Roller device of auxiliary stress mechanism

A technology of rollers and mounting holes, which is applied in the direction of engine lubrication, slitting machinery, mechanical equipment, etc., can solve problems such as wear of sliding shoes and walking wheels, and complex working conditions on site, so as to avoid friction and wear, reduce wear, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

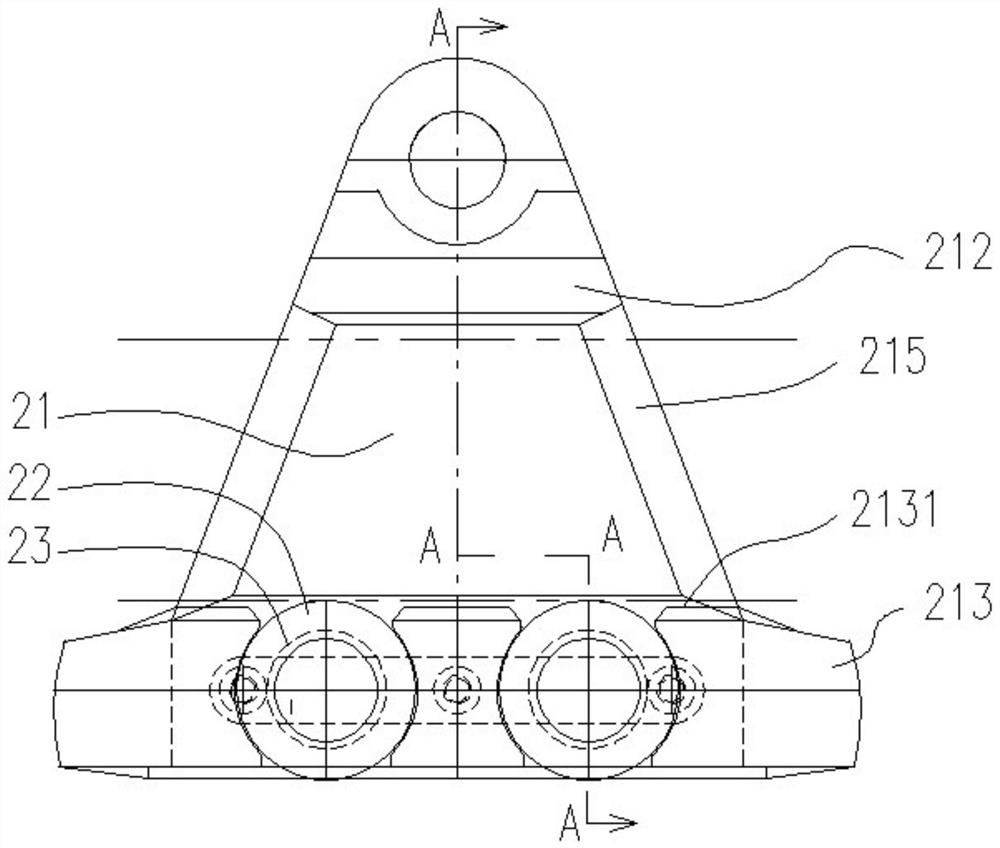

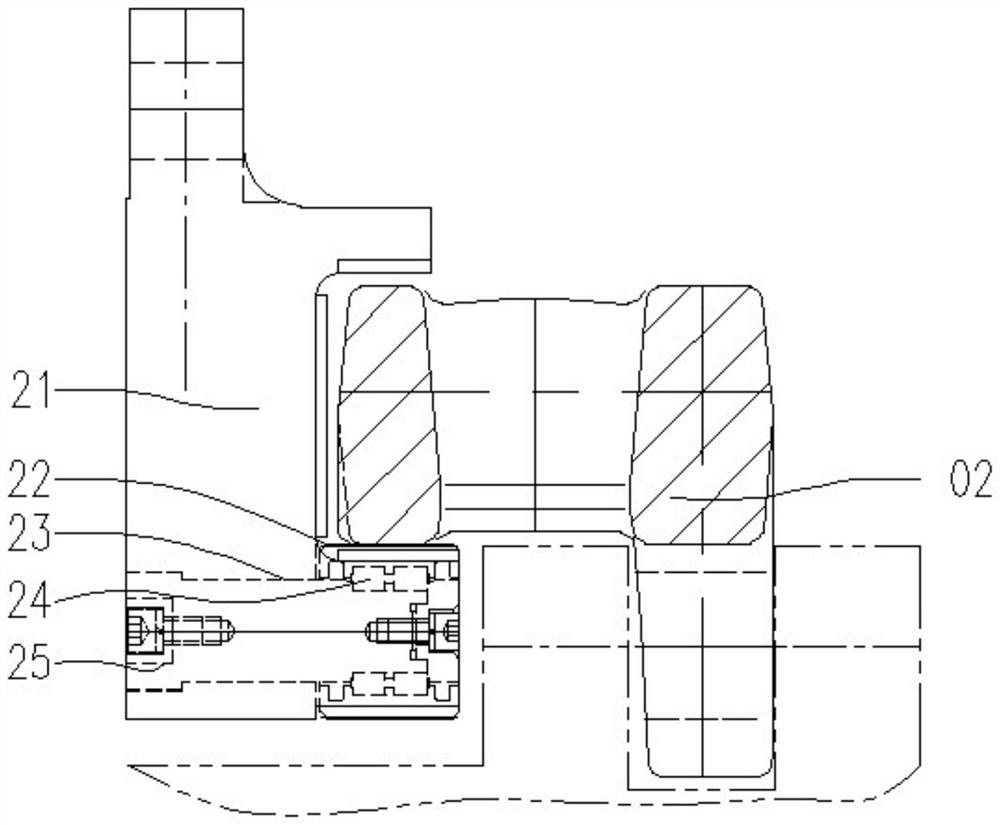

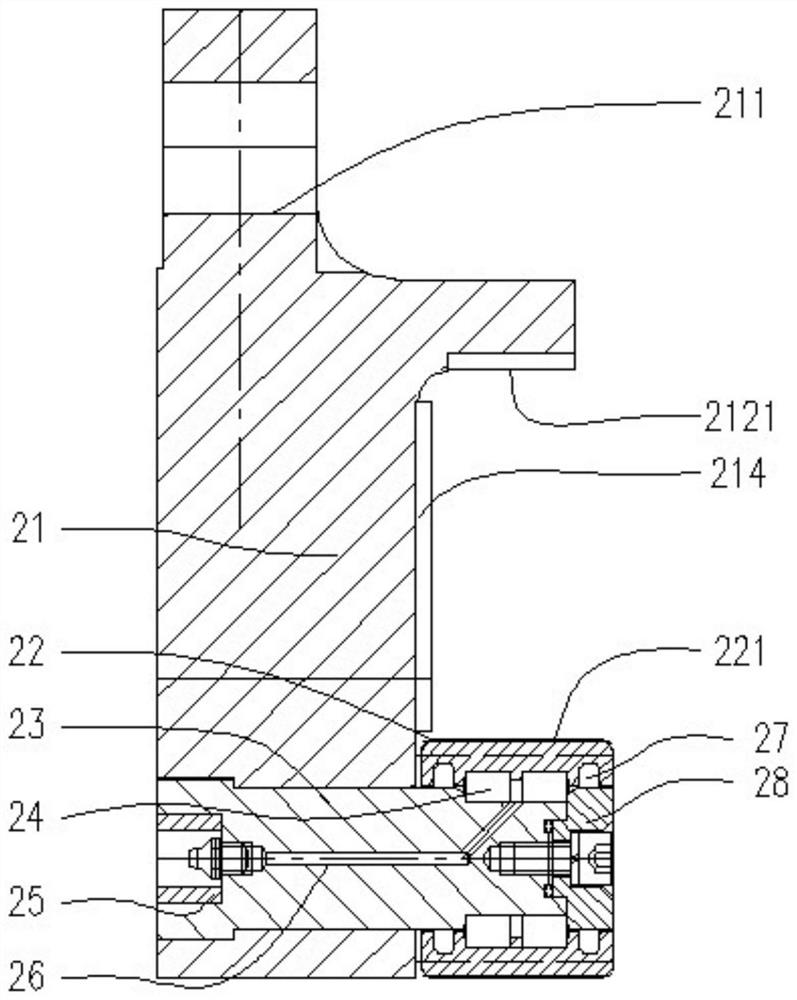

[0028] like Figure 1-3 As shown, the present invention discloses a roller device (which can be referred to as a roller device for short) of an auxiliary force-bearing mechanism, comprising a vertical plate 21 and a roller 22, the upper part of the vertical plate is provided with a connecting hole 211 that runs through the front and rear, the vertical plate A rearwardly protruding upper beam body 212 is provided on the upper middle and upper portion of the rear side panel surface of the panel and below the connecting hole, and a rearwardly protruding guide body 213 is provided on the lower portion of the rear side panel surface of the vertical panel. Both the upper beam body and the guide body are in the shape of strips extending left and right. The guide body is provided with a plurality of left and right spaced roller mounting holes, the axis of the roller mounting holes extends horizontally front and rear, and the top and bottom of the roller mounting holes are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com