Removal method of LED electrode structure

A technology of electrode structure and metal electrode, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as inapplicable rework treatment, and achieve the effects of complete and effective corrosion rework, wide application range, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

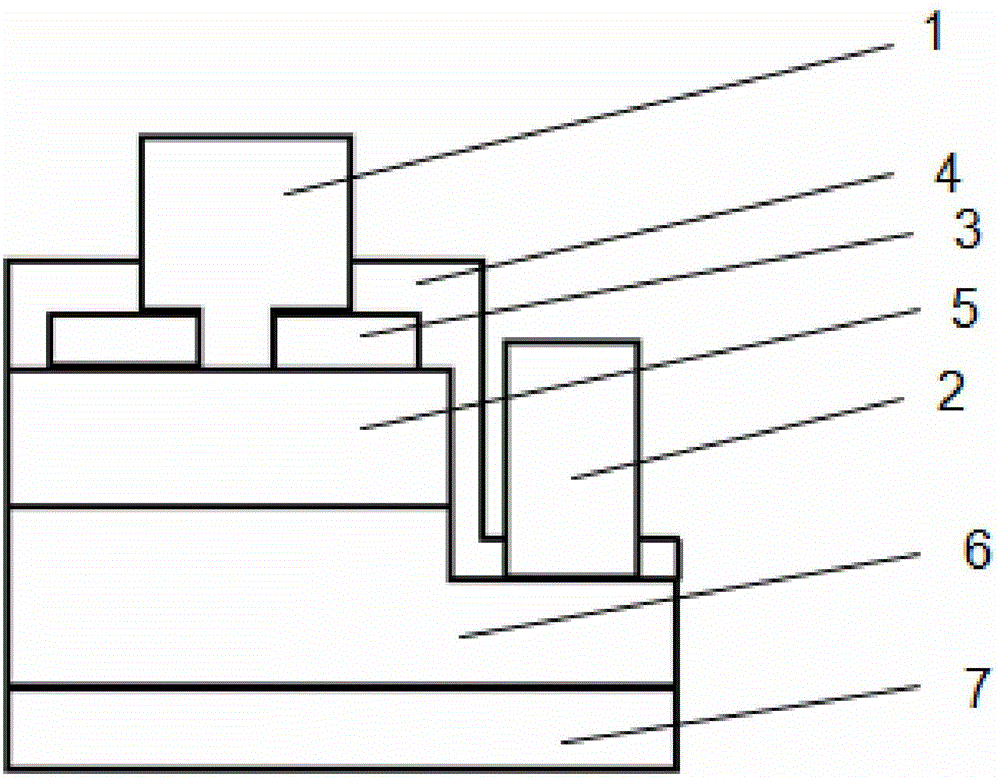

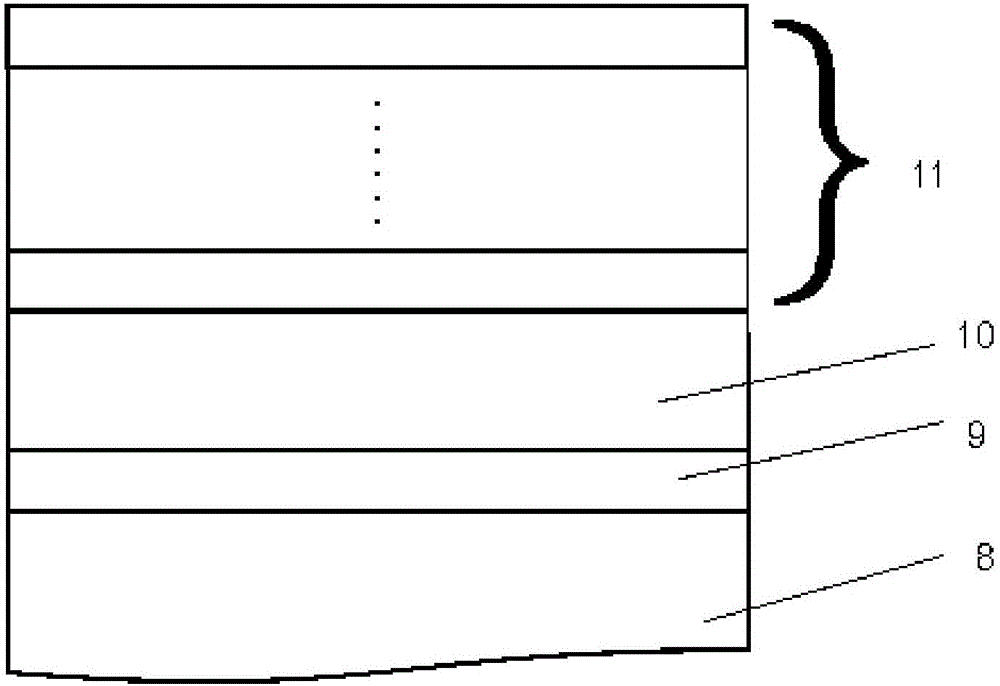

[0043]A method for removing a sapphire wafer LED tube core, the sapphire wafer LED tube core comprising a sapphire substrate layer 7, N-type gallium nitride, 6, a P-type gallium nitride layer 5, an ITO layer 3, and a silicon dioxide protection layer 4 , P electrode 1, N electrode 2, P electrode 1, N electrode 2 are made of metal electrode layer, the metal electrode layer is provided with sapphire substrate 8, metal chromium layer 9, metal aluminum layer 10, mixed metal layer in sequence from bottom to top Layer 11, mixed metal layer 11 is provided with metal platinum layer, metal gold layer successively from bottom to top, and the thickness of silicon dioxide protection layer 4 is The thickness of the ITO layer 5 is The thickness of metal chromium layer 9 is The thickness of the metal aluminum layer 10 is The thickness of the platinum layer is The thickness of the metal gold layer is Schematic diagram of the structure of the sapphire wafer LED die figure 1 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com