Method for assembling and welding large skirt supporting structure spherical tank

A technology of supporting structure and welding method, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of long adjustment and welding seam alignment, large dimensional deviation, ball deformation, etc., to improve assembly and Welding efficiency, light hoisting tooling, and the effect of solving deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The assembly and welding method of the large skirt support structure spherical tank of the present embodiment includes the following steps:

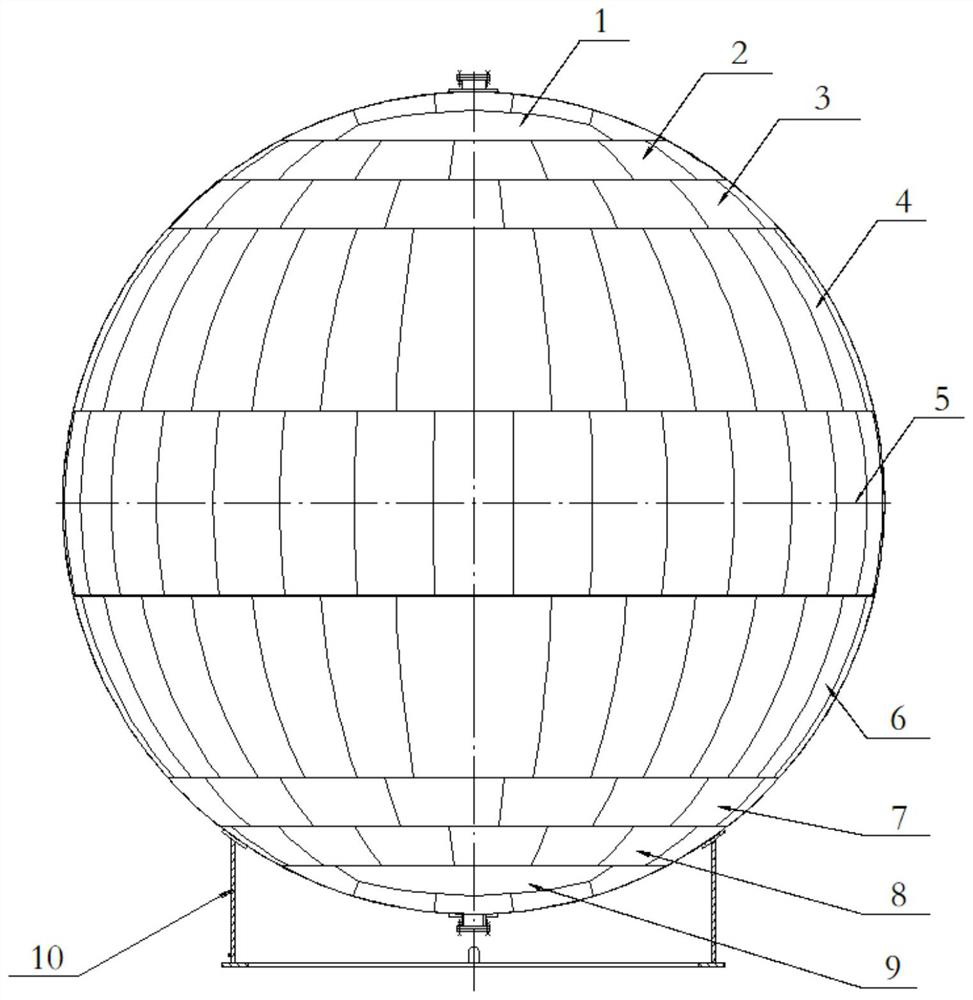

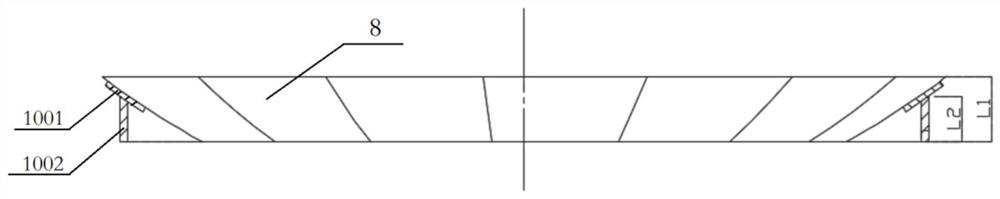

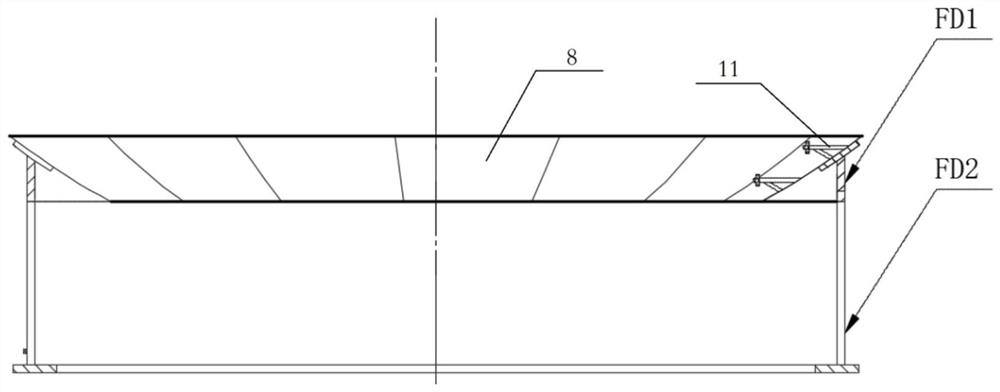

[0055] a. will be greater than 10000m 3 The spherical tank, from top to bottom, is divided into figure 1 The upper polar zone 1, the upper and upper frigid zone 2, the upper frigid zone 3, the upper temperate zone 4, the equatorial zone 5, the lower temperate zone 6, the lower arctic zone 7, the lower lower arctic zone 8 and the lower polar zone 9 are shown in a total of 9 rings. The belts are connected by annular seams, and the annular seams are parallel annular seams, which constitute the weft of the spherical tank;

[0056] Each annular belt is evenly divided into spherical pieces with the same shape, and the adjacent spherical pieces are connected by longitudinal seams, and the longitudinal seams constitute the weft of each annular belt; the longitudinal seams of each annular belt are staggered;

[0057] like figure 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com