Washing and drying equipment for textile cloth

A technology for drying equipment and textile fabrics, which is applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

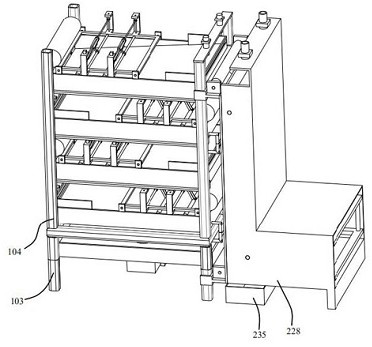

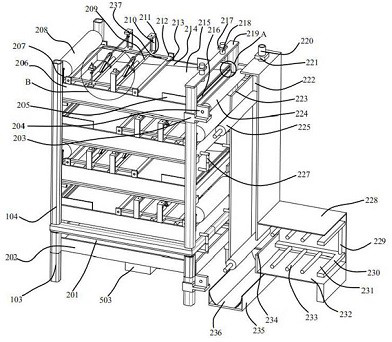

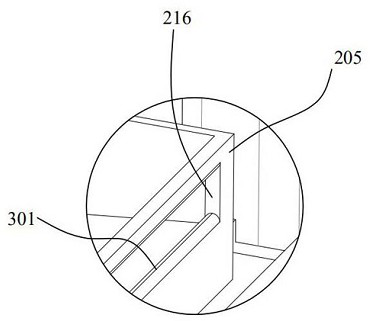

[0023] like Figure 1-Figure 5 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1The up, down, left, right, front and back directions of the projection relationship are consistent. A kind of fabric washing and drying equipment of the present invention includes a support bracket 104 of a frame structure. The right side of the leg 103 is provided with a drying device that hangs the textile cloth vertically for drying and dehydration. A number of rinsing devices for rinsing the textile cloth are arranged in a staggered manner in the support bracket 104. Below the rinsing device, there is a device for draining the water. For the water discharge device of the equipment, a water liquid introduction device fixed to the support bracket 104 to guide the water liquid into the rinse device is arranged above the rinsing device, and a symmetrical fixed block 203 is fixed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com