Fragile front cover of missile and preparation method thereof

A front cover and missile technology, applied in the direction of warheads, ammunition, offensive equipment, etc., can solve problems such as the splash of front cover fragments, and achieve the effect of eliminating safety hazards, reducing impact force, and opening easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

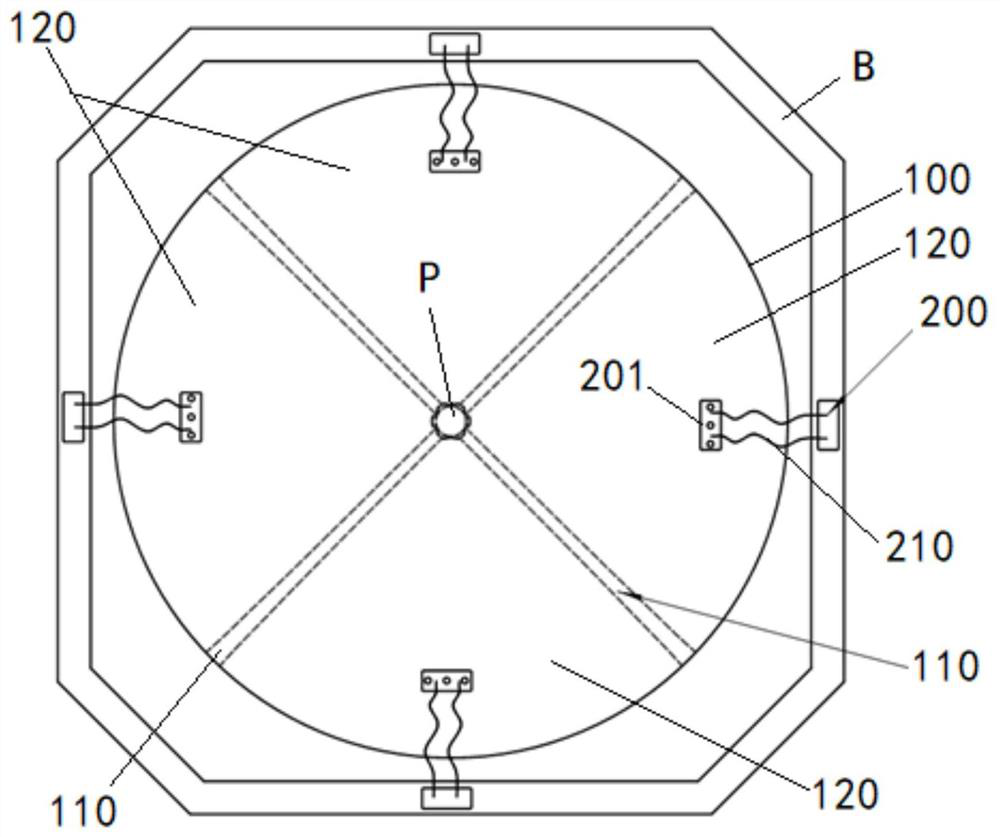

[0042] see figure 1: The present application provides a missile fragile front cover, comprising: a front cover body 100 provided with a weakened groove 110, and a mooring mechanism 200 for constraining splashing of the front cover body; the weakened groove 110 extends to the front The radial and / or latitudinal arrangement of the cover body 100 divides the front cover body 100 into a plurality of regions 120 to be broken by the weakened groove; the mooring mechanism 200 is provided with fixed ends 201 at both ends Rope 210; one end of the mooring mechanism 200 is used for fixed connection with the cylinder wall B of the missile launching cylinder;

[0043] Preferably, in one of the preferred technical solutions of this embodiment, the weakening groove is arranged along the radial direction of the front cover body, and the end of the mooring mechanism fixedly connected with the region to be ruptured is located at the region to be ruptured. On the axis of symmetry of the zone, a...

Embodiment 2

[0047] Such as figure 2 As shown, the fragile front cover of the missile is composed of a front cover body 100, an upper flange ring 300, a lower flange ring 400, a sealing ring 500 and a mooring mechanism 200, wherein the front cover body 100 and the upper flange ring 300, the lower The flange ring 400 is connected by bolts, and the mooring mechanism 200 is connected with the front cover body 100 and the upper flange ring 300 .

[0048] Specifically, in the above structure, the lower flange ring is used for fixed and sealed connection with the barrel edge of the missile launching tube; The hole position is matched with the through hole, and is fixedly connected with the missile launching tube through the fastening and pressing between the upper flange ring and the lower flange ring.

[0049] Preferably, in one of the preferred technical solutions of this embodiment, the fragile front cover structure of the missile includes: a body layer 101, a reinforcement layer 102, a shi...

Embodiment 3

[0059] This embodiment provides a method for preparing a missile fragile front cover, the method comprising the following steps:

[0060] The upper flange ring and the lower flange ring whose shape is compatible with the launch port of the missile launching tube are manufactured by mechanical processing technology; bolt holes are respectively processed on the upper flange ring and the lower flange ring;

[0061] The reinforcement layer is manufactured by compression molding injection molding process;

[0062] The front cover body is made on the upper end surface of the reinforcement layer by foaming process; the edge of the front cover body is provided with a cover edge required for press-fit sealing connection with the flange ring; the radial and radial directions of the front cover body / or Weakening grooves are provided in the weft direction;

[0063] Spraying or brushing the heat-resistant paint after grinding the upper end surface of the front cover body;

[0064] Maki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com