Leather traction device for shoemaking leather

A traction device and leather technology, applied in raw hide/leather/fur manufacturing equipment, leather manufacturing, small raw hide/large raw hide/leather/fur processing, etc. Avoid stacking, low cost, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

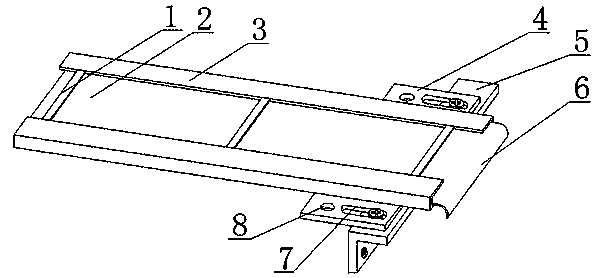

[0017] Such as figure 1 The shown leather traction device for shoemaking leather includes a traction plate 2, the two sides of the traction plate 2 are bent upwards and then horizontally bent to form a pressure plate 3, and a connecting plate 1 is arranged between the two pressure plates 3, so that Both sides of the lower end of the traction plate 2 are also connected with a positioning plate 4, and the positioning plate 4 is connected with a right-angle bending plate 5 by screws.

[0018] There are three connection plates 1 in total, located at the middle and two ends of the pressing plate 3 respectively.

[0019] The positioning plate 4 is provided with a positioning through hole 8 and a key-shaped through-slot 7, and the screw is connected to the right-angle bent plate 5 through the key-shaped through-slot 7, and the diameter of the head of the screw is not smaller than the key-shaped through-slot 7 width.

[0020] The two right-angle plates of the right-angle bending pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com