Threading machine

A threading machine and body technology, applied in the field of threading machines, can solve the problems of transmission stability, poor coordination, poor synchronization of traction wheels, and many follow-up problems, and achieve the effects of ensuring traction stability, improving stability and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

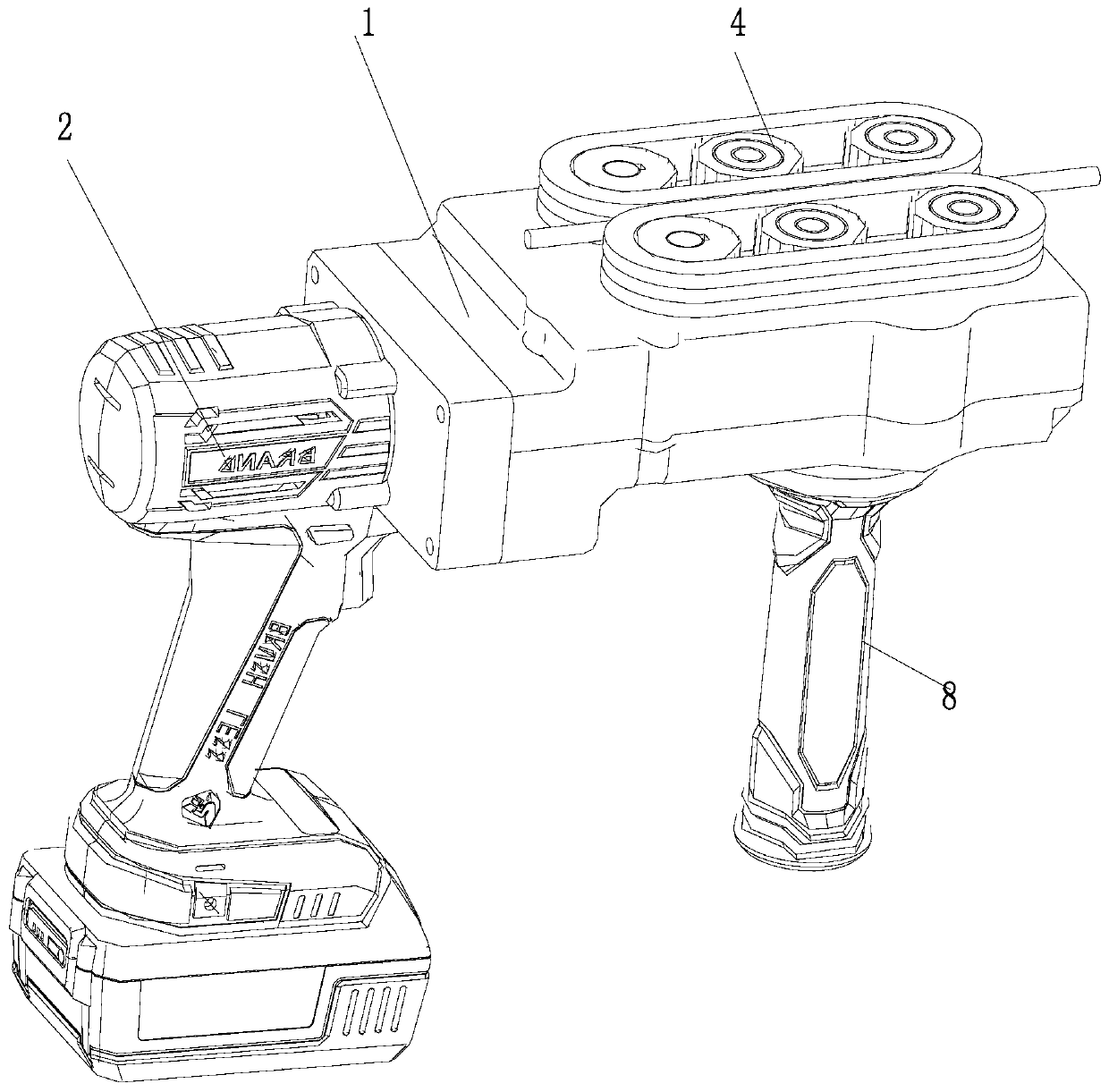

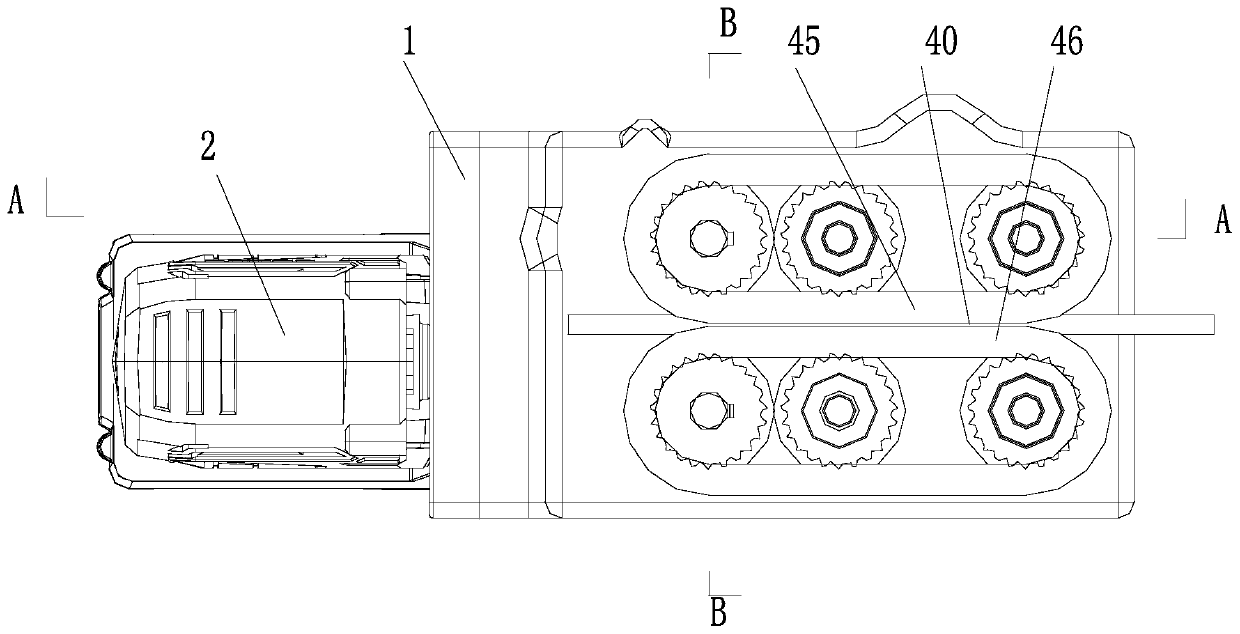

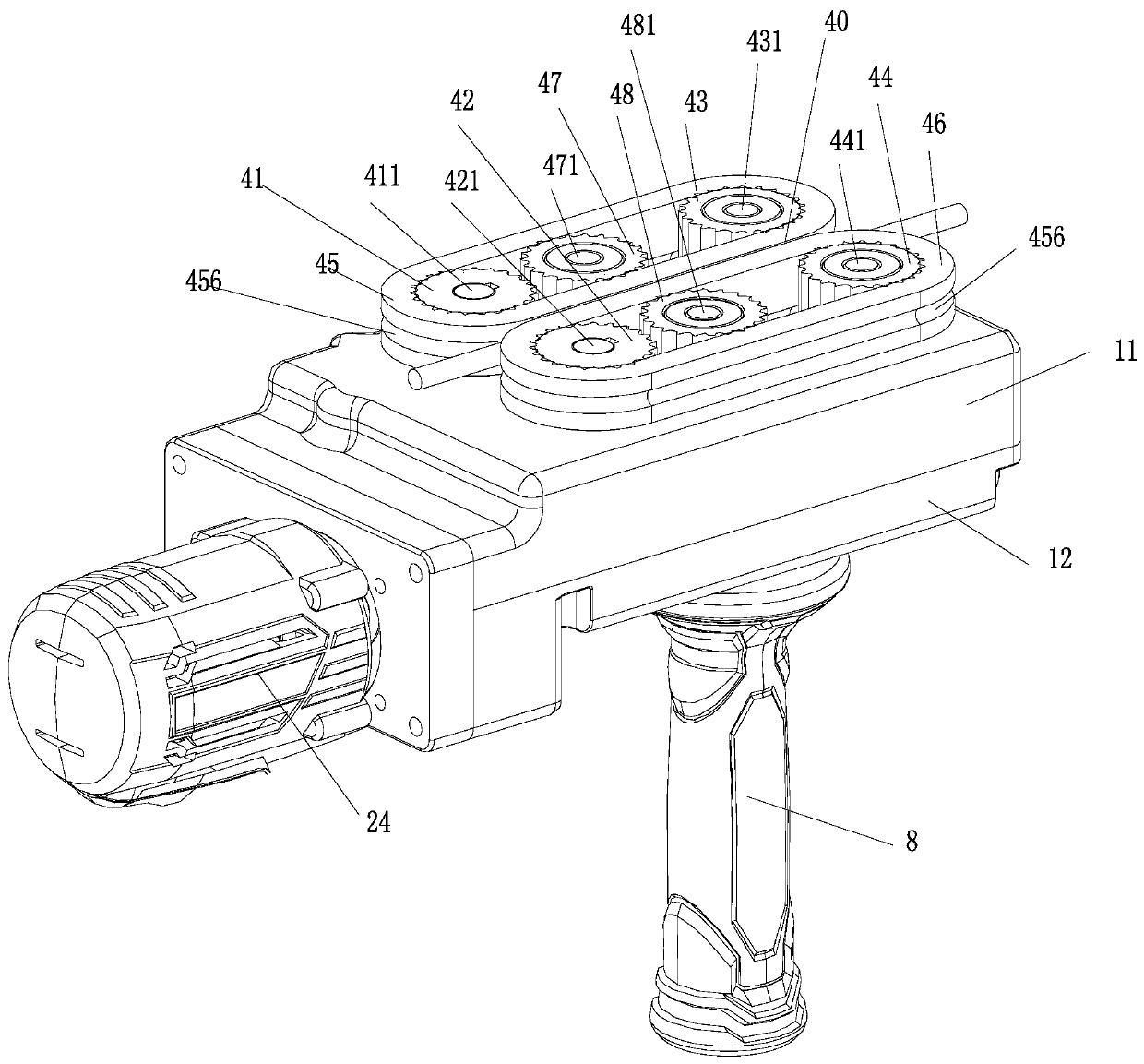

[0040] Embodiment 1: refer to Figure 1-15 . A preferred embodiment of a threading machine according to the present invention includes a body 1 and a driver 2, a transmission assembly 3 is arranged inside the body 1, the driver 2 is connected to the transmission assembly 3 by transmission, and a threading guide assembly 4 is provided at the upper end of the body 1. The threading guide assembly 4 comprises a left driving pulley 41, a right driving pulley 42, a left driven pulley 43, a right driven pulley 44, a left synchronous belt 45, and a right synchronous belt 46. There are left driving pulley 41 and right driving pulley 42 arranged longitudinally, the upper end left driving pulley 41 rear side of body 1 is provided with left driven pulley 43, and right driving pulley 42 rear side is provided with right driven pulley 44, left driving pulley 41 and left driven pulley 43 overcoats are provided with left synchronous belt 45, right driving pulley 42 and right driven pulley 44 ...

Embodiment 2

[0048] Embodiment 2: refer to Figure 10-15 . On the basis of embodiment 1. The left driven pulley 43, the right driven pulley 44 and the left middle pulley 47 and the right middle pulley 48 that are added are passed through the left driven shaft 431, the right driven shaft 441 and the left middle driven shaft 471, the right middle slave The moving shaft 481 is used to adjust the distance between threading gaps, and the adjustment mechanism involved is replaced by a structure that uses the adjustment block 100, the adjustment screw 101 and the adjustment handle 103 to complete the adjustment. Compared with Embodiment 1, the structure of this solution is simpler and more practical. The production and processing are simple, the production cost is lower, and in actual use, the operation is simpler and more in line with the requirements of actual use and usage habits. This solution is also the optimal solution. The specific technical solution is as follows:

[0049] Technical so...

Embodiment 3

[0052] Embodiment 3: In the above embodiment 1 or 2, it involves bearings provided on multiple shaft ends, and the corresponding positions of the upper casing and the lower casing of the machine body are respectively provided with bearing installation positions 111, and the bearings are fixed through the bearing installation positions. The bearings involved are not marked and described one by one in this embodiment, and the rectangles at both ends of the shafts or the simplified bearings in the drawings are indicated by reference numeral 10 .

[0053] On the basis of the above-mentioned embodiment 1 or 2, the power output end of the motor 21 can also be directly connected to the transmission shaft 31 through the coupling 211 without passing through the intermediate transmission assembly 5, and the coupling and the transmission shaft can be directly docked or The purpose of transmission through a worm gear drive connection.

[0054] On the basis of the above-mentioned embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com