Nondestructive detection method for web plate bonding area of a wind turbine blade

A non-destructive testing, wind power blade technology, applied in the field of wind turbine blade quality testing devices, can solve the problems of high cost, high transportation cost, affecting the stability and safety of the unit, etc., so as to improve the service life and ensure the bonding. Quality, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

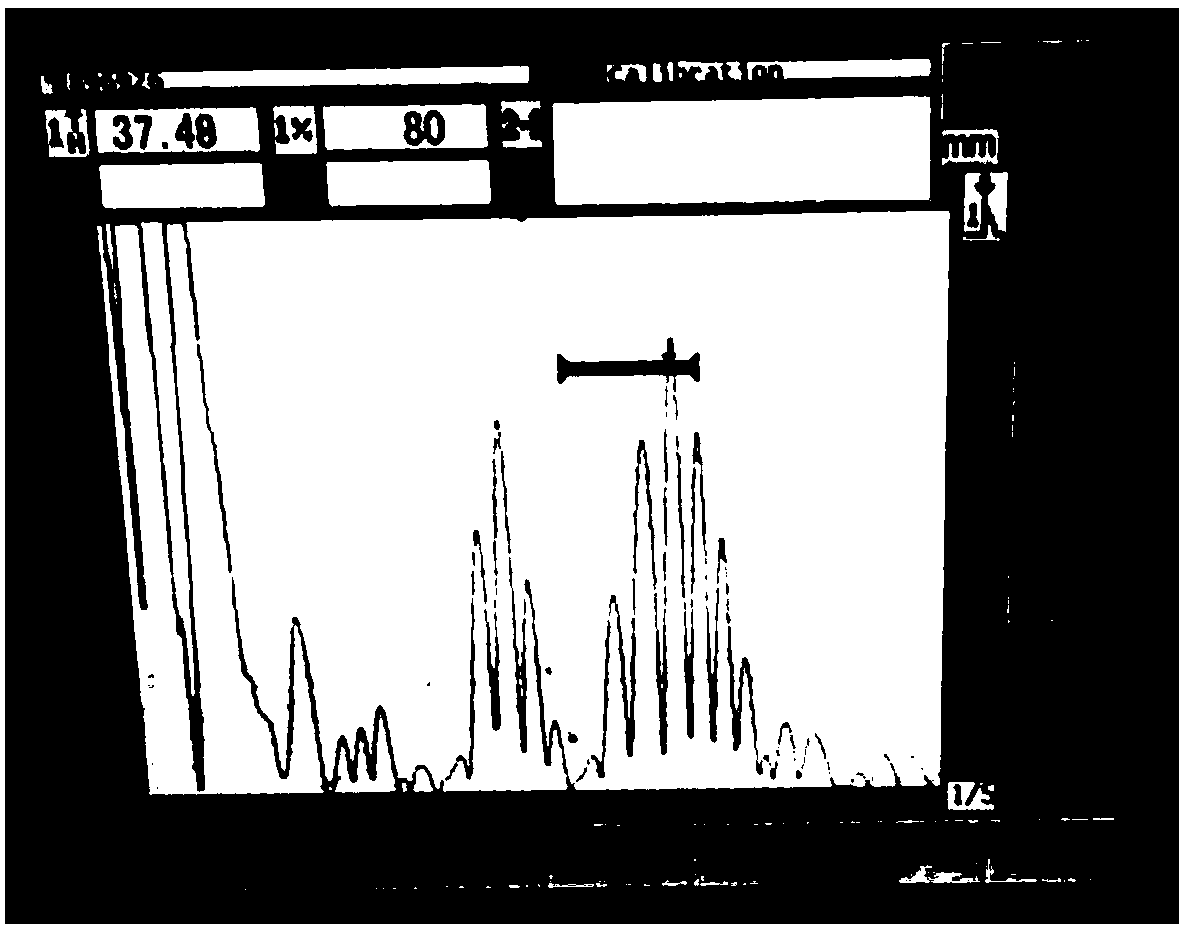

[0041] This embodiment uses an OLYMPUS EPOCH 600 / 650 ultrasonic flaw detector and an OLYMPUS V101 (0.5MHz 1 inch) probe.

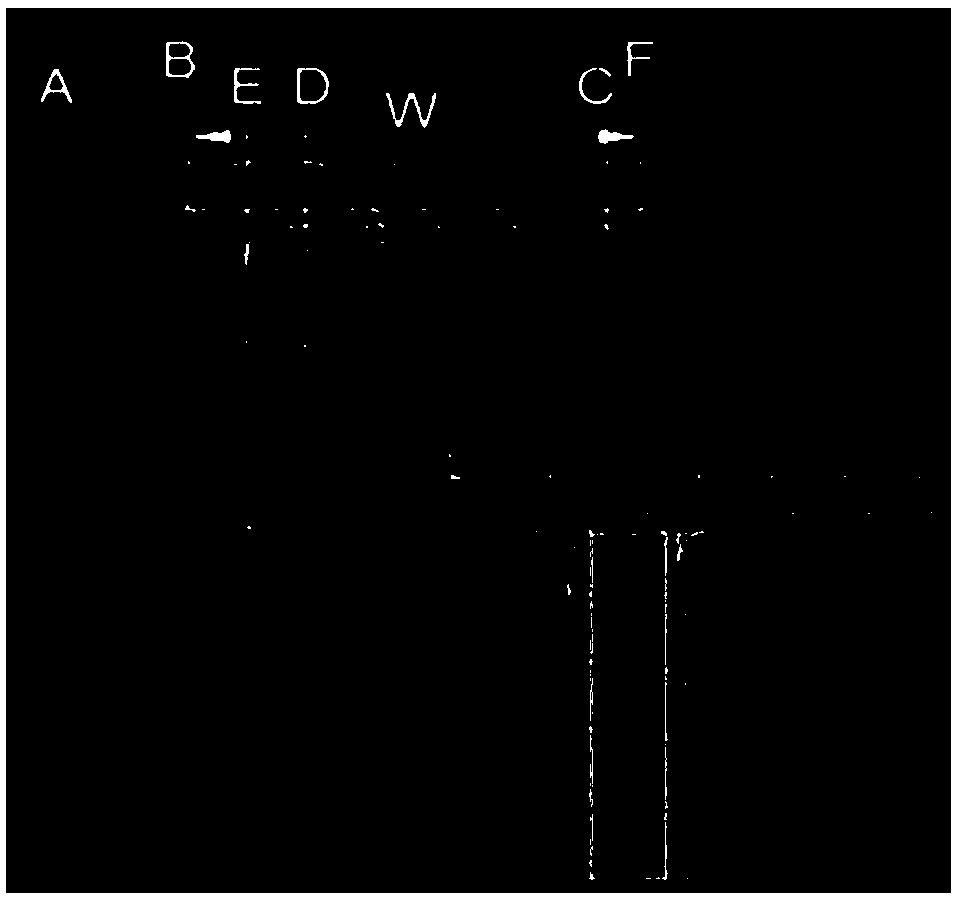

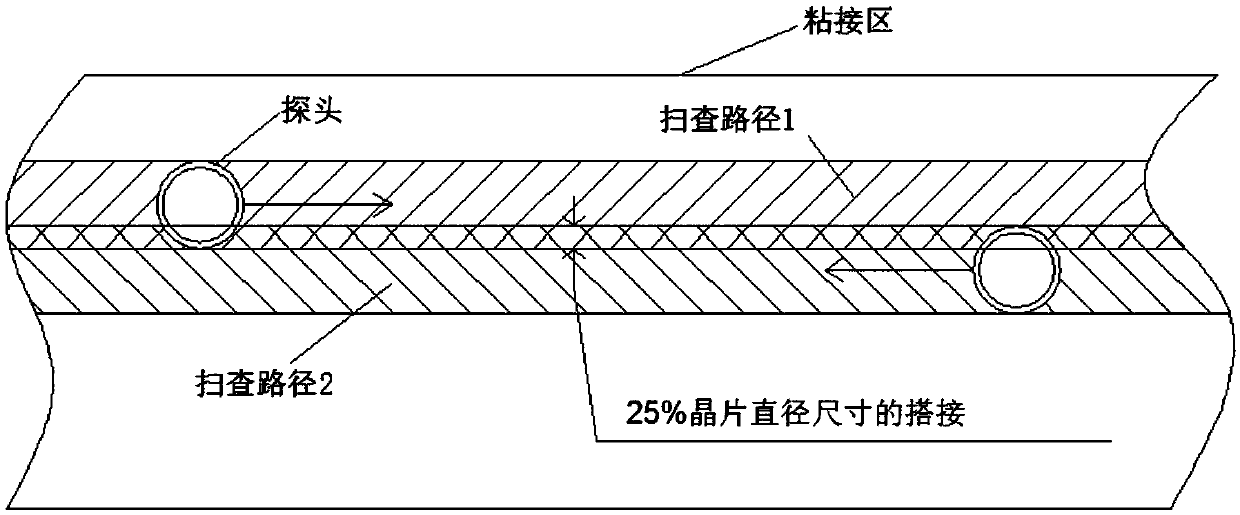

[0042] like figure 1 As shown, a non-destructive testing method for the bonding area of a wind turbine blade web, which includes the following steps:

[0043] (1) Determination of the starting point and end point of the web bonding area

[0044] (1.1) If figure 1 As shown, first place the probe on the E-D surface of the web core material area, set the bottom wave height of the web core material to 80% of the full screen height; then move the probe slowly to point C, when the web core material echo Stop when the amplitude drops 6dB, this point is point D; then move the probe slowly towards point B, stop when the echo amplitude of the web core material drops 6dB, this point is point E or the bonding area of the web starting point;

[0045] (1.2) Then place the probe on the C-D surface of the web bonding area, set the echo height of the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com