Traction equipment for extrusion production of silicon rubber

A technology of traction equipment and silicone rubber, which is applied in the field of traction equipment for silicone rubber extrusion production, can solve the problems of difficult traction by traction equipment and heavy weight of high-voltage busbars, and achieve the effects of simple equipment, improved production efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

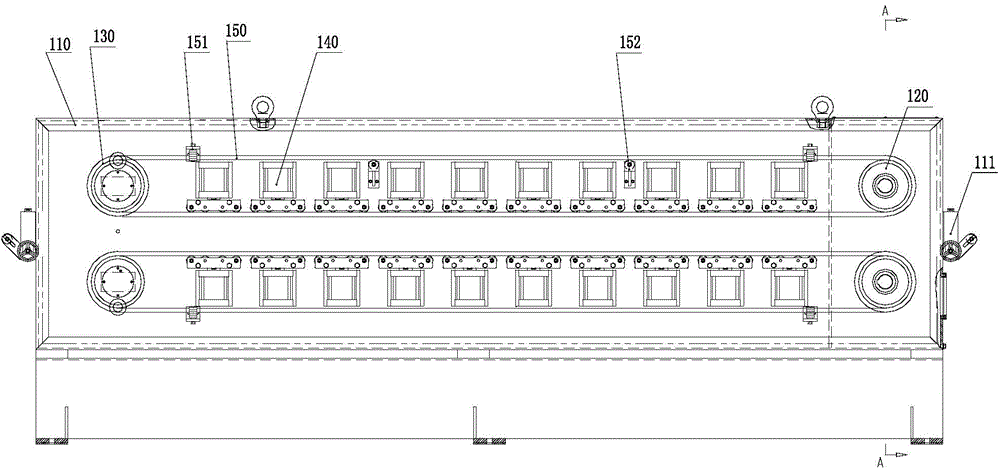

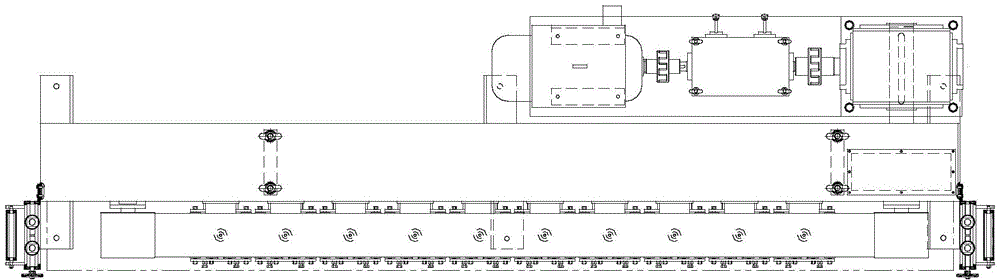

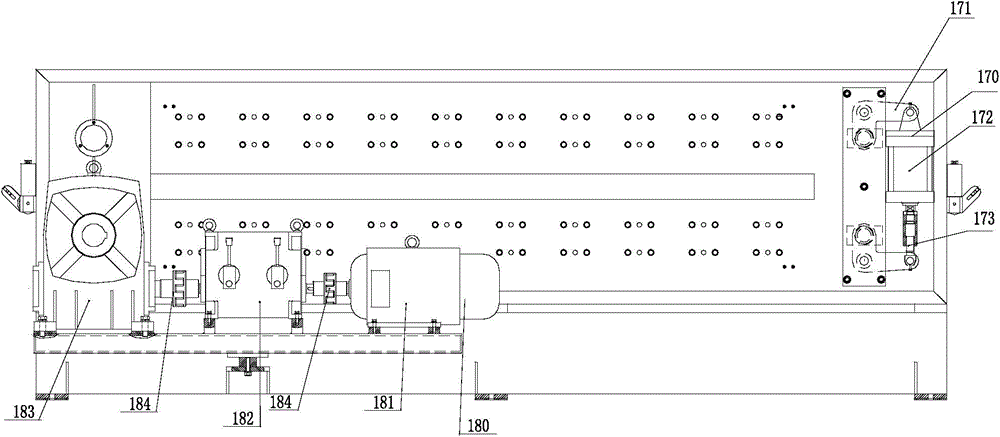

[0020] Such as Figure 1~4 As shown, the traction device includes a box body 110 and a pair of transmission runners 120, a pair of pressure regulation runners 130, a compression cylinder 140, a flat tape 150, a pressure regulation mechanism 170 and a driving mechanism respectively arranged on the box body 110. 180;

[0021] The transmission runner 120 is arranged on the discharge end of the box body 110, and the pressure regulating runner 130 is arranged on the feed end of the box body 110. The transmission runner 120 includes an upper transmission runner and a lower transmission runner, and the pressure regulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com