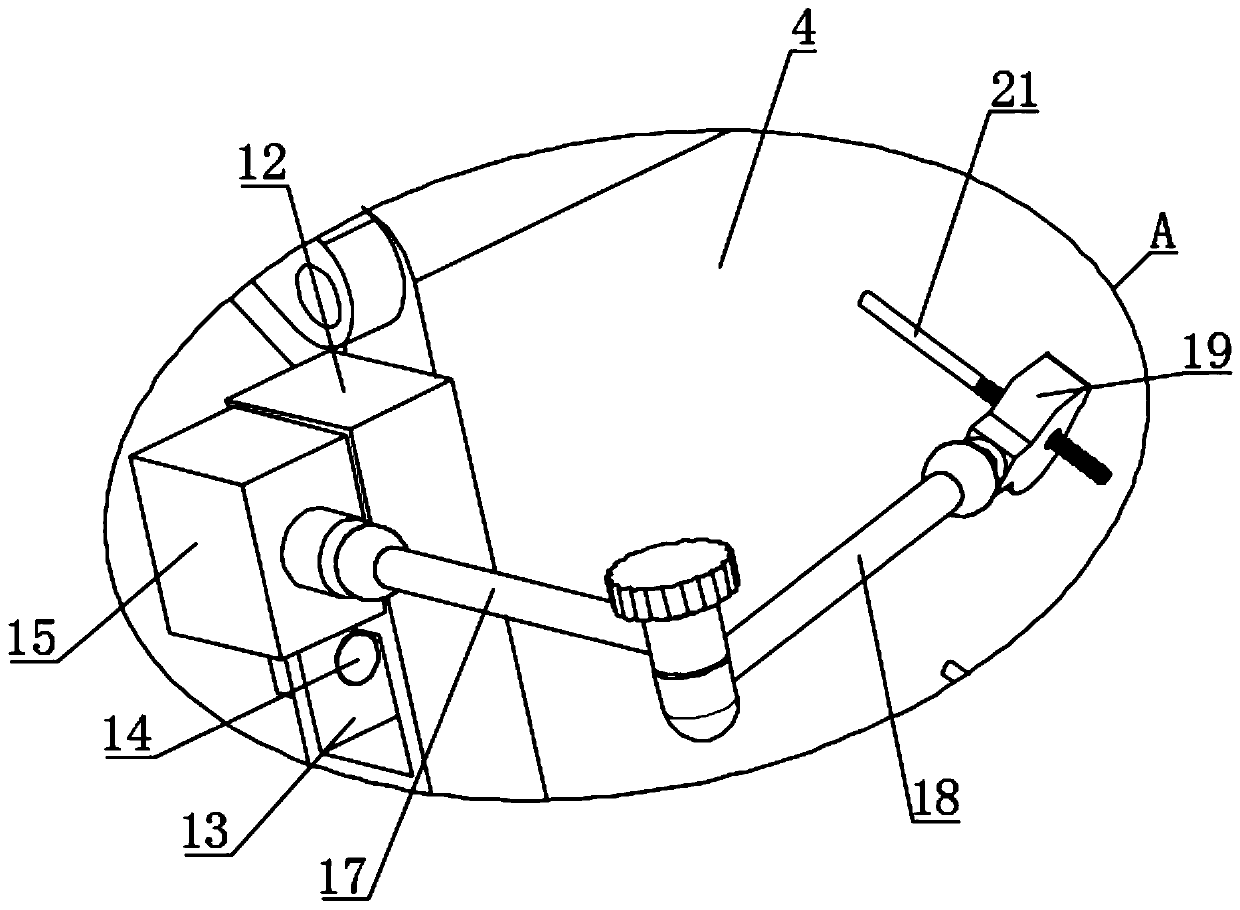

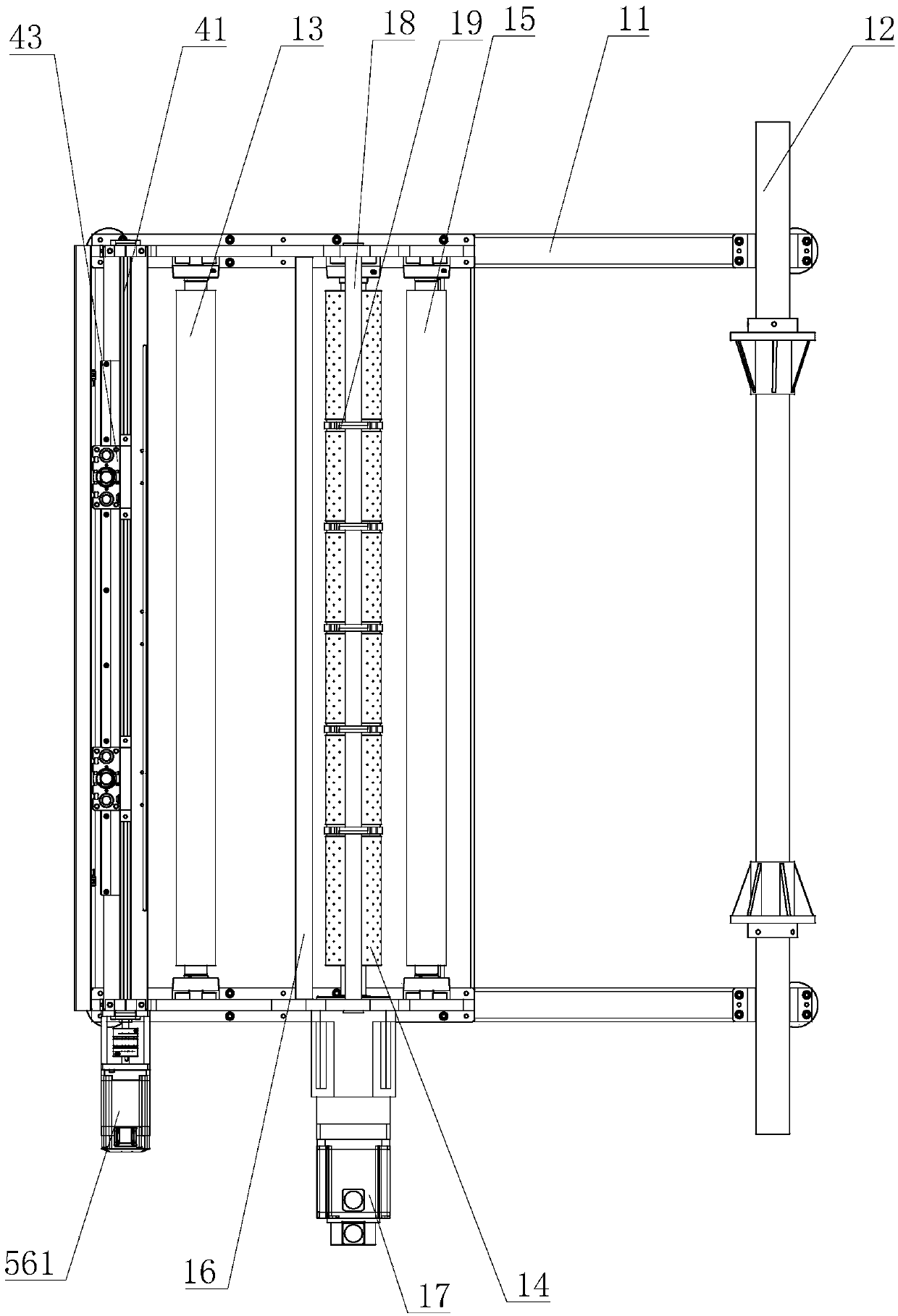

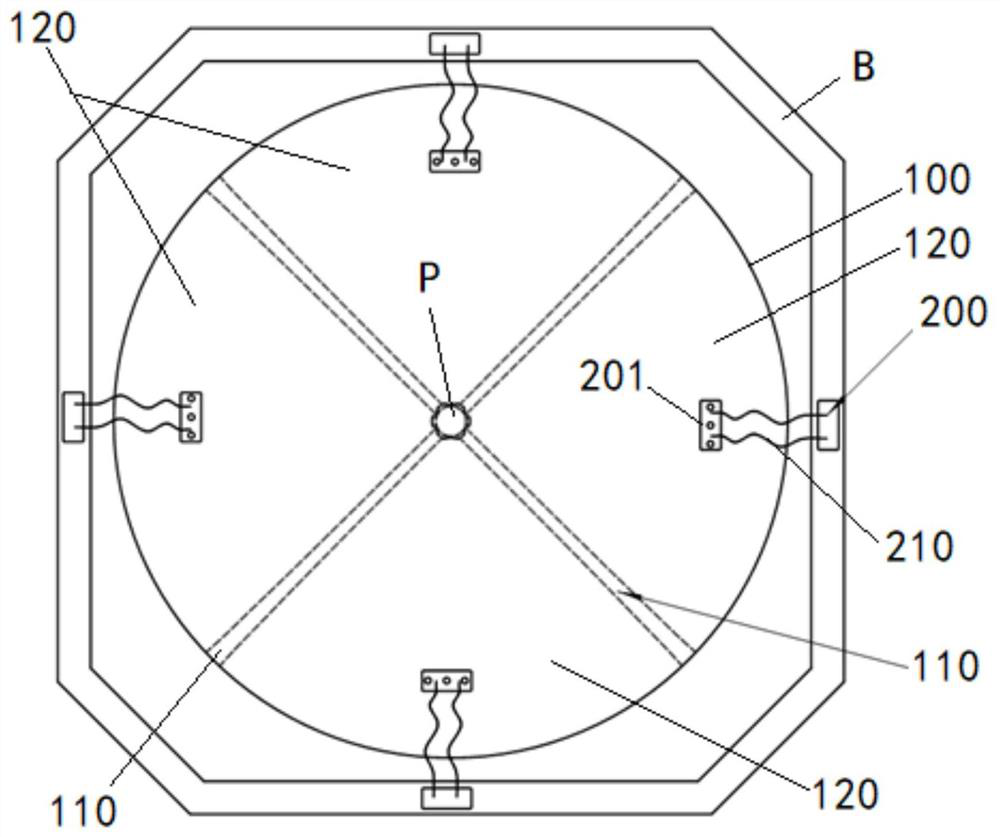

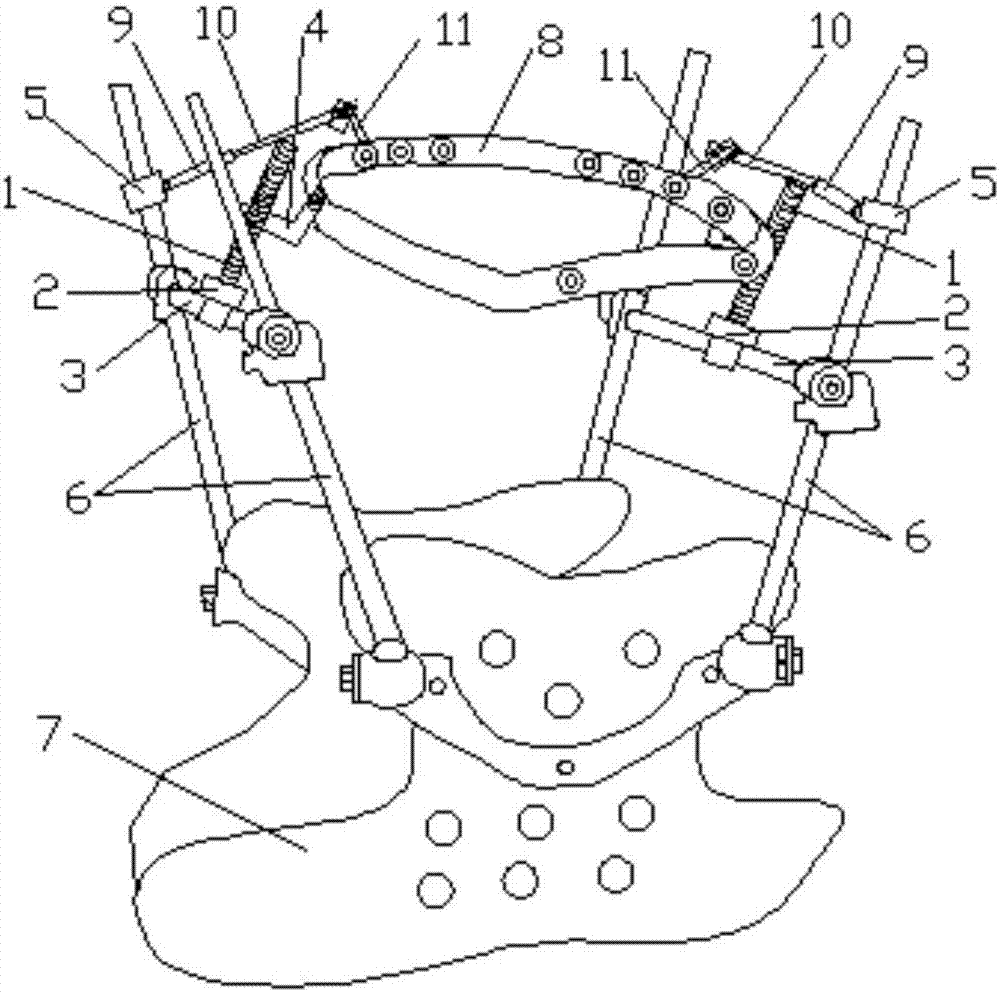

Multi-directional traction frame for closed reduction of tibial fracture

PendingCN109700514ALarge degree of curvatureMinimally invasive and easy to implantExternal osteosynthesisTraction frameEngineering

The invention discloses a multi-directional traction frame for closed reduction of tibial fracture. The multi-directional traction frame comprises a bottom plate having a bearing effect, wherein the bottom plate is fixed to an outside device through four-corner mounting holes; sliding chutes are formed in two ends in the bottom plate, and a sliding block is in sliding connection to the inner partof each sliding chute; a first supporting plate and a second supporting plate are rotatably connected to the upper sides of the two sliding blocks, and the upper side of the first supporting plate andthe upper side of the second supporting plate are rotatably connected through a hinge; a plurality of clamping chutes are formed in a fixed rod; a movable block is in movable and clamped connection to the inner part of each clamping chute; and a first connecting rod, a second connecting rod and a holding plate are sequentially and rotatably connected to each movable block, a rotating button is rotatably connected to the inner part of each holding plate, and a clamping rod is in meshed connection to the center of each rotating button. According to the multi-directional traction frame disclosedby the invention, through discretionary rotation of the first connecting rod and the second connecting rod, and through rotating second screw rods, the multi-directional traction frame can be fixed at discretionary position, and besides, the angle of the holding plates can be in universal regulation, so that the clamping rods can be moved leftwards, rightwards, forwards and backwards, and furthereffective traction for multiple fracture sites can be achieved.

Owner:袁建敏

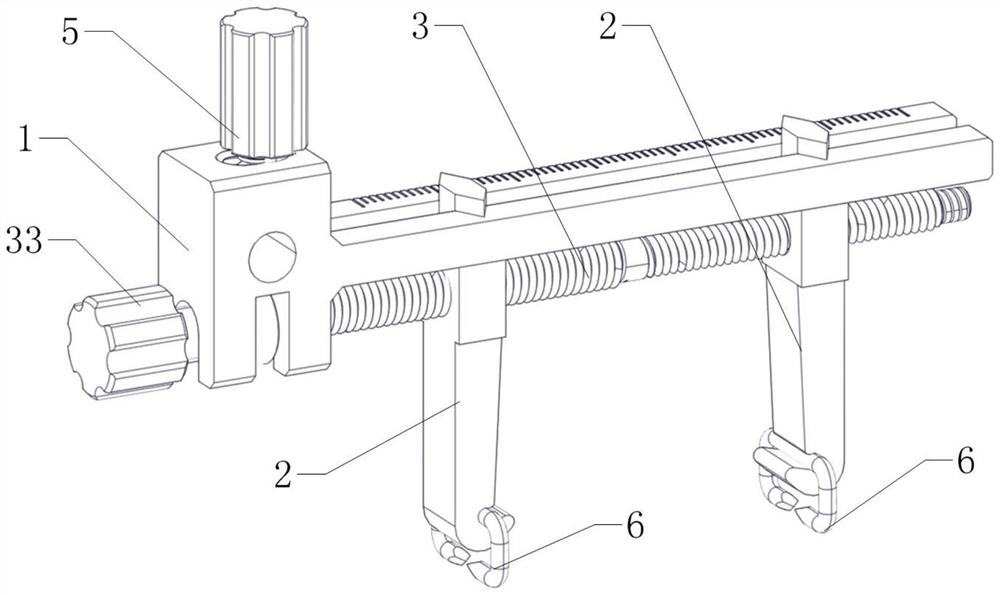

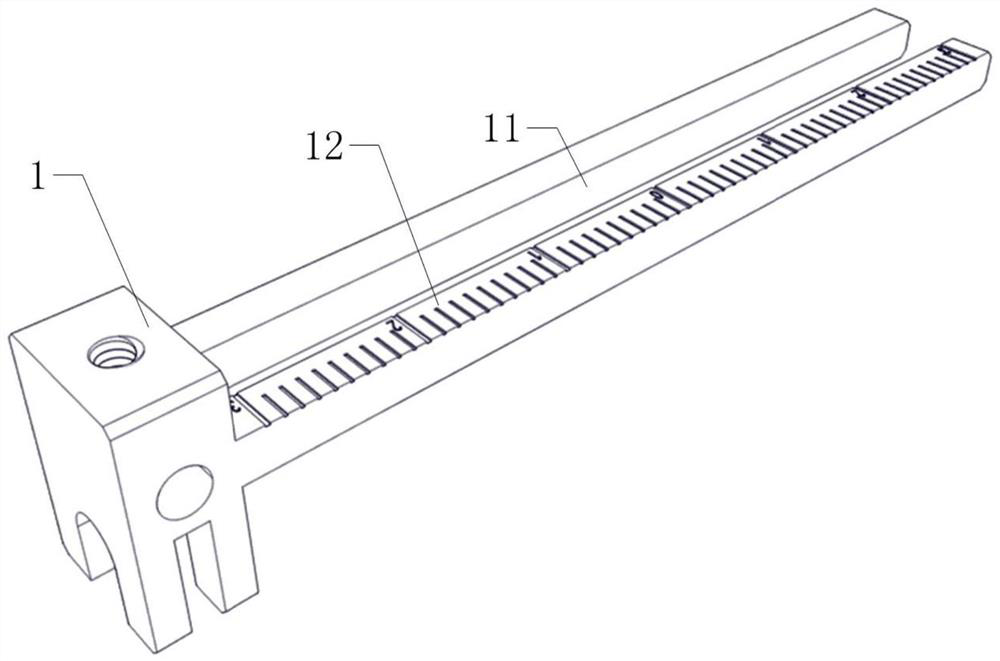

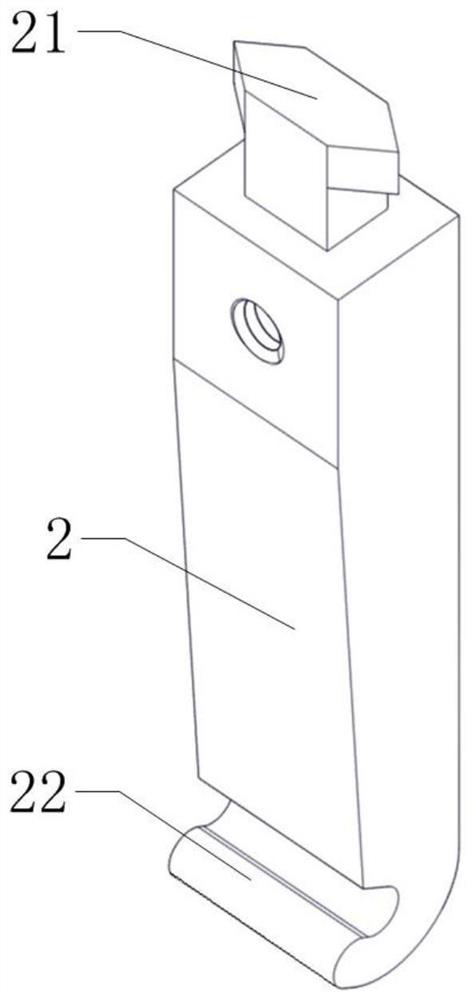

Skin tension reducer

The invention discloses a skin tension reducer. The skin tension reducer comprises a guide frame and two sliding blocks, wherein the two sliding blocks are located at two sides of a skin wound; the extending direction of the guide frame is perpendicular to those of the sliding blocks; a sliding chute extending in the same direction is formed in the guide frame; the upper ends of the sliding blocksare movably installed in the sliding chute; fixing needles penetrating through the skin are installed at the lower ends of the sliding blocks; and an adjusting screw is installed on the guide frame in parallel, is in threaded connection with the sliding blocks and is used for driving the two sliding blocks to get close to or away from each other. The skin at two sides of the wound is fixed through the fixing needles at the lower ends of the two sliding blocks, and then the distance between the two sliding blocks is adjusted through the adjusting screw, so that the traction distance is adjusted; and when a patient with a large wound and multiple skin defects is treated, quantitative, stable, continuous and effective traction can be achieved.

Owner:THE SECOND XIANGYA HOSPITAL OF CENT SOUTH UNIV

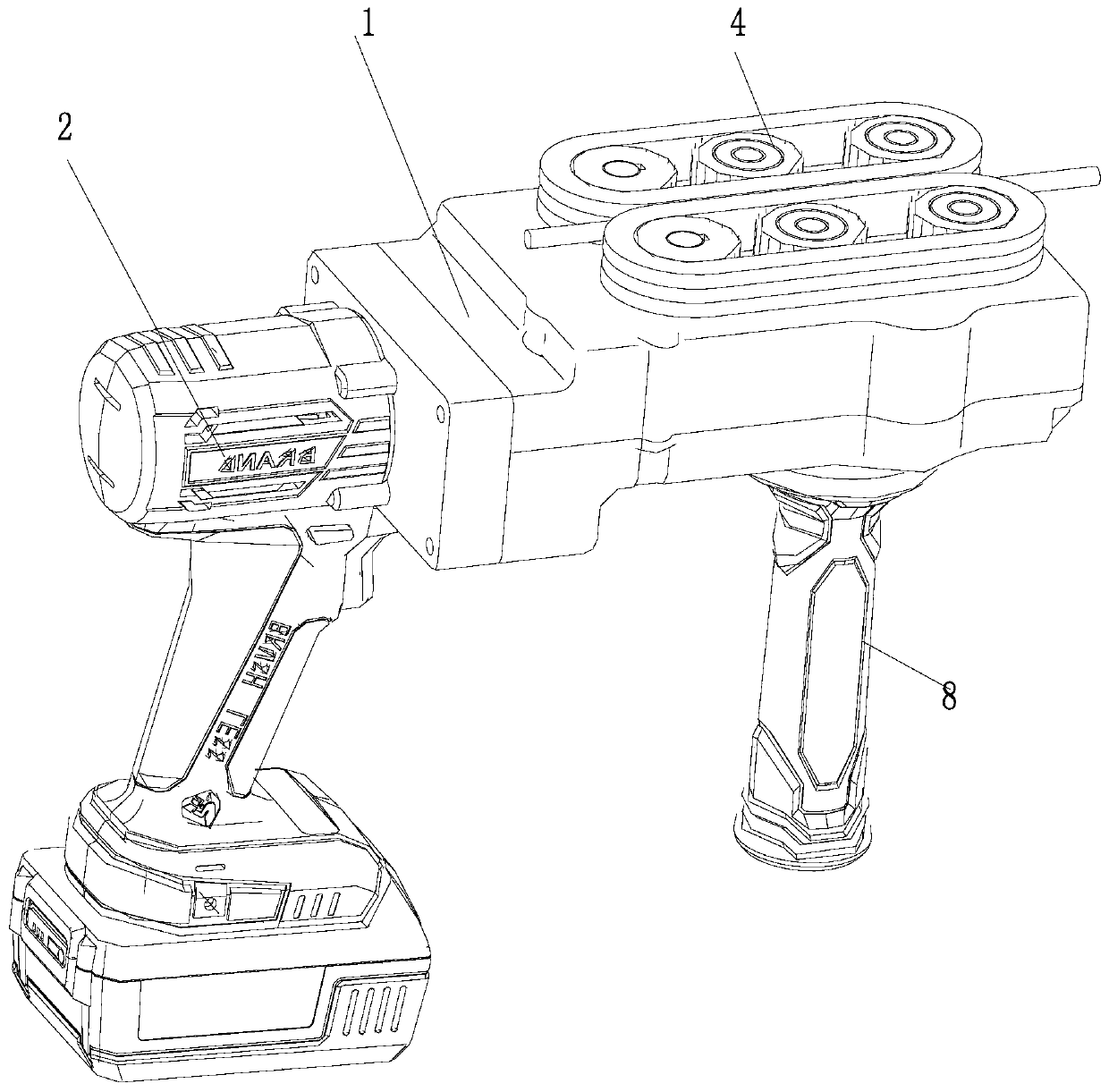

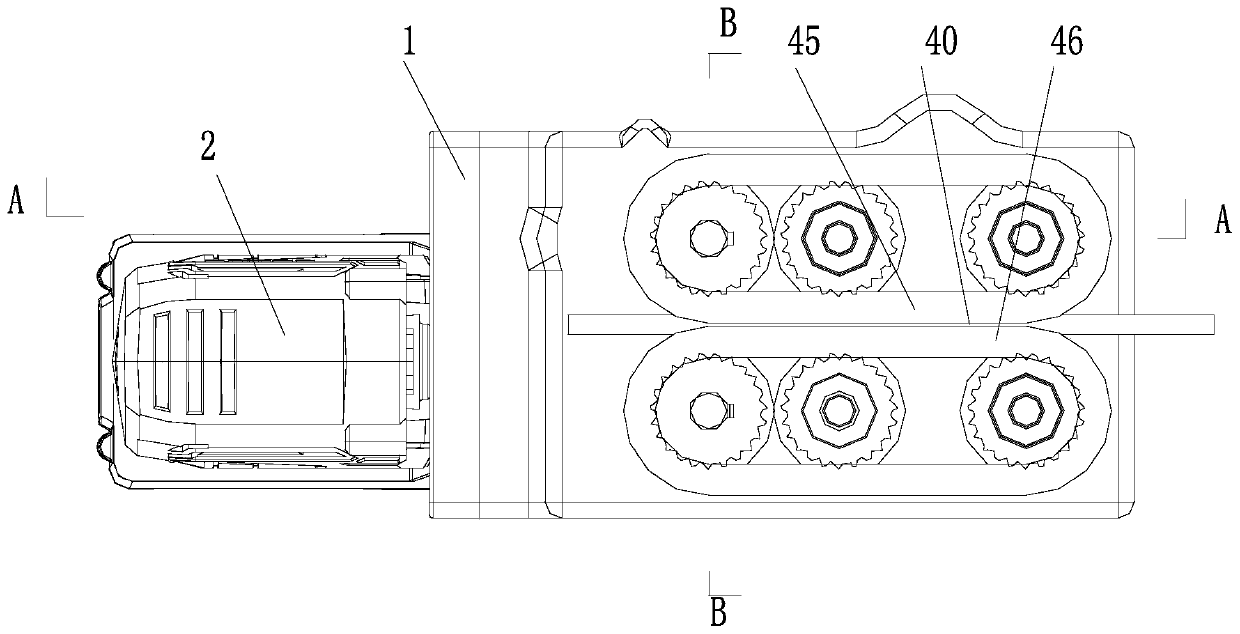

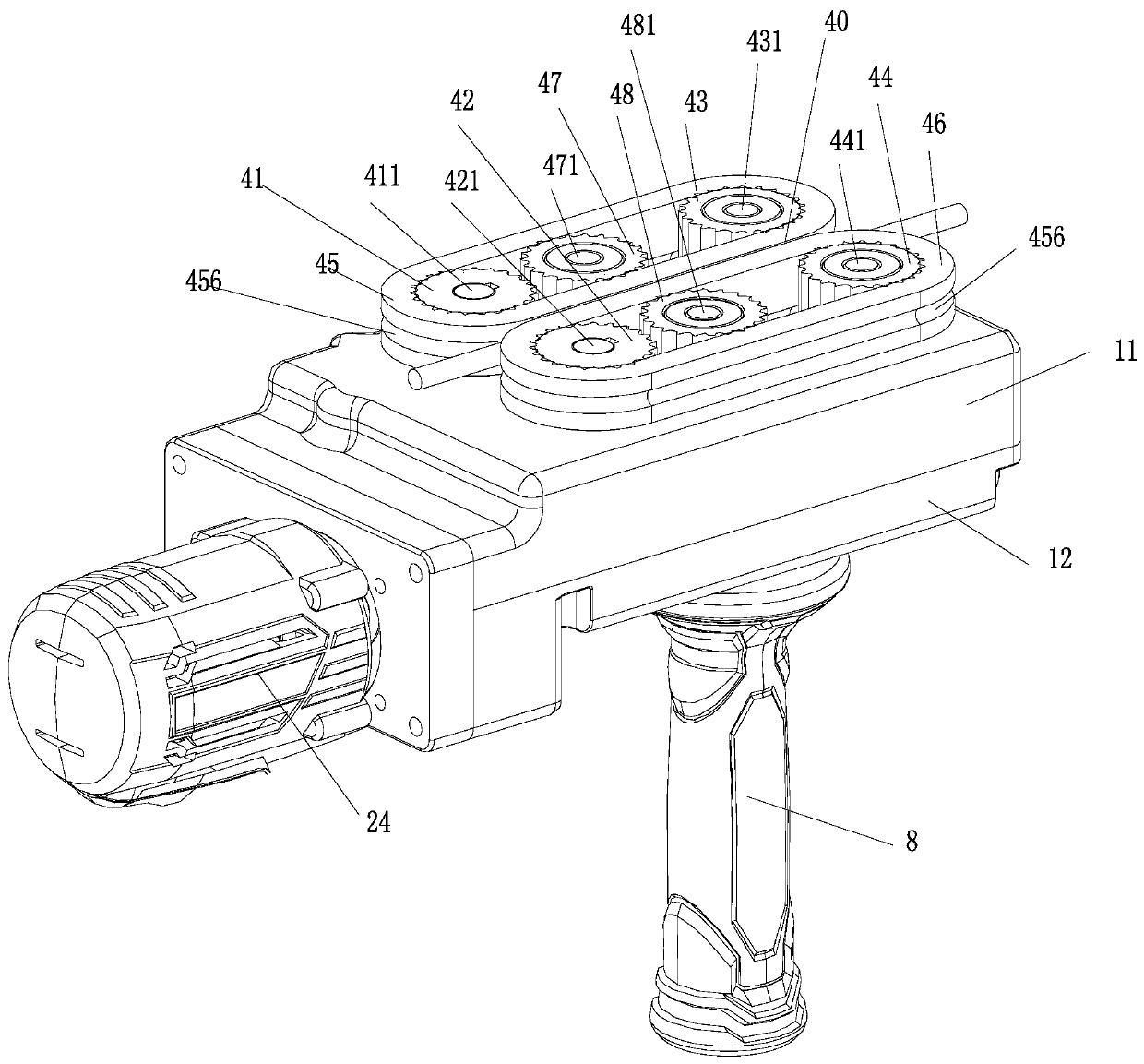

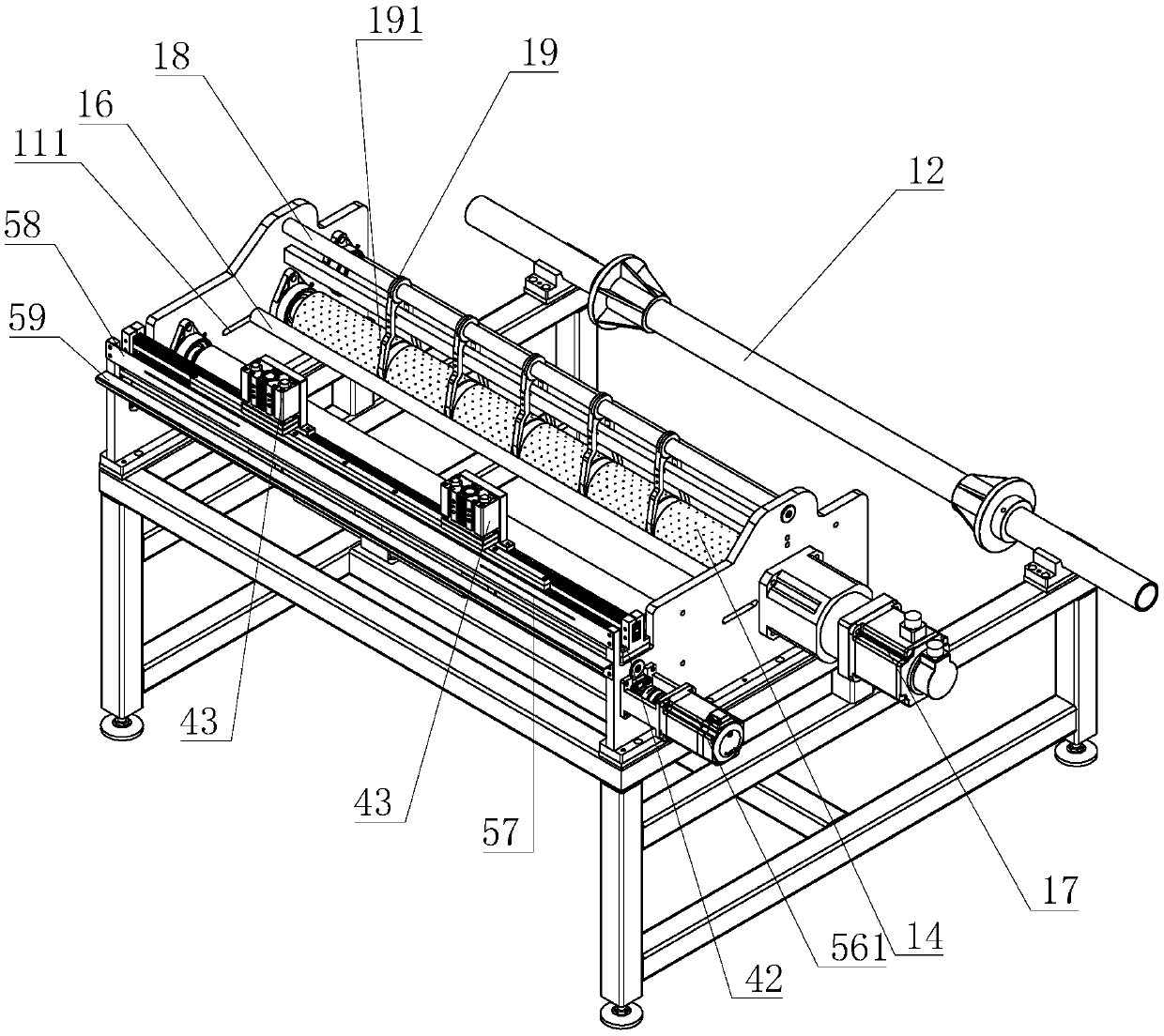

Threading machine

PendingCN110021895AGood synchronizationGuaranteed traction stabilityApparatus for laying cablesAutomotive engineeringSynchronism

The invention relates to a threading machine. The threading machine comprises a machine body and a driver, wherein the machine body is internally provided with a transmission component; the driver isin transmission connection with the transmission component; the upper end of the machine body is provided with a threading guiding component; the threading guiding component comprises a left synchronous belt and a right synchronous belt; a left driving pulley and a right driving pulley arranged longitudinally are arranged on two sides of the upper end of the machine body respectively; a left driven pulley is arranged on the right side of the left driving pulley at the upper end of the machine body, and a right driven pulley is arranged on the rear side of the right driving pulley at the upperend of the machine body; the synchronous belt is arranged outside the left driving pulley and the left driven pulley; the right synchronous belt is arranged outside the right driving pulley and the right driven pulley; and a gap between the left synchronous belt and the right synchronous belt serves as a threading gap. According to the threading machine, the synchronism of a traction threading lead is high, synchronous traction of a cable is carried out through mutual clamping of the left synchronous belt and the right synchronous belt, in the transmission process, power needs to be output tothe left driving pulley and the right driving pulley, and the left driven pulley, the right driven pulley, an additional left intermediate pulley and an additional right intermediate pulley are drivenby the synchronous belts.

Owner:永康市闳骏机电有限公司

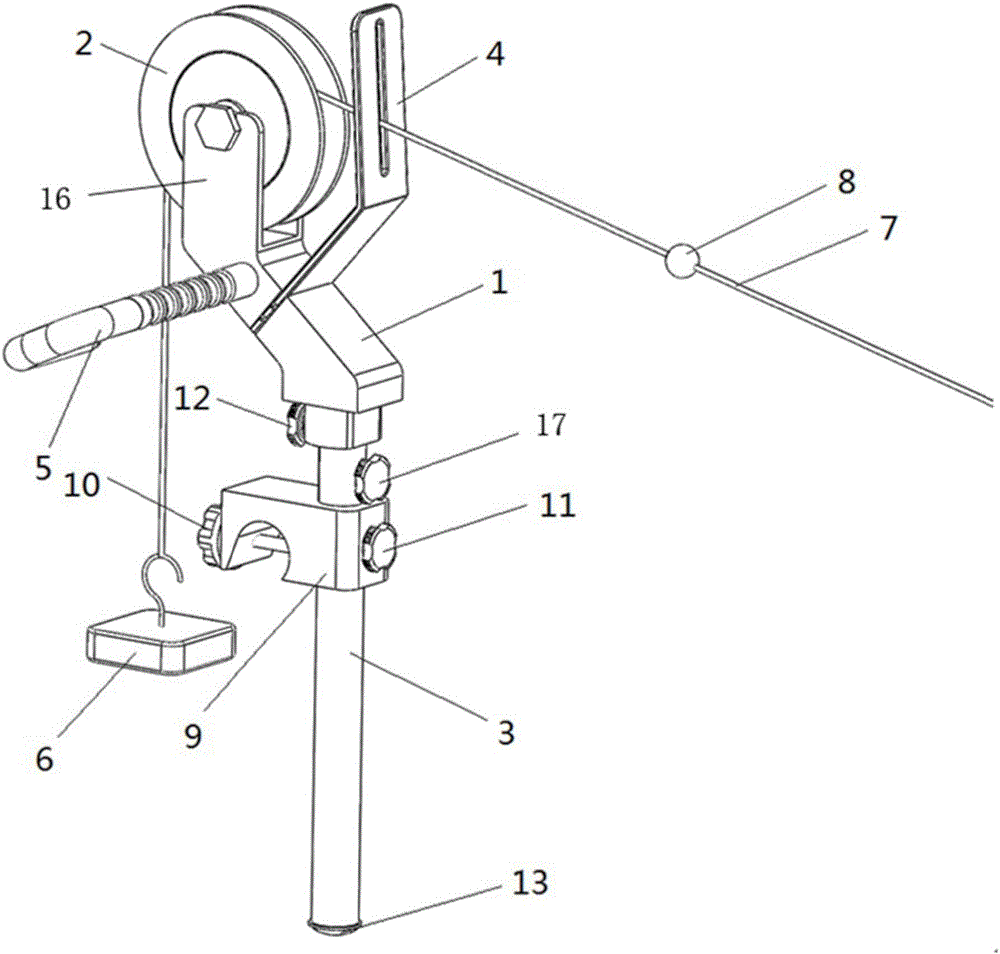

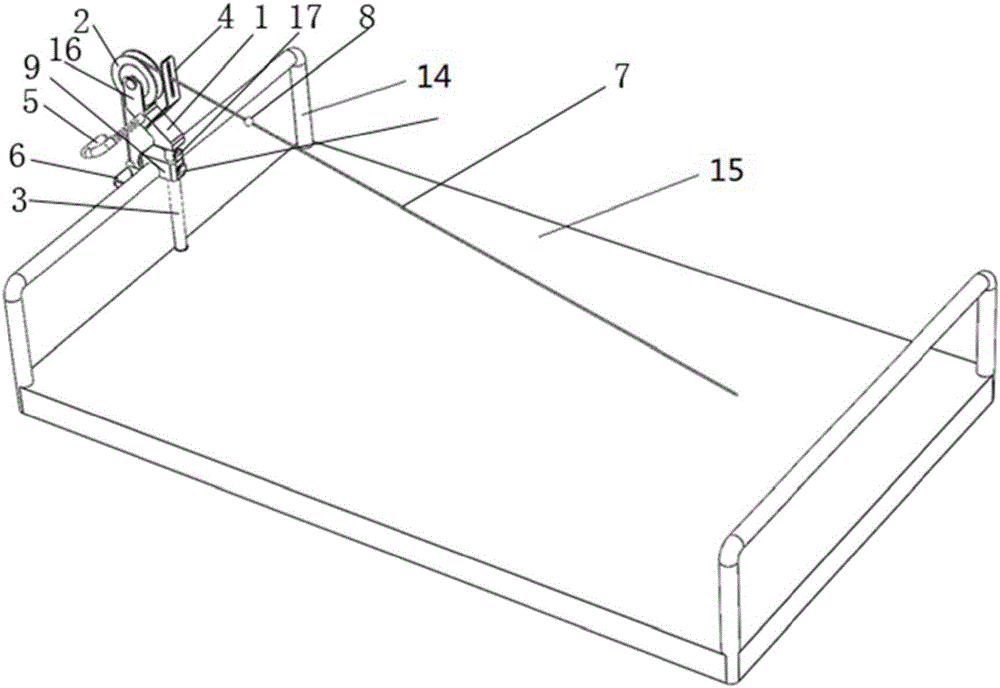

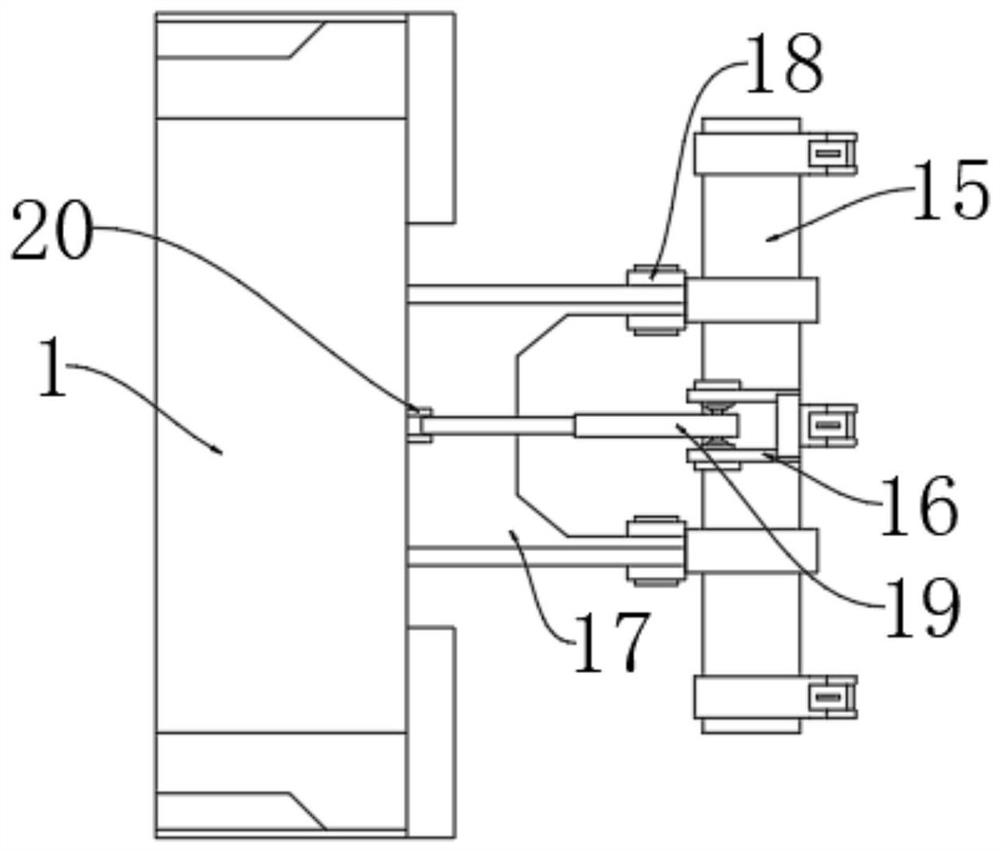

Multi-dimensional adjustable traction fixing rack for sengstaken-blakemore tube and nursing bed with same

Aiming at the situation that a device for fixing a sengstaken-blakemore tube is unavailable, the invention discloses a multi-dimensional adjustable traction fixing rack for the sengstaken-blakemore tube and a nursing bed with the multi-dimensional adjustable traction fixing rack. The multi-dimensional adjustable traction fixing rack consists of a support base, a pulley, an adjusting rod, a limiting rack, a weight, a traction rope, a limiting ball, a fixing base, a horizontal moving locking knob, a lifting locking knob and a rotation locking knob. The nursing bed with the multi-dimensional adjustable traction fixing rack comprises a hospital bed and a fixing bracket. The multi-dimensional adjustable traction fixing rack has the beneficial technical effects that by adopting the multi-dimensional adjustable traction fixing rack, the convenience and the security can be improved when the sengstaken-blakemore tube is adopted for nursing of hemostasis by compression, meanwhile the comfort degree of the sengstaken-blakemore tube retained in a patient can be increased, the treatment effect can be improved, and the patient can be recovered rapidly.

Owner:张玲

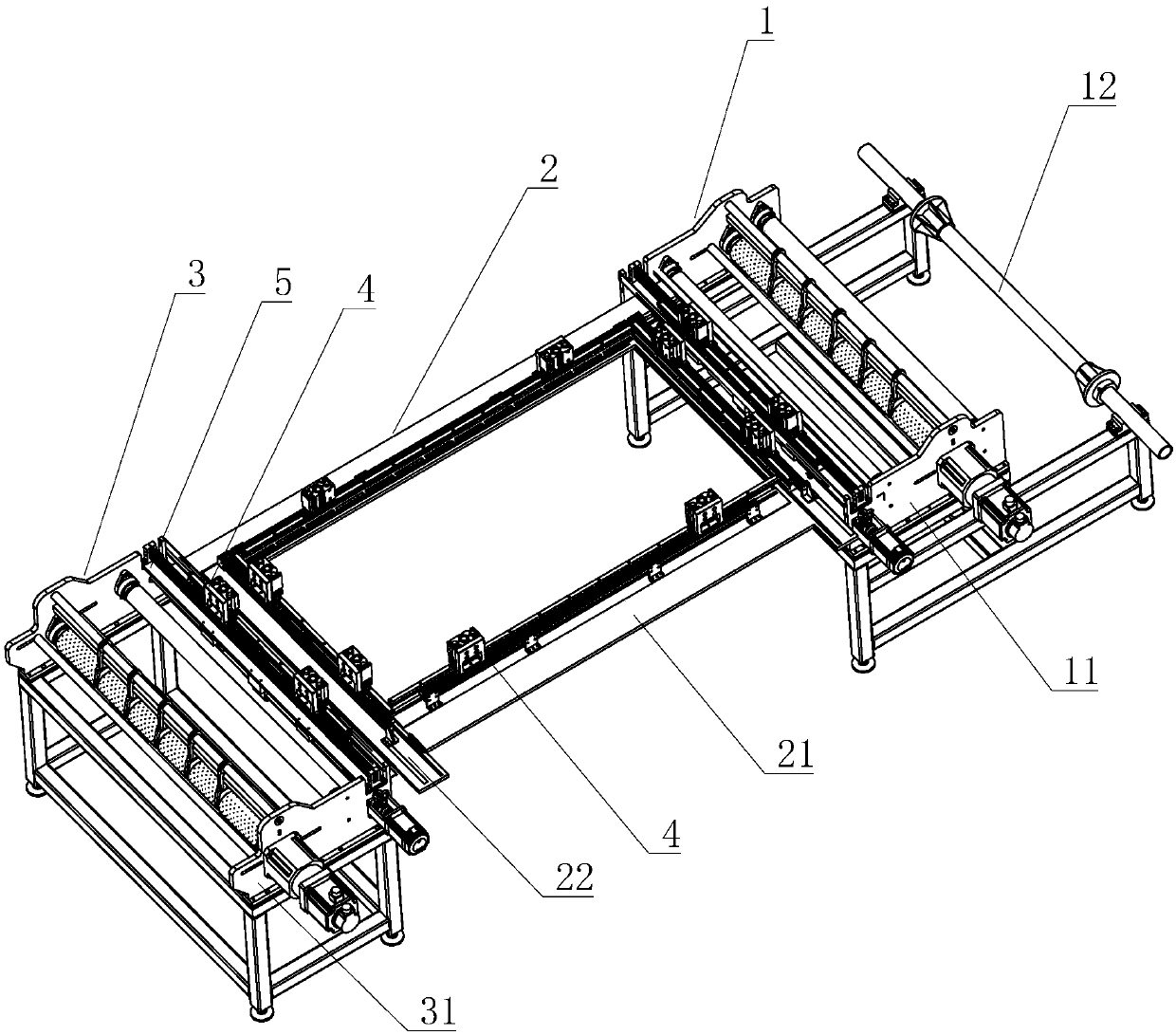

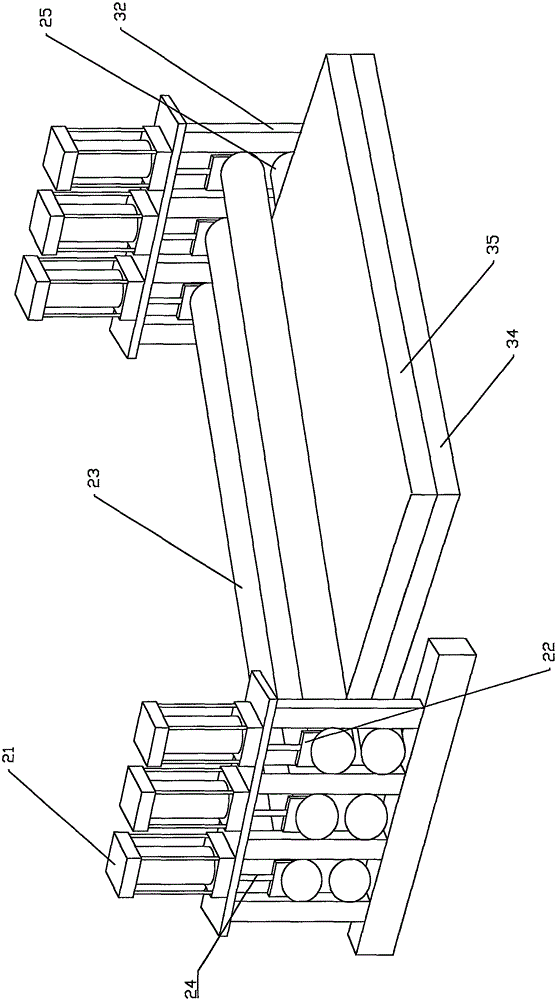

Conveying device of tufting embroidering machine

PendingCN109537201AImprove embroidery qualityPrecise positioningFeedersDegrees of freedomEngineering

The invention discloses a conveying device of a tufting embroidering machine. The device comprises a conveying part for conveying base blanket cloth to the lower part of the tufting embroidering machine for embroidering, a positioning part which is positioned below the tufting embroidering machine and is used for fixing and tensioning the base blanket cloth, and a collecting part for collecting the embroidered blanket cloth, wherein a discharging end of the conveying part and a feeding end of the collecting part are correspondingly provided with positioning mechanisms for fixing and releasingthe base blanket cloth; correcting mechanisms for correcting skewed base blanket cloth are arranged below the positioning mechanisms. According to the device, the conveying part, the positioning partand the collecting part are matched to realize automatic conveying of the tufting embroidering machine, so that the tufting embroidering efficiency is improved; a plurality of sets of positioning mechanisms are matched to effectively limit the degree of freedom, to be limited during tufting embroidering, of the base blanket cloth, so that the coaxiality in tufting embroidering can be greatly controlled, and the stability of surface tension of the base blanket cloth can also be greatly controlled; and the two sets of correcting mechanisms are matched to correct the skewed base blanket cloth, sothat the embroidering quality is improved.

Owner:JINHUA JIELING HOUSE WARES CO LTD

Fragile front cover of missile and preparation method thereof

ActiveCN110806151BSafe out of the boxImpact fastAmmunition projectilesProjectilesStructural engineeringFront cover

The invention is used to improve the technical problem of poor safety of the existing fragile front cover of the missile, and provides a fragile front cover of the missile and a preparation method thereof; wherein the structure includes: a front cover body provided with a weakening groove, and a mooring mechanism The weakening groove is set along the radial and / or latitudinal direction of the front cover body, and the front cover body is divided into multiple regions to be broken by the weakening groove; the mooring mechanism is a rope with fixed ends at both ends. The method comprises the following steps: making an upper flange ring and a lower flange ring; manufacturing a reinforcement layer and a front cover body; setting weakening grooves in the radial direction and / or latitudinal direction of the front cover body; grinding the upper end surface of the front cover body After spraying or brushing heat-resistant paint; making a gasket whose shape matches the shape of the pressing surface between the upper flange ring and the lower flange ring; making the seal between the lower flange ring and the outer wall of the missile launch tube launch port sealing strip. The invention can simultaneously meet the use requirements of both bursting and bursting, and it is not easy to cause fragments to splash when the front cover is broken.

Owner:北京玻钢院复合材料有限公司

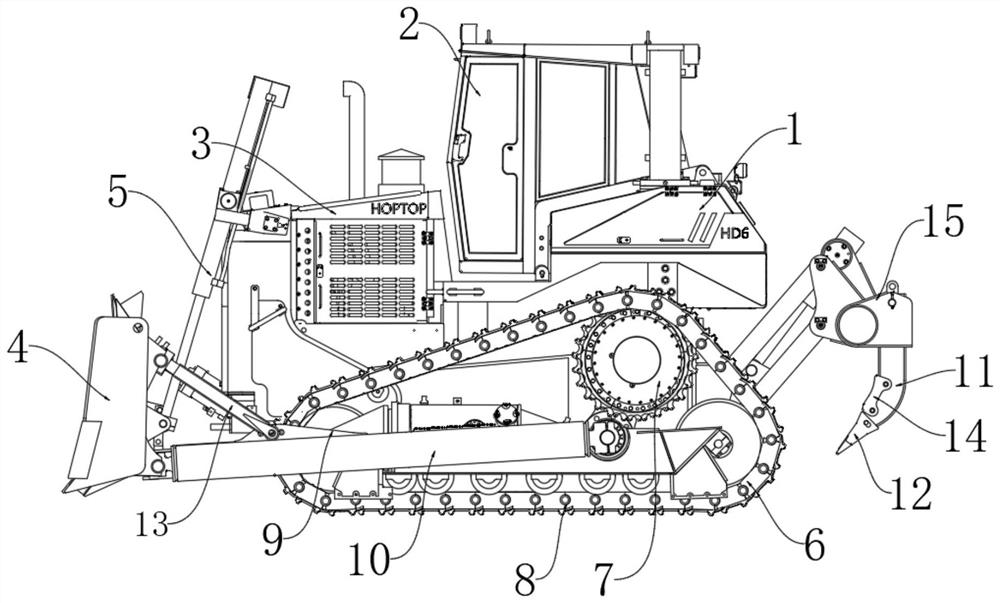

Hydrostatic bulldozer applying high-drive structure

PendingCN112195990AExtended service lifeEliminate shock loadsMechanical machines/dredgersGround rollerEngineering

The invention discloses a hydrostatic bulldozer applying a high-drive structure, relates to the technical field of bulldozers, and aims to solve the problems that an existing bulldozer is heavy in operation, poor in flexibility, extremely hard for operators to work, low in engineering machinery energy utilization rate and not energy-saving and environment-friendly. A cab is arranged at the upper end of a high-drive bulldozer body, an advancing crawler belt is arranged at the lower end of the cab, an engine compartment is arranged at one side of the cab, a lifting oil cylinder is arranged at one side of the engine compartment, a bulldozing hopper is arranged at the lower end of the lifting oil cylinder, and an inclined oil cylinder is arranged on one side of the bulldozing hopper; and a grounding supporting plate is arranged at the lower end of the bulldozing hopper, an auxiliary grounding roller is arranged in the grounding supporting plate, and a scarifier is installed at the tail ofthe high-drive bulldozer body.

Owner:江苏汉推重工有限公司

Limb traction device

InactiveCN105748185AEffective tractionPlay a role in reducing and supporting fracturesFractureEngineeringBone fracture

The invention discloses a limb traction device.The limb traction device comprises fixing bands, bearing pedestals and traction devices; the number of the fixing bands is two, and the fixing bands include the front fixing band and the rear fixing band; the bearing pedestals include two front bearing pedestals and two rear bearing pedestals, the two front bearing pedestals are fixed to the front fixing band, and the two rear bearing pedestals are fixed to the positions, corresponding to the two front bearing pedestals, of the rear fixing band; the number of the traction devices is two, the two ends of each traction device are fixed to the front bearing pedestals and the rear bearing pedestals respectively, and each traction device comprises an inner supporting rod and an outer supporting rod, wherein the front end of the outer supporting rod is fixed to the corresponding front bearing pedestal, a threaded hole is formed in the rear end of the outer supporting rod, an external thread matched with the threaded hole is formed in the outer wall, close to the front end, of the inner supporting rod, the front end of the inner supporting rod penetrates through the corresponding rear bearing pedestal and is connected with the outer supporting rod through threads, and the inner supporting rod can rotate on the corresponding rear bearing pedestal.By means of the mode, limb traction can be realized for reset, and the effects of resetting and supporting bone fracture are achieved.

Owner:SUZHOU RUIHUA HOSPITAL

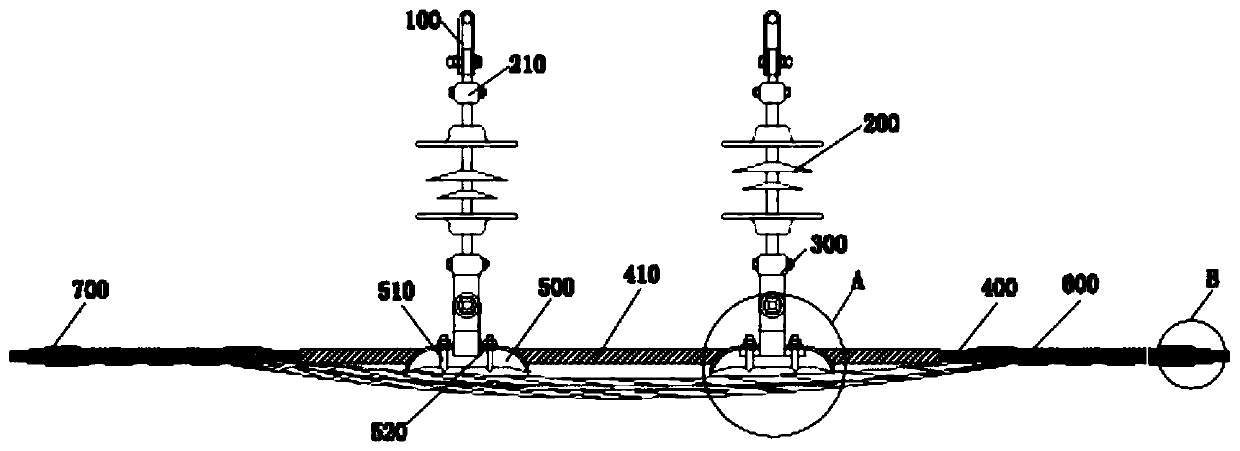

Pre-twisted safety backup wire clamp for suspension

InactiveCN109904820AEffective tractionSuspension arrangements for electric cablesEngineeringElectric power

The invention belongs to the technical field of power transmission. More specially, the invention relates to a pre-twisted safety backup wire clamp for suspension, which comprises a hanging point hardware fitting, an insulator, a socket hanging plate, a power transmission cable, a suspension wire clamp, a backup stranded wire and an end binding wire. The upper end and the lower end of the insulator are provided with integrally formed sockets, the bottom end and the top end of the hanging point hardware fitting are fixedly connected with the sockets, the backup stranded wires are bundled and wound on the power transmission cables at the left side and the right side of the suspension wire clamp, and the end binding wires are used for bundling and winding at the ports of the backup stranded wires, when the power transmission cable suspension wire clamp is worn and broken seriously, the backup stranded wire can effectively pull cables on two sides of a fracture, so that the problem that the power transmission cable and the suspension wire clamp are subjected to long-term vibration, abrasion and the like to cause the outer broken strand at the joint is avoided, and the problem that thesudden drop of the wire due to failure in timely discovery or other problems in inspection causes accidents is solved.

Owner:上海神勇机械技术有限公司

Multifunctional orthopaedic tractor

The invention discloses a multifunctional orthopaedic tractor, which comprises rollers, bottom barrels, lifters, a fixing nut, and a connecting belt, the rollers are fixed on the bottoms of the bottom barrels, fasteners are arranged on the right sides of the rollers, the lifters are arranged in the bottom barrels, fixed blocks are arranged on the top and bottom of each lifter, retractable frames are arranged upon the fixed blocks, the middle of each retractable frame is provided with joints, a rotary shaft is fixed at the middle of each retractable frame, fastening bolts are arranged on the rotary shafts, and fixed disks are fixed at the tails of the rotary shafts. The structure of the multifunctional orthopaedic tractor disclosed by the invention is simple, and the appearance is attractive; the design of the lifters can easily adjust the heights of a bed board and a lifting rod, so that a patient can be conveniently treated; the design of movable blocks can effectively adjust the force of traction; acting force therein can be effectively cushioned; and the whole tractor is easy to operate, and has diversified functions.

Owner:AFFILIATED HOSPITAL OF ZUNYI MEDICAL COLLEGE

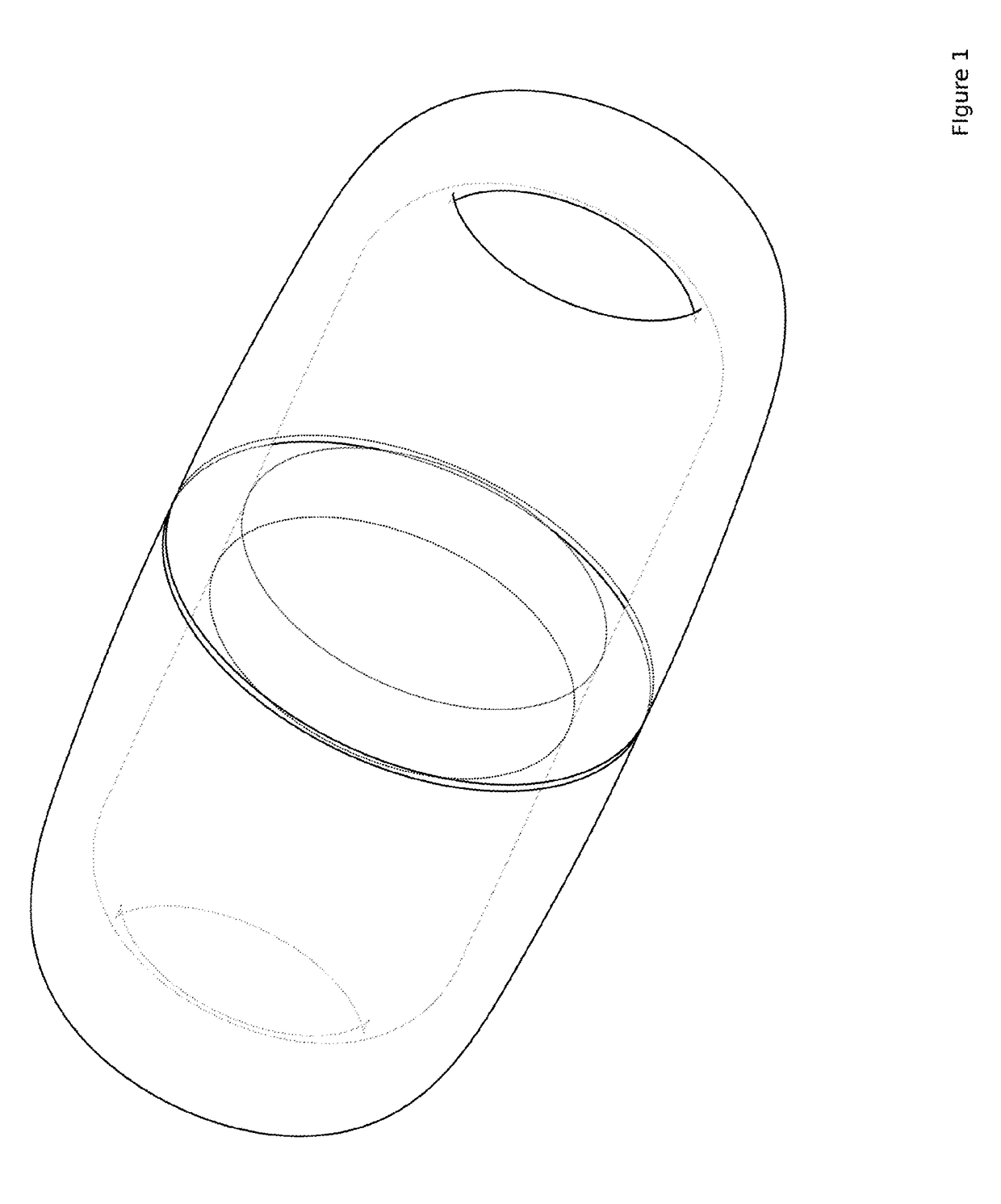

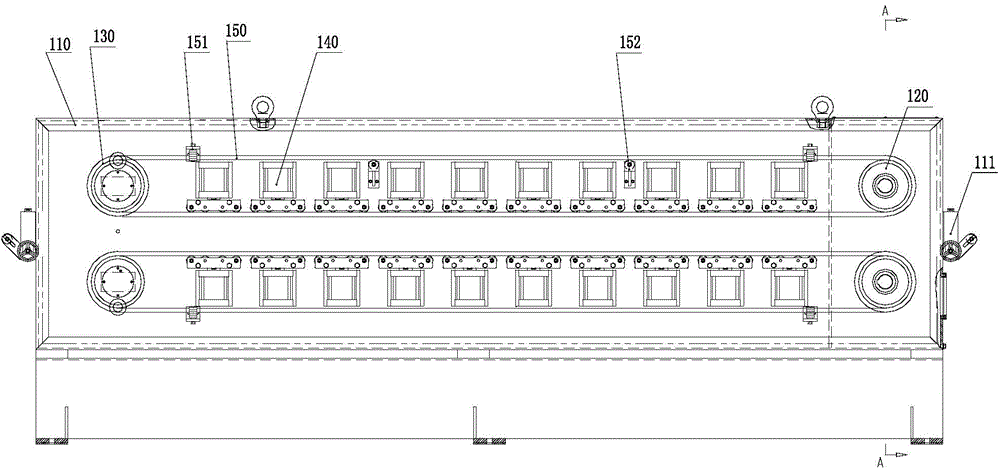

Fabric Tube Propulsion Drive

InactiveUS20170143192A1Moderate longitudinal rigidityEffective tractionSurgeryEndoscopesBody organsMotor drive

Fabric Tube Propulsion Drive is a system for propelling medical devices through hollow body organs and within body cavities without causing trauma to the body surfaces upon which it operates. Fabric Tube Propulsion Drive consists of a hollow tube surrounded by a continuous loop of elastic fabric or mesh. Within the tube is a motor drive system that moves the fabric through the lumen of the tube such that the fabric on the outside of the tube can continuously interface with the body part through which the Fabric Tube Propulsion Drive is operating, and thereby drive the whole device through the body cavity or over the surface in question. Furthermore, the motor drive system can selectively apply tension to the fabric over specific areas within the tube to cause flexion of the whole tube.

Owner:NAGASE DANIEL

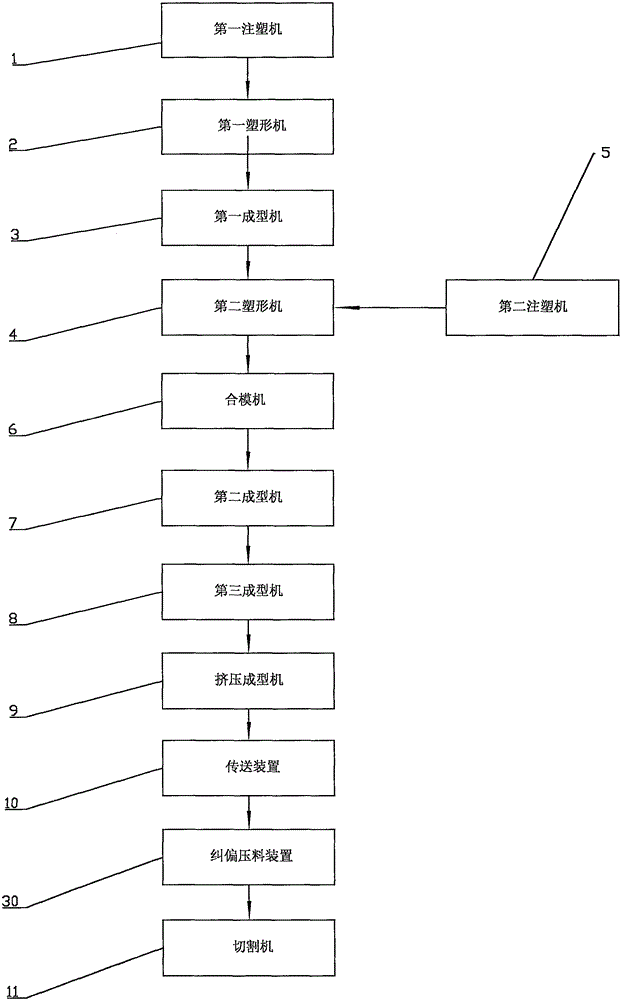

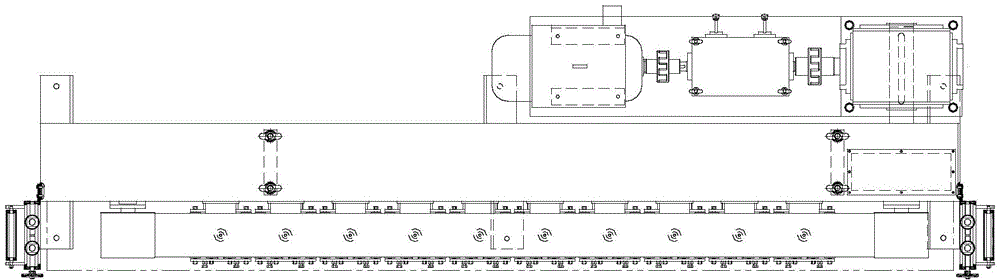

Plastic honeycomb building formwork production line

The invention discloses a plastic honeycomb building formwork production line. The plastic honeycomb building formwork production line comprises a first injection molding machine and a second injection molding machine. A lower formwork is formed on the first injection molding machine in an injection molding manner. An upper formwork is formed on the second injection molding machine in an injection molding manner. The discharging end of the first injection molding machine is connected with a first molding machine. The discharging end of the first molding machine is connected with a first forming machine. The discharging end of the first forming machine is connected with a second molding machine. The second molding machine is connected with the discharging end of the second injection molding machine. The discharging end of the second molding machine is connected with a mold combining machine. The discharging end of the mold combining machine is connected with the second forming machine. The discharging end of the second forming machine is connected with a third forming machine. The discharging end of the third forming machine is connected with an extrusion forming machine. A conveying roller is arranged at the discharging end of the extrusion forming machine. A deviation correcting material pressing device is arranged at the discharging end of the conveying roller, and the discharging end of the deviation correcting material pressing device is connected with a cutter. A combined type production assembly line is adopted, injection molding, forming, mold combining, cutting and other procedures are carried out on a double-layer plastic building formwork in the production and machining process, and the plastic formwork needed for construction is produced.

Owner:高超

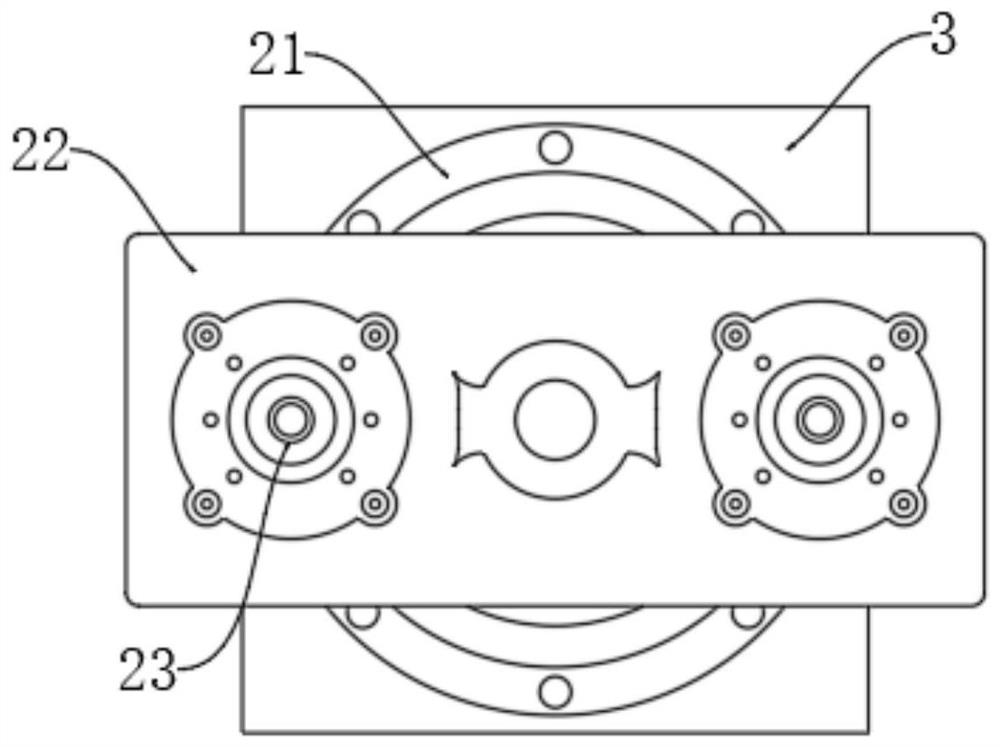

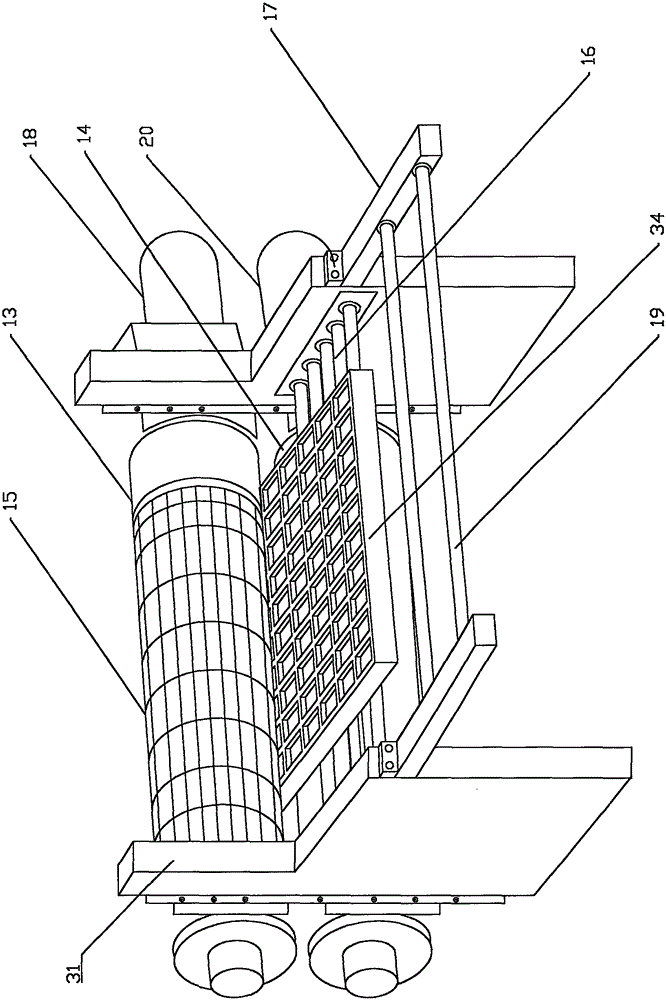

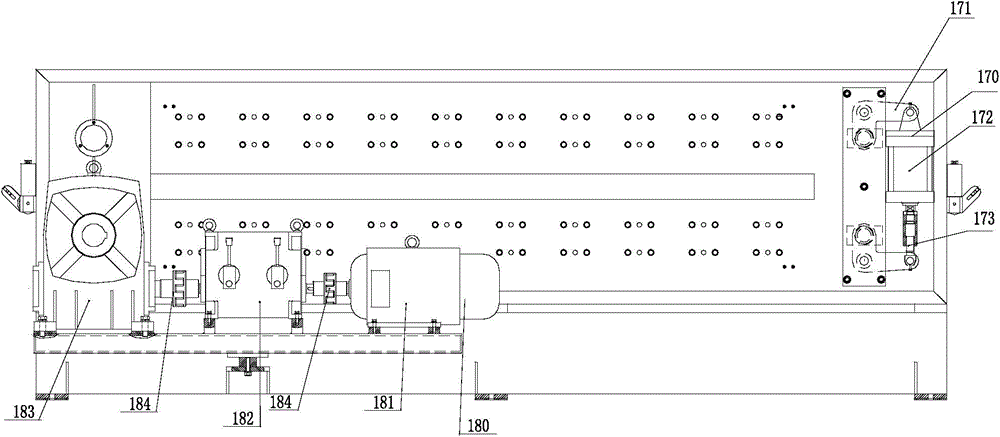

Traction equipment for extrusion production of silicon rubber

The invention discloses traction equipment for the extrusion production of silicon rubber. The traction equipment comprises a box body, and a pair of transmission rotating wheels, a pair of pressure regulating rotating wheels, pressed air-cylinder pieces, flat adhesive tapes, a pressure regulating mechanism and a driving mechanism which are separately arranged on the box body, wherein the transmission rotating wheels are arranged at the discharging end of the box body; the pressure regulating rotating wheels are arranged at the feeding end of the box body; the transmission rotating wheels comprises an upper transmission rotating wheel and a lower transmission rotating wheel; the pressure regulating rotating wheels comprise an upper pressure regulating rotating wheel and a lower pressure regulating rotating wheel; the upper transmission rotating wheel and the upper pressure regulating rotating wheel are arranged in a sleeving manner through one flat adhesive tape so as to form an upper traction piece; the lower transmission rotating wheel and the lower pressure regulating rotating wheel are arranged in a sleeving manner through one flat adhesive tape so as to form a lower traction piece; the upper traction piece and the lower traction piece are parallel mutually. The traction equipment disclosed by the invention can effectively pull a high-voltage bus into a silicon rubber coating device; the traction equipment is simple, and is convenient to use; the production efficiency can be effectively improved, and the pneumatic traction of 5000kg can be realized.

Owner:安庆钰龙橡塑机械制造有限公司

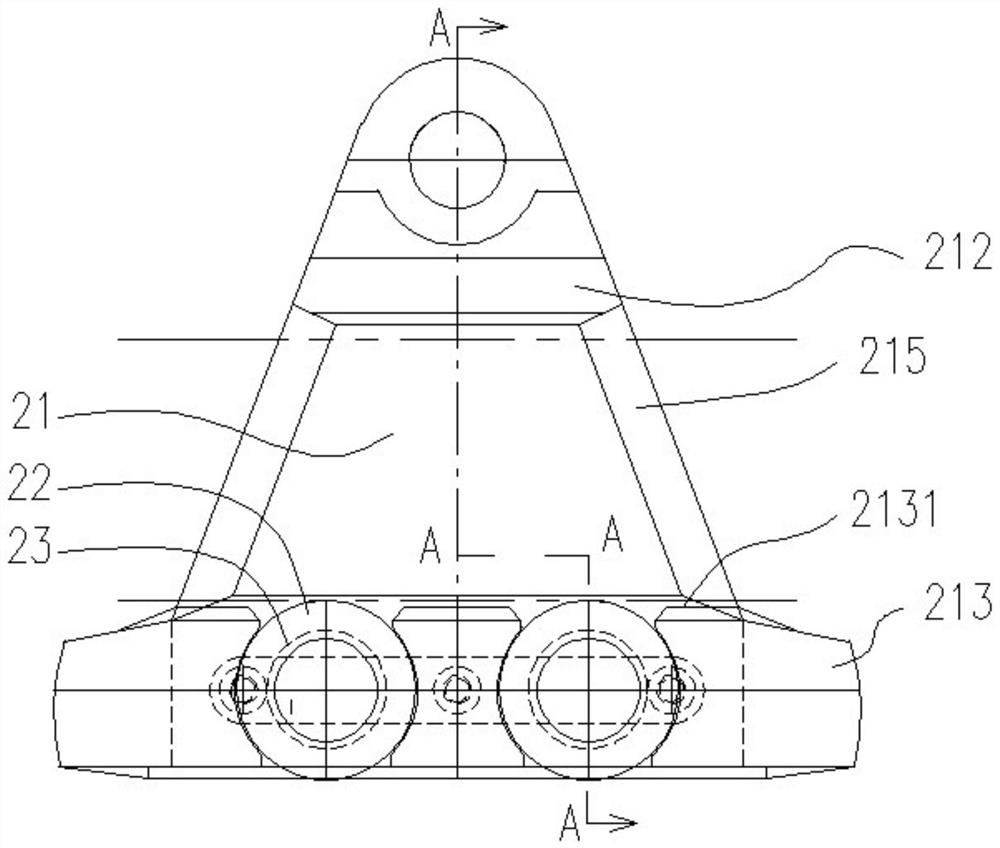

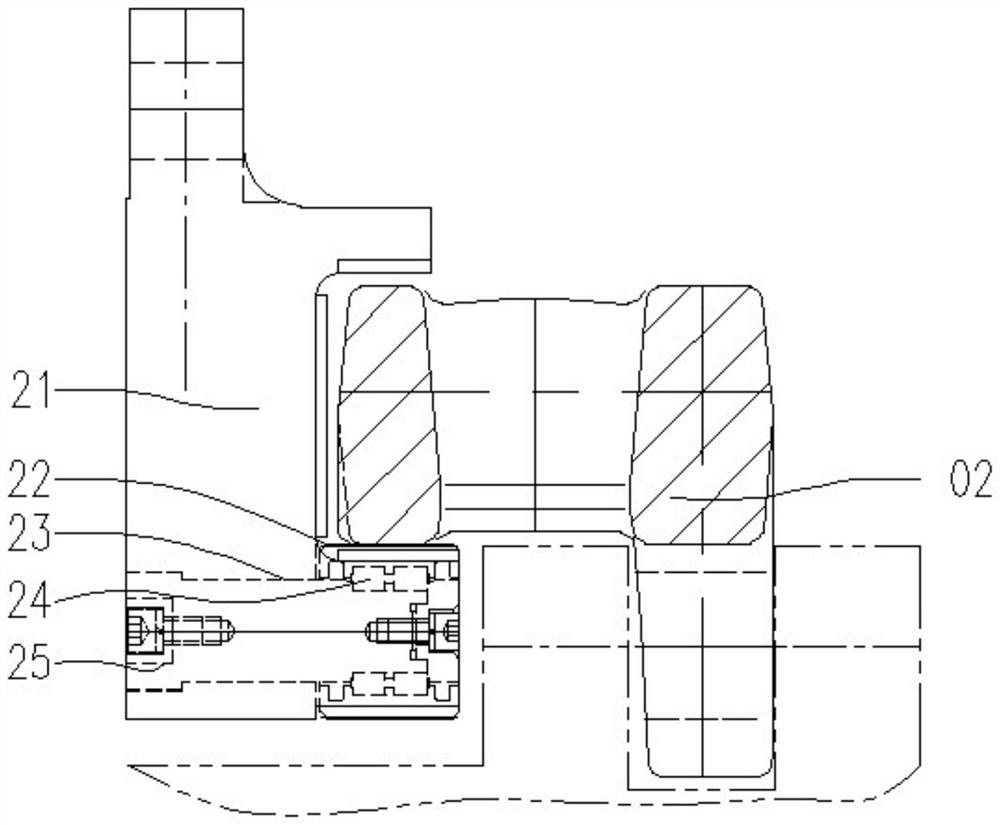

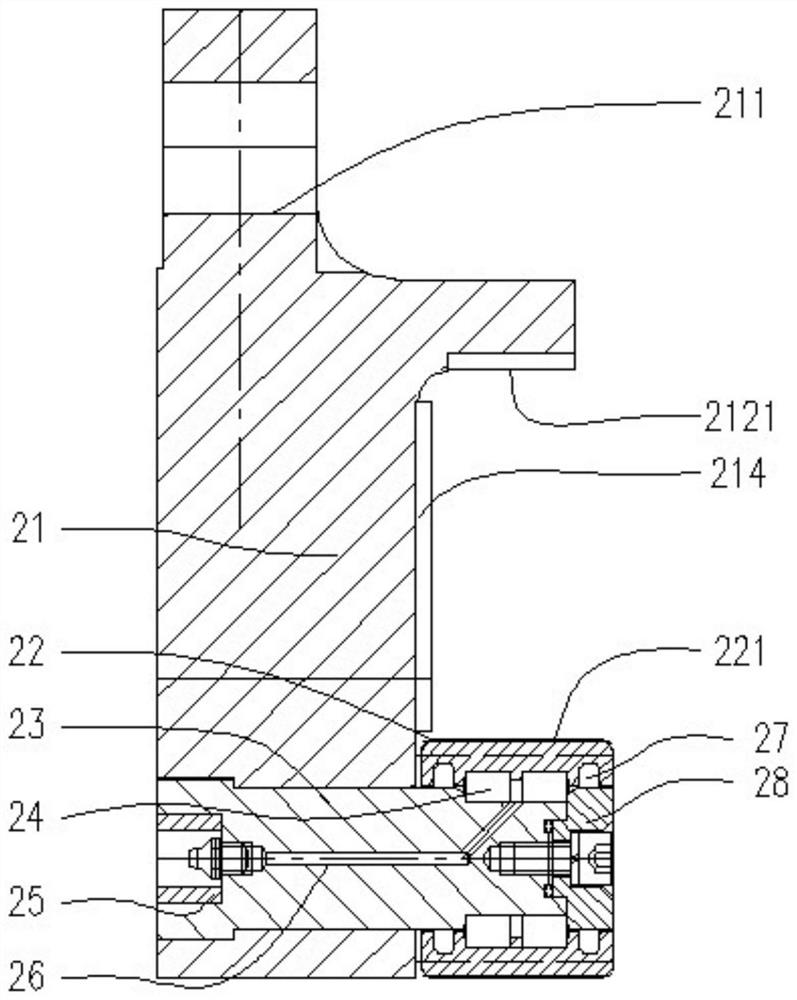

Roller device of auxiliary stress mechanism

The roller device of the auxiliary stress mechanism comprises a vertical plate and a roller, a front-back through connecting hole is formed in the upper portion of the vertical plate, an upper beam body protruding backwards is arranged on the upper middle portion of the rear side plate face of the vertical plate and below the connecting hole, and a guide body protruding backwards is arranged on the lower portion of the rear side plate face of the vertical plate. A plurality of roller mounting holes are formed in the guide body, the axes of the roller mounting holes horizontally extend front and back, the top and the bottom of each roller mounting hole are respectively provided with a top notch and a bottom notch which are through front and back, one roller is arranged in each roller mounting hole, the rollers are mounted on the vertical plate, and gaps are kept between the rollers and the roller mounting holes; the highest point of the idler wheel is higher than the top face of the guiding body, and the upper beam body, the idler wheel and the vertical plate part located between the upper beam body and the guiding body define a three-face surrounding structure with a backward opening. The device is used in an auxiliary stress mechanism, and is used for applying constant downward thrust to a walking system, so that the walking mechanism is always kept in a normal meshing state, and effective traction force is provided.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

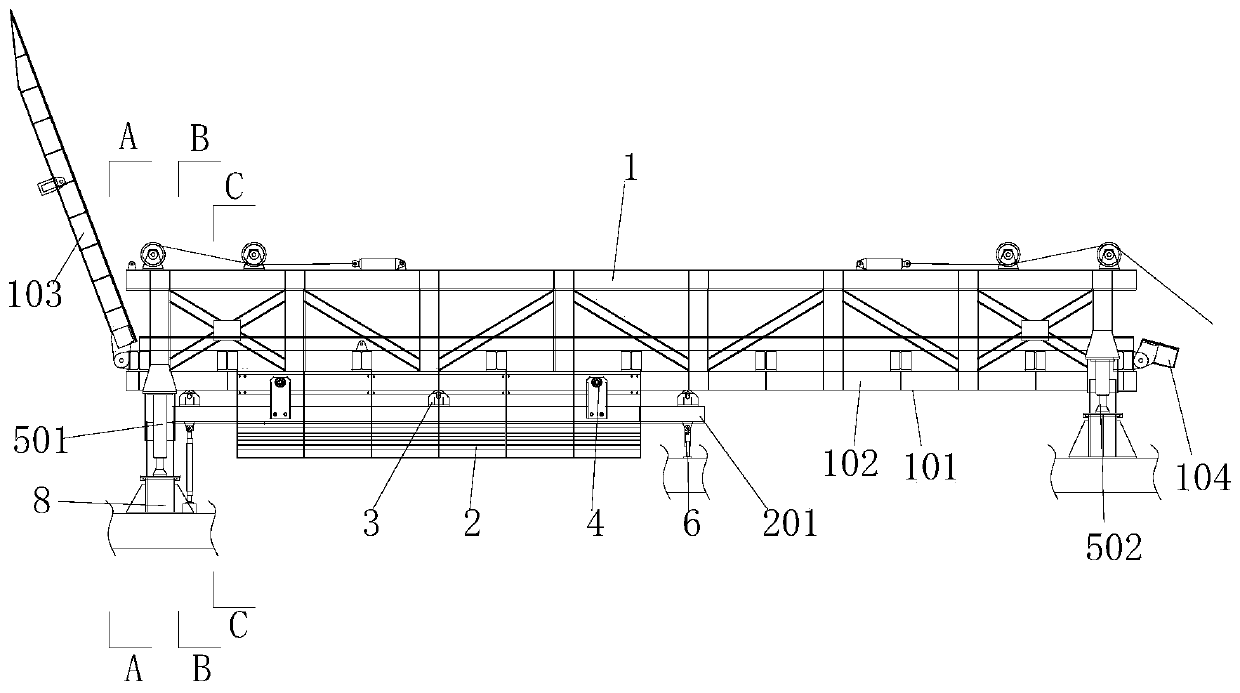

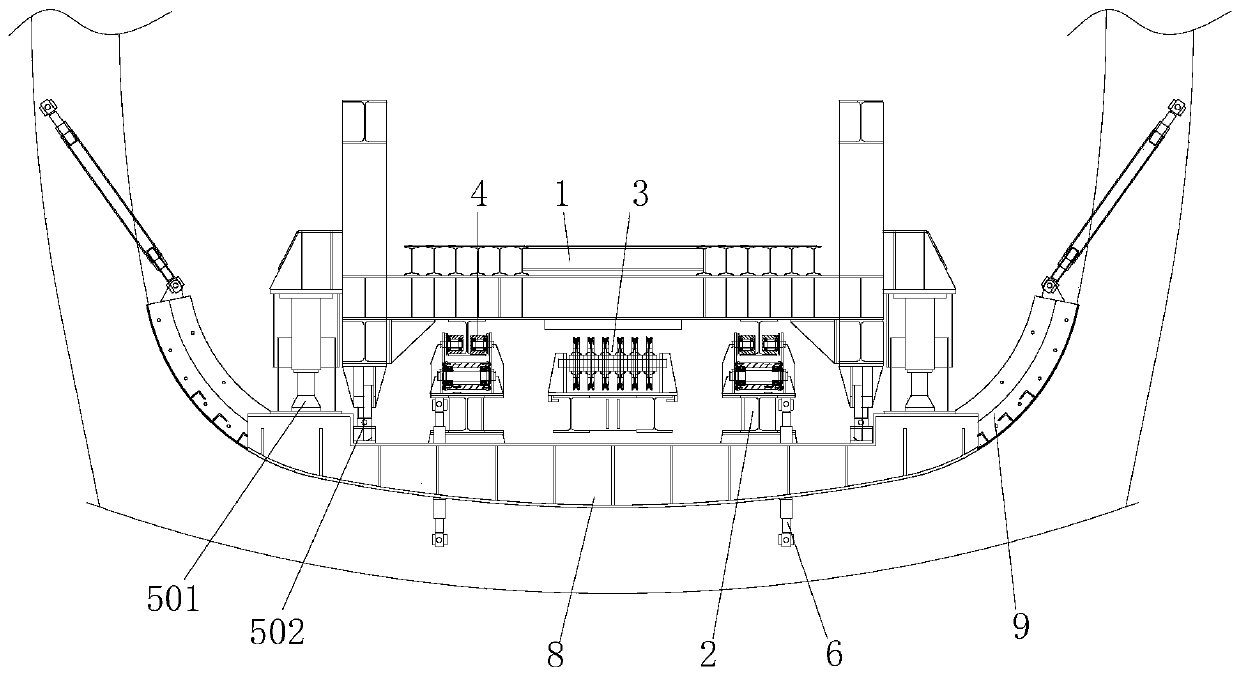

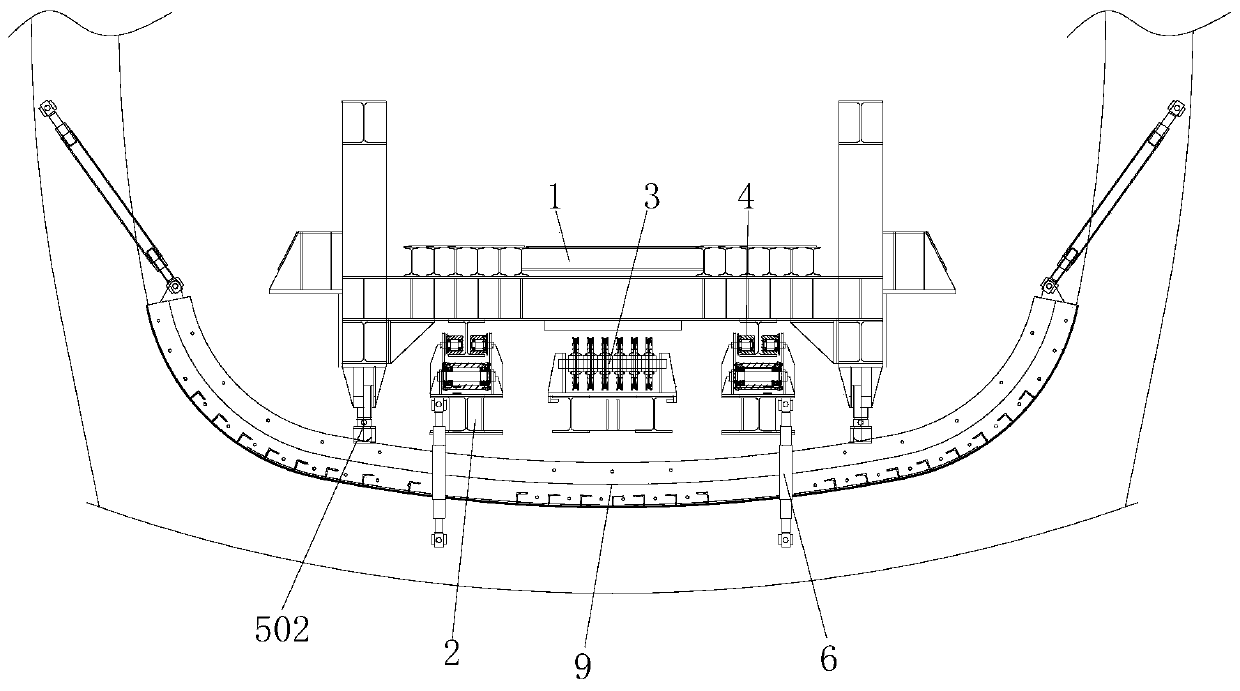

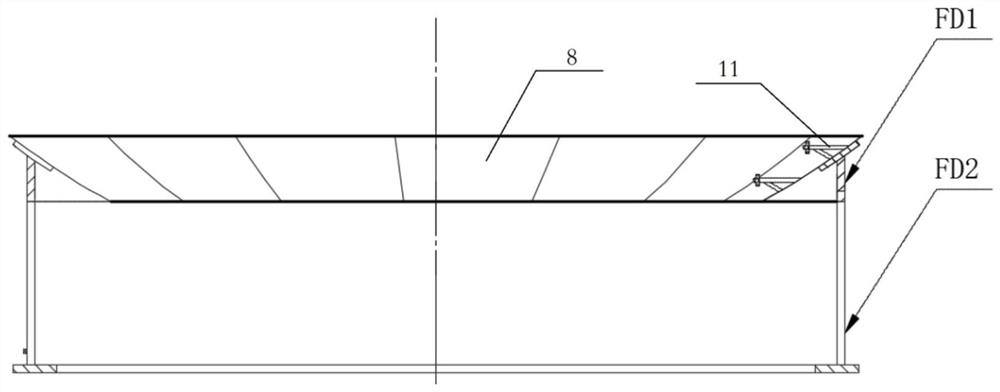

Traction fixing method for inverted arch formwork

ActiveCN111058869AEffective tractionEffective immobilizationUnderground chambersTunnel liningArchitectural engineeringStructural engineering

Owner:CHINA RAILWAY 19TH BUREAU GRP 3RD

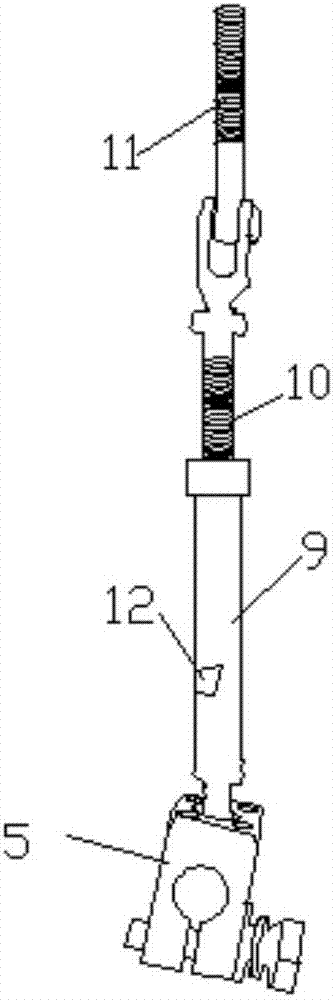

A three-dimensional controllable head ring vest traction reset device for cervical spine and its application method

Owner:XIAN HONGHUI HOSPITAL

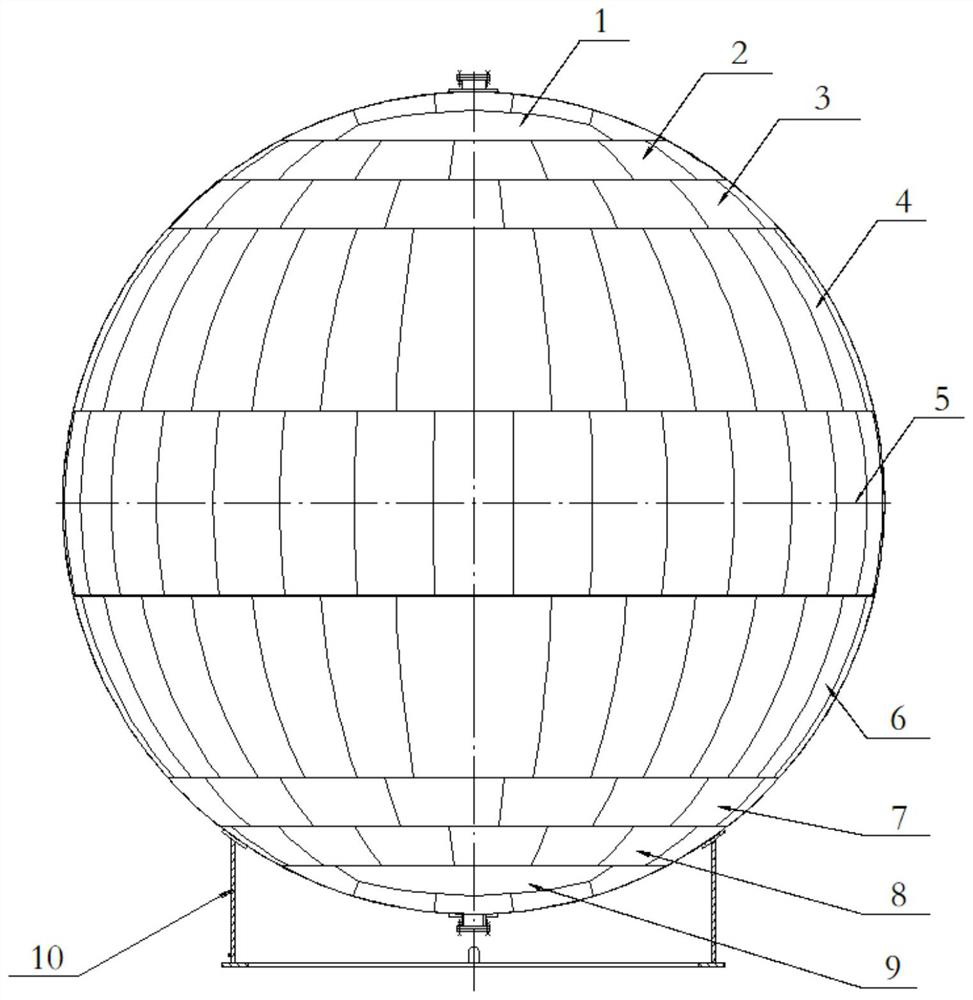

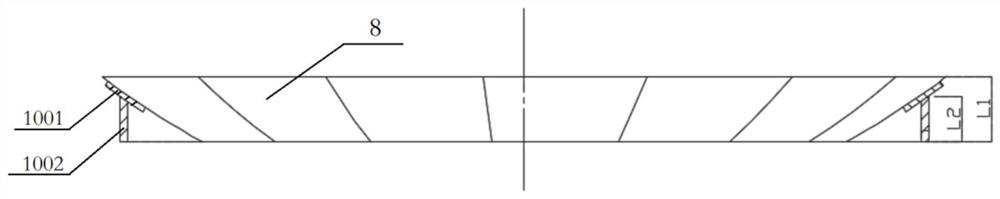

Method for assembling and welding large skirt supporting structure spherical tank

ActiveCN111716034AEffective tractionEffective adjustmentWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention discloses a method for assembling and welding a large skirt supporting structure spherical tank. According to the method for assembling and welding the large skirt supporting structure spherical tank, a tubular triangular support, a stay cable, a clamping ring and an adjustable elastic joint are utilized for carrying out effect traction and adjustment on sphere sheets below an equatorial zone in the assembling process. For a lower half sphere of the large skirt supporting structure spherical tank, according to the assembling and welding method, external supporting hoisting is changed into internal cable-stayed hoisting, and a hoisting tool is light and handy, diversified in combination form and convenient to operate. The method for assembling and welding the large skirt supporting structure spherical tank is a new method for carrying out assembling and welding at the same time, the problem of overhung spherical sheet deformation is effectively solved, and the assembling and welding efficiency of the large spherical tank is improved.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com