Traction fixing method for inverted arch formwork

A fixing method and formwork technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems affecting the construction period, cumbersome process, interference, etc., and achieve the effects of reducing construction interference, speeding up construction progress, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the described embodiments are some, not all, embodiments of the present invention. The specific embodiments described here are only used to explain the present invention, but not to limit the present invention. All other embodiments obtained by those skilled in the art based on the described embodiments of the present invention belong to the protection scope of the present invention.

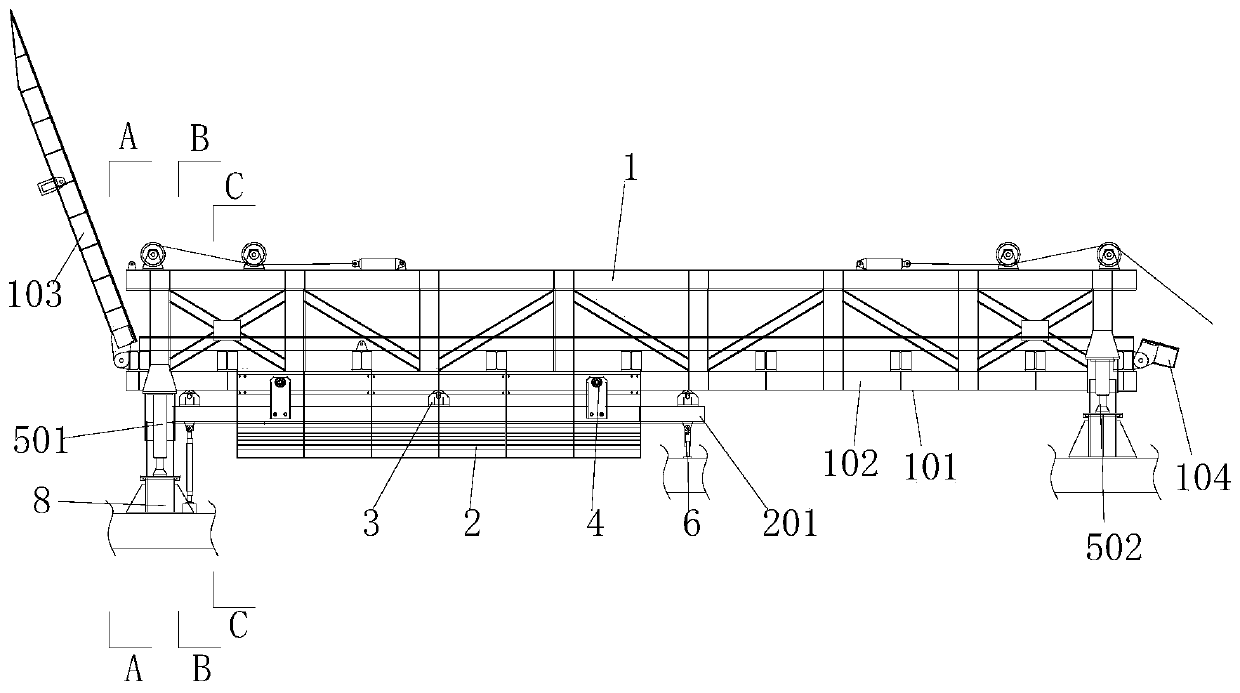

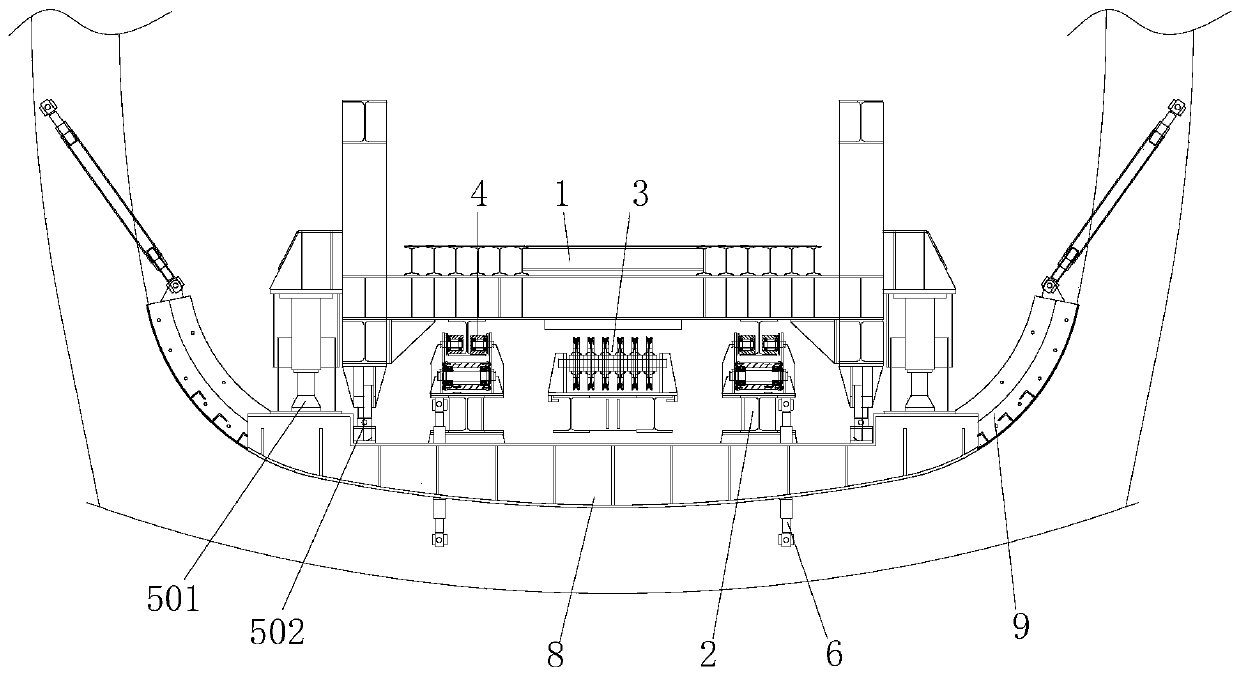

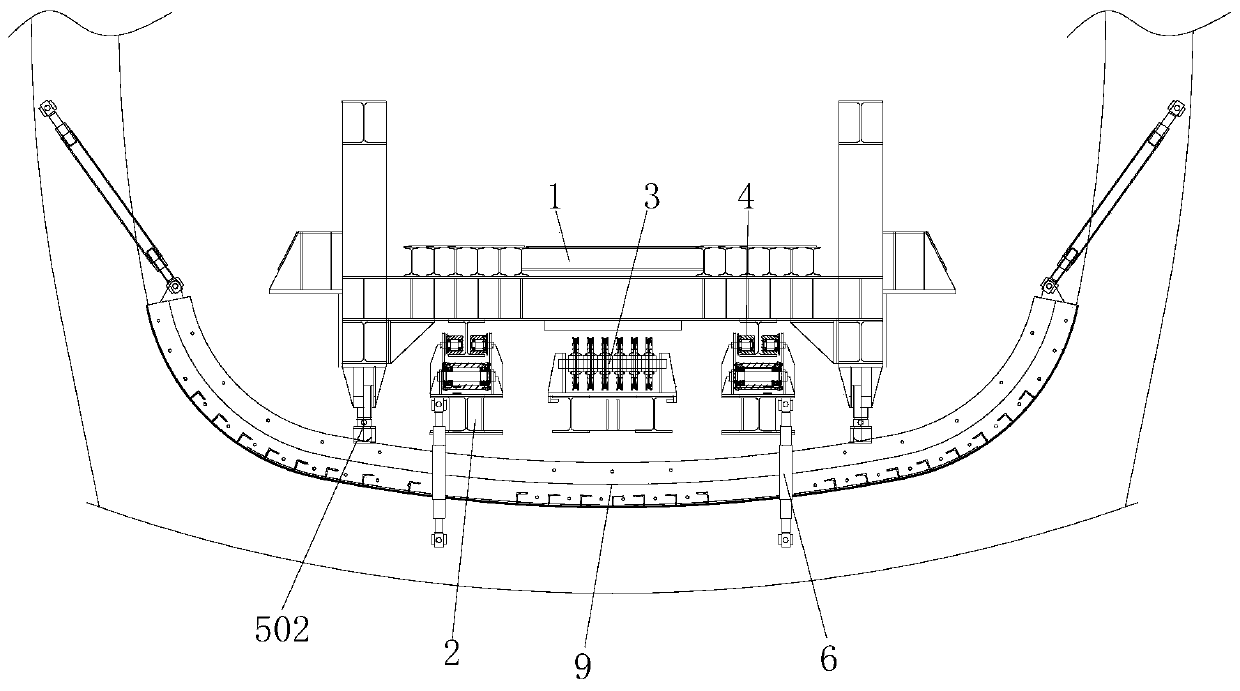

[0039] refer to figure 1 , the application provides an inverted arch trestle, including a trestle body 1, a plurality of support wheels 3 and a plurality of anti-hanging wheels 4, in the length direction of the tunnel, the two ends of the bottom of the trestle are respectively provided with front outriggers 501 and rear legs 501 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com